Screw device for high-adjusting a track span

A lead screw and track technology, which is used in tracks, track laying, track maintenance, etc., can solve the problems of track tipping, vertical screw tipping, etc., and achieve the effect of simple disassembly and simple horizontal adjustment device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

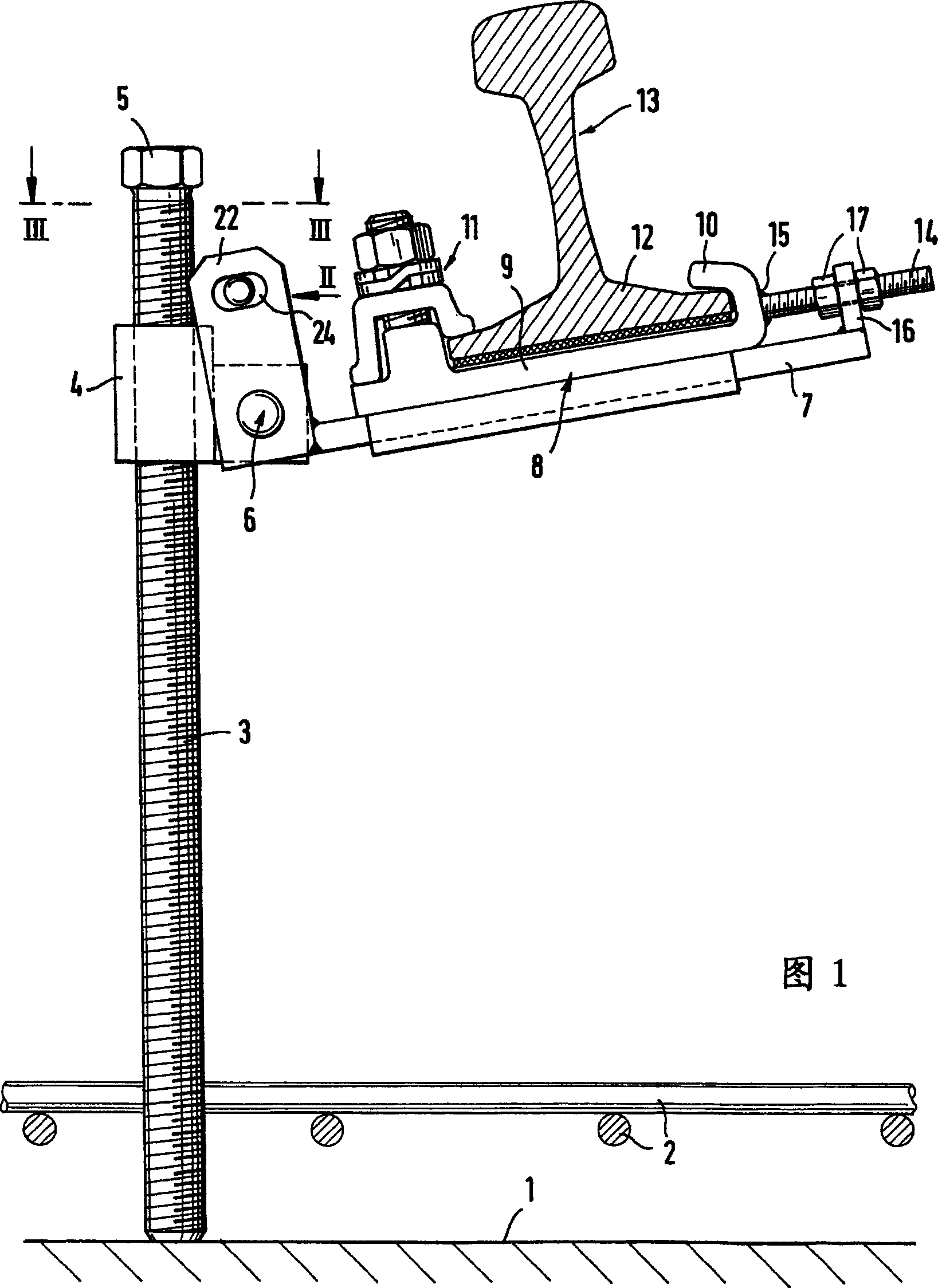

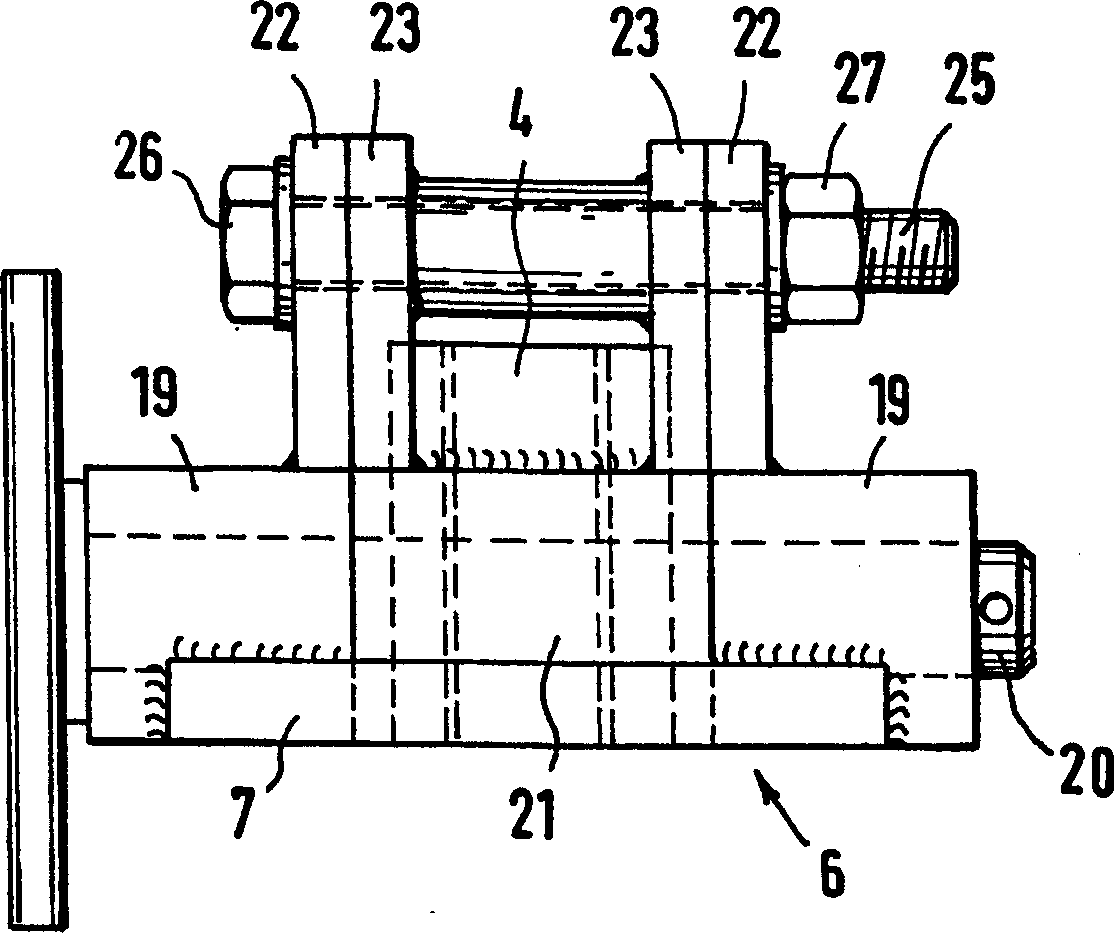

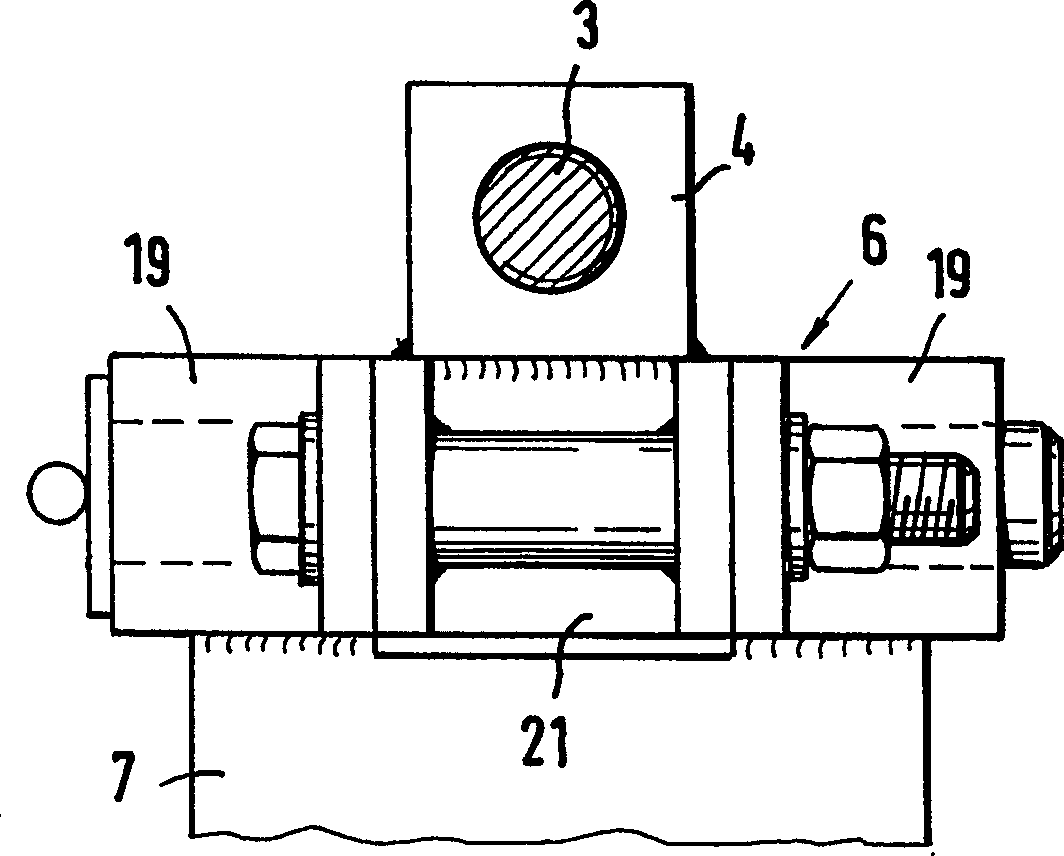

[0024] In FIG. 1 the upper side of the track substructure 1 can be seen, on which reinforcing steel bars 2 can be seen, which are embedded together in the subsequent pouring structure. Mounted on the substructure 1 is a height-adjusting spindle 3 , on which an elongated nut 4 is guided. The height of the elongated nut can be adjusted by turning the screw, for example via its hexagonal head 5 , to which a horizontal screw plate 7 is fixed by means of an articulation 6 . A slide 8 is mounted on said horizontal screw plate in a transversely slidable manner, said slide comprising a rib 9 with a clamping hook 10 and a conventional rail for fixing the rail base 12 of a rail 13 Bottom screw clamp 11. The rails 13 are here rails of a rail block with not shown sleepers connecting the rails, wherein the screw arrangements according to the invention are arranged at intervals along one or the other rail. A leveling screw 14 is used to level the track group, said leveling screw is fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com