Device for overturning and installing base of wind driven generator

A technology for wind turbines and installation devices, which is applied in the directions of lifting devices and hoisting devices, can solve the problems of difficult control, easy accidents, easy damage to installation parts and bases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

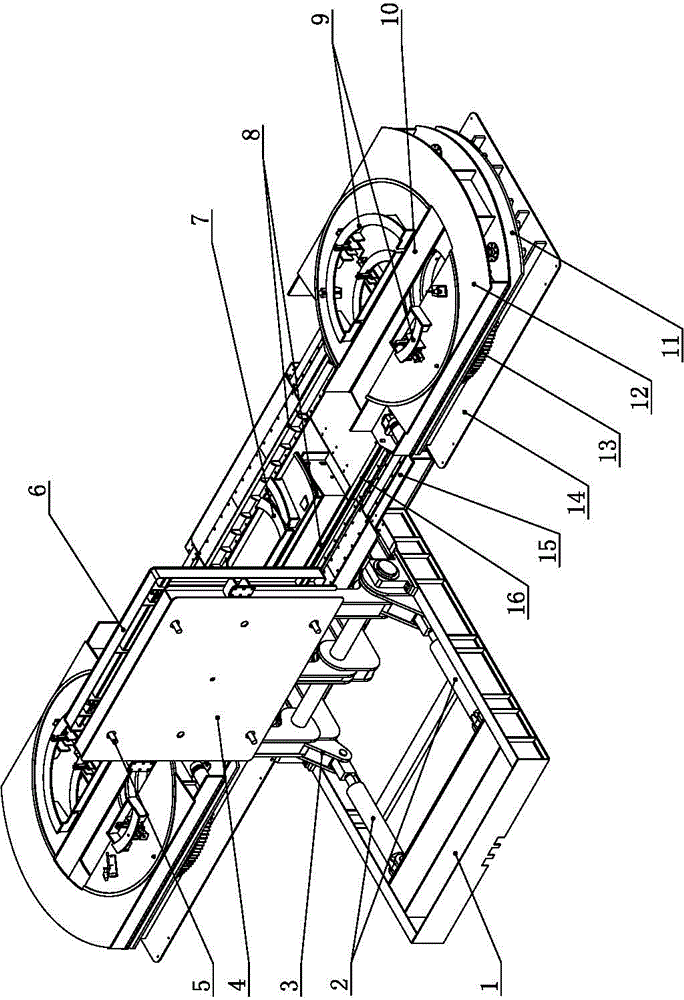

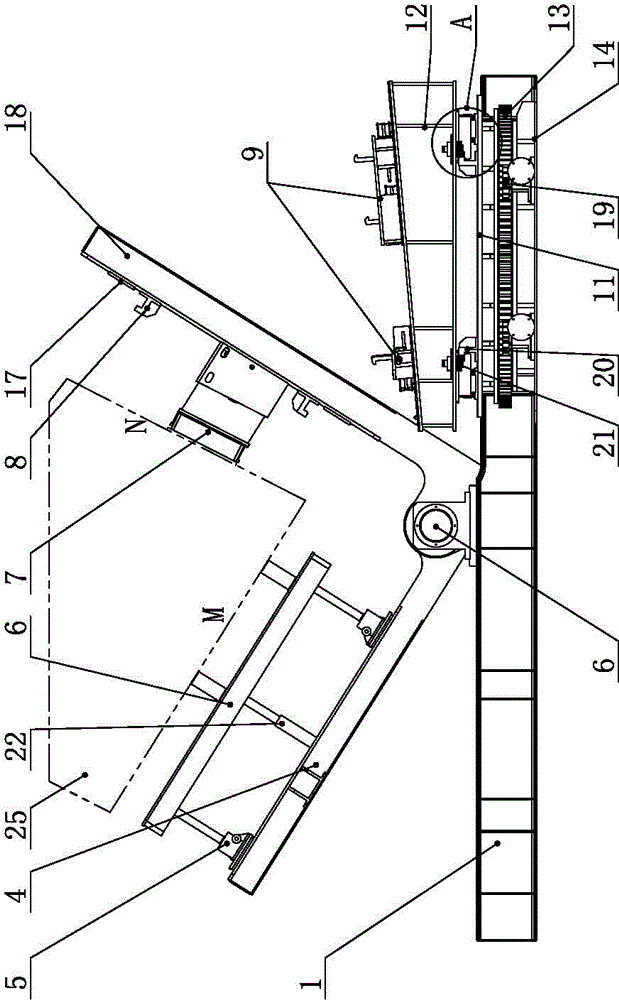

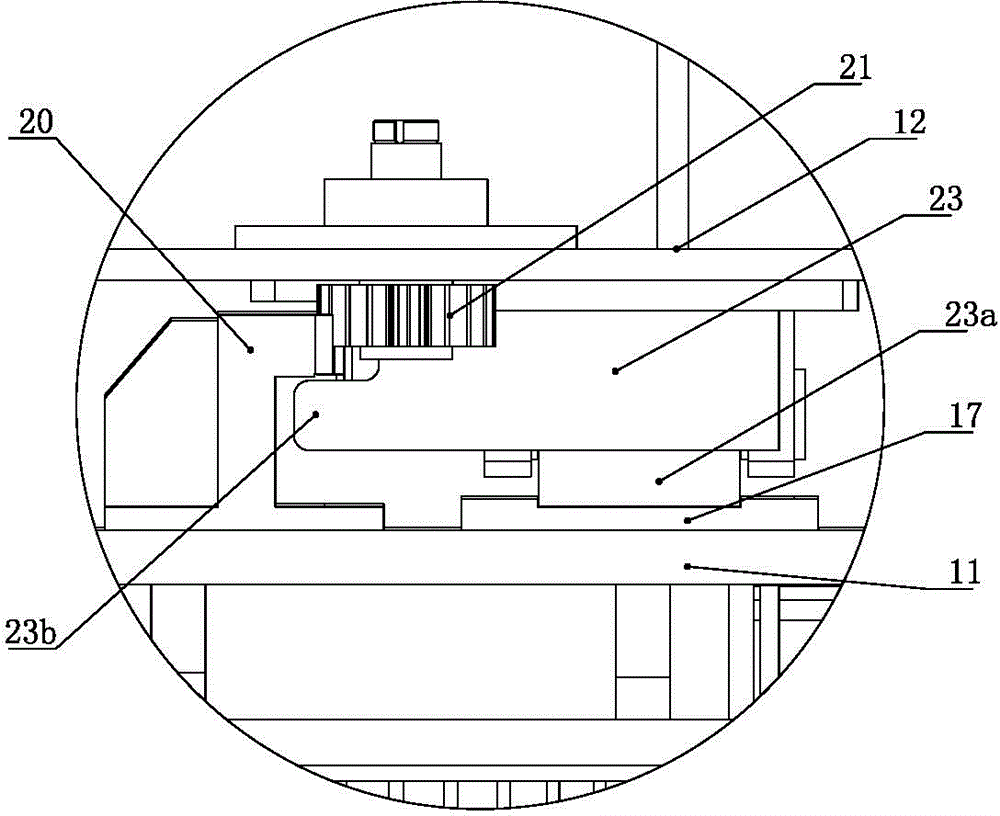

[0023] like Figure 1-8 As shown, it is a wind turbine base flip installation device, including a main support 1, an L-shaped flip frame is hinged in the middle of the main support 1, and the flip frame includes a base frame 1 4 and a frame 2 18 connected in an L shape. The bottom frame one 4 and the bottom frame two 18 are respectively connected with the lifting platform one 6 and the lifting platform two 7 through the lifting mechanism 5, and the lower side of the lifting platform one 6 is provided with a guide assembly 22, and the guide assembly 22 includes a guide rod and a guide rod arranged in cooperation. Cover, guide rod is parallel with corresponding screw mandrel elevating mechanism 5 axes, and guide rod is connected on the elevating platform one 6, and guide sleeve is arranged on the chassis one 4. The surface shape of lifting platform one 6 and lifting platform two 7 matches with two installation surfaces of the base 25 of wind-driven generator, and the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com