Patents

Literature

93results about How to "Won't fall over" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

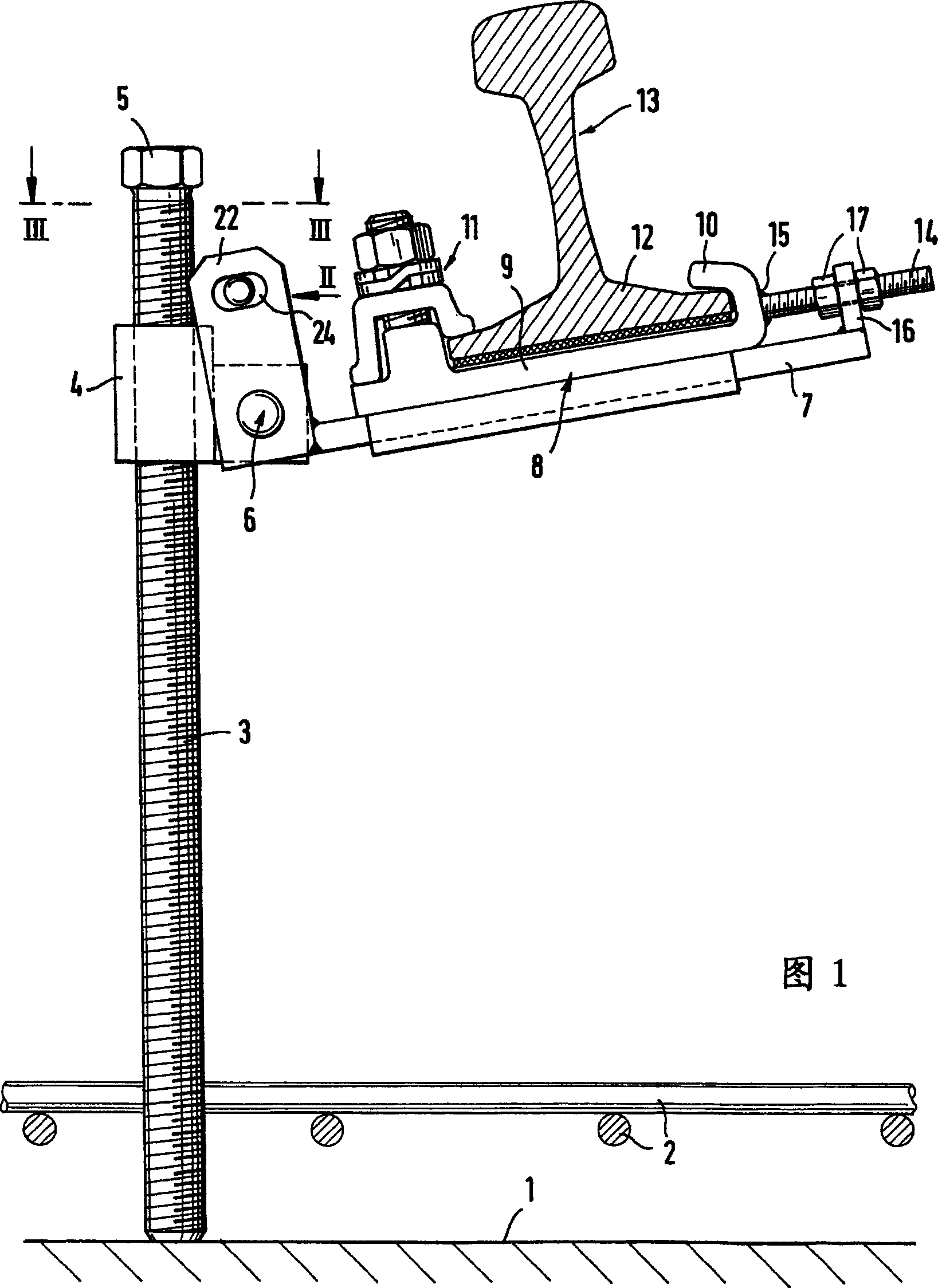

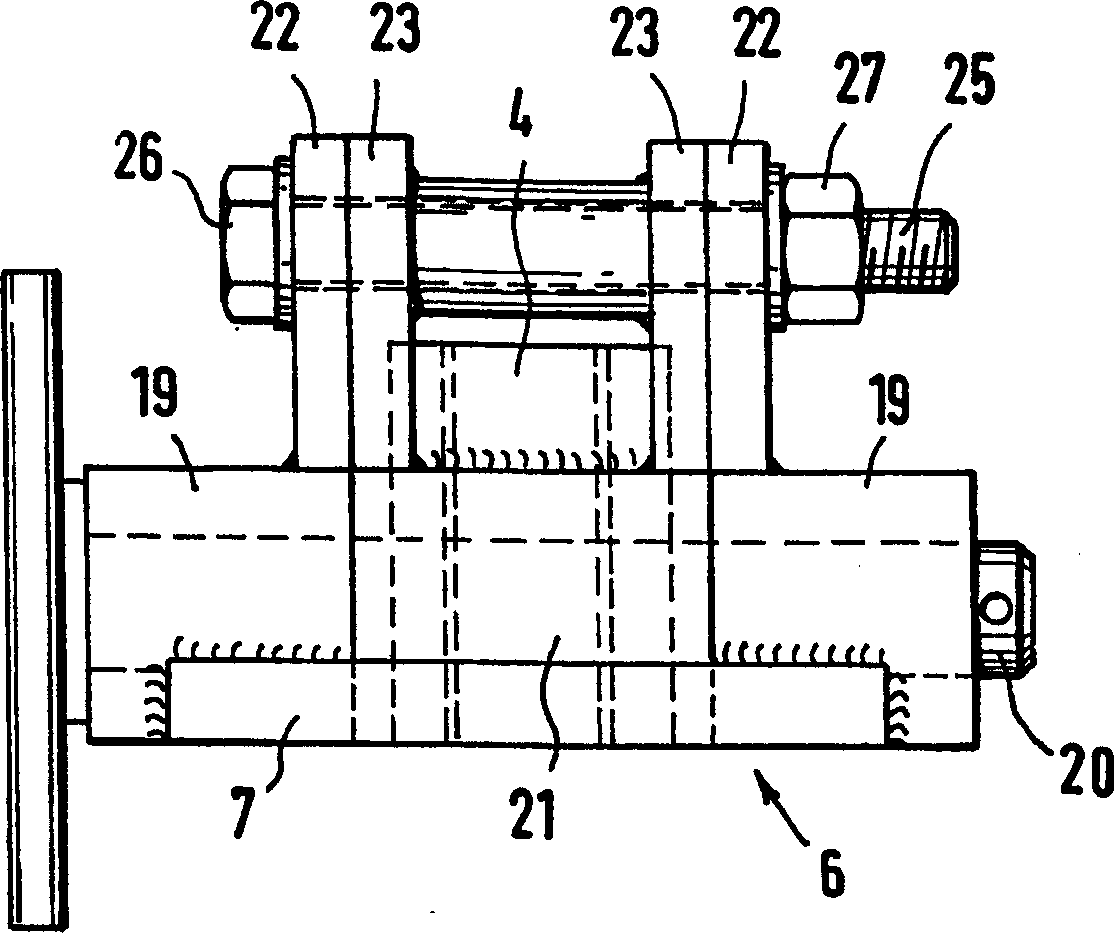

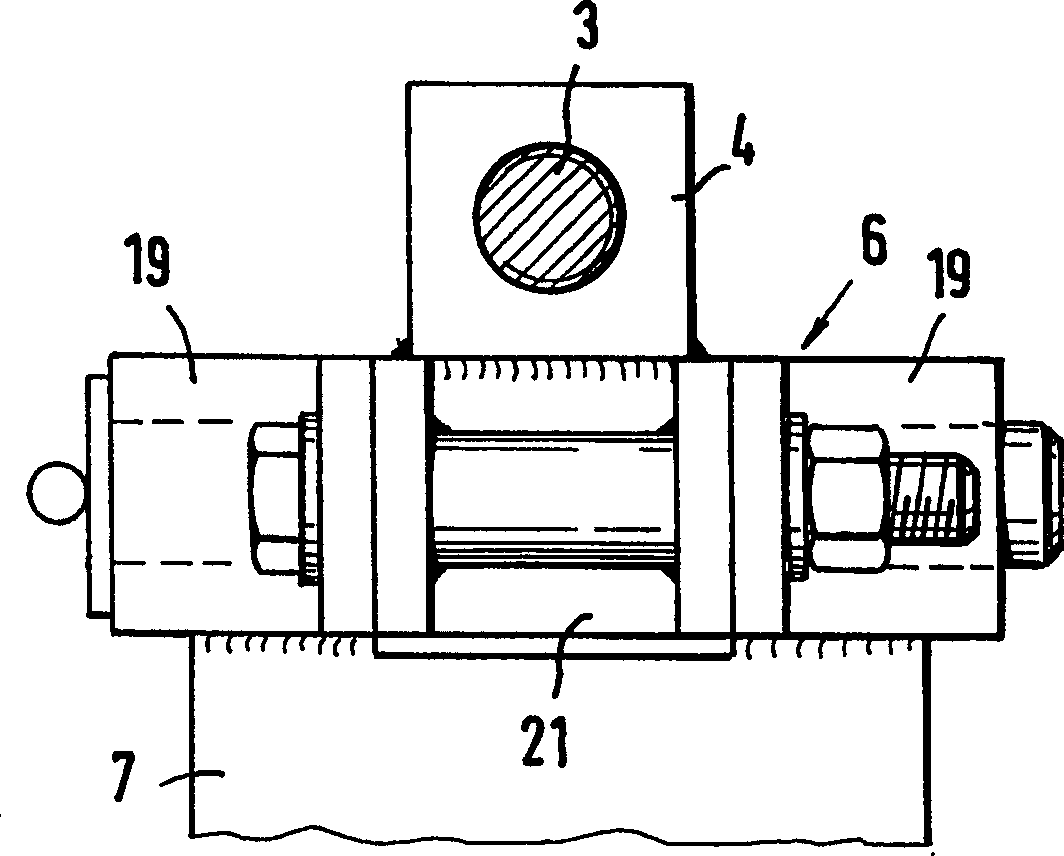

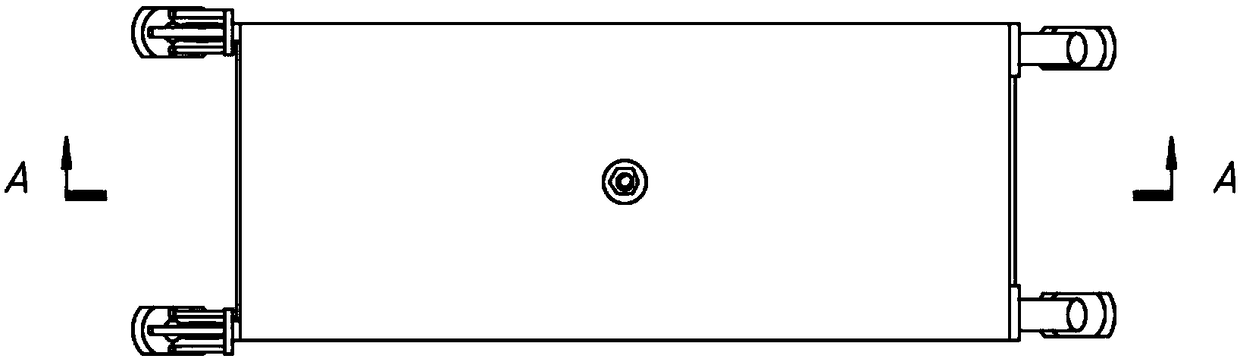

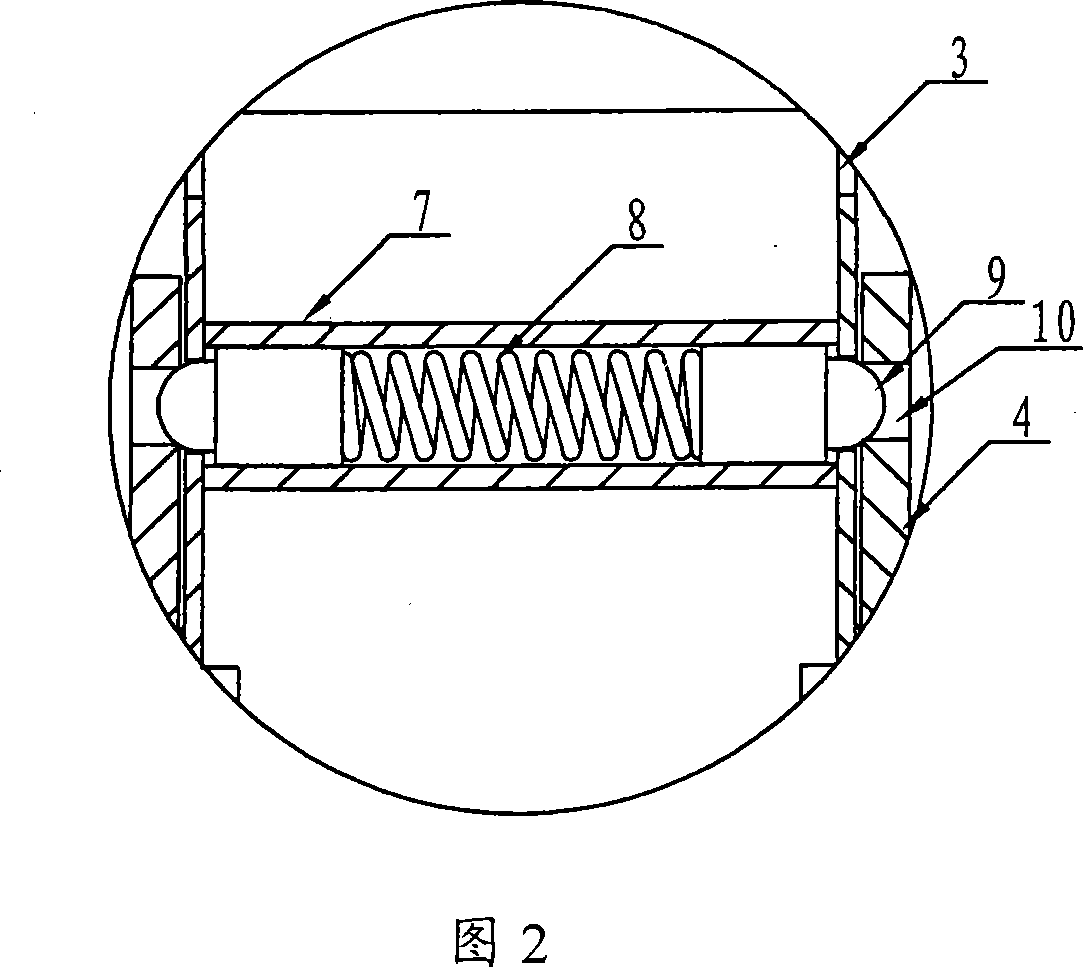

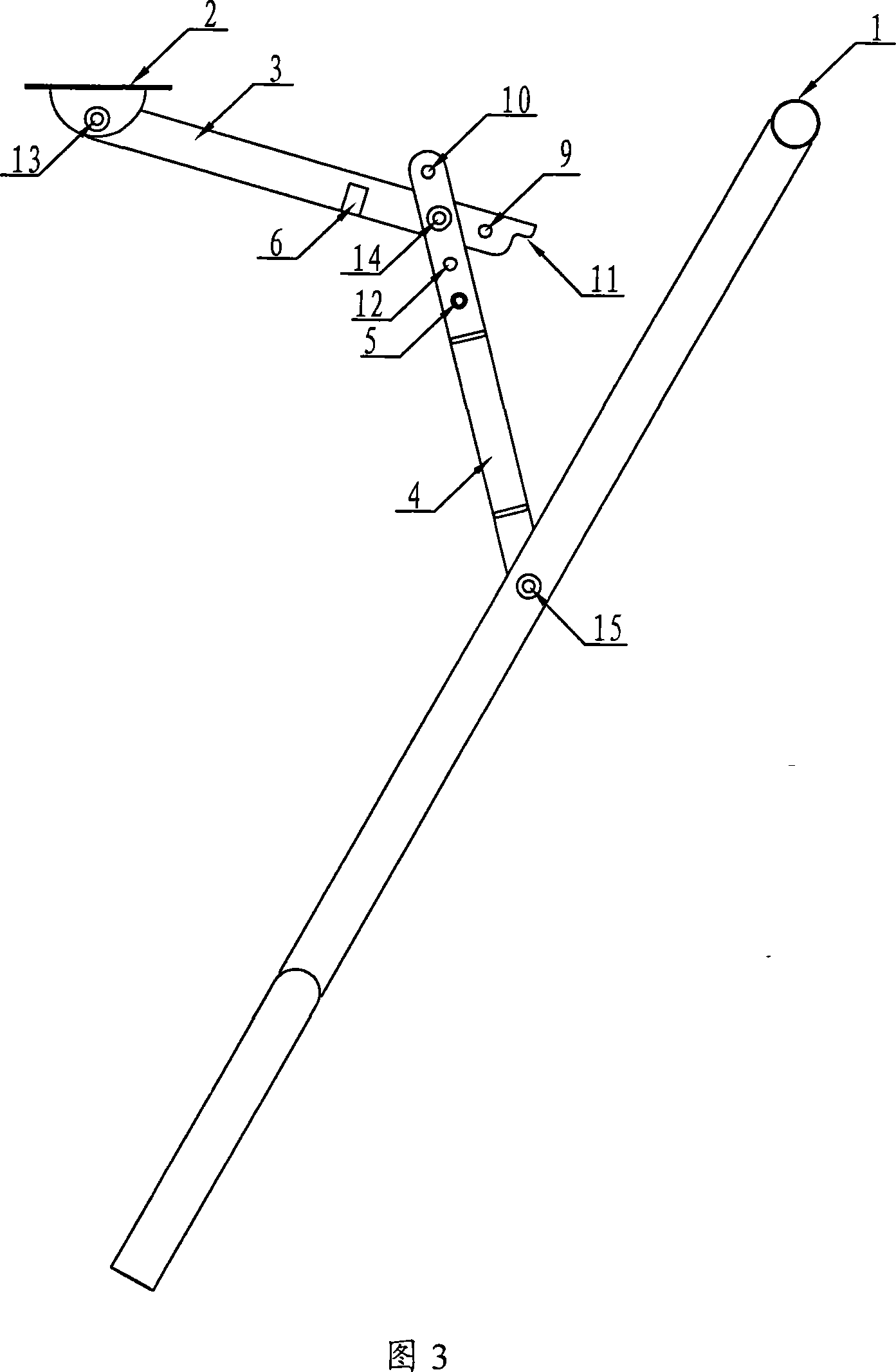

Screw device for high-adjusting a track span

InactiveCN1742140AEasy to pull outReduce protrusionBallastwayRailway track constructionCantilevered beamHorizontal axis

The invention relates to a screw device for high-adjusting and a snaping to track on a lower structure, having a transverse cantilever on a guided long nut with an adjustable height acting on the rail from beneath and fixed on a height regulating screw. The transverse cantilever is designed to be a horizontal screw plate beard on the long nut and swung around a horizontal axes. A slide block with a clamping holding device for rail base is able to move on the horizontal screw plate transversely to the high-adjusting screw recurring to the first and second screw apparatus.

Owner:PCM RAIL ONE AG

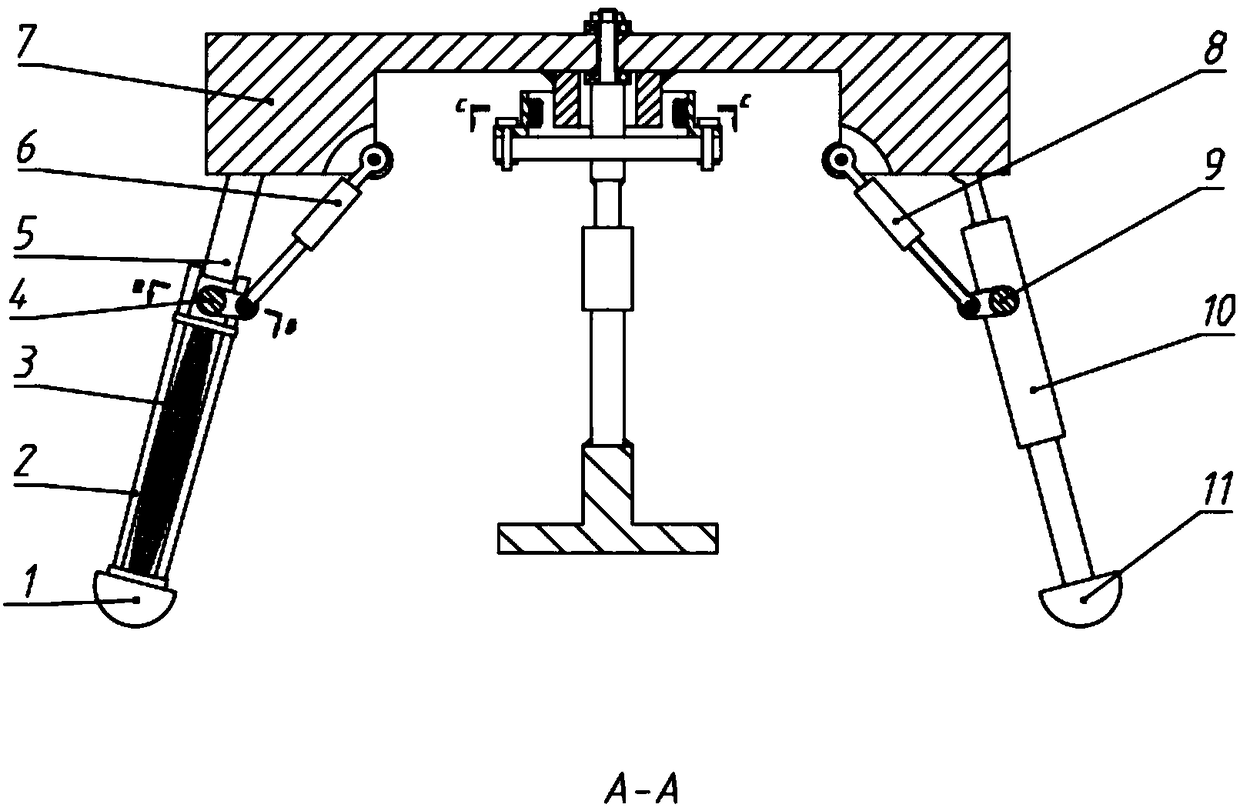

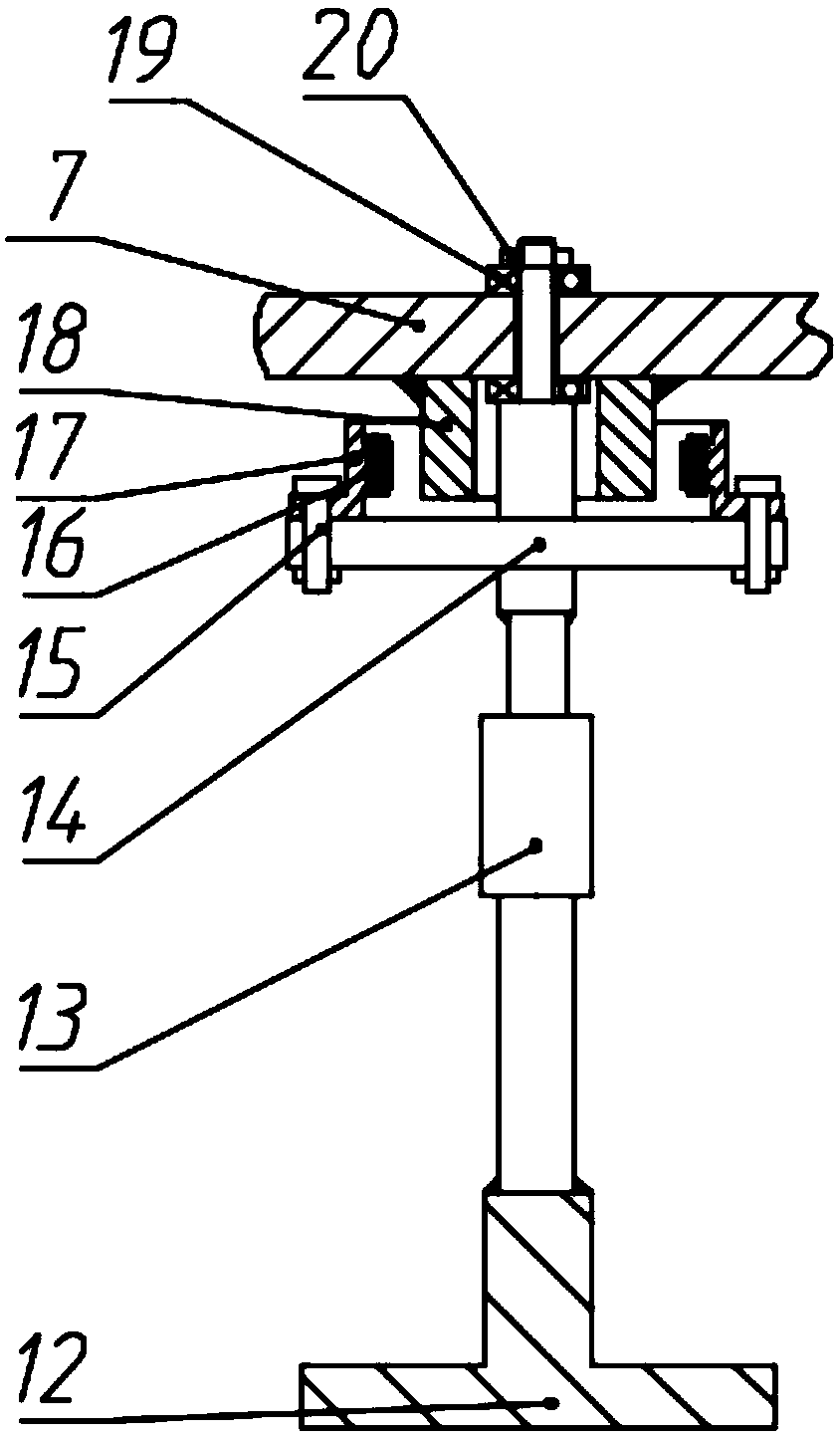

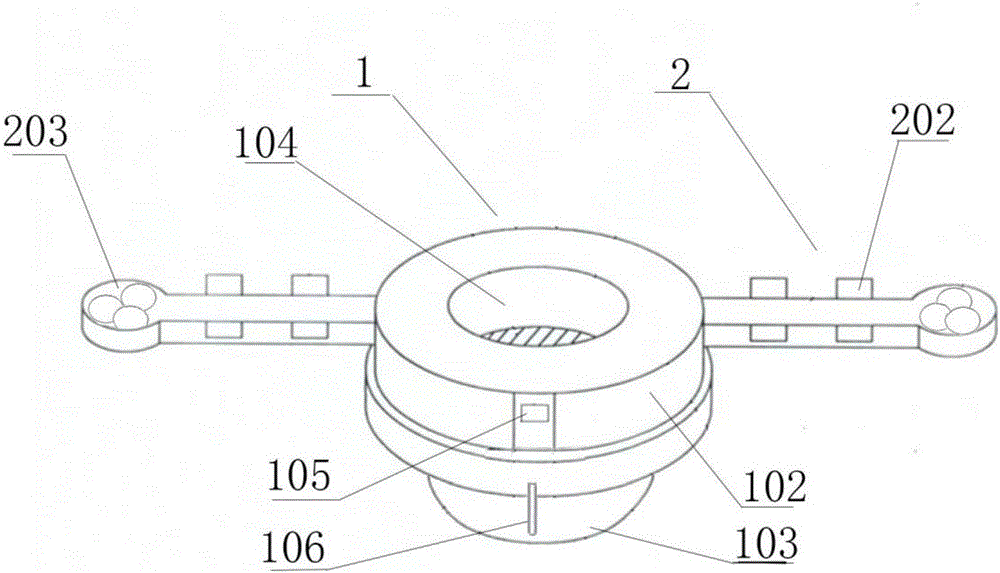

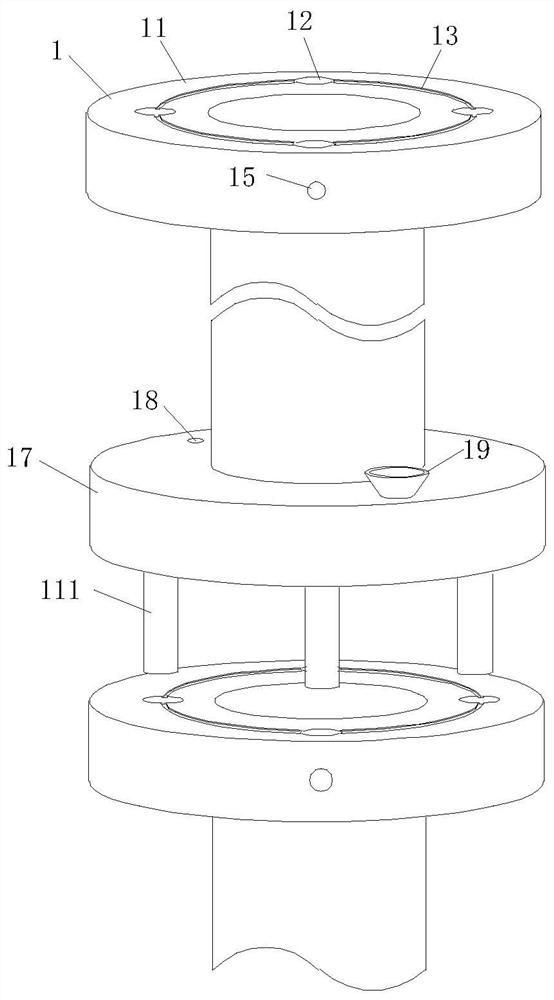

Steering device and four-legged robot comprising same

The invention discloses a steering device and a four-legged robot comprising the same. The steering device includes a supporting base, a hydraulic telescopic device is vertically arranged on the supporting base, a disc-shaped supporting shaft is installed at the top of the hydraulic telescopic device, and a stator core is arranged on the upper portion of the supporting shaft. A coil winding is arranged on the stator core, a rotor permanent magnet is arranged in the center of the stator core, and the rotor permanent magnet is fixed to the bottom of a machine body of the robot. The coil windingis controlled to be energized or cut off, a rotating magnetic field is formed, the rotor permanent magnet rotates under the action of the magnetic field, the permanent magnet is fixed together with the machine body of the robot, so that the machine body of the robot rotates at an angle when four feet are off the ground.

Owner:SHANDONG UNIV

Vehicle-mounted environment-friendly garbage can

The invention discloses a vehicle-mounted environment-friendly garbage can which comprises a garbage can body, wherein the interior of the garbage can body is composed of a waste paper bin, a soot binand a water tank, and the water tank is positioned above the space between the waste paper bin and the soot bin. Firstly, the vehicle-mounted environment-friendly garbage can disclosed by the invention is mainly composed of the garbage can body and a base, the base is sleeved into a cup groove of a center control console of a vehicle through a support column, and by arranging two clamping rods connected with the bottom end of the support column through a spring, the garbage can body can be placed steadily under the effect of elasticity; and secondly, because a hanging rack is arranged on theback of the garbage can body, the garbage can is hung on an air outlet of a front air conditioner of the vehicle through a clamping column at the center of the hanging rack. By virtue of placement oftwo modes, the vehicle-mounted environment-friendly garbage can is more convenient to use and can not turn over in a driving process, thereby preventing the environment in the vehicle from being polluted by garbage in the garbage can so as to achieve the purpose of environmental protection.

Owner:四川新天地环保科技有限公司

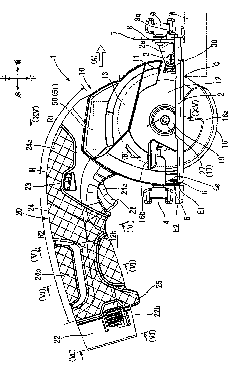

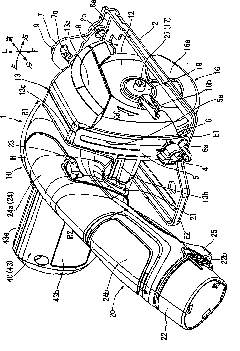

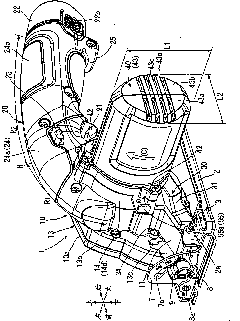

Cutting tools

InactiveCN102189294AImprove balanceSmooth mobile operationMetal sawing devicesPortable power driven sawsCircular sawEngineering

On a cutting tool generally named as a portable circular saw, a conventional handle part is in a rod shape perpendicularly backwards extending, it is necessary to keep a wrist in a constrained posture, because the rod-shaped handle at the using end can be freely grasped and the operation can be easily applied on the handle. The handle (20) is viewed to be a mountain form bending upwards from the side surface and the highest part (H) of the handle is at the front position and the downward extending region from the highest part (H) to the rear end bends upwards in a curvature samller than that of the highest part (H).

Owner:MAKITA CORP

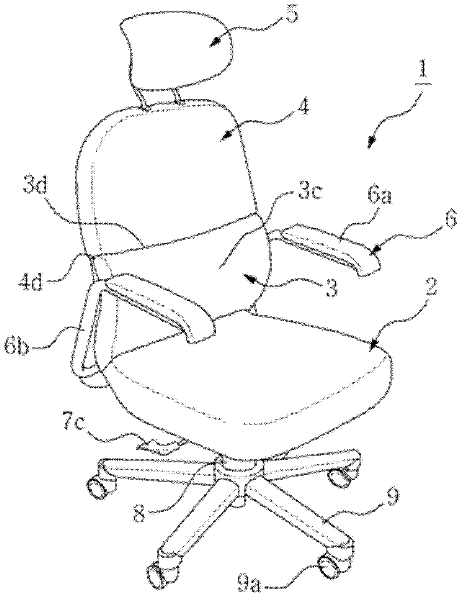

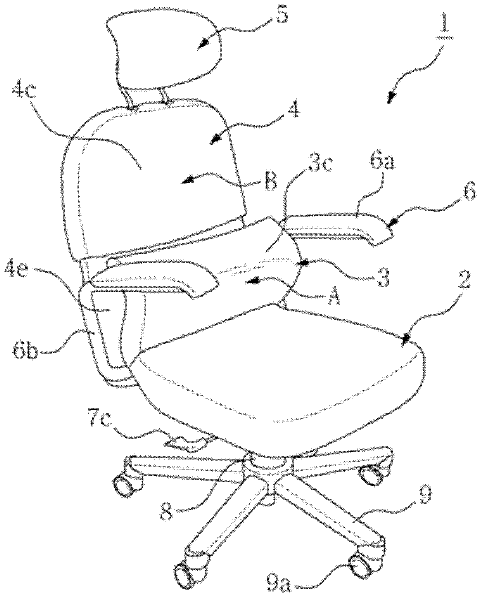

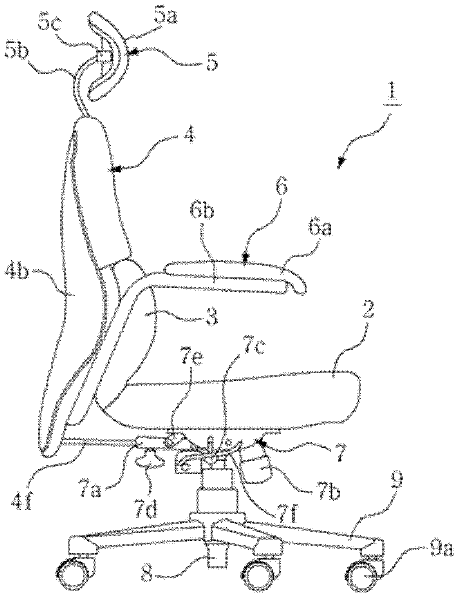

Chair with separate but interconnecting lumbar and thoracic supports

The present invention relates to a chair with separate but interconnecting lumbar and thoracic supports. A back support is physically divided into a lumbar support and a thoracic support. The lumbar support is formed to be curvable, and the lumbar and thoracic supports are configured to be interconnecting. Thus, when a sitter tilts his / her upper or lower back backward for rest or tension relief, the lower back area of the sitter is comfortably brought into contact with and supported by the lumbar support with a backward tilt of a relatively large angle, and at the same time, the upper back area of the sitter is comfortably brought into contact with and supported by the thoracic support with a backward tilt of a relatively small angle. Therefore, the lumbar and thoracic supports share the task of comfortably supporting the lumbar vertebra and thoracic vertebra respectively. In addition, the chair has high posture stability without falling backward when a sitter tilts his / her upper and lower back far backward, and also has an elegant look.

Owner:CHAIRO

Folding table leg

InactiveCN101233972AWon't fall overConnectivityFoldable tablesStowable tablesEngineeringSupport plane

Owner:黄荣丰

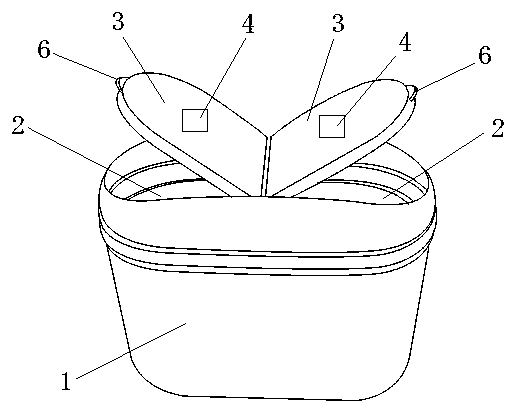

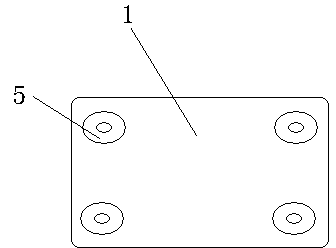

Vehicle-mounted garbage can provided with suckers

The invention discloses a vehicle-mounted garbage can provided with suckers. The vehicle-mounted garbage can provided with the suckers comprises a garbage can body, wherein a baffle is arranged inside the garbage can body, the garbage can body is divided into two storage chambers by the baffle, an upper cover is arranged on the upper portion of each storage chamber, the rear end of each of the two upper covers is fixed at the upper end of the baffle through a movable shaft, a garbage classification label is arranged on the upper surface of each upper cover, and the rubber suckers which are used for enabling the garbage can body to be fixed inside a car are arranged on the four corners of the bottom of the garbage can body. According to the vehicle-mounted garbage can provided with the suckers, due to the fact that the two storage chambers are arranged, garbage can be recycled in a classified mode, and space is large; due to the fact that the rubber suckers are arranged on the bottom of the garbage can body, the vehicle-mounted garbage can can be fixed inside the car and can not fall over when the car shakes; the structure is simple, using is convenient, the garbage can be classified, environmental friendliness is achieved, and the application prospect is good.

Owner:王双双

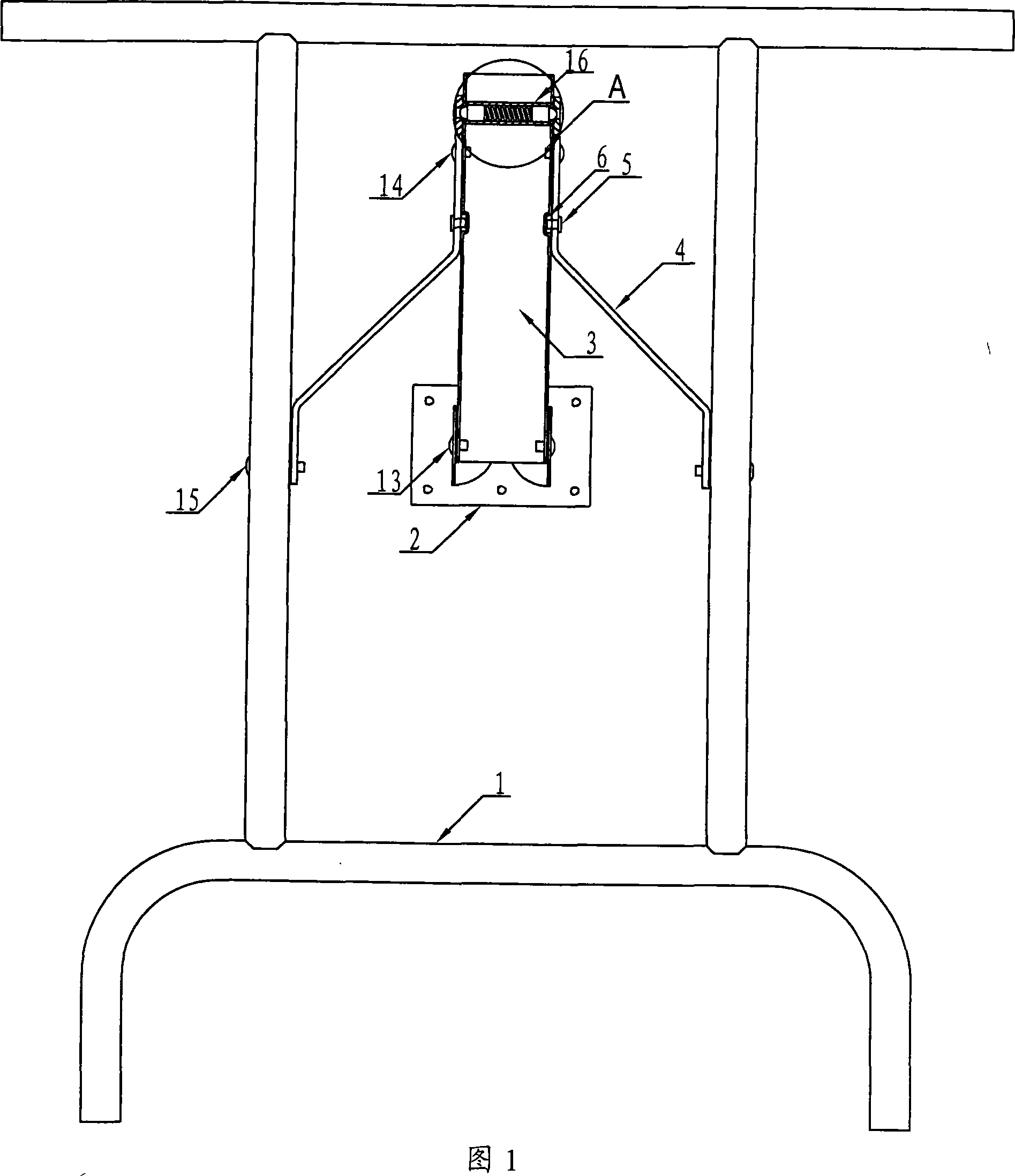

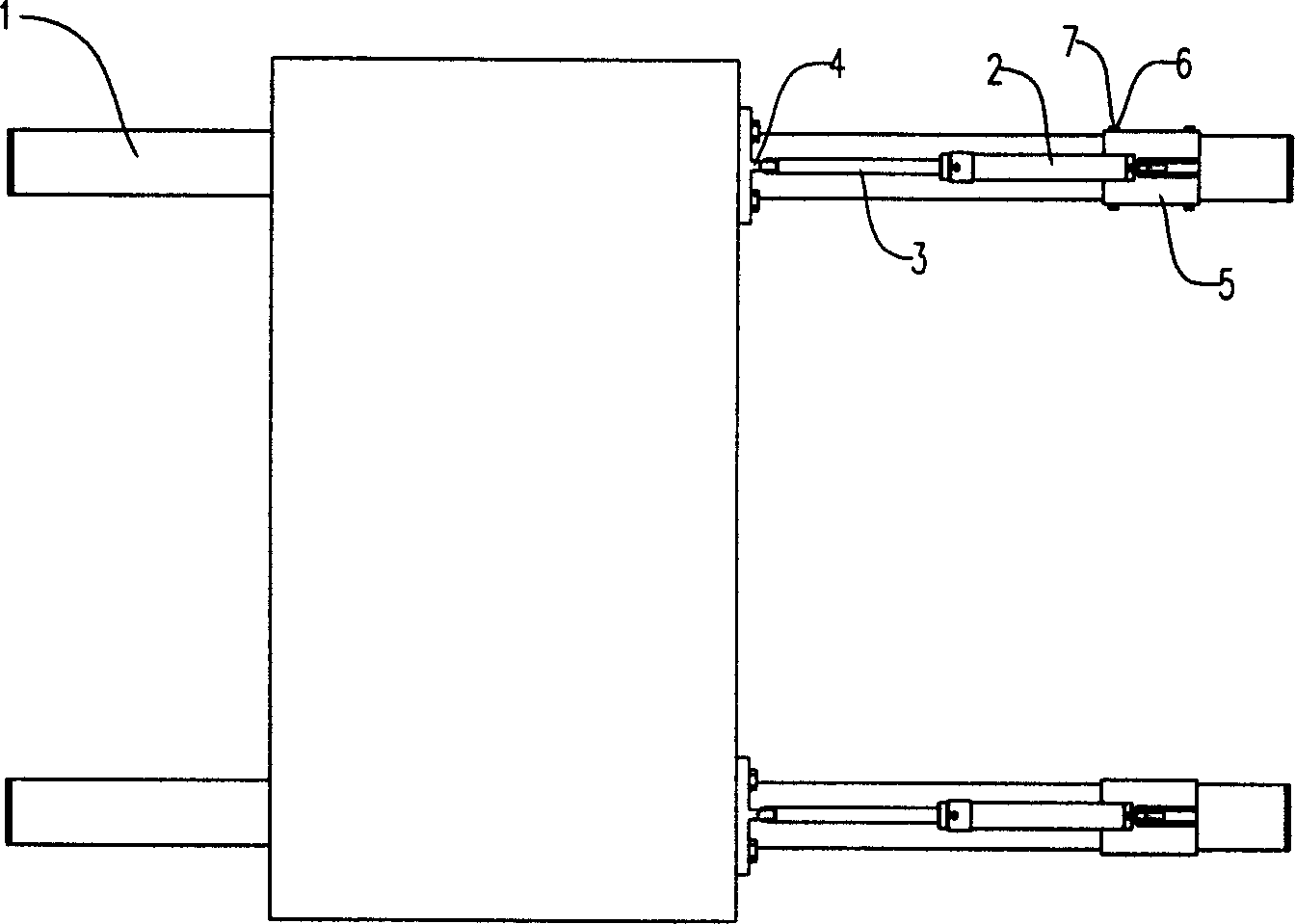

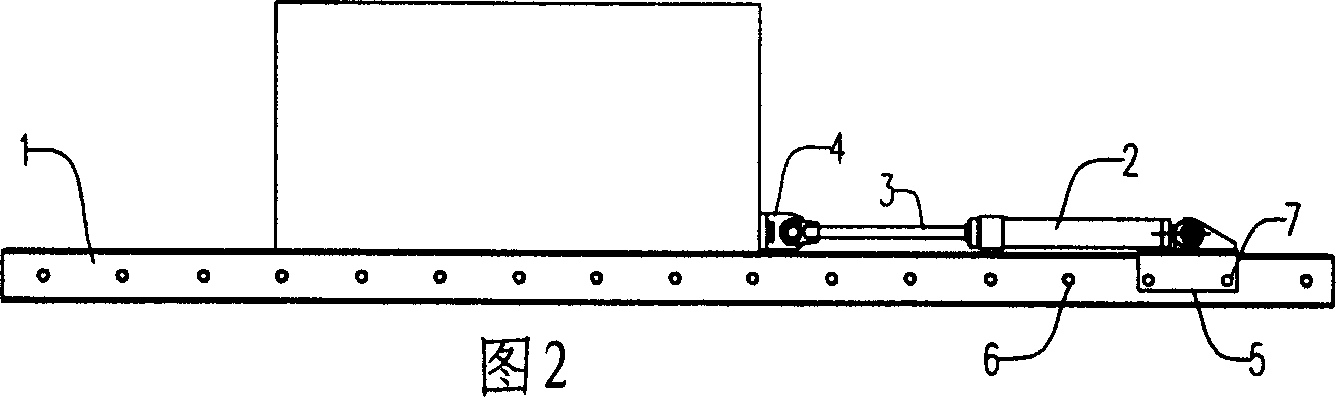

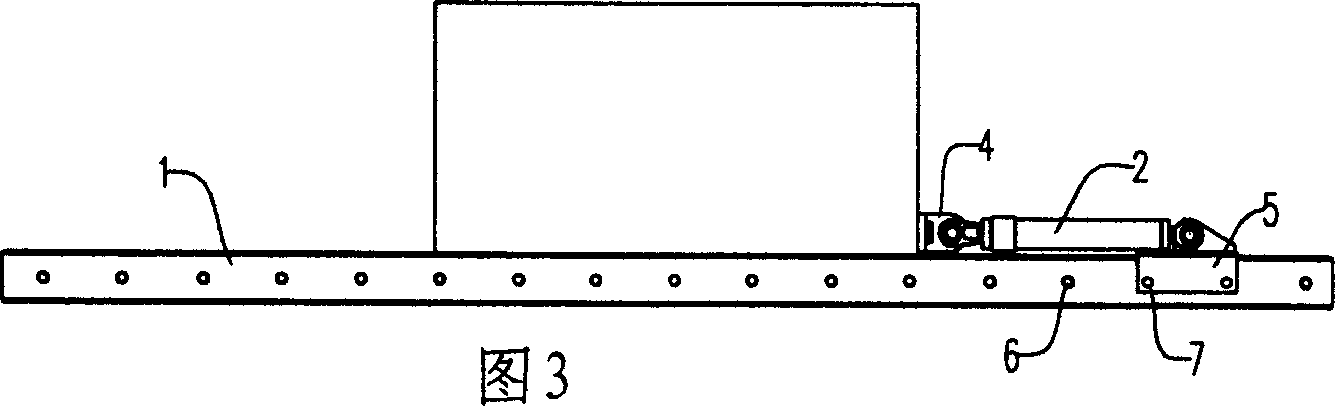

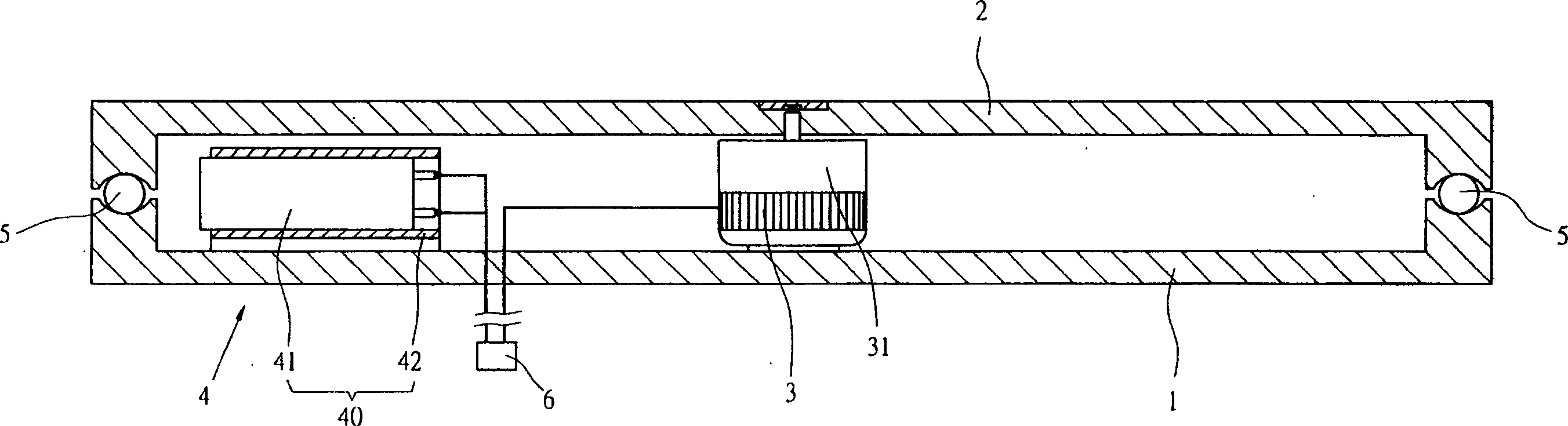

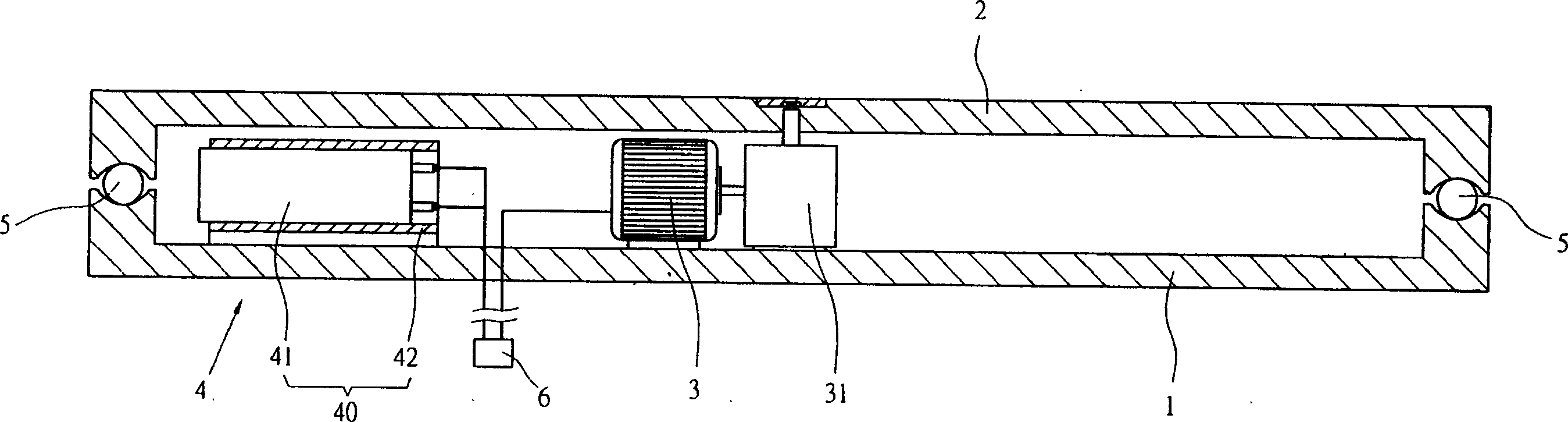

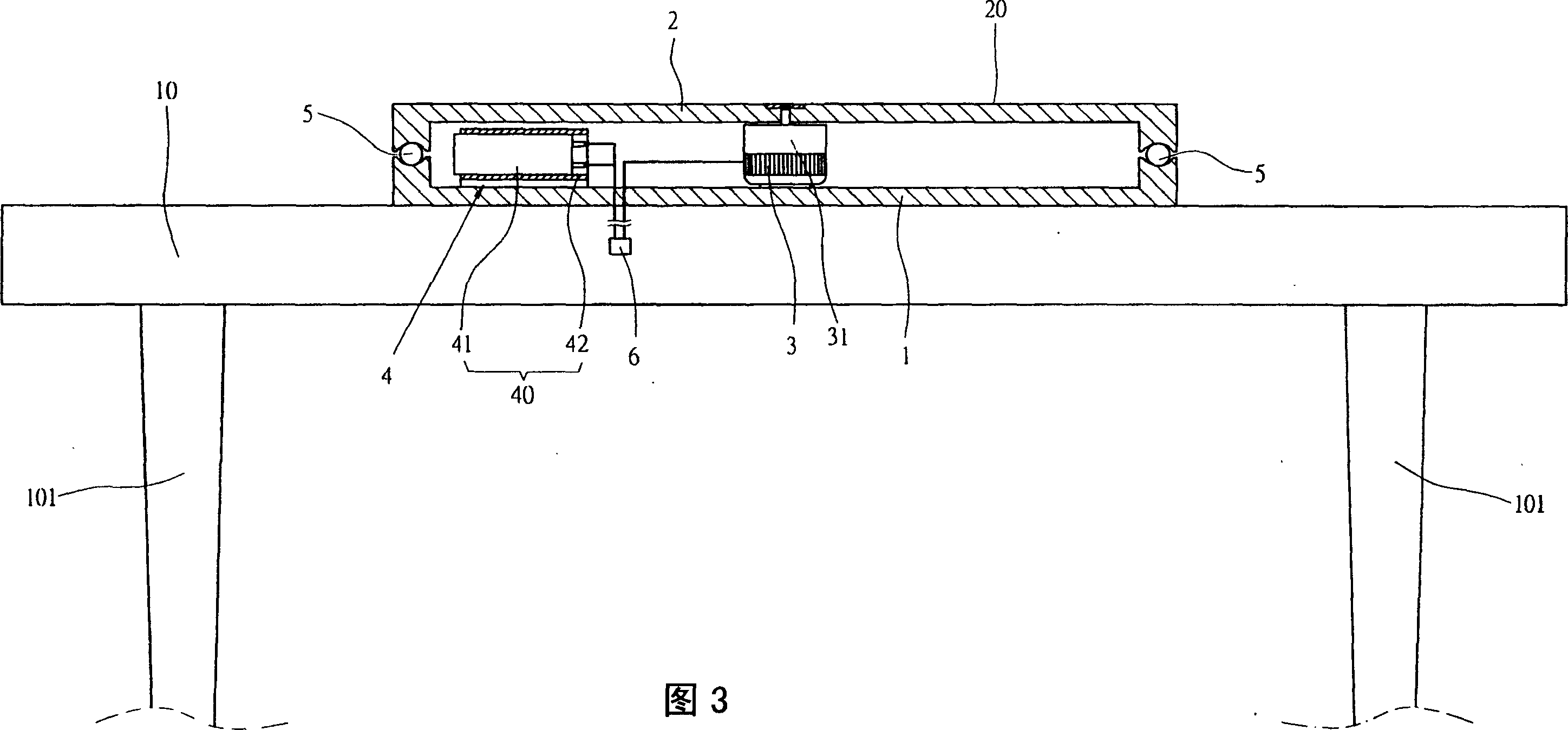

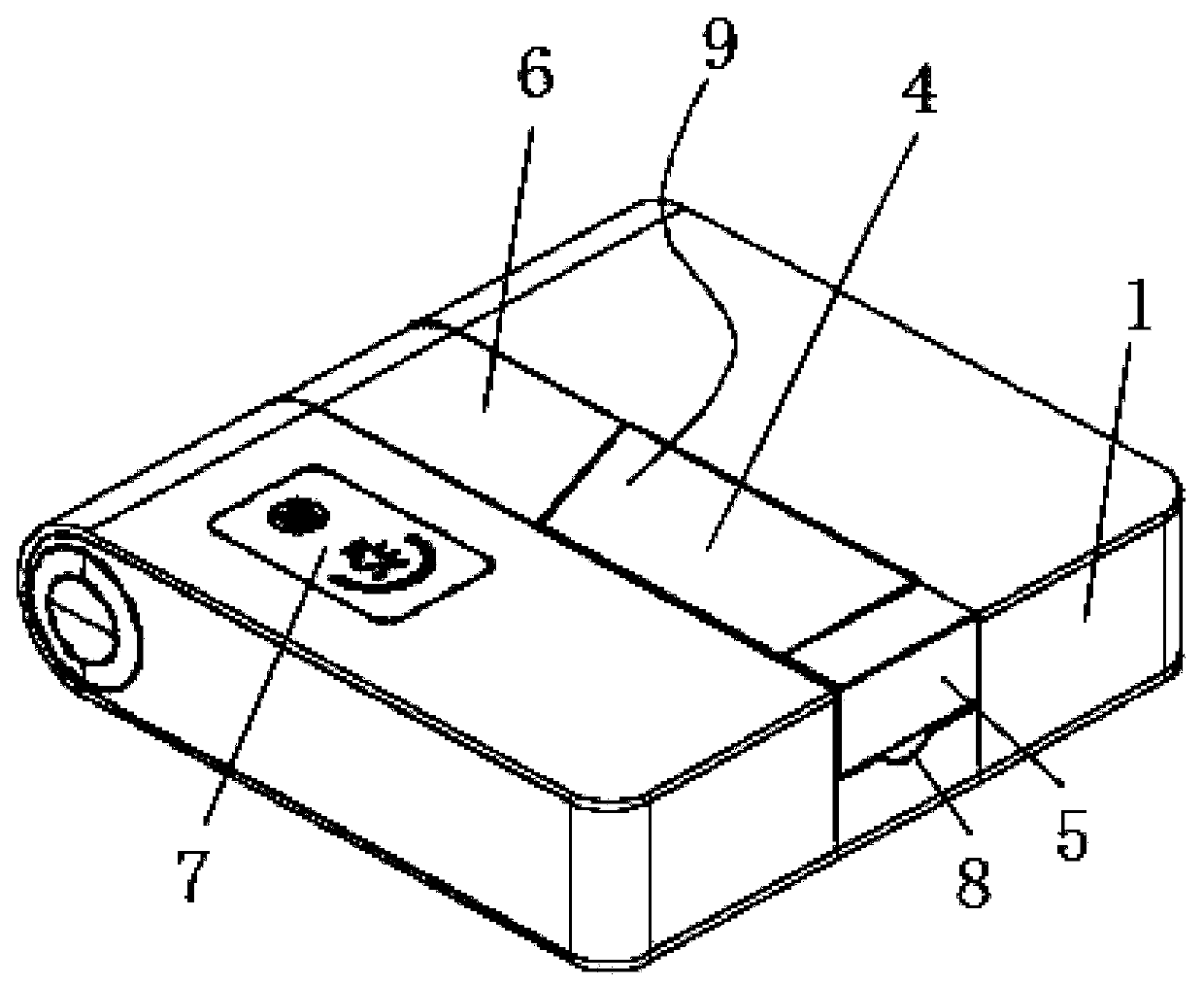

Method and device for moving heavy object

InactiveCN1785792AWon't fall overWon't hurtLifting devicesHoisting equipmentsHydraulic cylinderTrackway

The present invention relates to a method for moving weight and its equipment. Said method includes the following steps: firstly, laying moving trackway on the moving foundation surface, placing the weight on the moving trackway, then using hydraulic cylinder to pull weight sectionally and make the weight be forward moved along the trackway. Said equipment includes the components of hydraulic cylinder, piston rod, connecting piece and fastening piece, etc.

Owner:中船海洋与防务装备股份有限公司

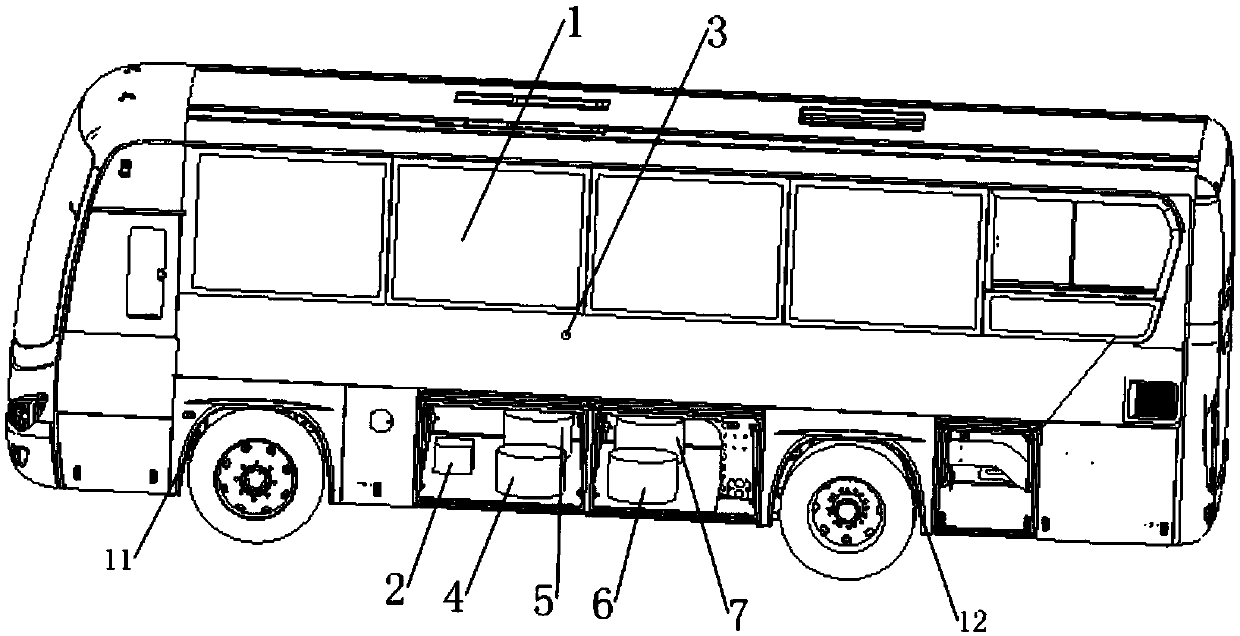

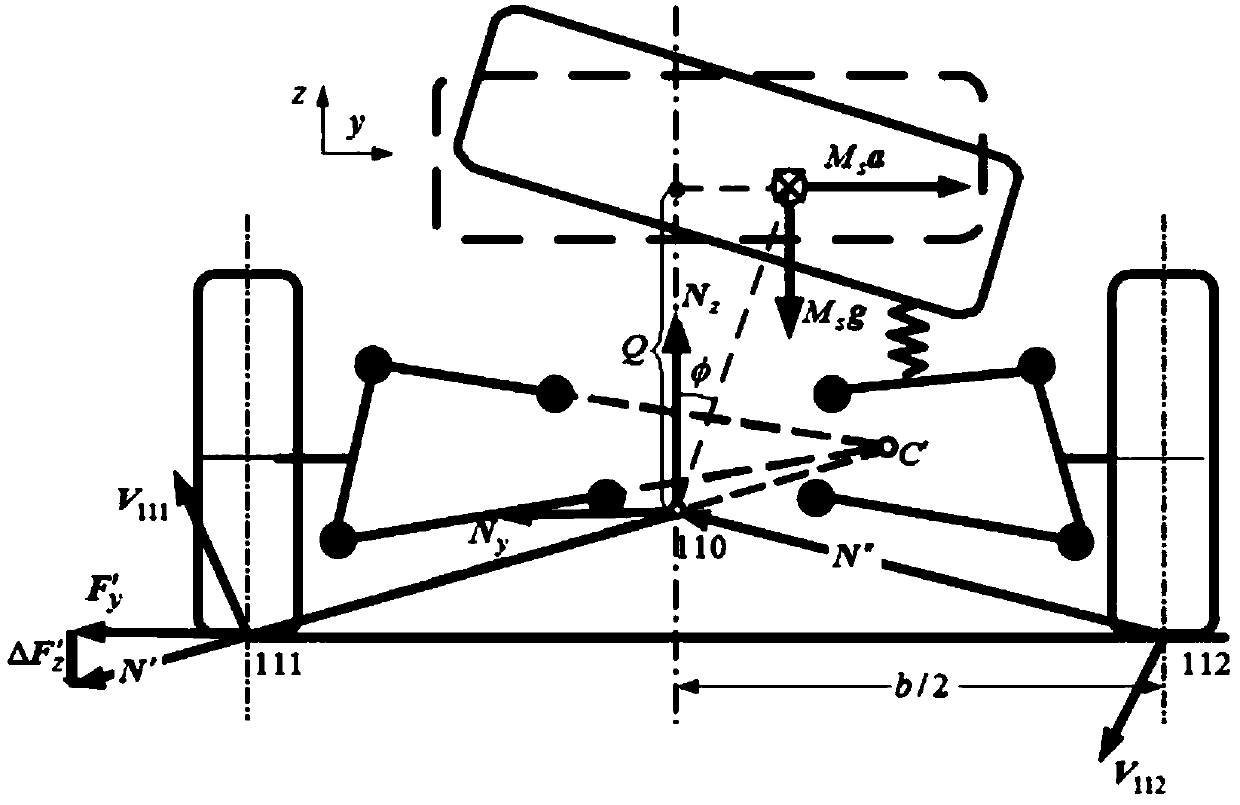

Vehicle anti-rollover method based on control moment gyroscope

ActiveCN110412995AWon't fall overAvoid singularity problemsAttitude controlRolloverMeasurement device

The invention relates to the field of vehicle rollover prevention, in particular to a vehicle anti-rollover method based on a control moment gyroscope. When a vehicle turns or is under external interference stimulation, a measurement device detects the response of the vehicle, the own suspension mechanism dynamics of the vehicle can be combined to estimate the state of the vehicle through a vehicle rollover model, the control moment gyroscope generates torques of thousands of N.m for keeping the balance of a vehicle body, and therefore, the vehicle is free from rollover under any situation even under a collision situation. A rollover judgment system can accurately estimate the tilt state of the vehicle so as to judge vehicle rollover. Meanwhile, the own mechanism characteristics of the vehicle are fully considered. Through a continuous anti-rollover moment output by the control moment gyroscope, the vehicle is free from rollover under any situation even under the collision situation, and a corresponding control algorithm can guarantee singularity avoidance and accurate moment output.

Owner:ZHENGZHOU YUTONG BUS CO LTD

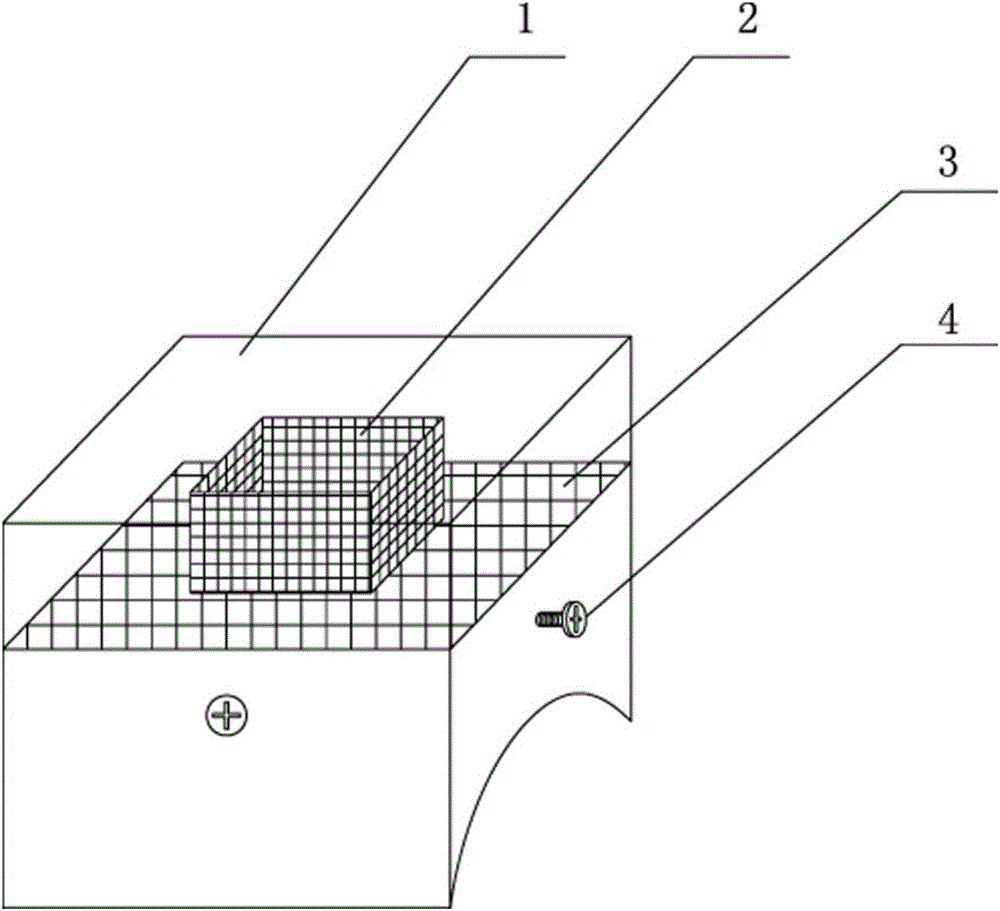

Moxibustion box

InactiveCN106389112AAvoid the safety hazard of scalding the skinEasy to fixDevices for heating/cooling reflex pointsEngineeringCorrosion resistant

The invention discloses a moxibustion box. The shape of a body of the moxibustion box is hexahedron, the bottom is empty, an active top cover is arranged on the top. A support net is installed near the middle position in the inner wall of the body of the moxibustion box horizontally. And the middle of the support net is vertically provided with a square non-covered barrier net for placement and limit of a moxa cone, and the inner wall of the body of the box and the inner surface of the top cover above the support net are covered with an insulating film. The middle parts of the outer surface of four facades of the body of the moxibustion box are provided with a screw respectively, and is provided with a porous elastic band in a matched way. The four facades of the body of the moxibustion box are thickened multilayer plates to ensure that the screws are securely mounted. The support net is a heat resistant and corrosion resistant metal net. The barrier net is a corrosion resistant metal net. The moxibustion box has the advantages of safety, convenience and durability, and solves the problems of an existing moxibustion box that the support net is easy to oxidate and corrode to form broken holes so as to scald skin, the moxibustion box is easy to overturn in the treatment and treatment positions are limited.

Owner:邱晓虎

Dining table, and automatic rotating disk thereof

InactiveCN1751627APlenty of timeRelax and enjoyServing tablesRevolvable tablesMechanical engineeringElectric power

Owner:江权哲 +3

Nano-film flow-through type flat microheater

InactiveCN110074665AReduce volumeReasonable structural designWater-boiling vesselsBeverage vesselsEngineeringMicroheater

The invention relates to the technical field of liquid heating, in particular to a nano-film flow-through type flat microheater. The nano-film flow-through type flat microheater comprises a case, wherein the case is in a flat shape; an embedding groove is formed in the upper part of the case; a strip-shaped water outlet pipeline matched with the embedding groove is arranged at the position of theembedding groove; the bottom end of the water outlet pipeline is rotatably connected with one side edge of the case; a water outlet part is arranged at the top end of the water outlet pipeline; a water source joint is arranged in the middle of the embedding groove and is communicated with a water inlet of a water pump through a flowmeter; a water outlet of the water pump is communicated with a water inlet of a nano-film liquid heater; a water outlet of the nano-film liquid heater is communicated with the water outlet part through a silicone tube; and the silicone tube is arranged in the wateroutlet pipeline. Because the device is in the flat shape, the nano-film flow-through type flat microheater is laid flat when being used, so that the heater is used stably and cannot turn over; and moreover, because the size of the device is smaller, the device is convenient to carry, is reasonable in structural design, is high in commonality and can meet use of broad masses.

Owner:WUHU ALDOC TECH CO LTD

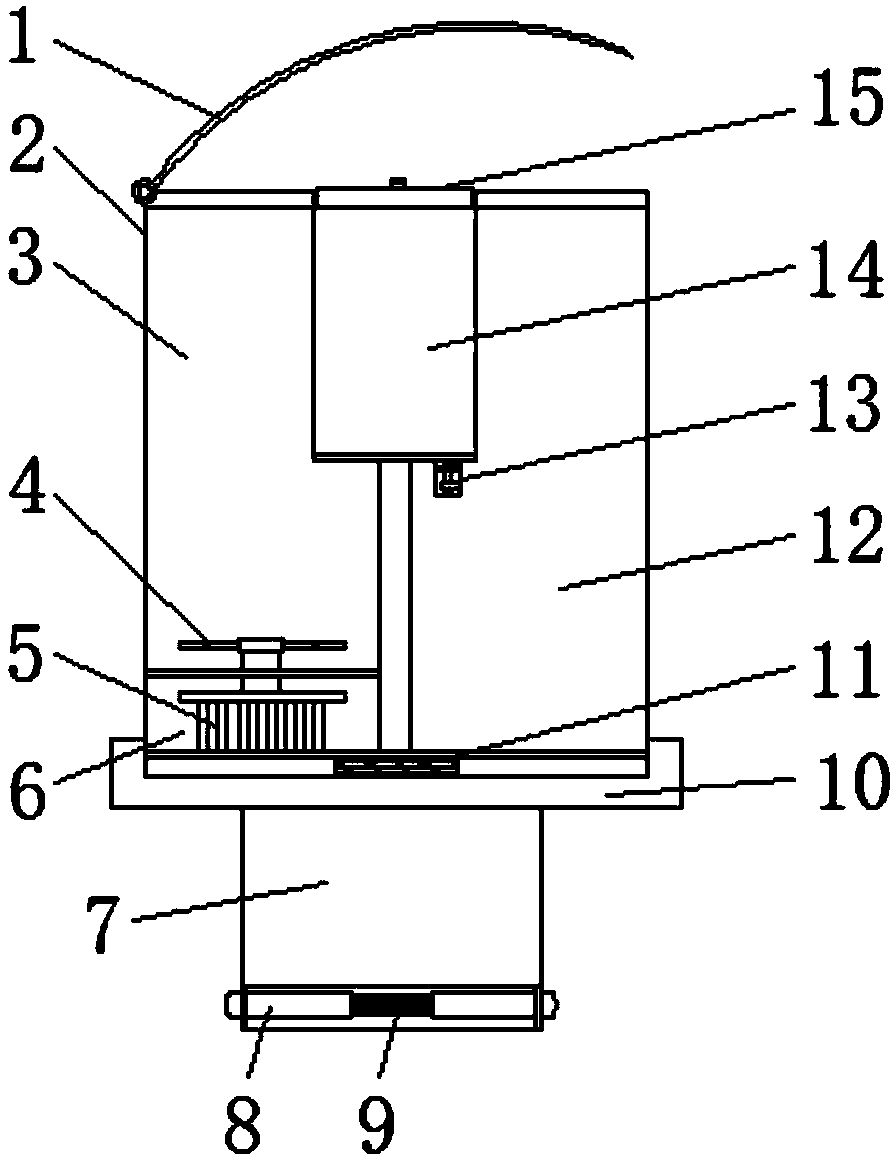

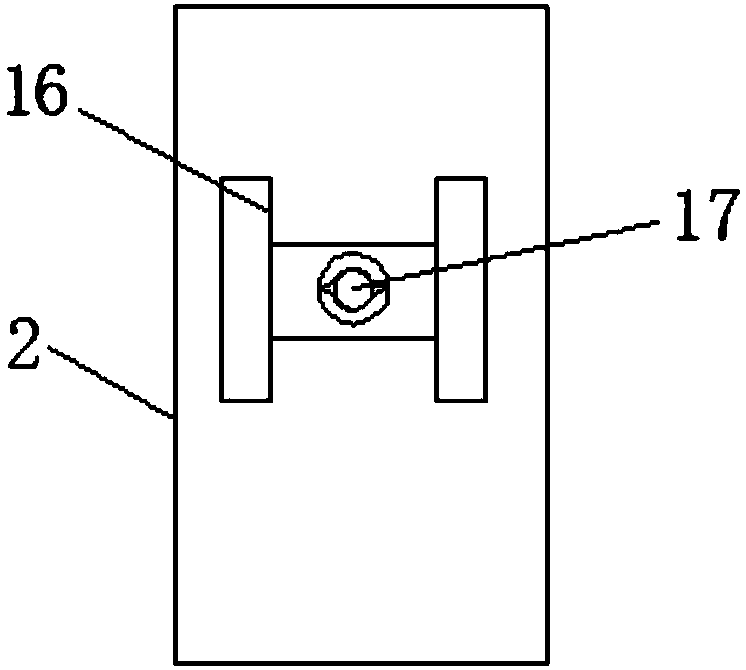

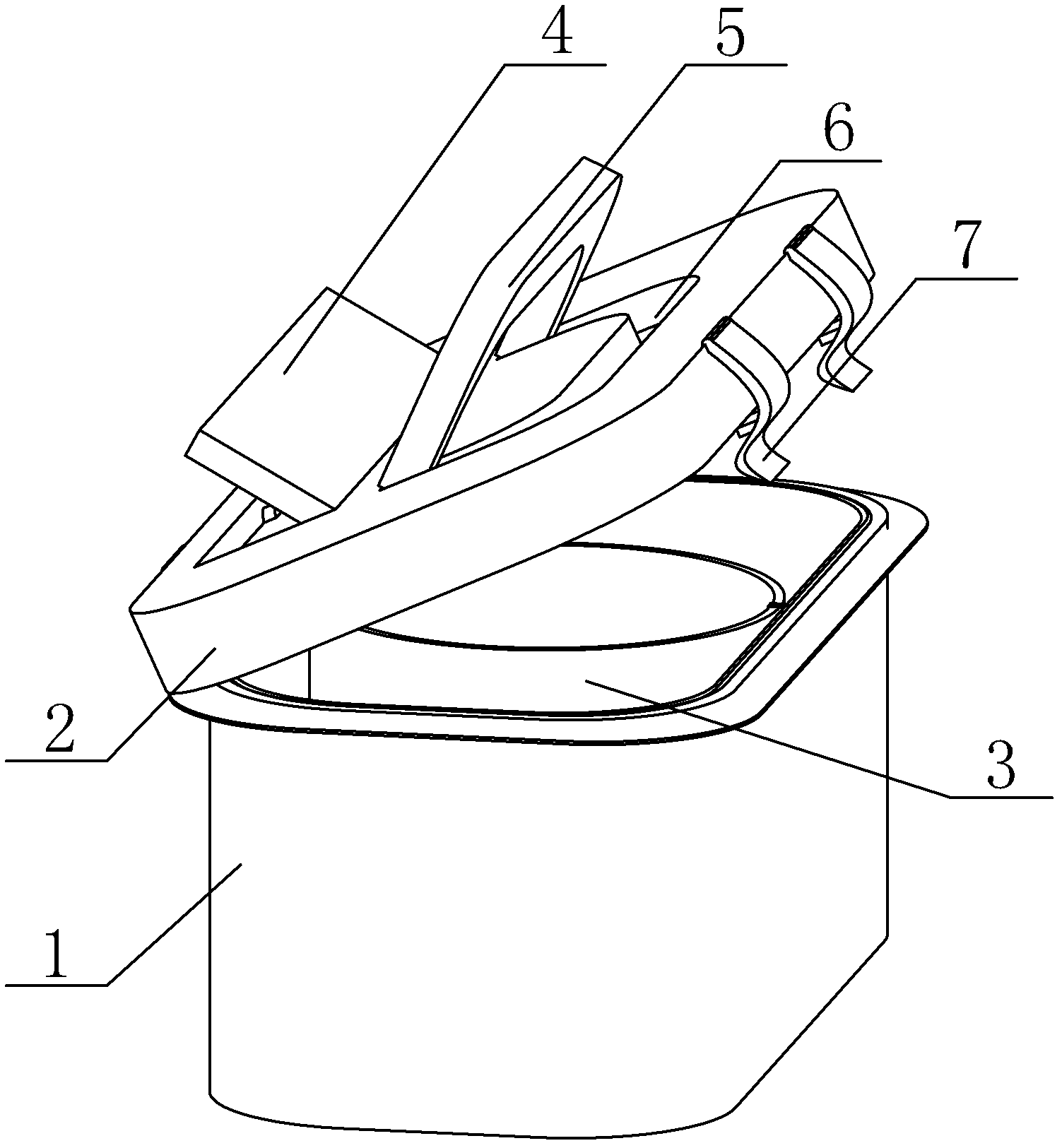

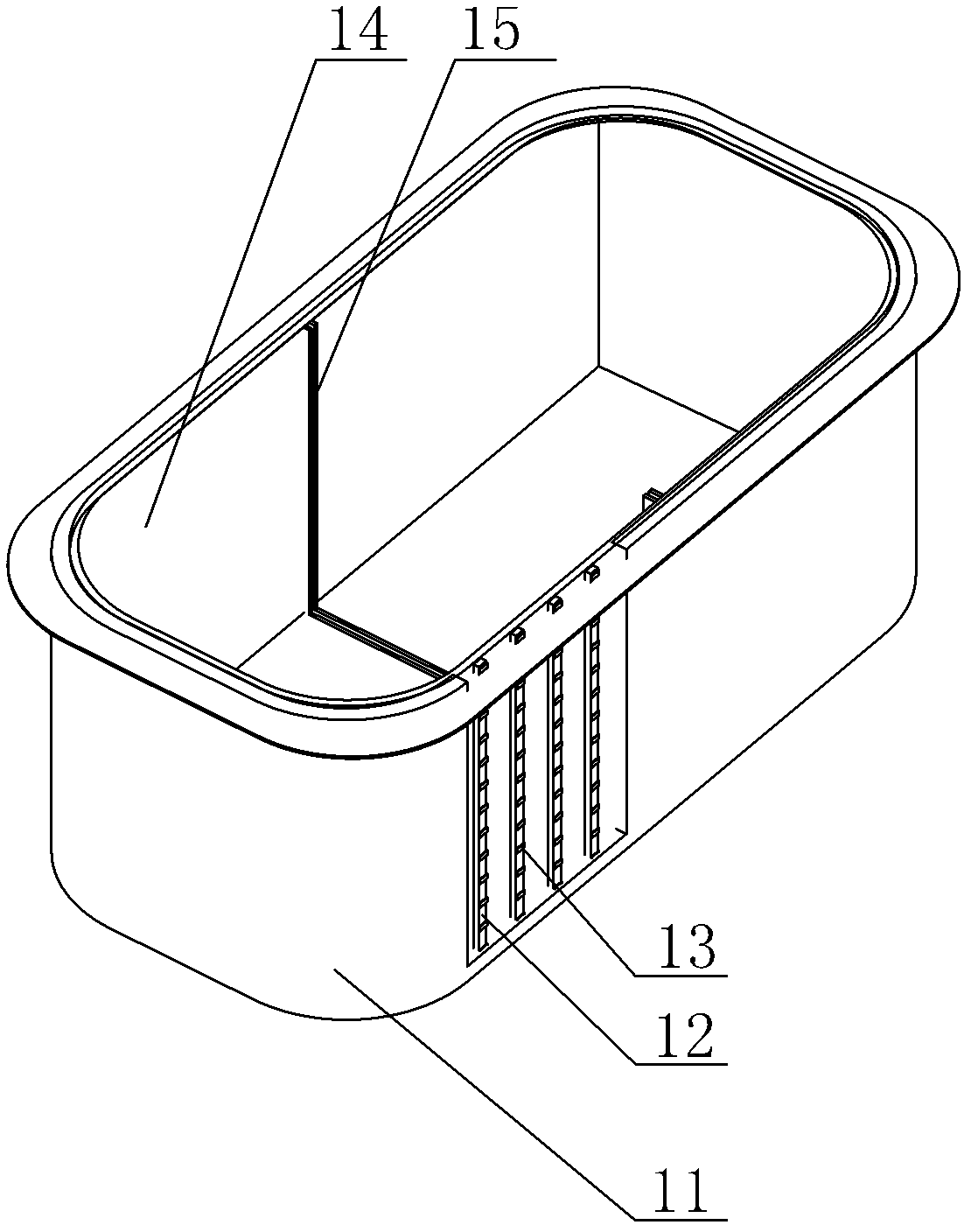

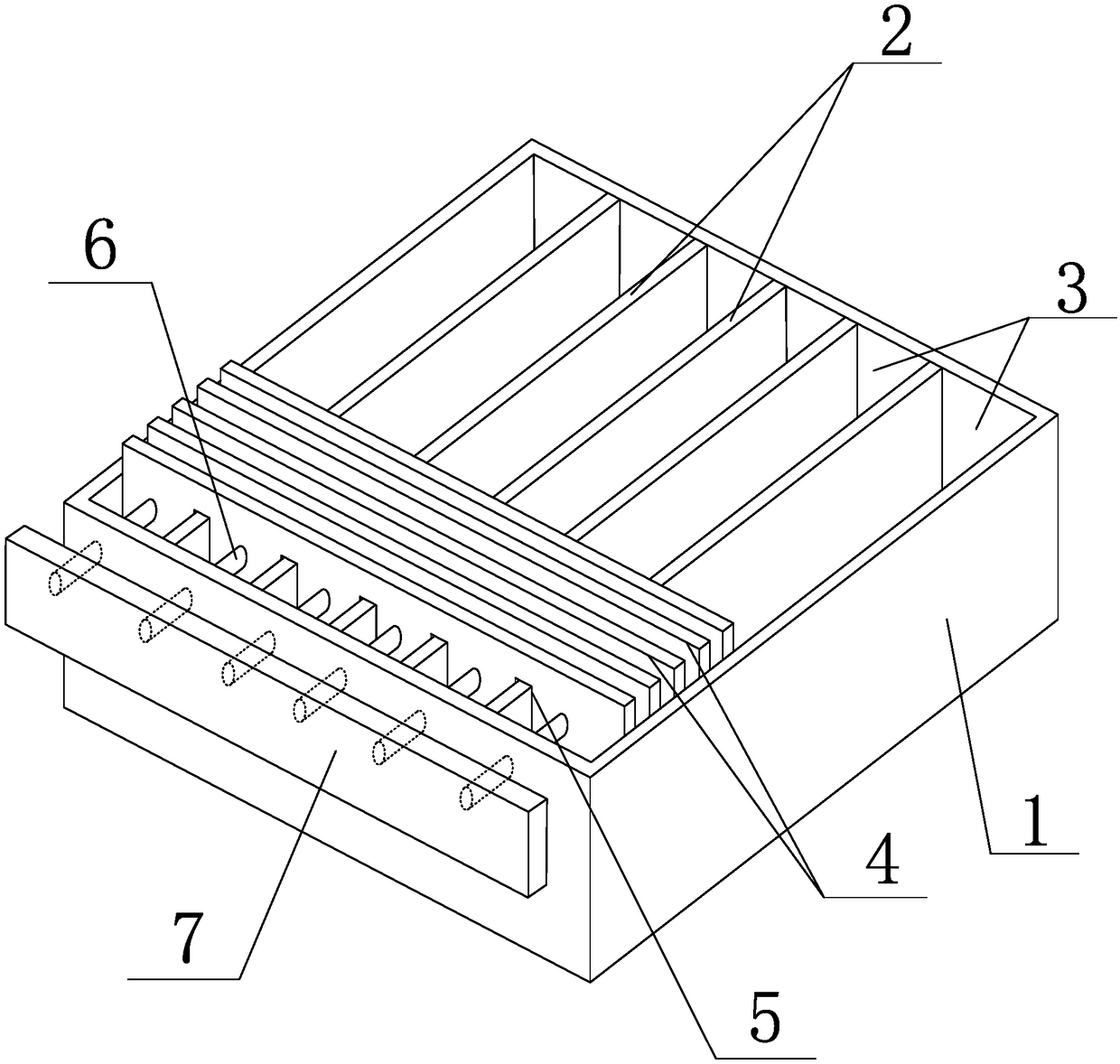

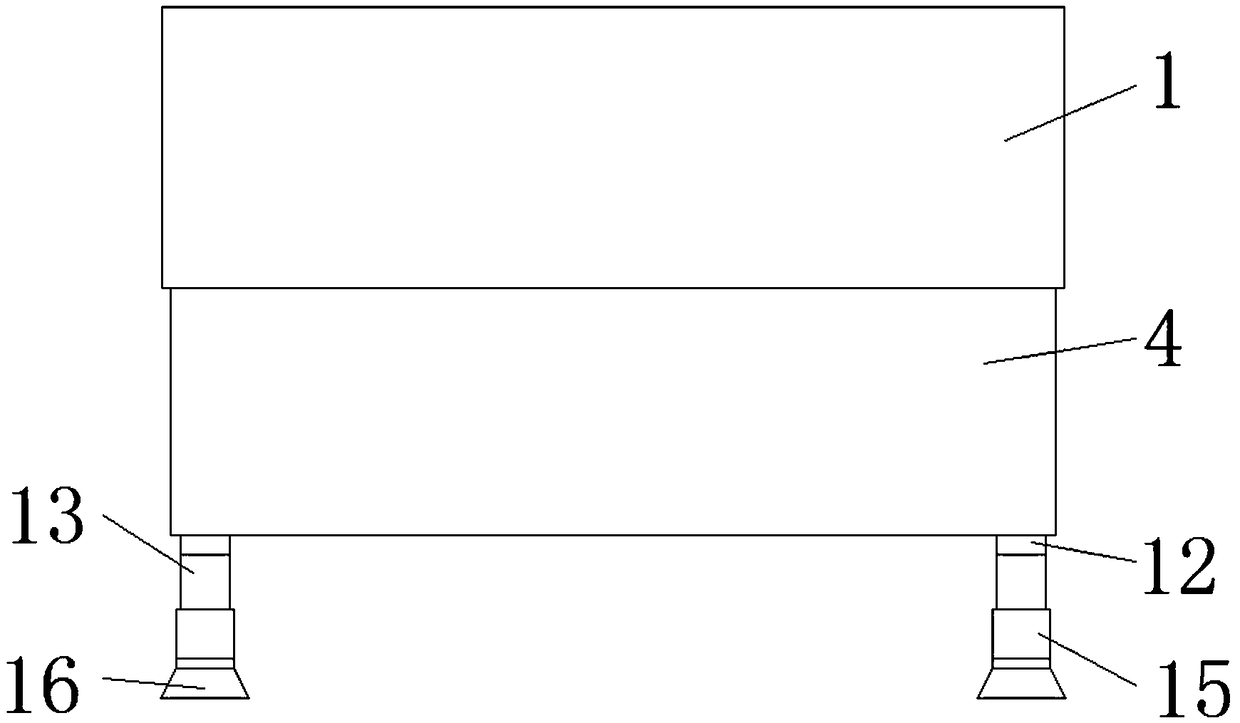

Lunch box with bowl

The invention discloses a lunch box with a bowl. The lunch box with the bowl comprises a box body (1) and a box cover (2), wherein the box cover (2) is arranged above the box body (1); the box body (1) is internally provided with the bowl (3) and an insertion groove (15); the bowl (3) is provided with an insertion plate (16) corresponding to the insertion groove (15); and the bowl (3) is inserted on the insertion groove (15) in the box body (1) through the insertion plate (16). The lunch box with the bowl, provided by the invention, not only can be used for containing dishes, but also can be used for containing soup, and simultaneously is provided with a cavity body for containing pieces of chopstick or a spoon; a handle is arranged, and the lunch box with the bowl is very convenient to carry; and heat insulation bars, heat insulation blocks and a rubber gasket are arranged, not only can a certain temperature preservation effect be played on the interior of the box, but also hands can be prevented from being burnt, and the convenience is brought about for living of people.

Owner:沈金根

Tray and device for stabilising a tray

Owner:SAFETRAY PRODS

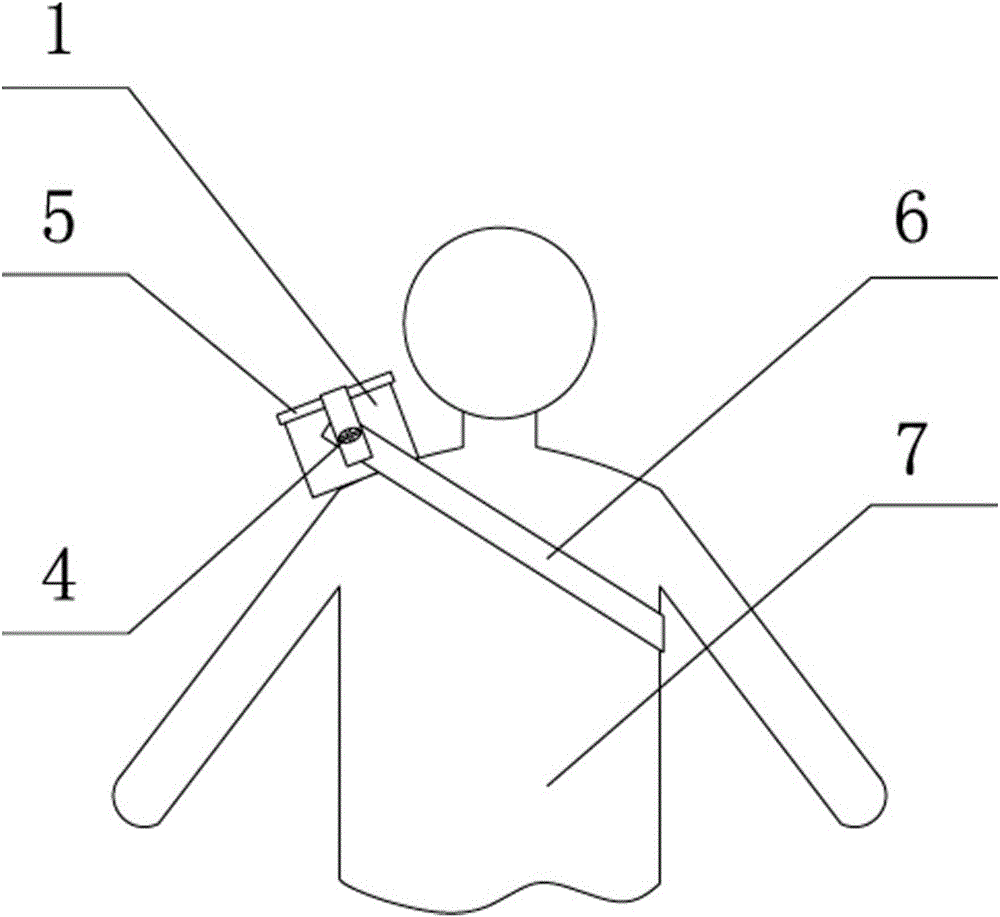

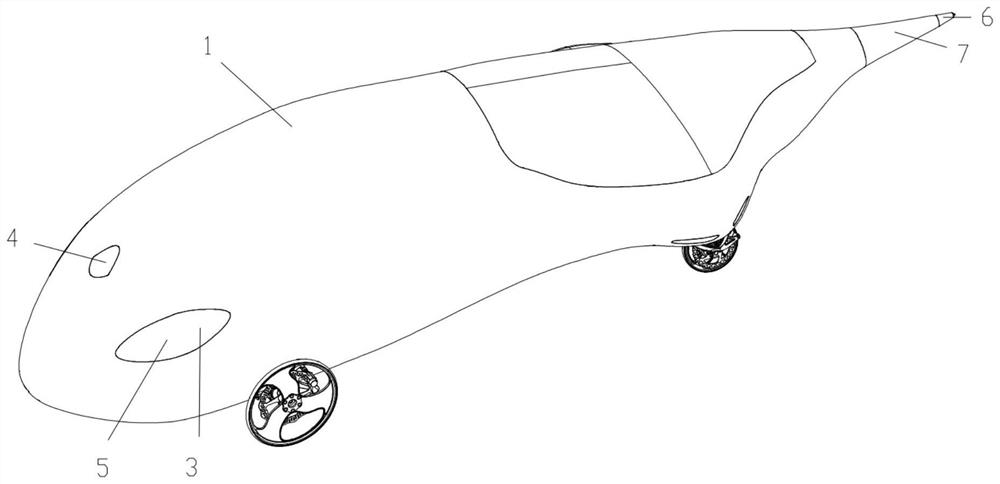

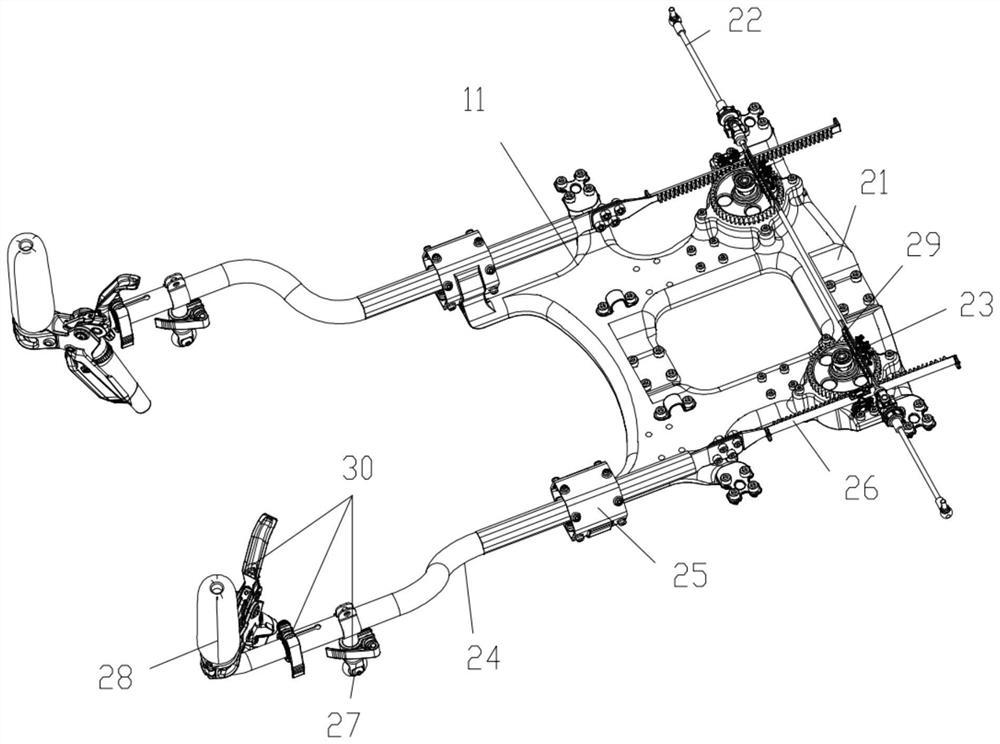

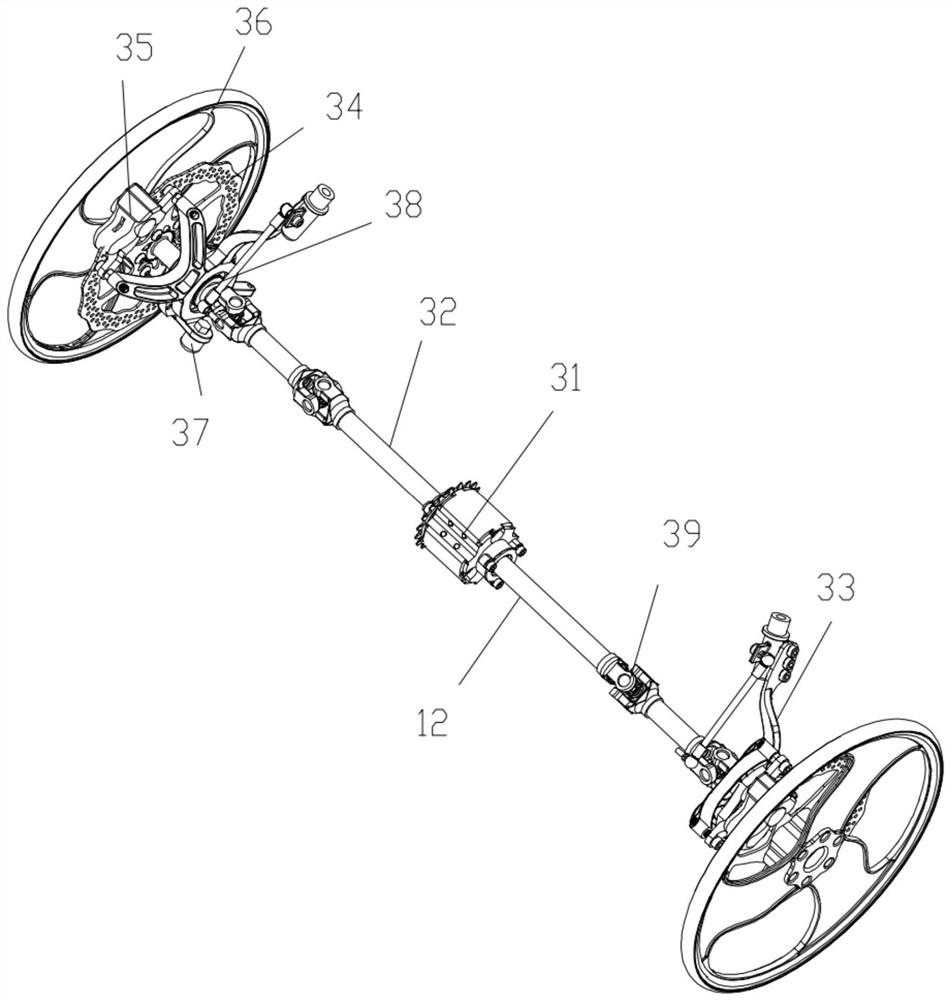

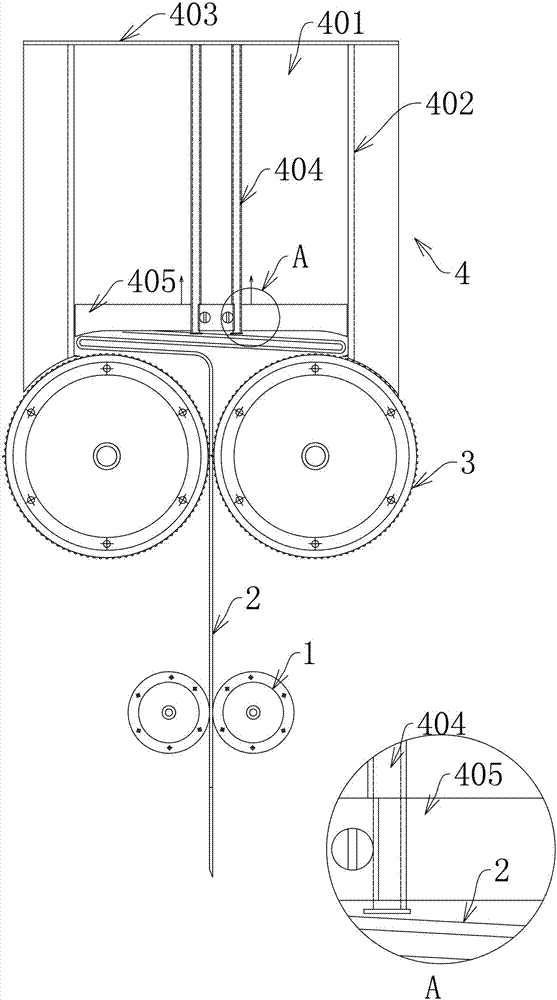

Low-wind-resistance lying type bicycle

InactiveCN112572665AImprove powerImprove work efficiencyCyclesWheel based transmissionVehicle frameCycle exercise

The invention provides a low-wind-resistance lying type bicycle, which comprises a shell, a bicycle frame, a bicycle lamp, a first camera, a second camera, a third camera, a bicycle tail, VR glasses,a seat, a driving system, a steering control device, a front braking device and a suspension system, can reach a considerable speed with small power and has good safety. Therefore, oil resource consumption and carbon emission are reduced, road congestion is relieved, personal safety of non-motor vehicle users is well guaranteed, and a new form is added for bicycle sports.

Owner:敖立鸿

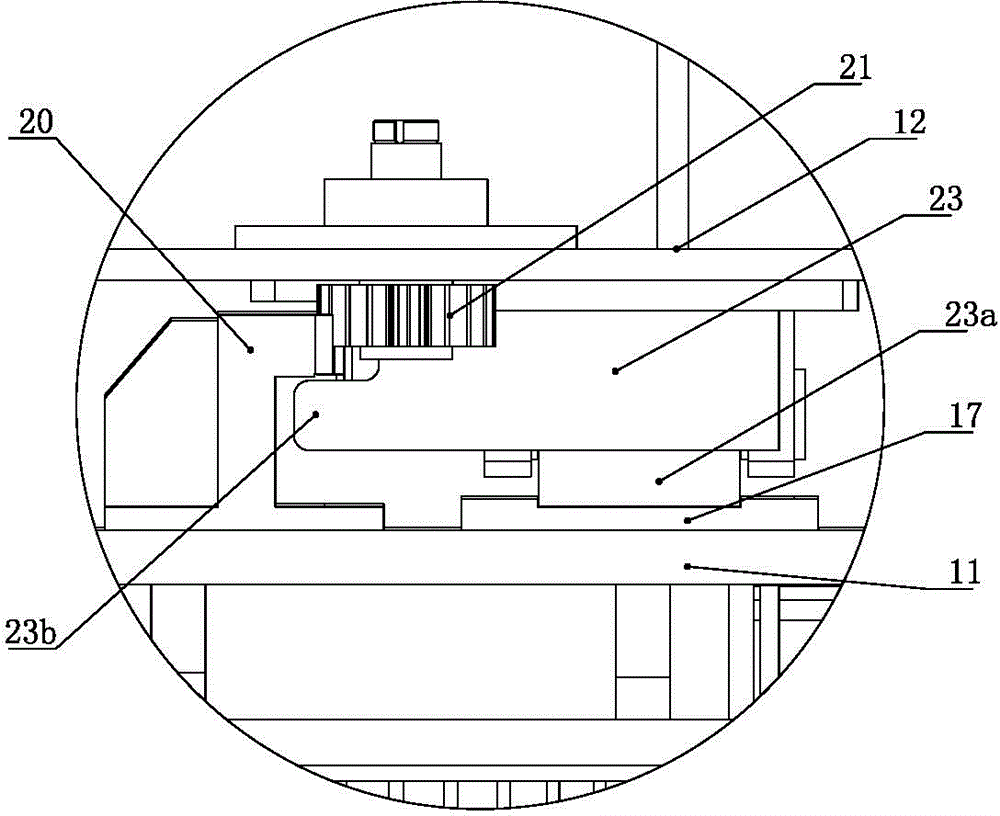

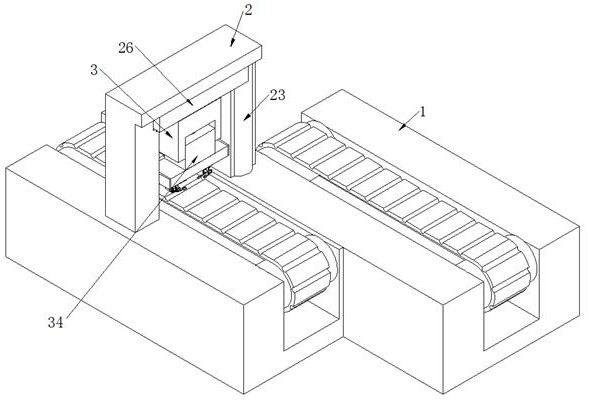

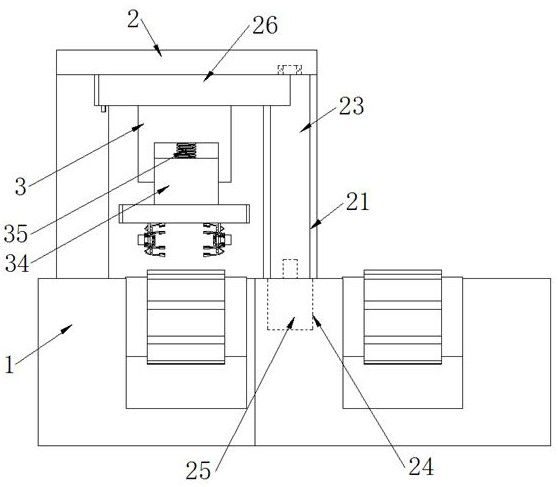

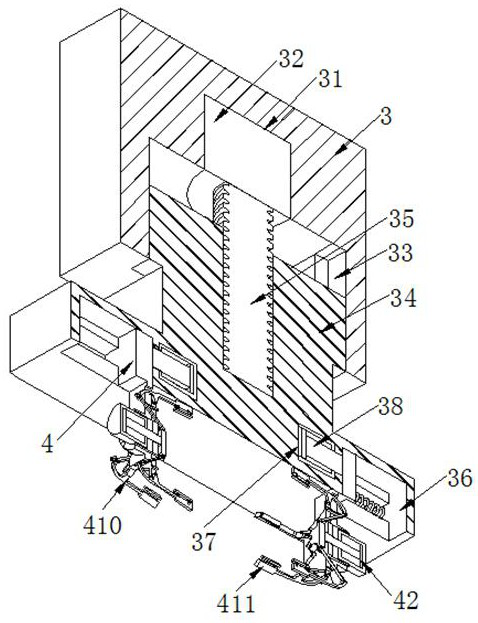

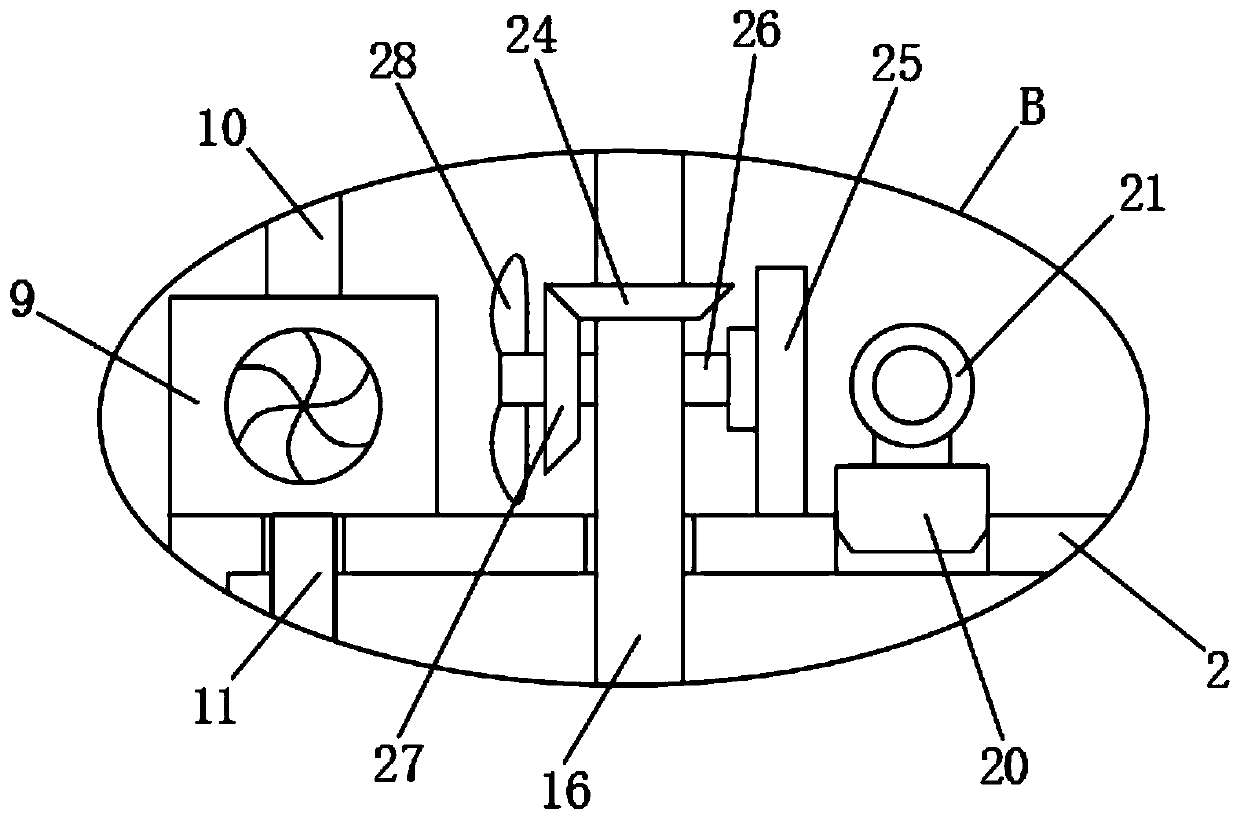

High-speed gauze folding machine

The invention provides a high-speed gauze folding machine. The problems that when gauze passing folding rollers enters a placing table, gauze mess easily occurs, inconvenience is brought to the following packaging procedure, the gauze is easily entangled on the folding rollers, and machine damage is caused are solved. The high-speed gauze folding machine comprises roller pairs for conveying gauze, a folding mechanism for folding the gauze and a placing table for collecting the gauze passing the folding rollers, wherein the placing table comprises a groove body; the two sides of the groove body are separately provided with vertical guide plates; a vertical baffle is arranged in the groove body; the baffle is in sliding fit with two guide shafts which are fixedly arranged in parallel through shaft holes; each guide shaft is fixed to a tail plate of the placing table; the guide shafts are in transmission fit with a runner which is driven by the guide shafts moving along the axes to rotate in the plane; and a structure that the baffle intermittently moves backwards is formed by the intermittent rotating of the runner. When the folding rollers carry out folding, a proper distance is always kept between the baffle and the folding rollers.

Owner:XINXIANG HUAXI MEDICAL SANITARY MATERIALS

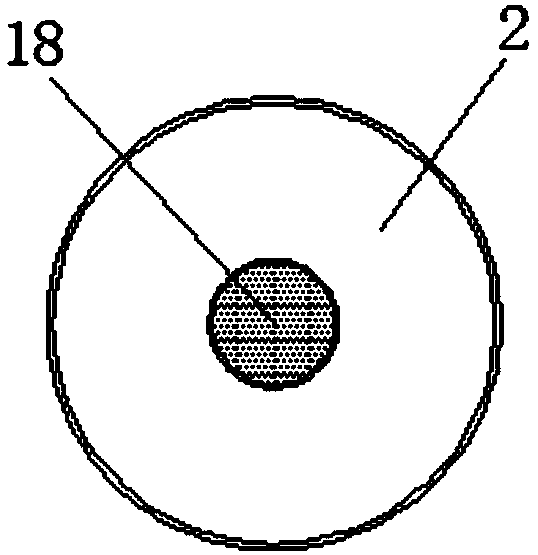

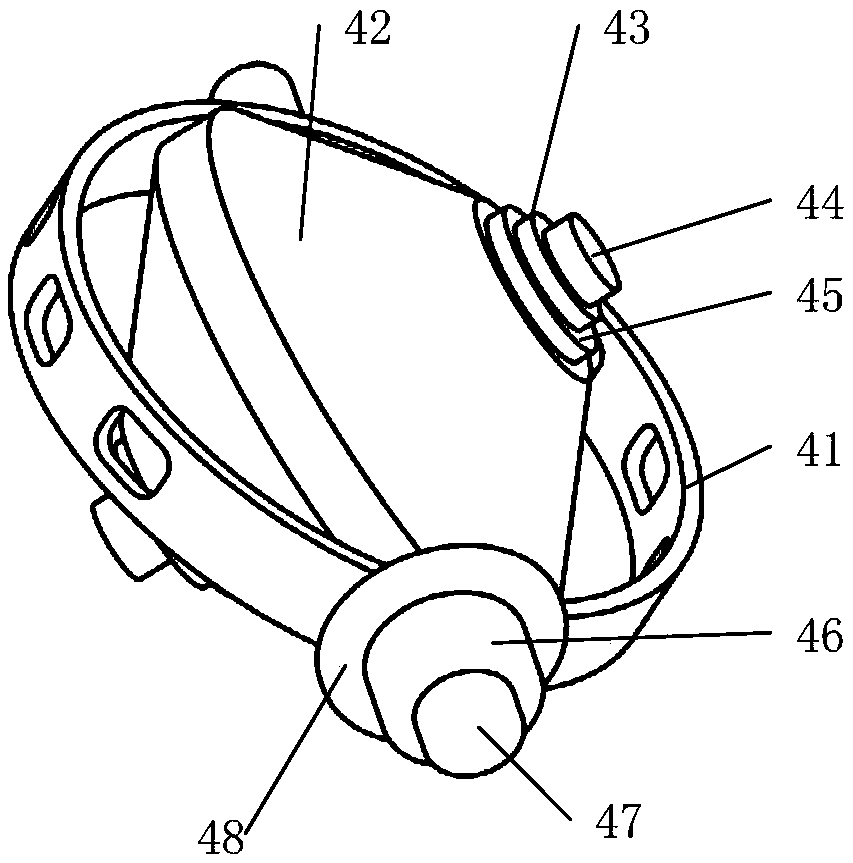

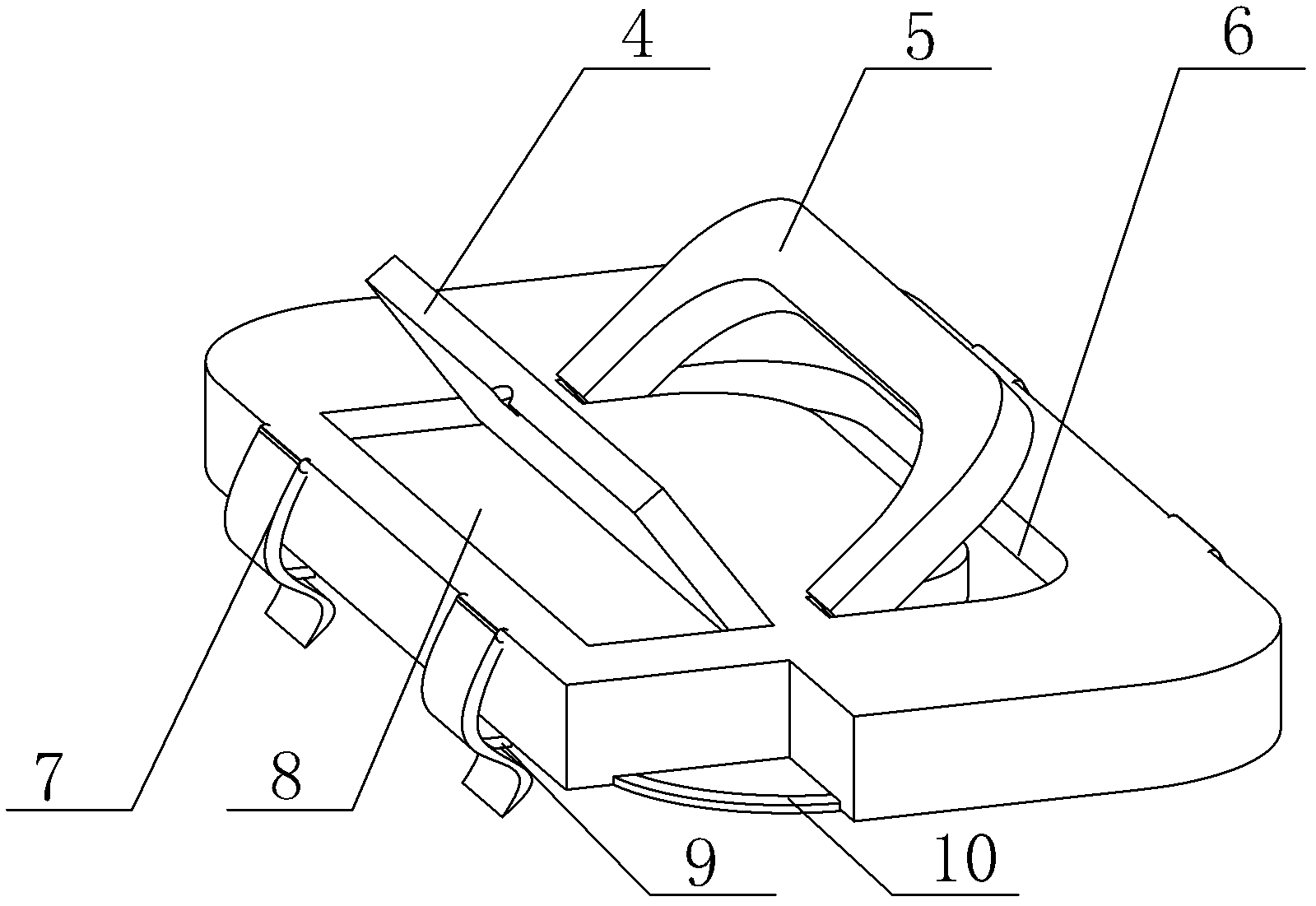

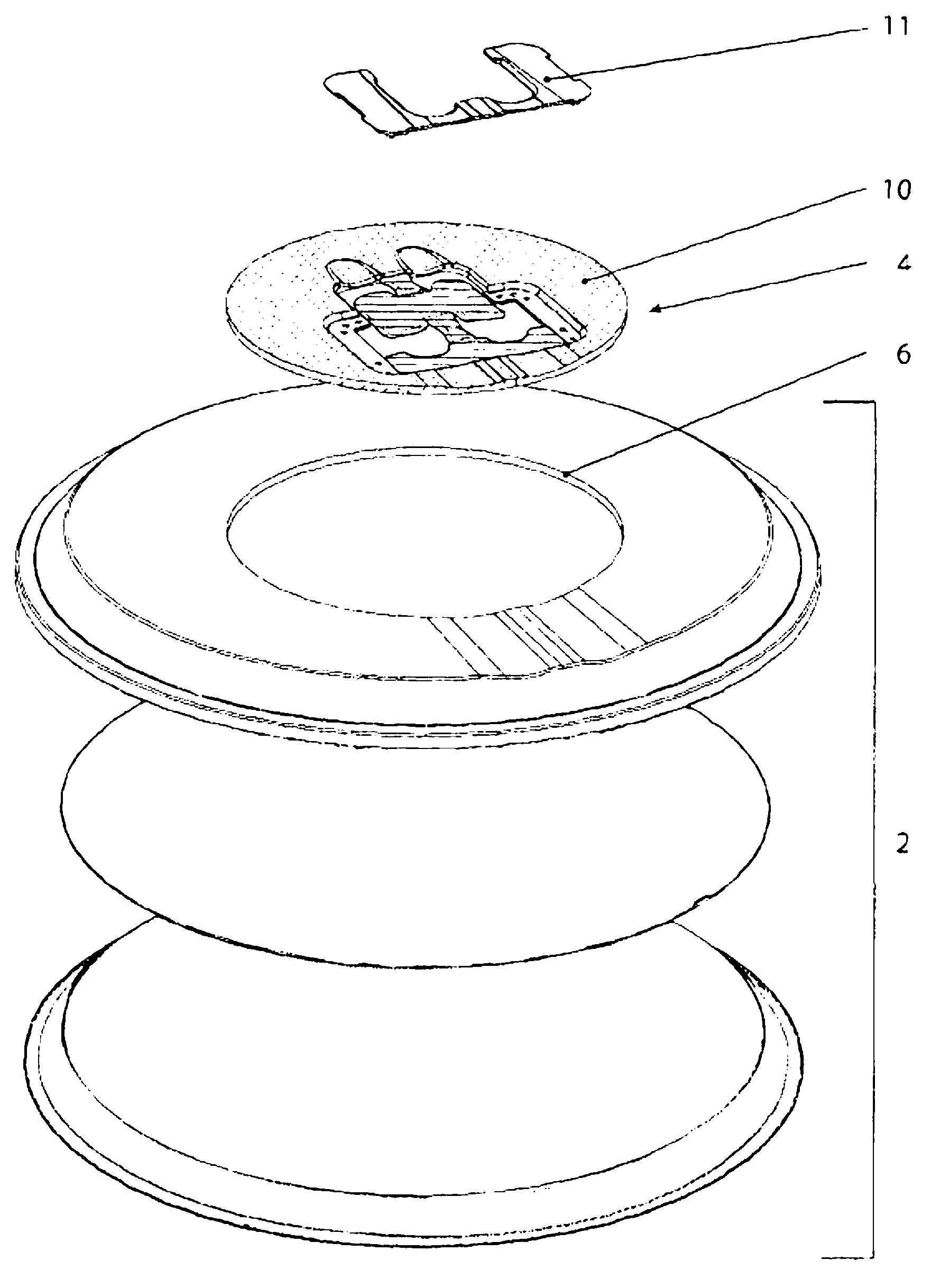

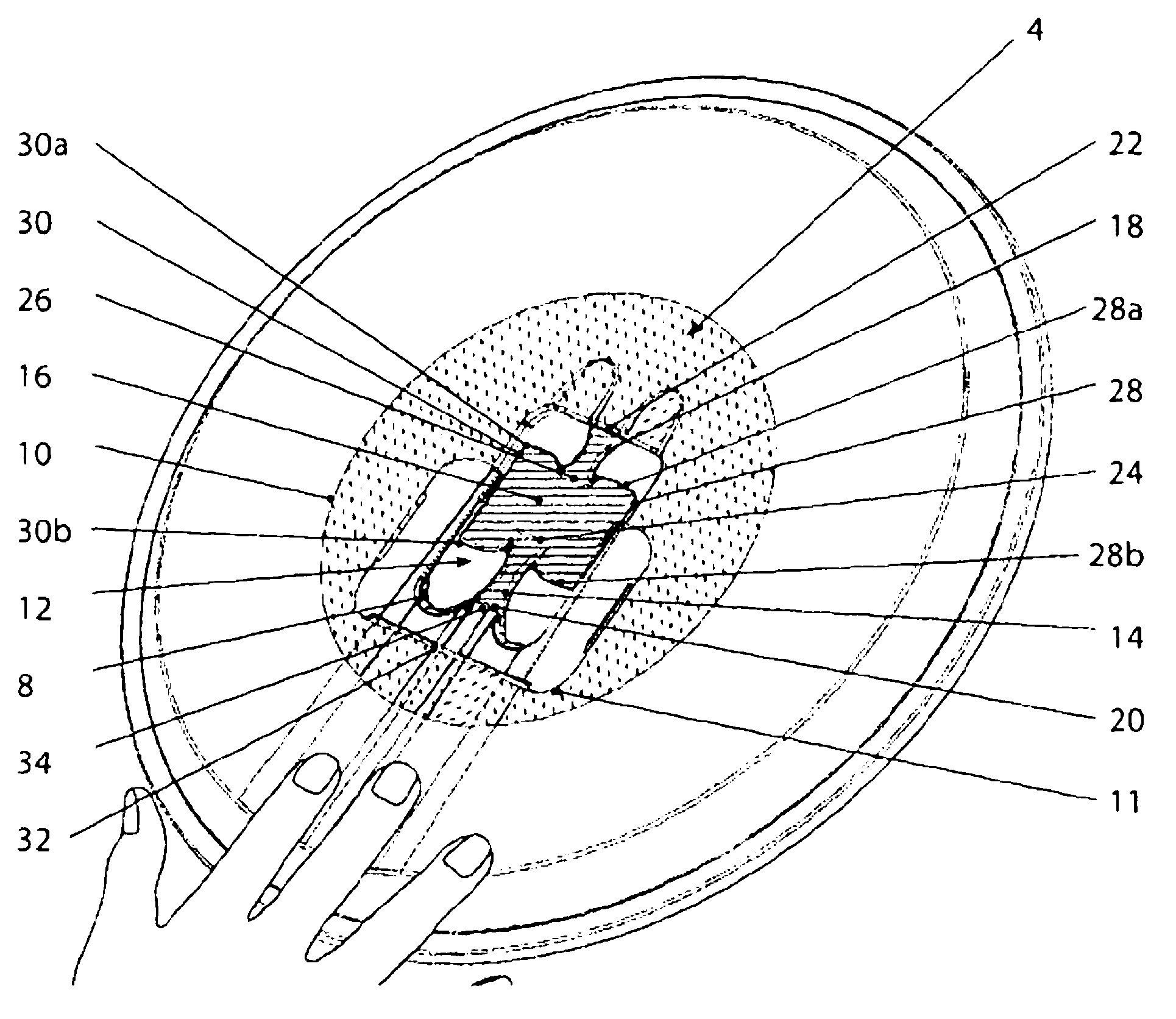

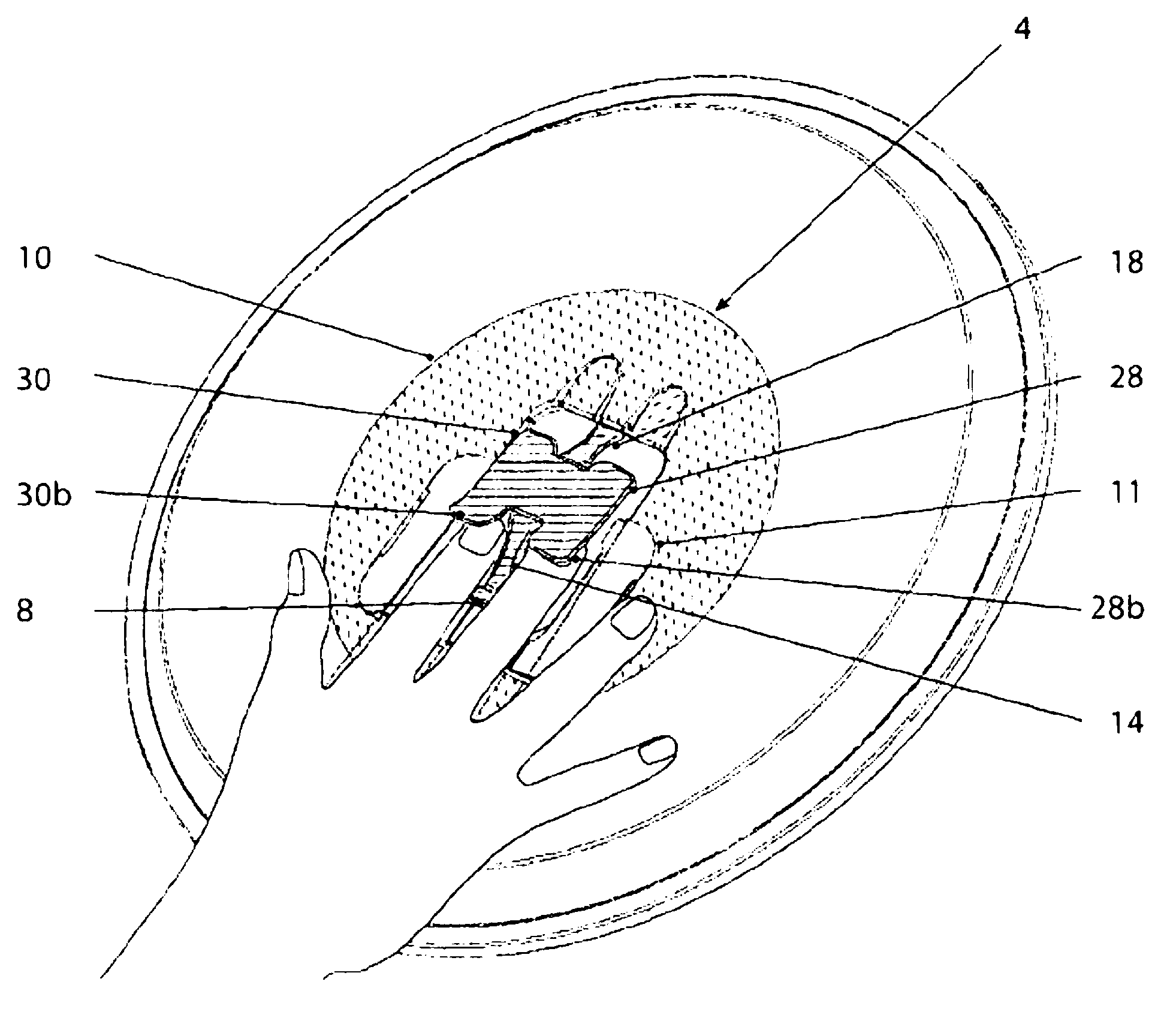

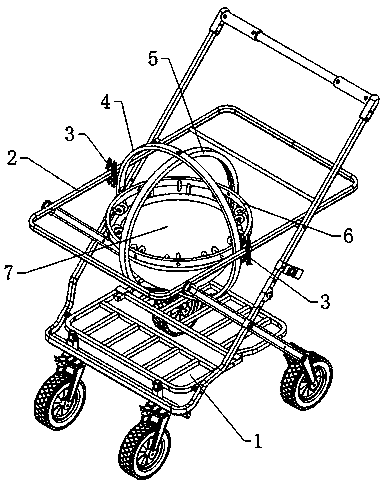

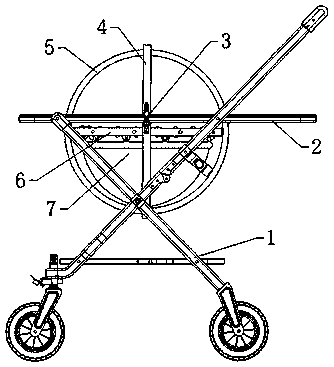

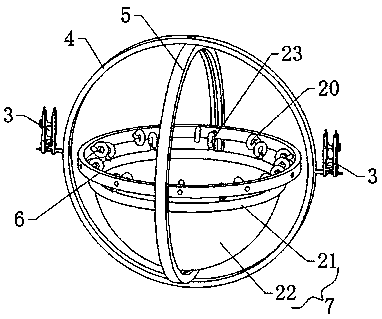

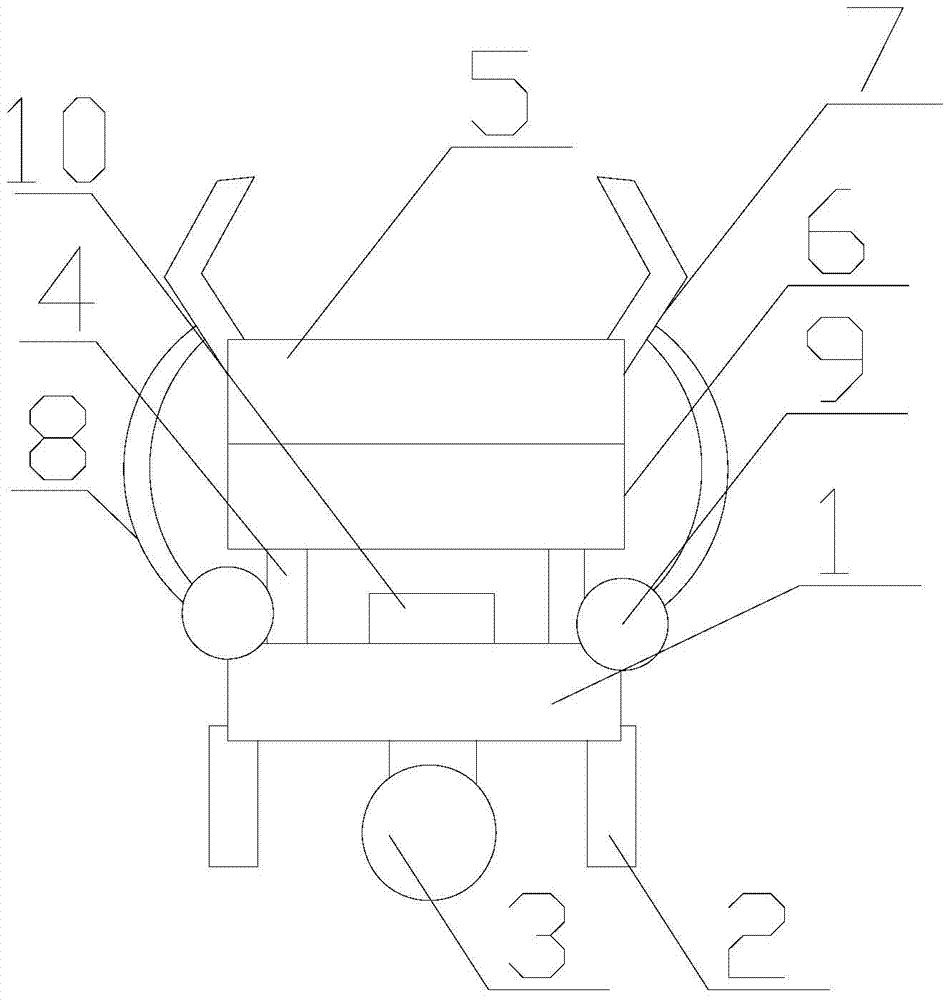

Anti-falling baby stroller based on gravity balance

InactiveCN110329337APrevent falling outPrevent unstable shakingCarriage/perambulator accessoriesCarriage/perambulator with multiple axesEngineering

The invention relates to the field of protective baby carriages, in particular to an anti-falling baby stroller based on gravity balance. The anti-falling baby stroller comprises a folding baby carriage and a gravity balancing assembly, wherein the folding baby carriage comprises a vehicle body and an upper frame; the upper frame is symmetrically provided with two adjusting assemblies used for being connected with the gravity balancing assembly in an axial mode, and the adjusting assemblies are movably arranged on the upper frame; and the gravity balancing assembly comprises an outer supporting ring, a middle supporting ring, an inner supporting ring and a baby cabin, wherein the middle supporting ring is positioned on the inner side of the outer supporting ring, the inner supporting ringis located on the inner side of the middle supporting ring, and the outer supporting ring is connected with the two adjusting assemblies in an axial mode, the middle supporting ring is in shaft connection with the outer supporting ring, the inner supporting ring is in shaft connection with the middle supporting ring, and the baby cabin is suspended at the bottom of the inner supporting ring. The anti-falling baby stroller based on gravity balance can be applied to a complex using environment, so that the baby carriage can still keep the stability of the baby cabin under the condition that thebaby carriage shakes violently, and the baby cabin is prevented from being turned over.

Owner:佘娟

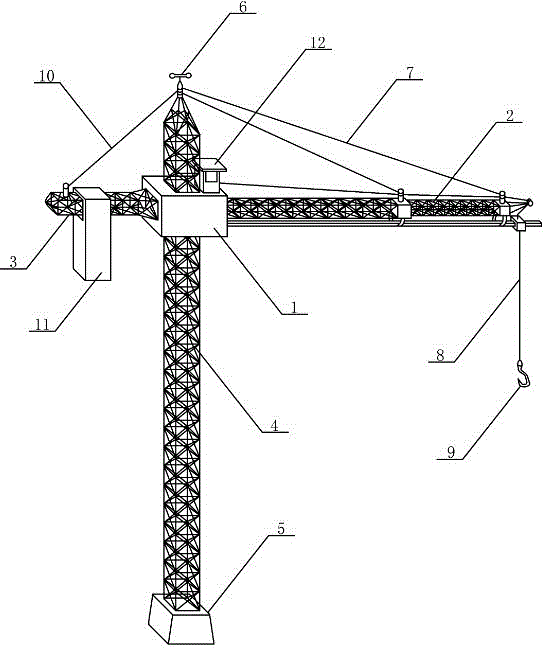

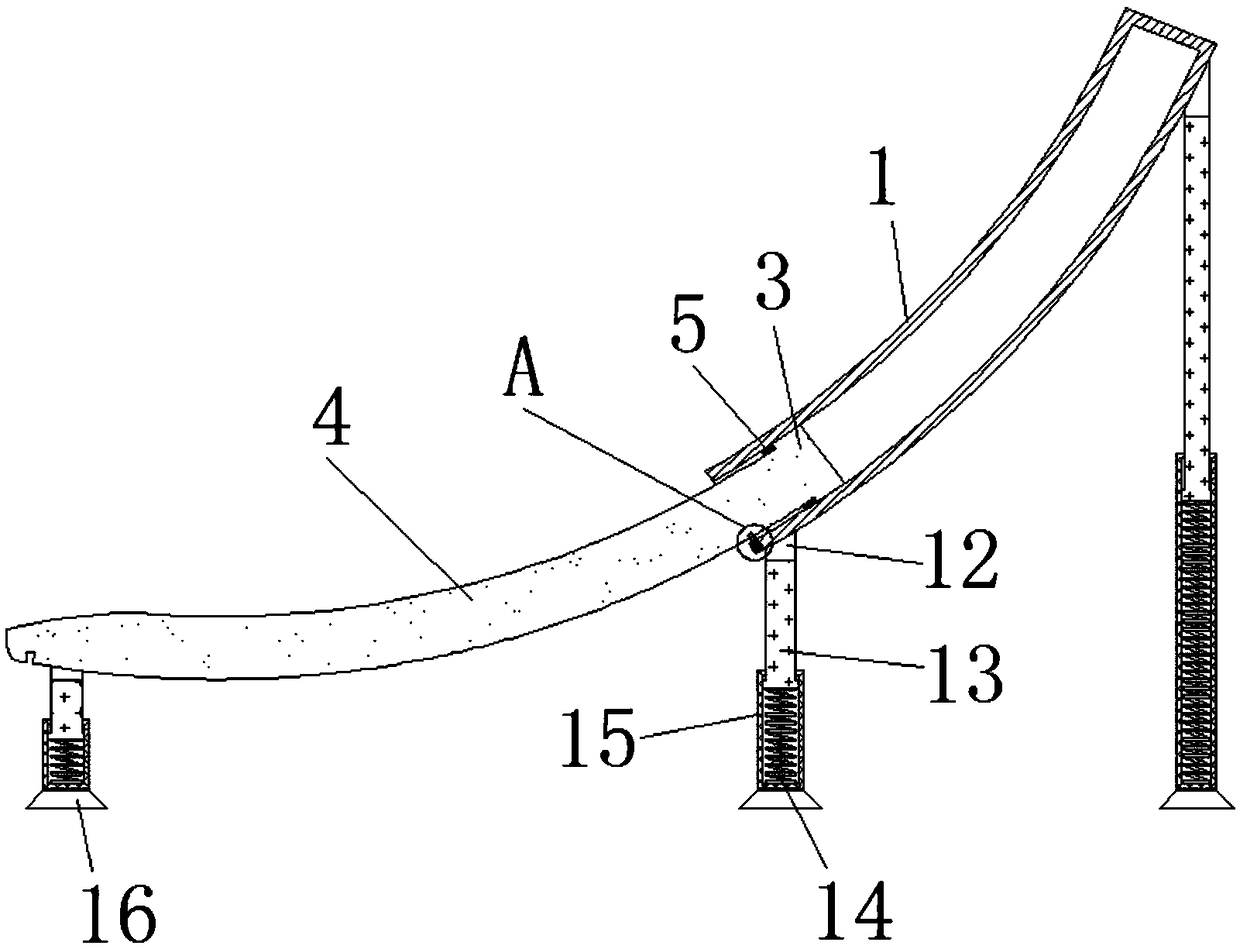

Graphene building tower crane

The invention relates to a graphene building tower crane, and belongs to the technical field of the application of new materials and new energy building machinery. According to the building tower crane, a crane body, a crane arm, a balance arm, a front cable-stayed horizontal bearing rope, a vertical hanging rope, a vertical lifting hook and a rear cable-stayed horizontal bearing rope are made of graphene; the graphene tower body is arranged on a concrete fixed foundation; the graphene crane arm and the graphene balance arm are arranged on the upper part of the graphene tower body; a balance weight is arranged on the graphene balance arm; an operating room is arranged on the joint of the graphene tower body and the graphene crane arm; a wind meter is arranged on the top of the graphene tower body; the graphene vertical hanging rope is arranged on the lower part of the front end of the graphene crane arm; the graphene vertical lifting hook is arranged at the lower end of the graphene vertical hanging rope; the front end of the graphene crane arm is connected with the top of the graphene tower body by the graphene front cable-stayed horizontal bearing rope; and the rear end of the graphene balance arm is connected with the top of the graphene tower body by the graphene rear cable-stayed horizontal bearing rope.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Children game frame

Owner:ANHUI BOLANGDAO AMUSEMENT EQUIP

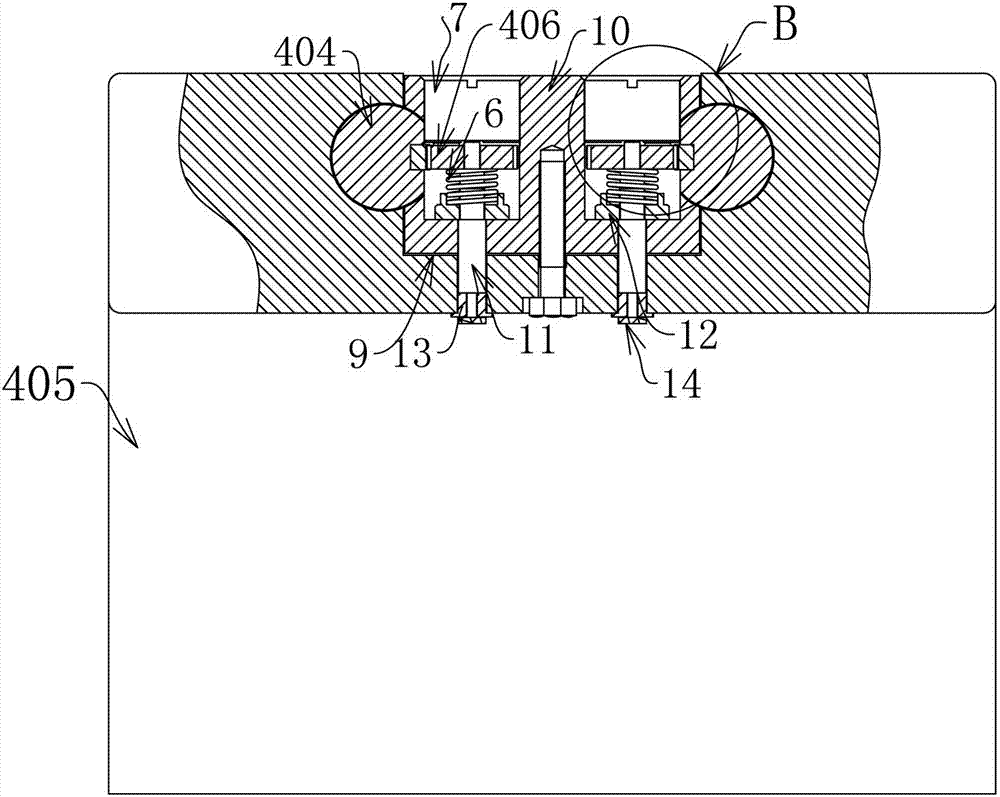

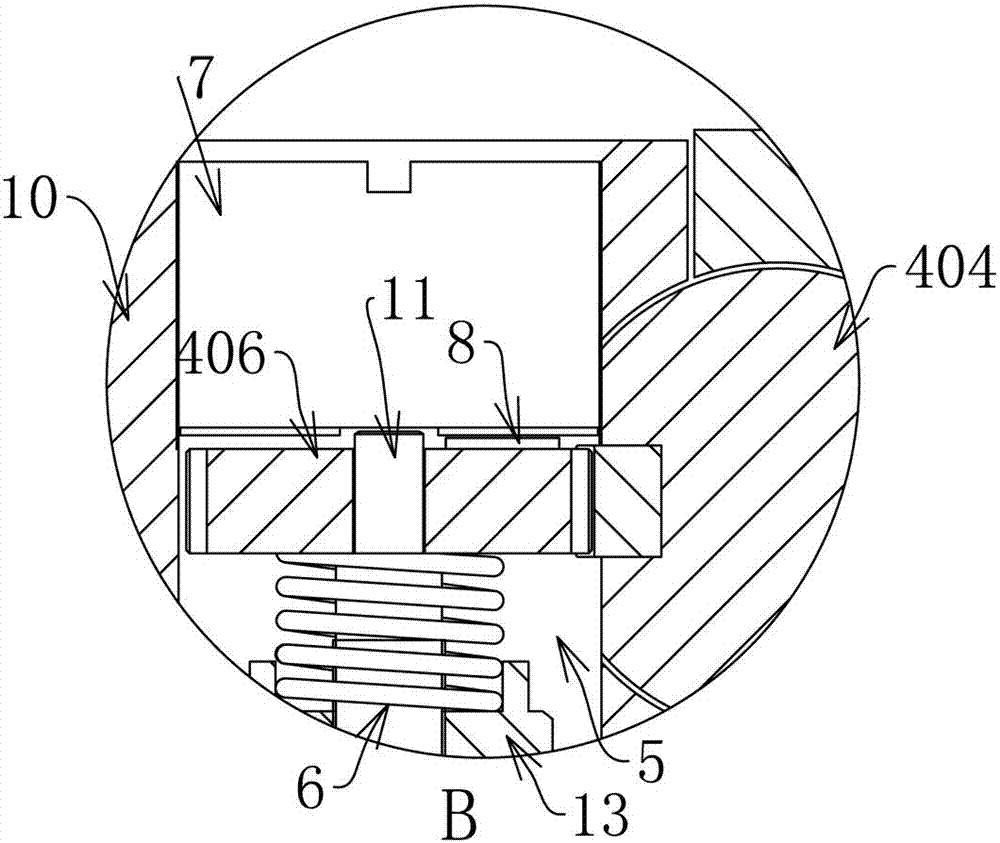

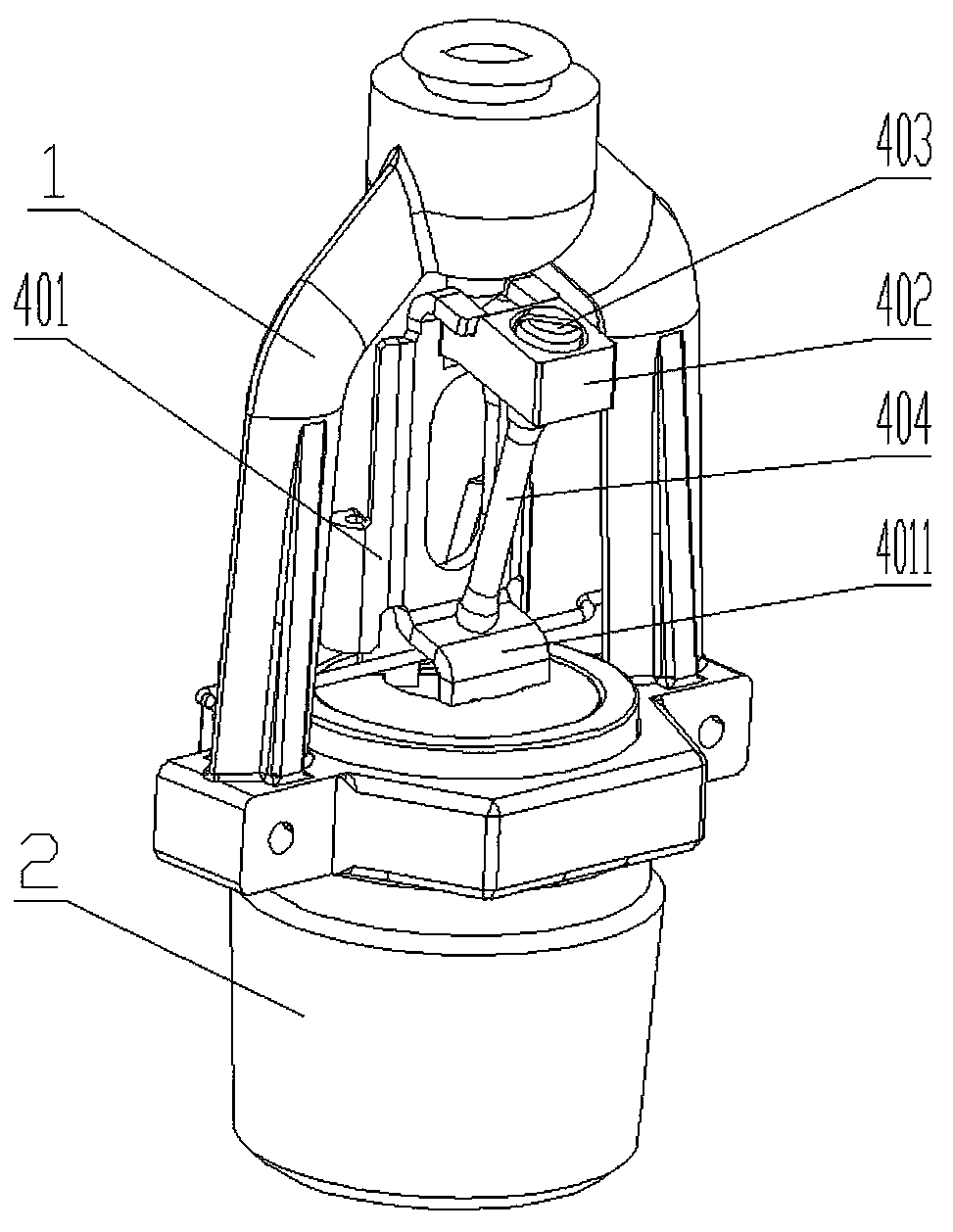

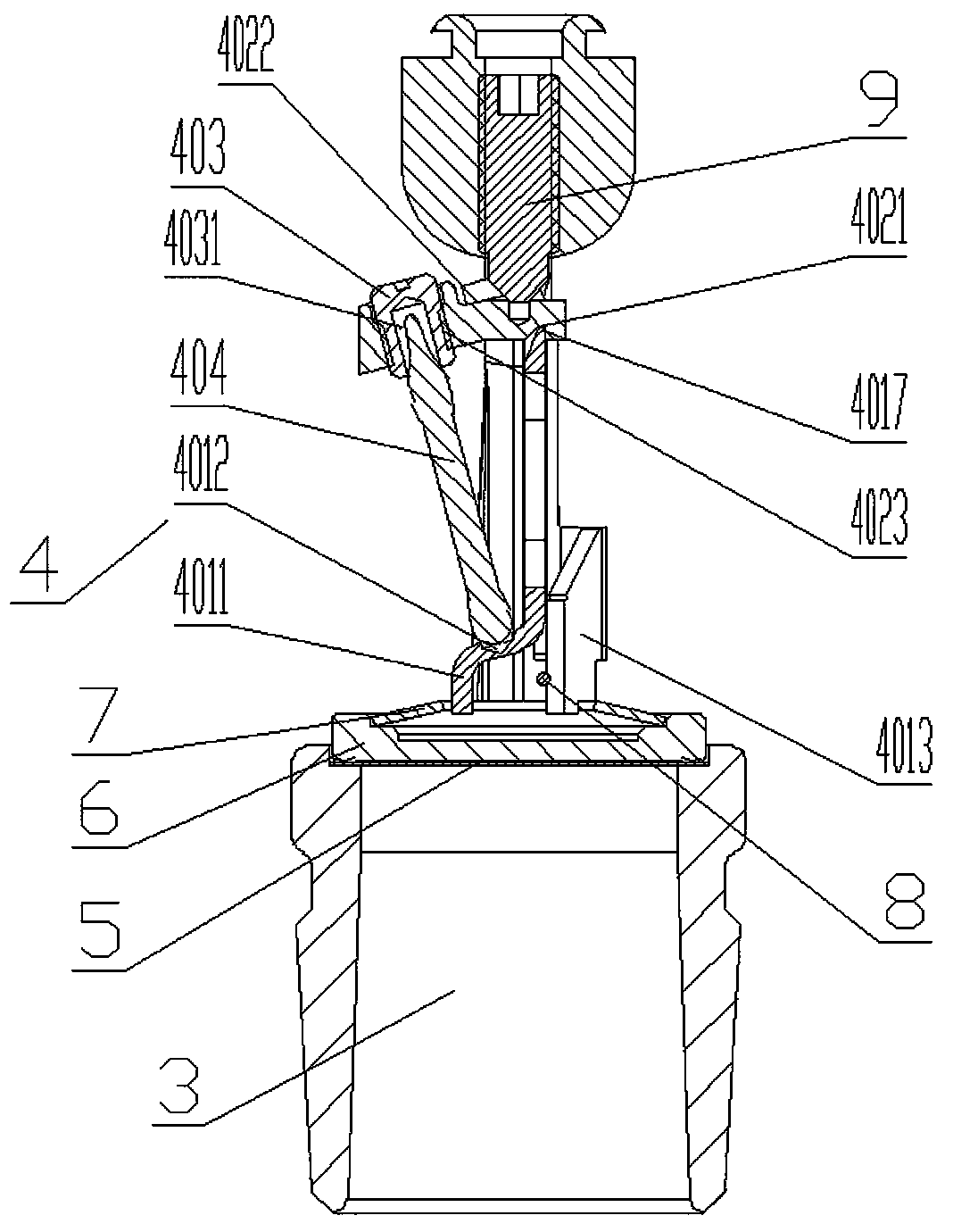

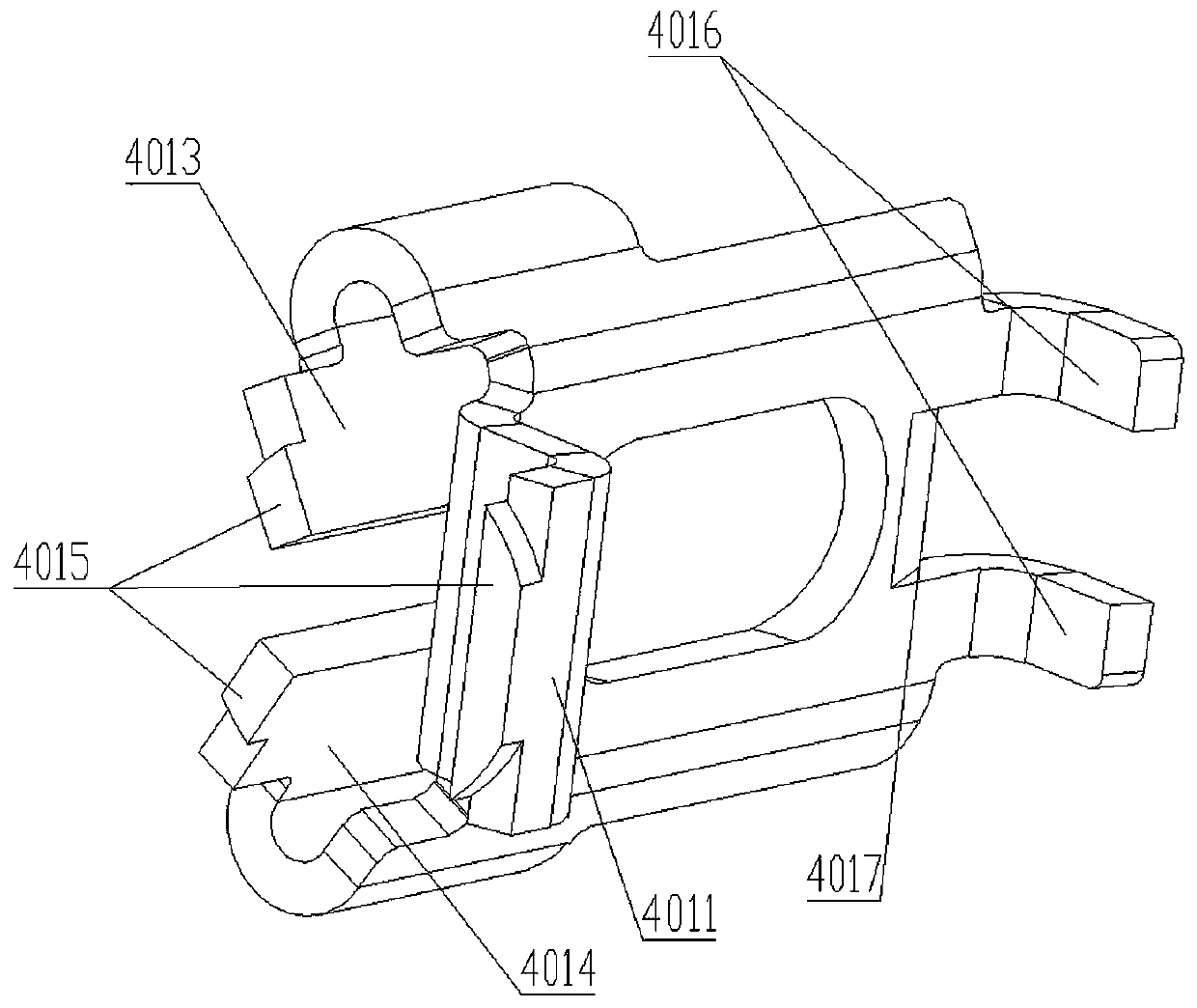

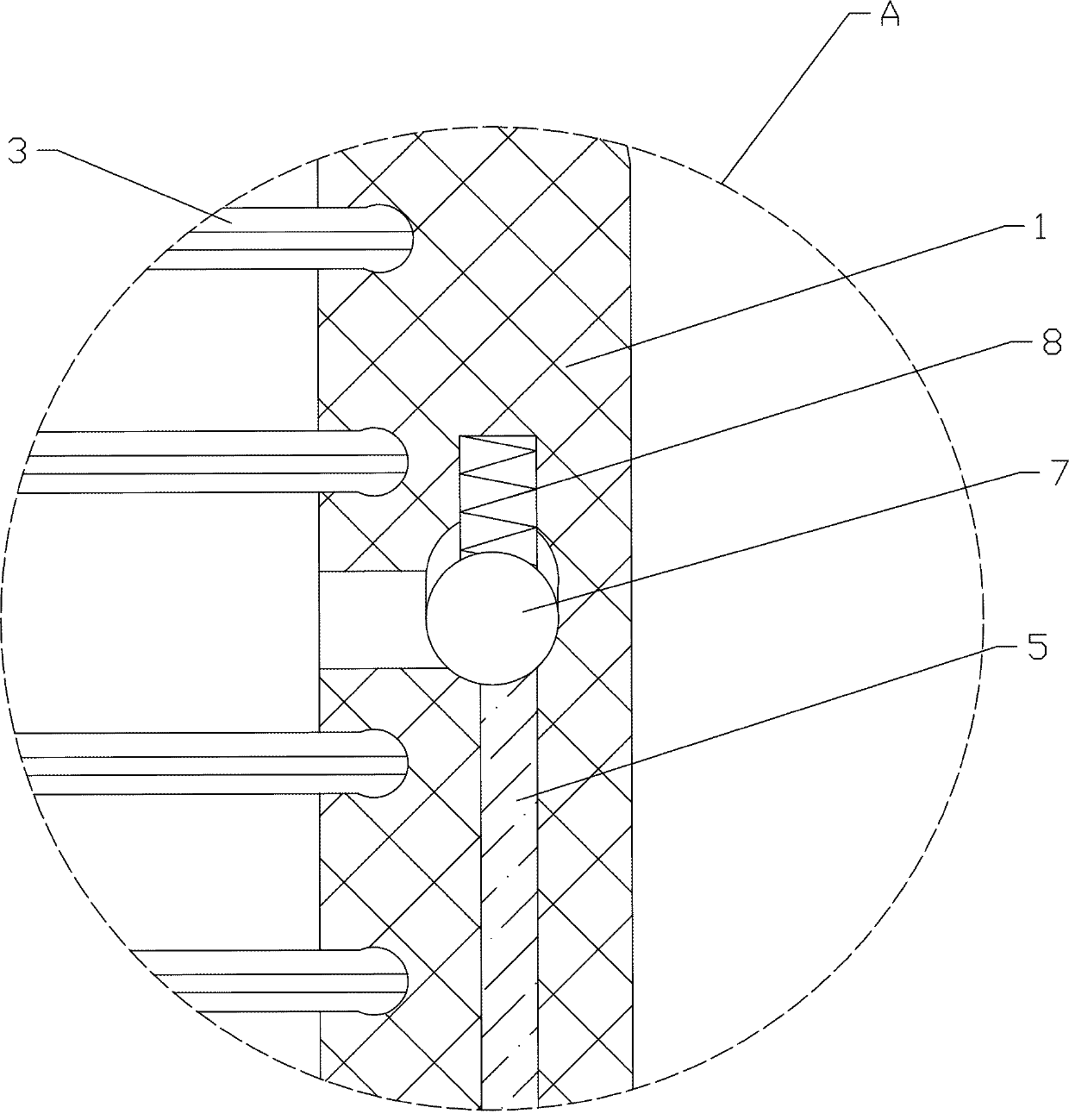

Temperature sensing mechanism of large-diameter spray nozzle, and large-diameter spray nozzle

The invention discloses a temperature sensing mechanism of a large-diameter spray nozzle. The mechanism comprises a temperature sensing trigger device, a first storage chamber, positioning stairs anda glass ball, wherein a first supporting leg, a second supporting leg, a third supporting leg and a supporting edge are disposed on a supporting frame, and stabilization tongues bent to the first supporting leg are symmetrically disposed on two ends of the supporting leg; a guide groove is formed in one end of a press block, a threaded hole is formed in the other end, and a shoulder part fitted with the stabilization tongues is disposed at the middle part; a second storage chamber is disposed on a glass ball screw; and the glass ball can sense temperatures, one end is mounted in the first storage chamber, and the other end is mounted in the second storage chamber. The large-diameter spray nozzle comprises a spray nozzle body, an end cap and a conical screw, wherein a water outlet channel and a spray nozzle frame are disposed on the spray nozzle body, the end cap is disposed on a water outlet end face of the water outlet channel, the conical screw is screwed on the spray nozzle frame and is coaxial with the end cap, and the large-diameter spray nozzle also comprises the temperature sensing mechanism.

Owner:SHANGHAI RUITAI FIRE FIGHTING EQUIP MFG CO LTD

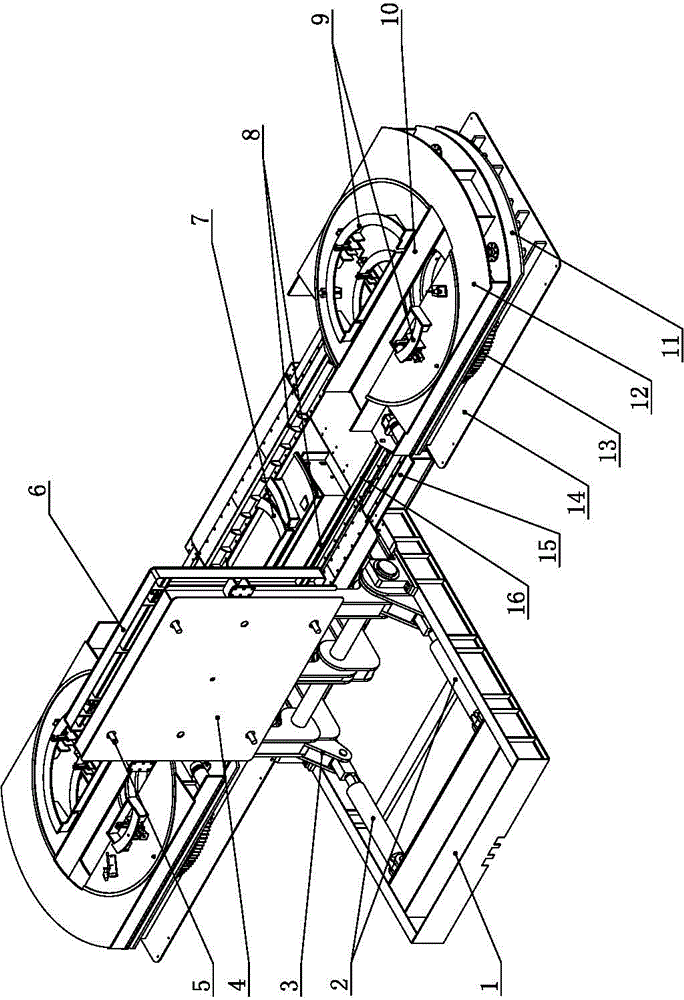

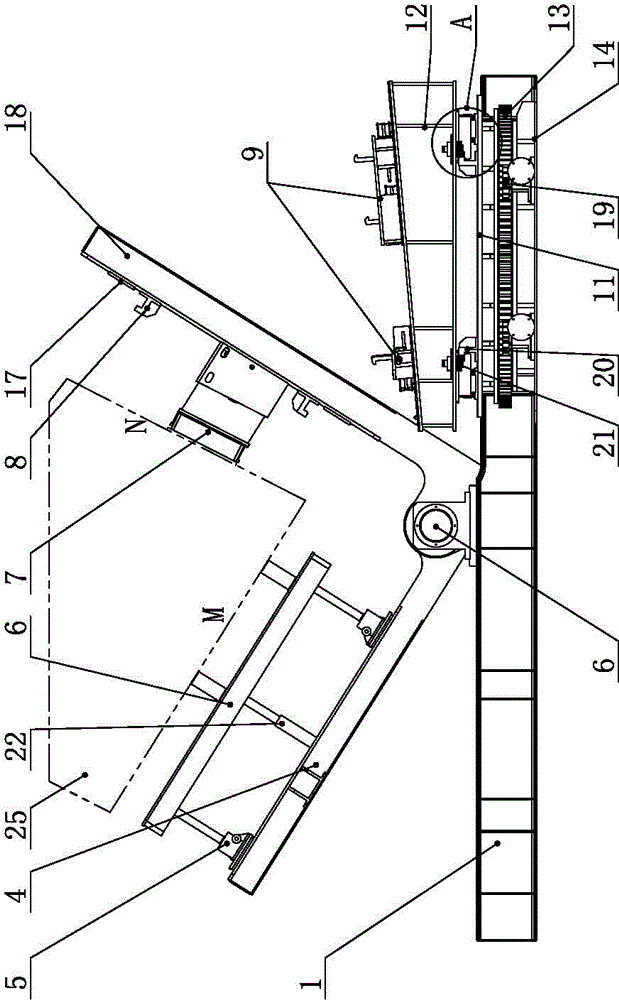

Device for overturning and installing base of wind driven generator

ActiveCN104925719AImprove work efficiencyIncrease productivityLifting devicesHoisting equipmentsWind drivenPiston rod

The invention discloses a device for overturning and installing a base of a wind driven generator and belongs to the field of wind driven generator manufacturing assisting equipment. An L-shaped overturning frame is hinged to the middle of a main support and comprises a first underbed and a second underbed which are connected into an L shape, a first lifting table and a second lifting table are connected to the first underbed and the second underbed through lifting mechanisms respectively, and an oil cylinder push plate is arranged on the outer side of the position where the first underbed is connected with the second underbed; an oil cylinder is hinged to the inner side of the rear end, corresponding to the first underbed, of the main support, the stretching-out end of a piston rod of the oil cylinder is hinged to the oil cylinder push plate, movable working tables are arranged on at least one side of the front end, corresponding to the second underbed, of the main support, and the movable working tables can rotate and can also move to the upper side of the second underbed. When the device works, the overturning frame overturns the whole base by 90 degrees and then moves the base to the movable working tables for installation. When the device is used for overturning and moving the base of the large wind driven generator, impact is avoided, the base can not be damaged, and working efficiency and safety performance are improved remarkably.

Owner:XINJIANG GOLDWIND SCI & TECH

Ionic intermediate membrane raw material modification method and manipulator applied to sterile production

InactiveCN113682803AImprove boiling resistanceDoes not affect transparencyConveyor partsPolymer scienceGlycidyl methacrylate

The invention belongs to the technical field of manipulators and particularly relates to an ionic intermediate membrane raw material modification method and a manipulator applied to sterile production. The ionic intermediate membrane raw material modification method comprises the following steps: step one, stirring a Sarin base material with a certain proportion of KH550 and ECH auxiliaries; step two, adding a silane coupling agent into a mixture obtained in the step one and stirring at a high speed; and step three, adding the mixture obtained in the step two into a granulator, and carrying out granulation modification at 170 DEG C in the granulator. According to the ionic intermediate membrane raw material modification method and the manipulator applied to sterile production, the silane coupling agent is added into the raw material, so that the adhesion between the material and glass is improved; meanwhile, due to the action of the coupling agent, the boiling resistance of the material is improved; monomer glycidyl methacrylate is added into the raw material, and an epoxy group is introduced into a polymer chain, so that the boiling resistance of the material is improved; meanwhile, transparency and haze of the material are not influenced.

Owner:东莞市群安塑胶实业有限公司

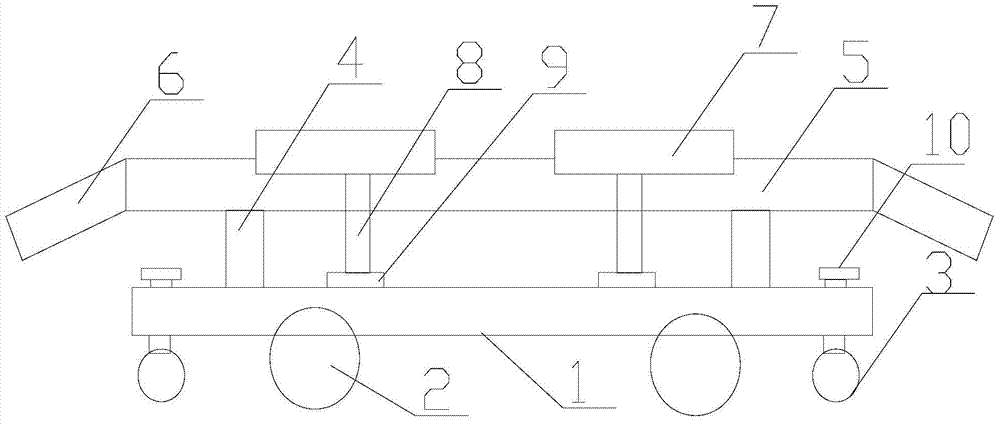

Transfer trolley for factory steel pipes

InactiveCN104290786AWon't fall apartWon't fall overHand carts with multiple axesArchitectural engineeringSteel tube

Owner:ZHEJIANG RUIMAI STAINLESS STEEL TUBE

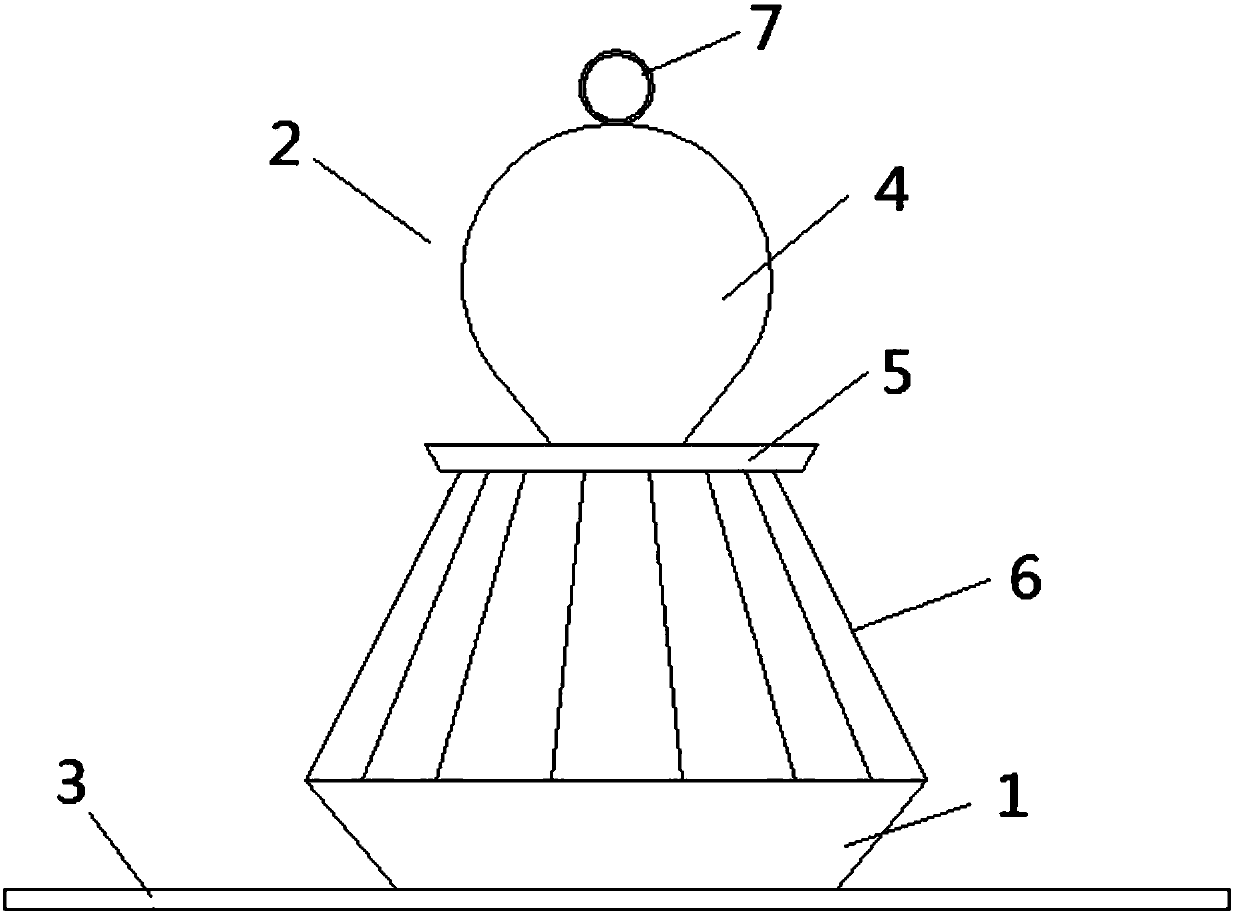

Food-feeding and water-drinking all-in-one pot for free-ranged chicken

The invention provides a food-feeding and water-drinking all-in-one pot for free-ranged chicken. The food-feeding and water-drinking all-in-one pot comprises a food-feeding pot, a water-drinking pot and a circular base plate, wherein the food-feeding pot and the circular base plate are molded into one piece; the food-feeding pot is located at the right center of the upper part of the circular baseplate; the water-drinking pot is composed of a spherical water-storage pot body and a water-drinking tray; the top end of the spherical water-storage pot body is fixedly provided with a handle ring;and the water-drinking tray is fixedly arranged right above the food-feeding pot through a plurality of isolation rods arranged at the bottom part of the water-drinking tray. The food-feeding and water-drinking all-in-one pot provided by the invention integrates food feeding and water drinking into a whole, can prevent chickens from standing in the food-feeding pot, and has anti-turning effect andhigh stability.

Owner:五河县鸭子汪蛋鸡养殖专业合作社

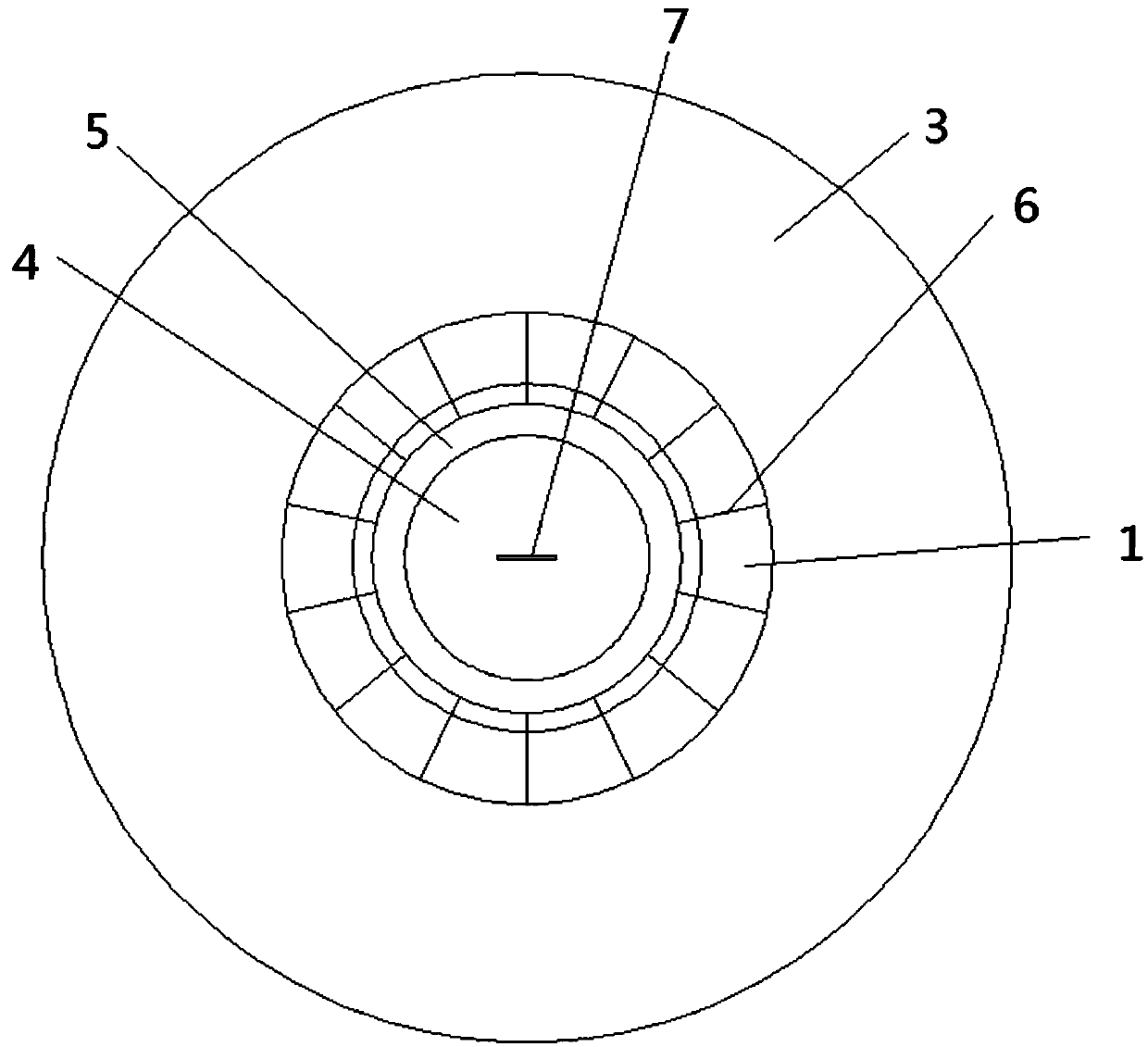

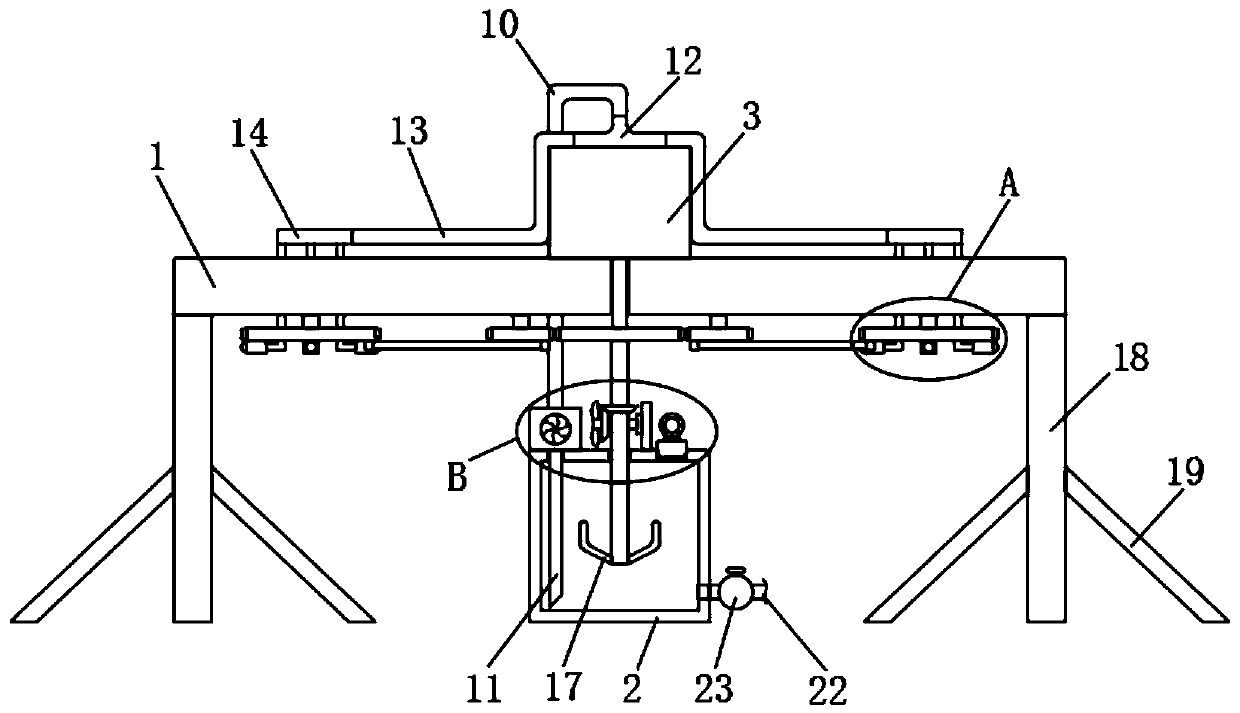

Fixed circular-sprinkling-range sprinkling machine

ActiveCN110199836AImprove solubilityImprove mixing efficiencyPositive displacement pump componentsTransportation and packagingSpray nozzleEngineering

The invention belongs to the field of irrigation and particularly discloses a fixed circular-sprinkling-range sprinkling machine. Aiming at problems of low speed and efficiency in mixing of existing pesticides with water and small sprinkling range, the scheme is put forward and includes that the sprinkling machine comprises a top plate and a water tank, a servo motor is fixedly connected to the side wall of the upper end of the top plate, an output shaft of the servo motor penetrates the top plate and is fixedly connected with a driving gear, the side wall of the lower end of the top plate isrotationally connected with two symmetrical driven gears through a rotating shaft, and a swing rod is rotationally connected to the side wall of the lower end, away from the circle center, of each driven gear. A circular plate is rotationally connected to the side wall of the lower end of the top plate through a rotating shaft, and a radius of the circular plate is larger than that of the driven gears. By the circular plate for driving a plurality of nozzles to rotate cyclically, comprehensive and thorough sprinkling can be realized, and sprinkling efficiency is improved. By a rotating rod andstirring shafts for stirring the pesticide with water in the water tank, mixing efficiency is improved, and time saving is realized.

Owner:JIANGSU PROVINCE SINGE IRRIGATION & DRAINAGE EQUIP

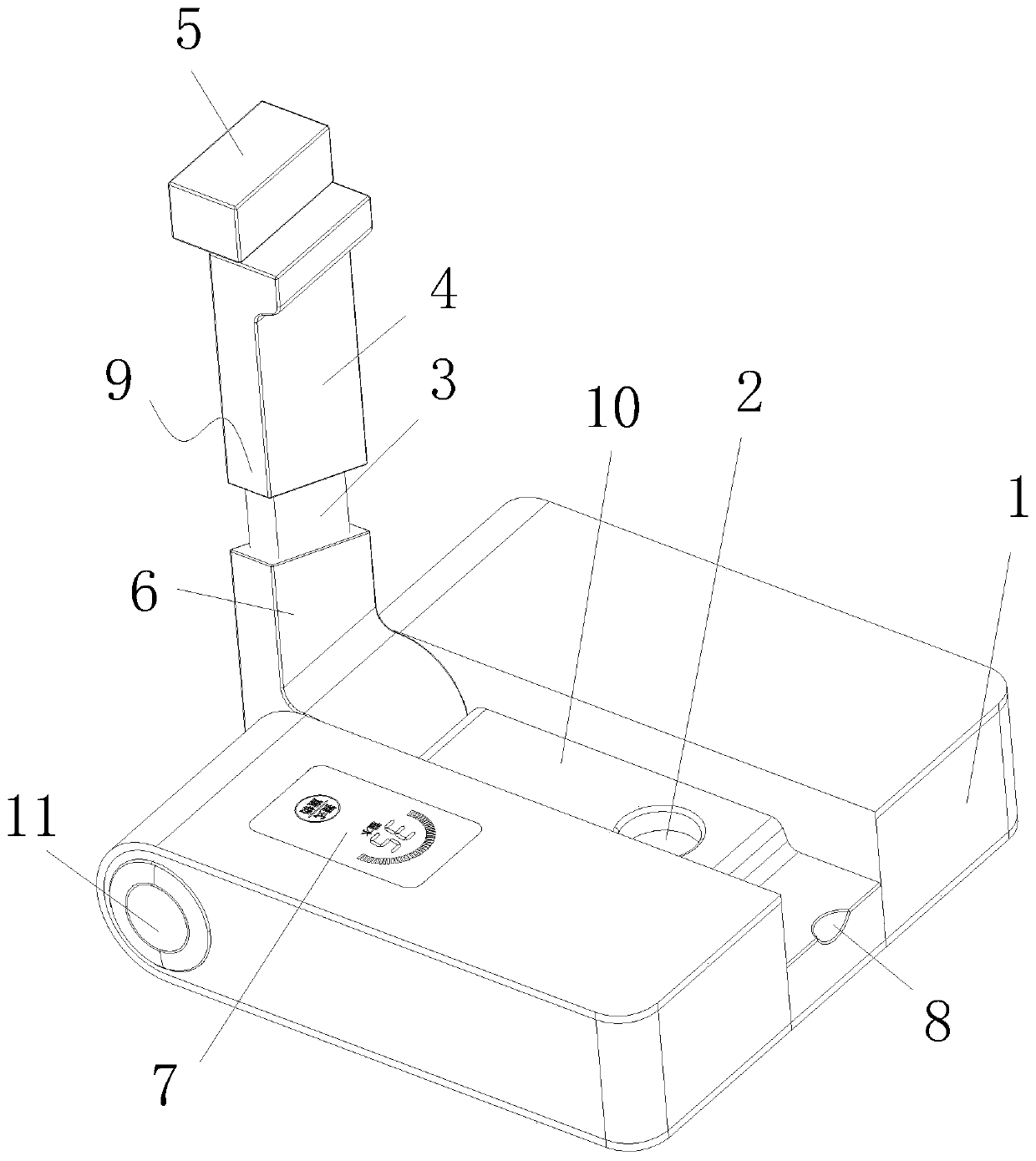

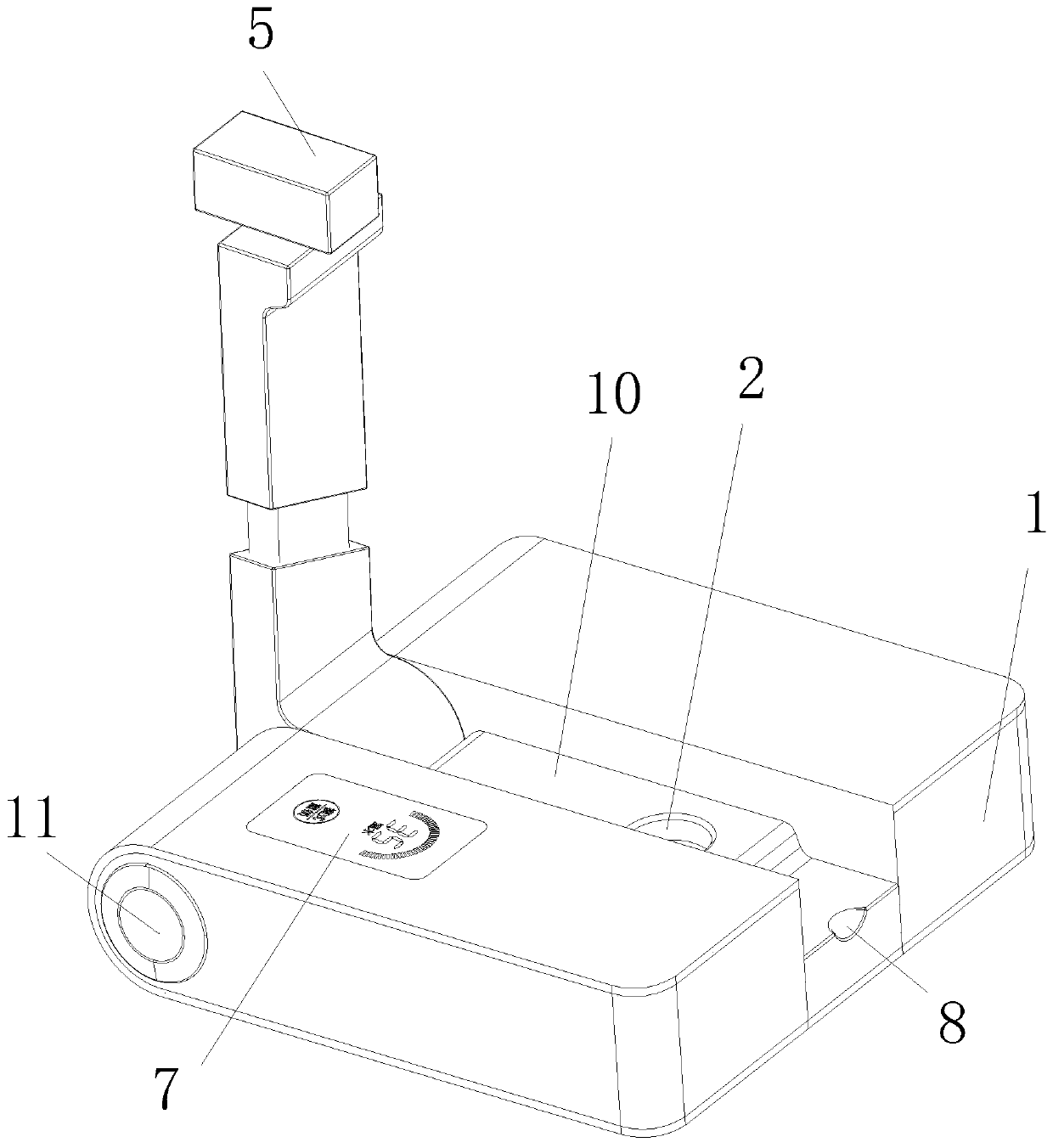

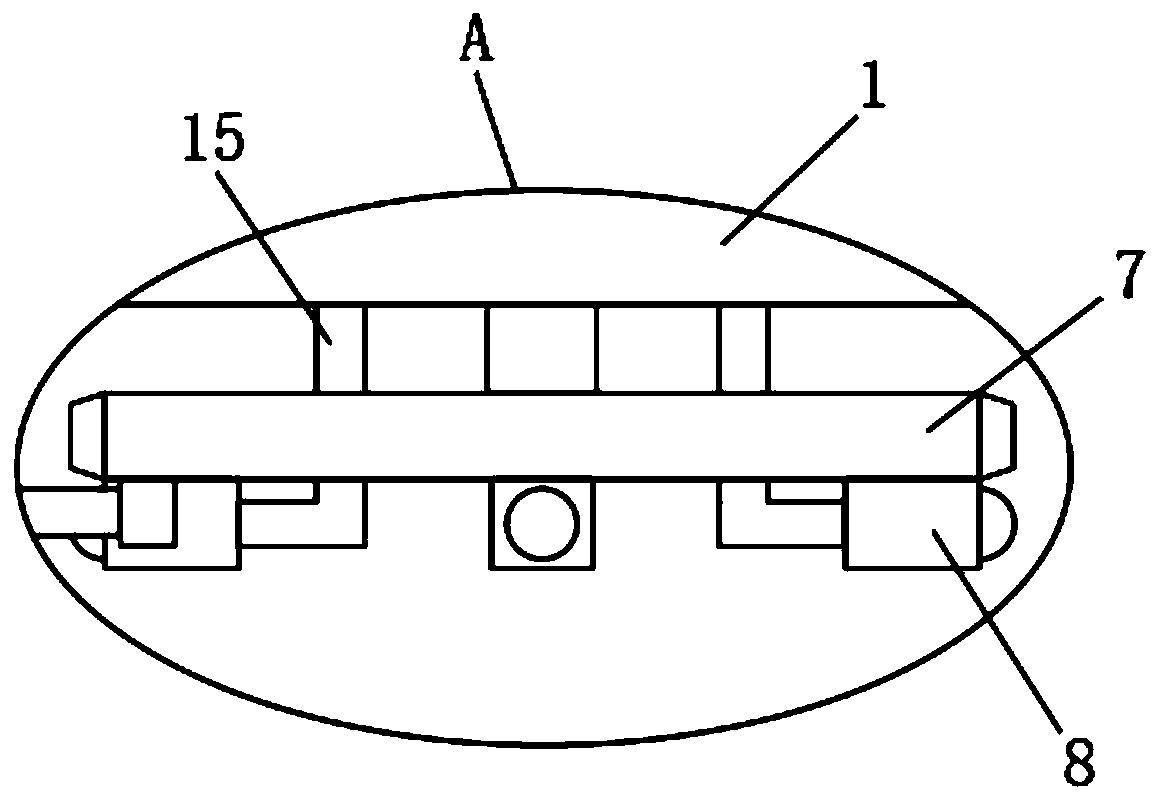

Fixing device capable of being used for various lithium battery sizes

InactiveCN109004144AEasy to useEasy to clamp and fixCell component detailsBiochemical engineeringEngineering

The invention discloses a fixing device capable of being used for various lithium battery sizes, the fixing device includes a clamping box body, a plurality of partition plates arranged vertically arearranged in parallel in the clamping box body, the partition plates divide the clamping box body into a plurality of placing cavities, a plurality of clamping plates arranged in parallel are also included, the clamping plates and the partition plates are perpendicular to each other, the bottom ends of the clamping plates are provided with clamping grooves, the clamping groove of each clamping plate can be inserted in each partition plate, and the bottom of the clamping plate is slidably connected with the bottom surface of the placing cavity, a through hole is arranged in the side wall of theclamping box body, a pressing rod is arranged in the through hole, one end of the pressing rod is vertically connected with the clamping plate closest to the side wall of the clamping box body, and the other end of the pressing rod is connected with a driving plate. The battery clamping device of the invention can be used for placing the battery and carrying out good clamping and fixing of the battery, so that the battery cannot be overturned in the placing process and the stability is improved; meanwhile, the battery clamping device can be applied to good clamping of batteries of various different sizes, and is more convenient to use.

Owner:杨冰

Mine slope protection frame convenient to disassemble and reuse

Owner:GUIZHOU UNIV

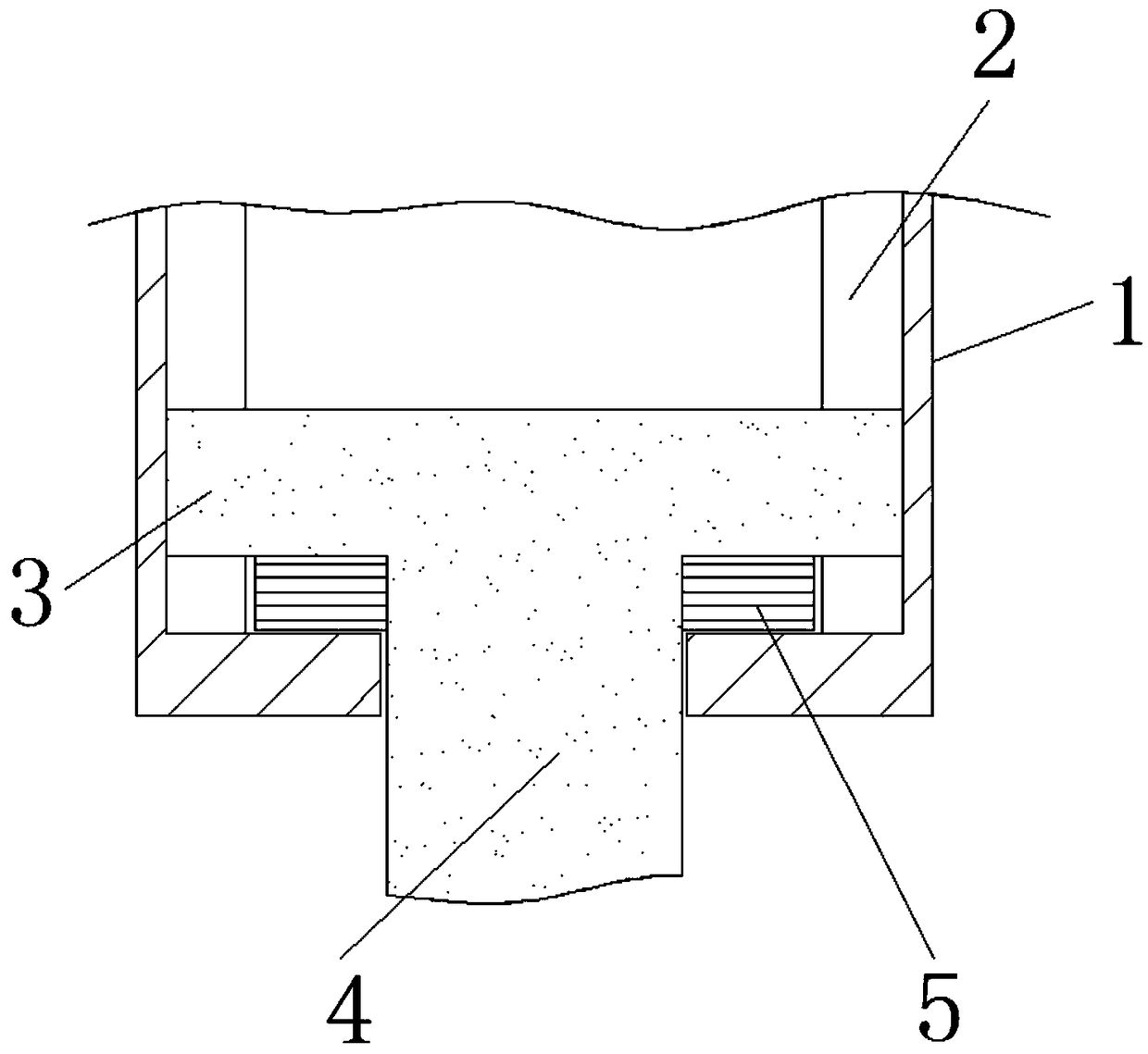

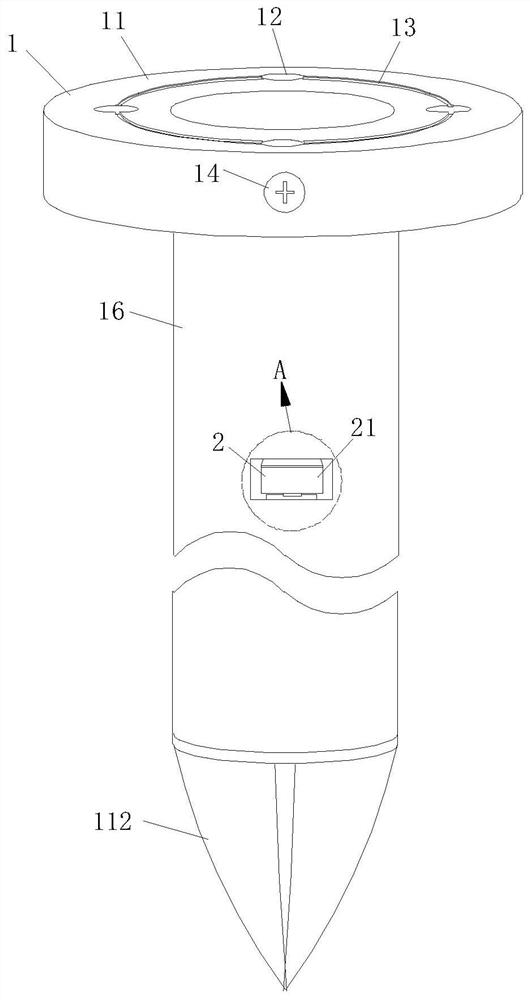

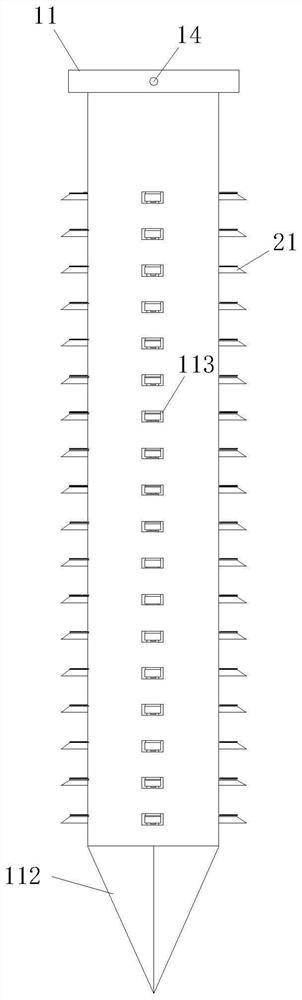

Prestressed concrete-filled steel tube pile

The invention relates to the technical field of steel pipe concrete pipe piles, in particular to a prestressed concrete-filled steel tube pile. The prestressed concrete-filled steel tube pile comprises a connecting mechanism, a stabilizing mechanism and an extrusion supporting mechanism. The connecting mechanism is mainly composed of an upper connecting disc, a lower connecting disc and a pile body, the upper connecting disc is matched with the lower connecting disc, the length of the pile body can be increased by connecting the upper connecting disc and the lower connecting disc, the stabilizing mechanism is arranged in the pile body on the connecting mechanism, the extrusion supporting mechanism is arranged above the stabilizing mechanism, and the extrusion supporting mechanism is arranged in the pile body; and the connecting mechanism is provided with the upper connecting disc and the lower connecting disc which are matched for use, two pipe piles can be connected, the length of the pipe piles is increased, the stabilizing mechanism can extend out of a telescopic cone from an opening after the pipe piles are driven into soil, the telescopic cone can be inserted into the surrounding soil to play a role in fixing and stabilizing the pipe piles, the extrusion supporting mechanism can extend out of a supporting rod in the pipe piles, and the pipe piles are prevented from being extruded and deformed.

Owner:胡天赐

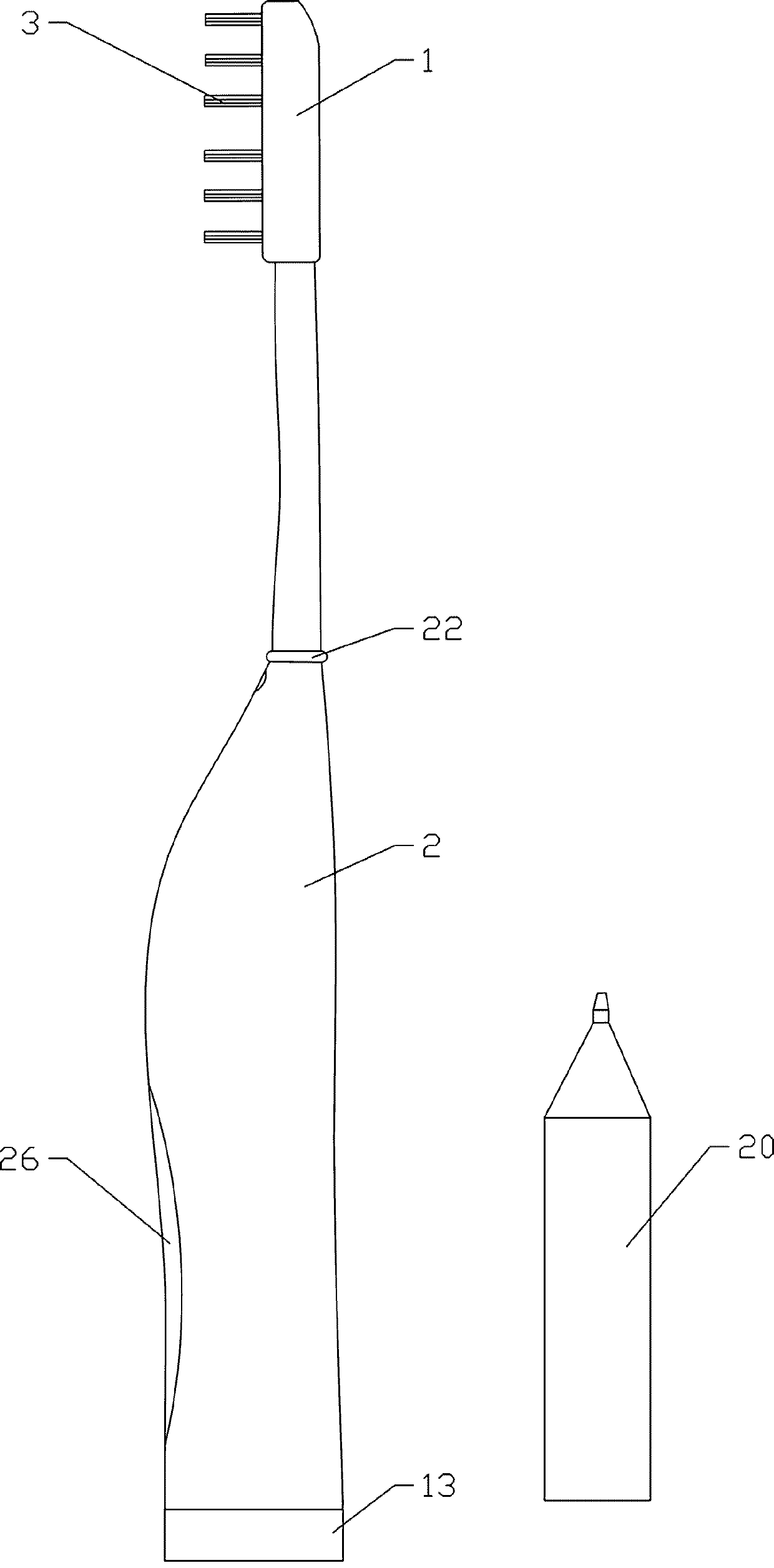

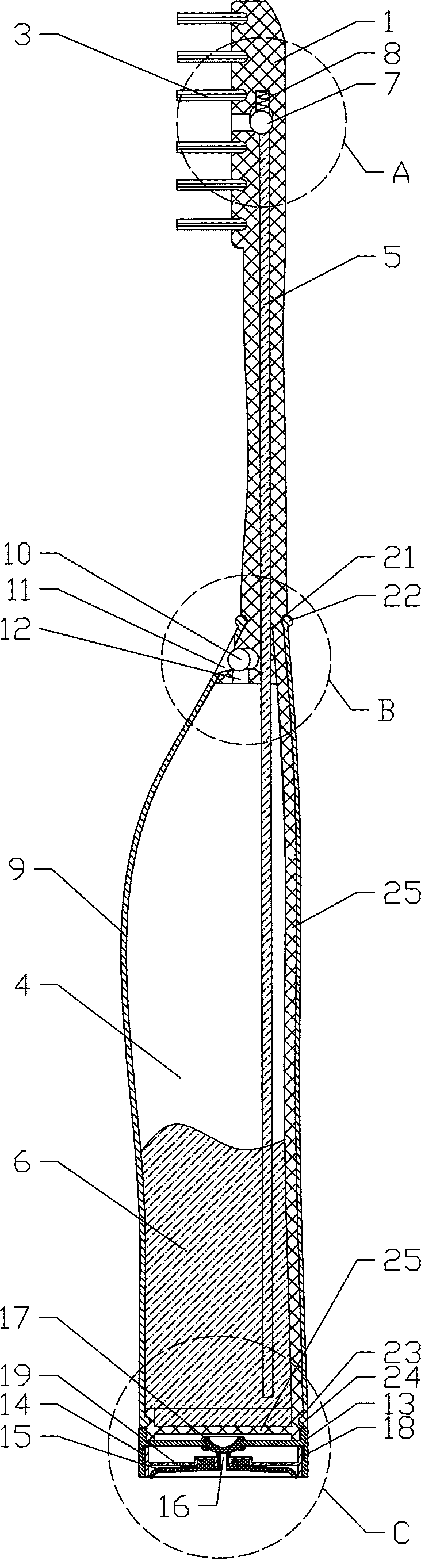

Toothbrush with toothpaste

The invention provides a toothbrush with toothpaste. The toothbrush comprises a brush head and a handle, wherein the brush head is provided with bristles, the handle is internally provided with a toothpaste mounting cavity, one end of a toothpaste flow passage is communicated with the brush head, and the other end of the toothpaste flow passage is communicated with the toothpaste mounting cavity;a squeezing mechanism squeezes toothpaste to the brush head through the toothpaste flow passage; the portion, in the toothpaste flow passage, of the brush head is provided with a check valve, and thecheck valve can be opened when the squeezing mechanism performs squeezing, and is automatically closed when no squeezing exists; an air pressure mechanism comprises an air bag, and an air inlet of theair bag is provided with a back-pressure valve; the bottom of the handle is provided with a base, the base is internally provided with a sliding seat, the sliding seat is provided with a sucking disc, the top of the sucking disc is provided with a hole, and the base is provided with an elastic valve plug cooperating with the top of the sucking disc; the base is internally provided with a slidinggroove allowing the sliding seat to move vertically; the sliding seat is provided with an air inlet hole, and the sucking disc can be opened or closes the hole.

Owner:吴昕乐 +1

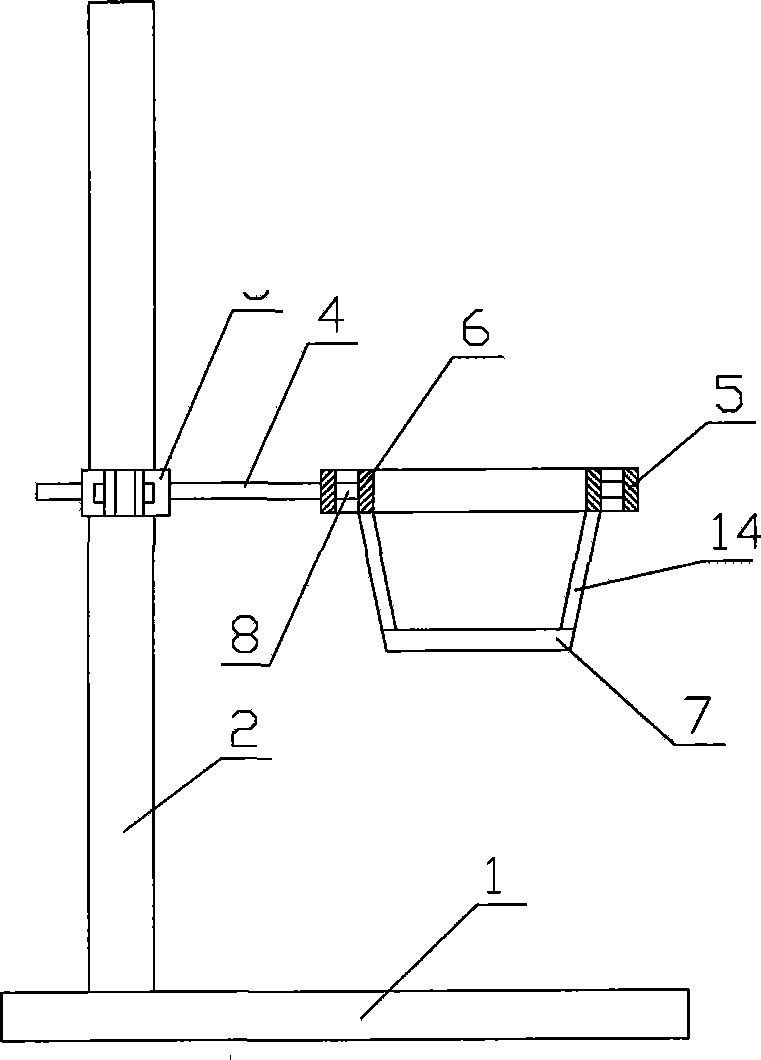

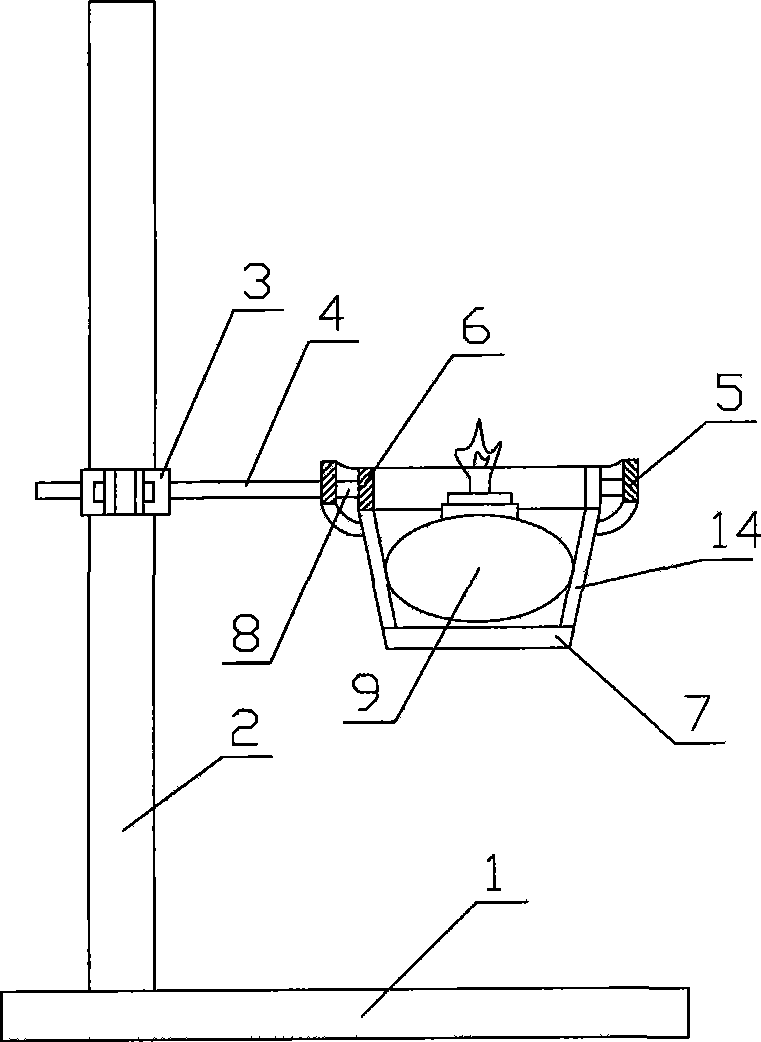

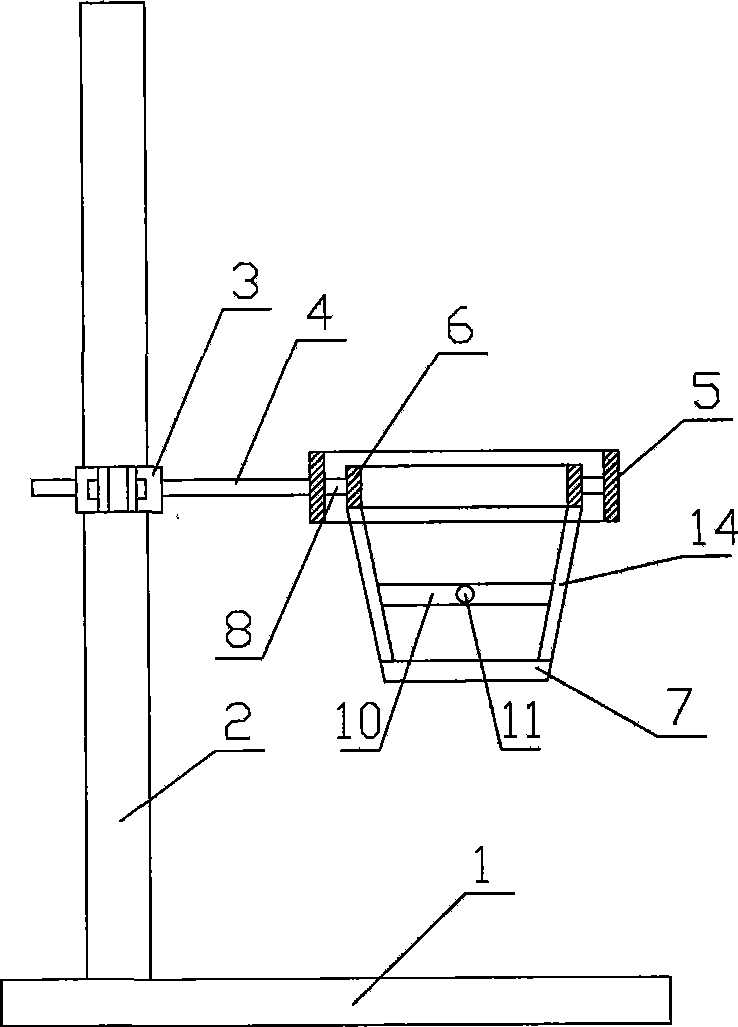

Multifunctional universal safety experiment bracket

The invention discloses a multifunctional universal safety experiment bracket, which comprises a fixed rod fixed on a tie rod through a clamping screw and a first circular ring fixed on the fixed rod. The bracket is characterized in that the bracket also comprises a second circular ring and a third circular ring; the second circular ring and the third circular ring are connected through a connecting piece; the second circular ring is movably connected with the first circular ring through two movable pins, so as to ensure that the second circular ring and the third circular ring can swing relative to the first circular ring by taking the movable pins as fulcrums; a fourth circular ring is arranged between the second circular ring and the third circular ring; a plurality of holding screws which are screwed in or out are arranged on the wall of the fourth circular ring; and the holding screws are used for clamping a built-in beaker. No matter whether the fixed rod is not firmly clamped or is inclined due to accidental causes, the bracket can always ensure that an alcohol lamp is vertical and can not be overturned or spill alcohol, and can ensure that heated containers can not be overturned, so as to ensure experiment safety.

Owner:SHANGHAI SHANGDE EXPERIMENTAL SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com