Patents

Literature

50 results about "Axial mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

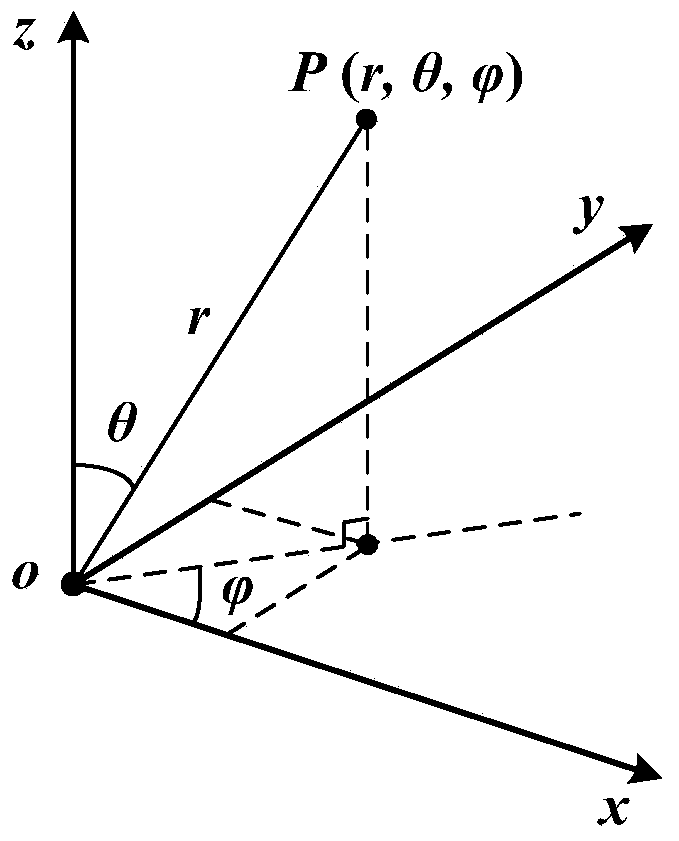

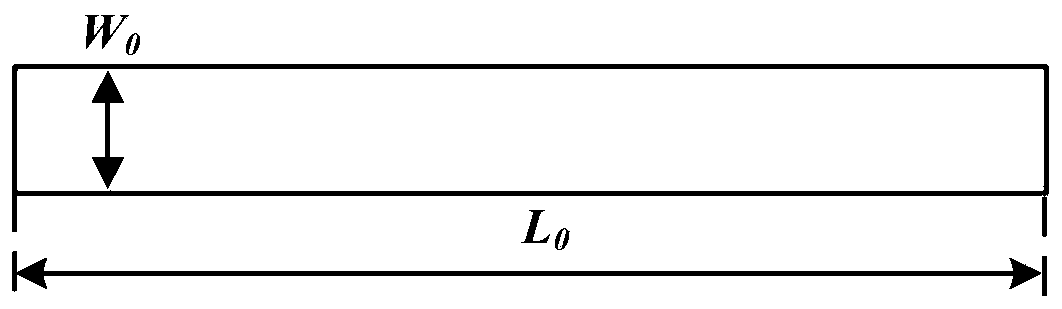

Axial Modes involve just two parallel surfaces – opposite walls, or the floor and ceiling. In other words, an Axial mode consist of waves resonating only along one dimension such as the length, width or height of the room. Normally the axial modes have the most strength while the oblique modes have the lowest strength.

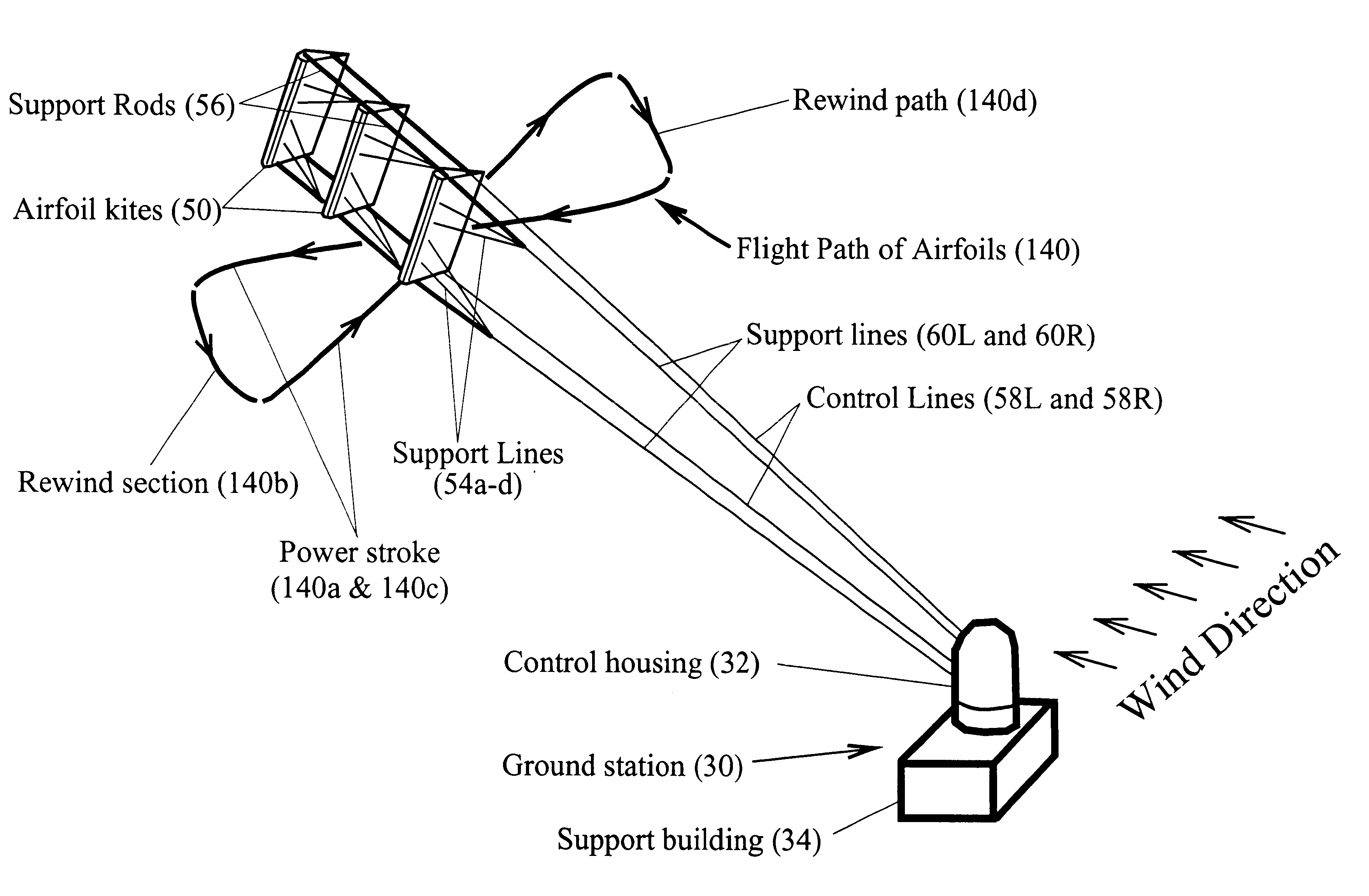

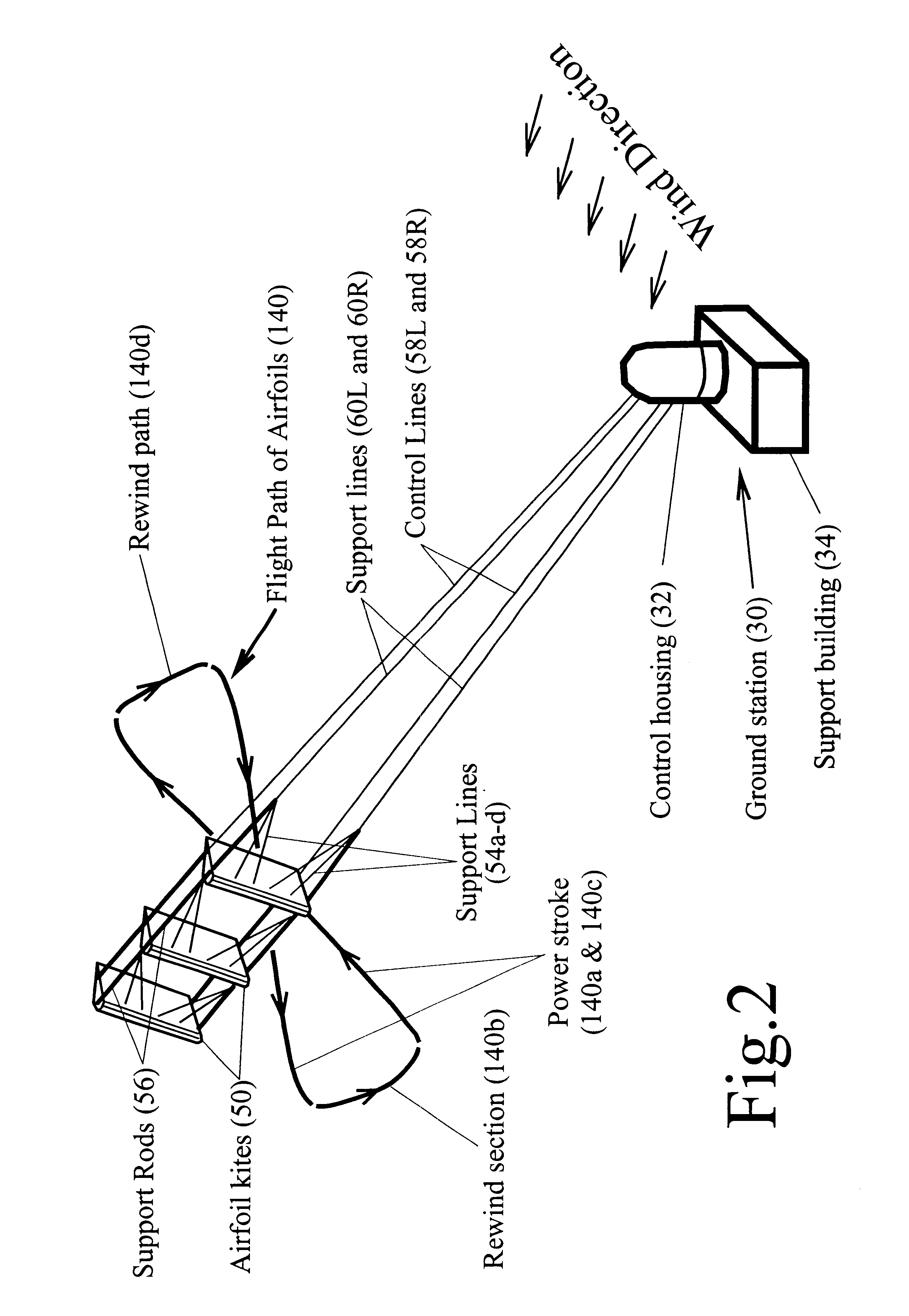

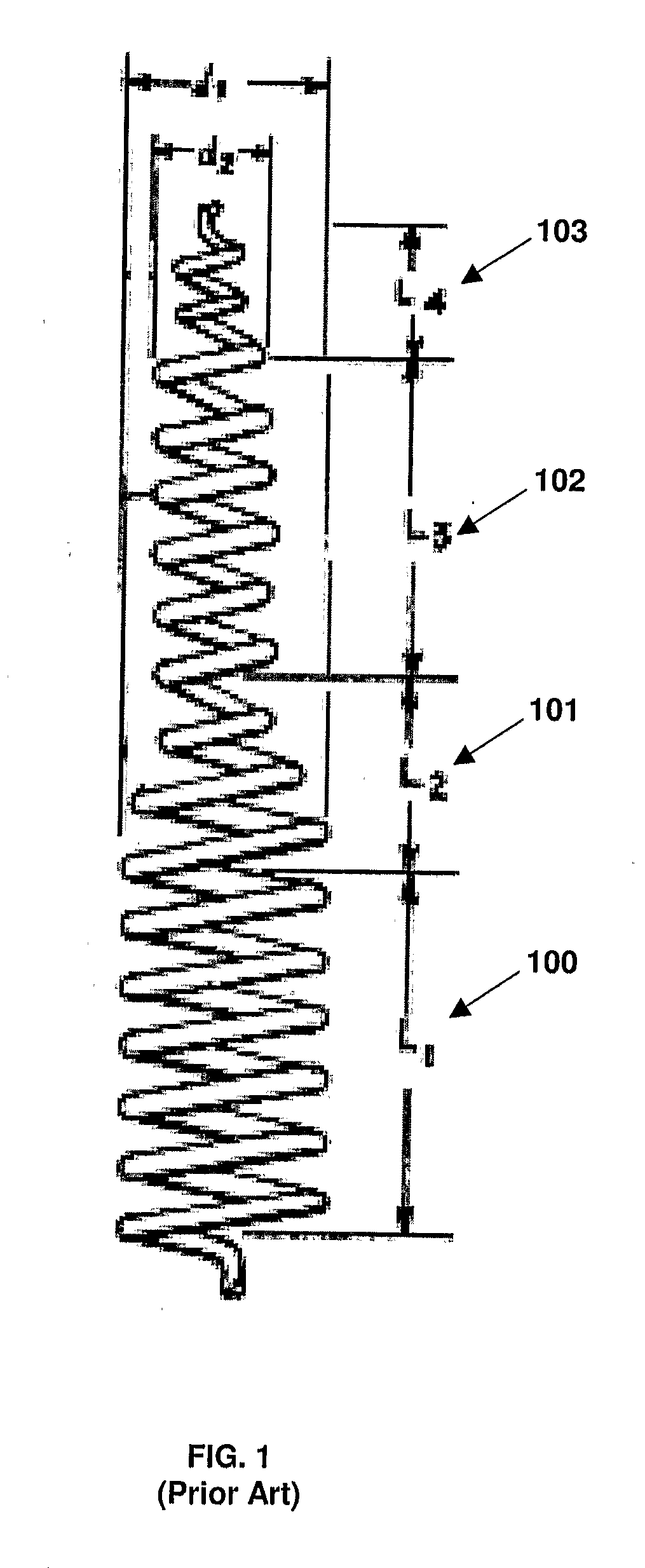

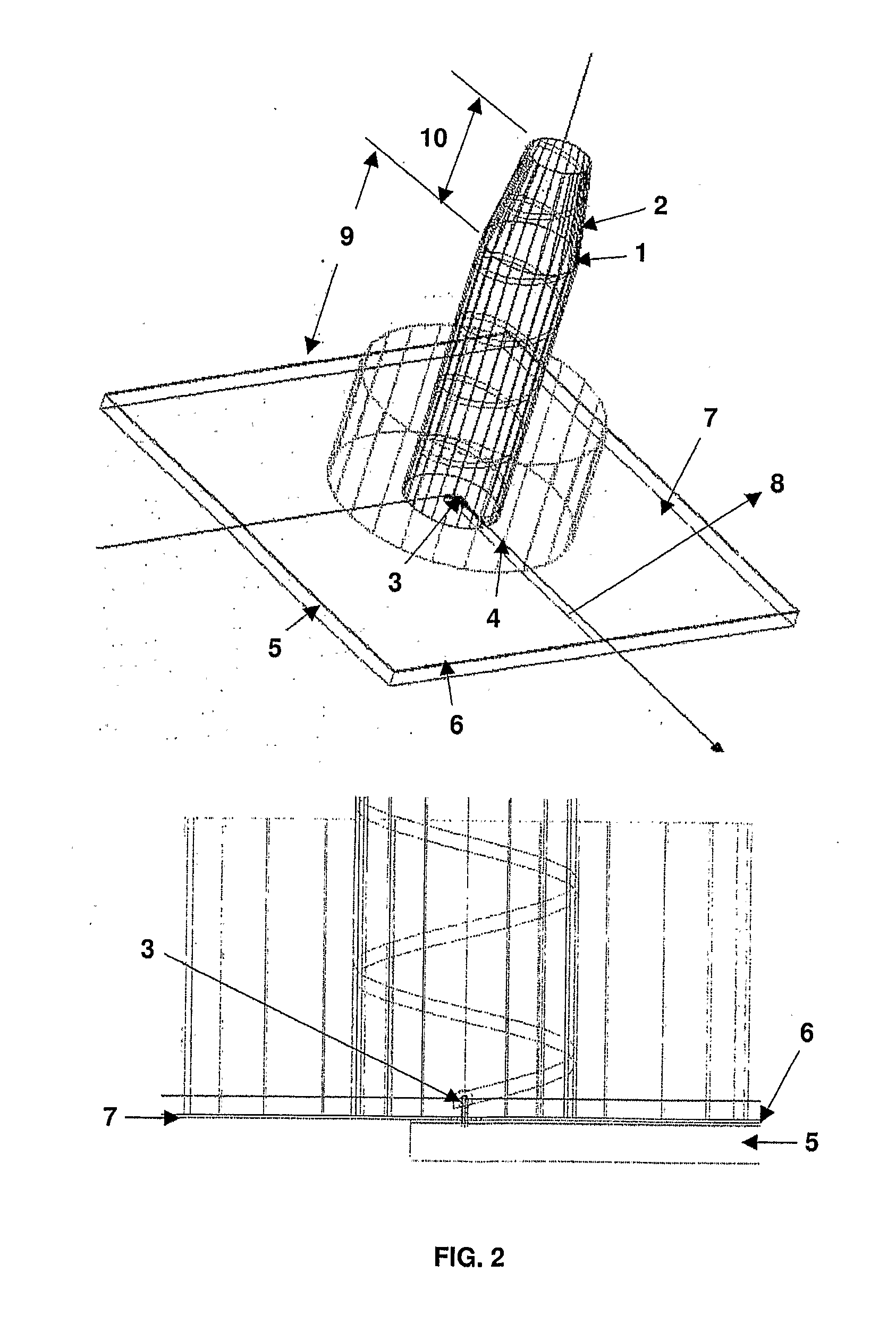

Axial-mode linear wind-turbine

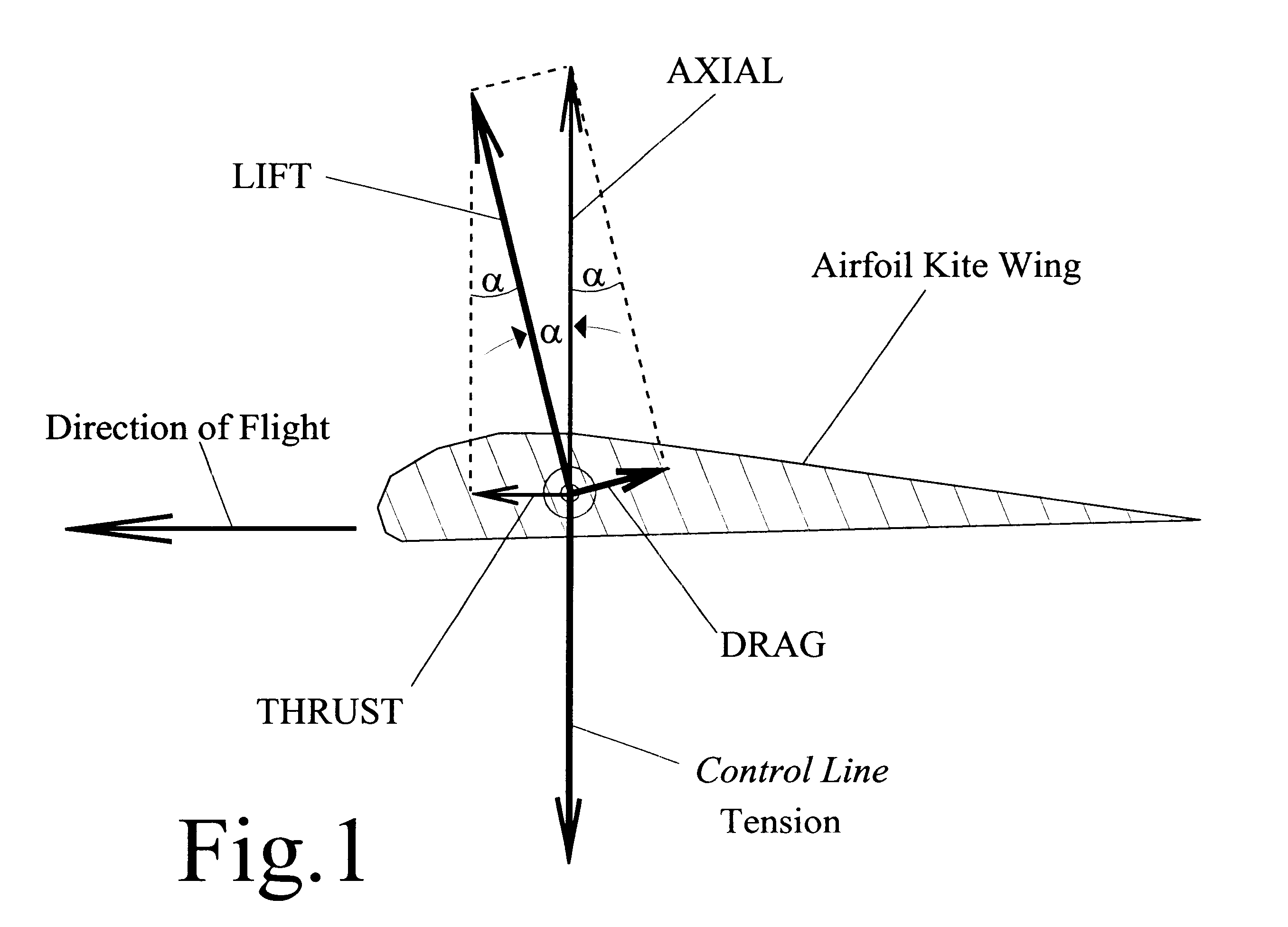

A wind harnessing system using a plurality of self supporting airfoil kites 50 for production of useful power. The system comprising multiple airfoil kites 50 in tandem attached to a pivotal control housing 32 by control lines 58L and 58R and support lines 60L and 60R. Control lines 58L and 58R can change length with respect to the length of support lines 60L and 60R to control the airfoil kites' 50 angle-of-attack, pitch angle, direction of flight, and flight speed. The length of control lines 58L and 58R are controlled from ground station 30 by a movable pulley system in control housing 32 to adjust the airfoils' direction to follow a specific flight path 140. Control lines 58R and 58L and support lines 60R and 60L are also wound on a power shaft and pulley system in control housing 32. As the airfoil kites are propelled by the wind at very-high speed, the airfoils generate a powerful AXIAL force. The control lines 58L and 58R and support lines 60L and 60R are then reeled-out under this AXIAL tension causing the power shaft and pulley system in control housing 32 to turn a generator to generate electricity. After airfoil kites 50 have finished their reel-out power stroke 140a, the airfoil's pitch angle is made negative so they can be reeled-in by their control and support lines using a minimum of force along path 140b. Once the airfoils have been rewound to the proper distance, the airfoils are again angled for high-speed operation to generate powerful AXIAL force and reeled-out along 140c to provide another power stroke. The airfoil kites are then reeled-in again along path 140d and the entire process repeats starting with power stroke 140a. Since the force to rewind the airfoils is much less than the force generated during reel-out, there is net power generated.

Owner:RAGNER GARY DEAN

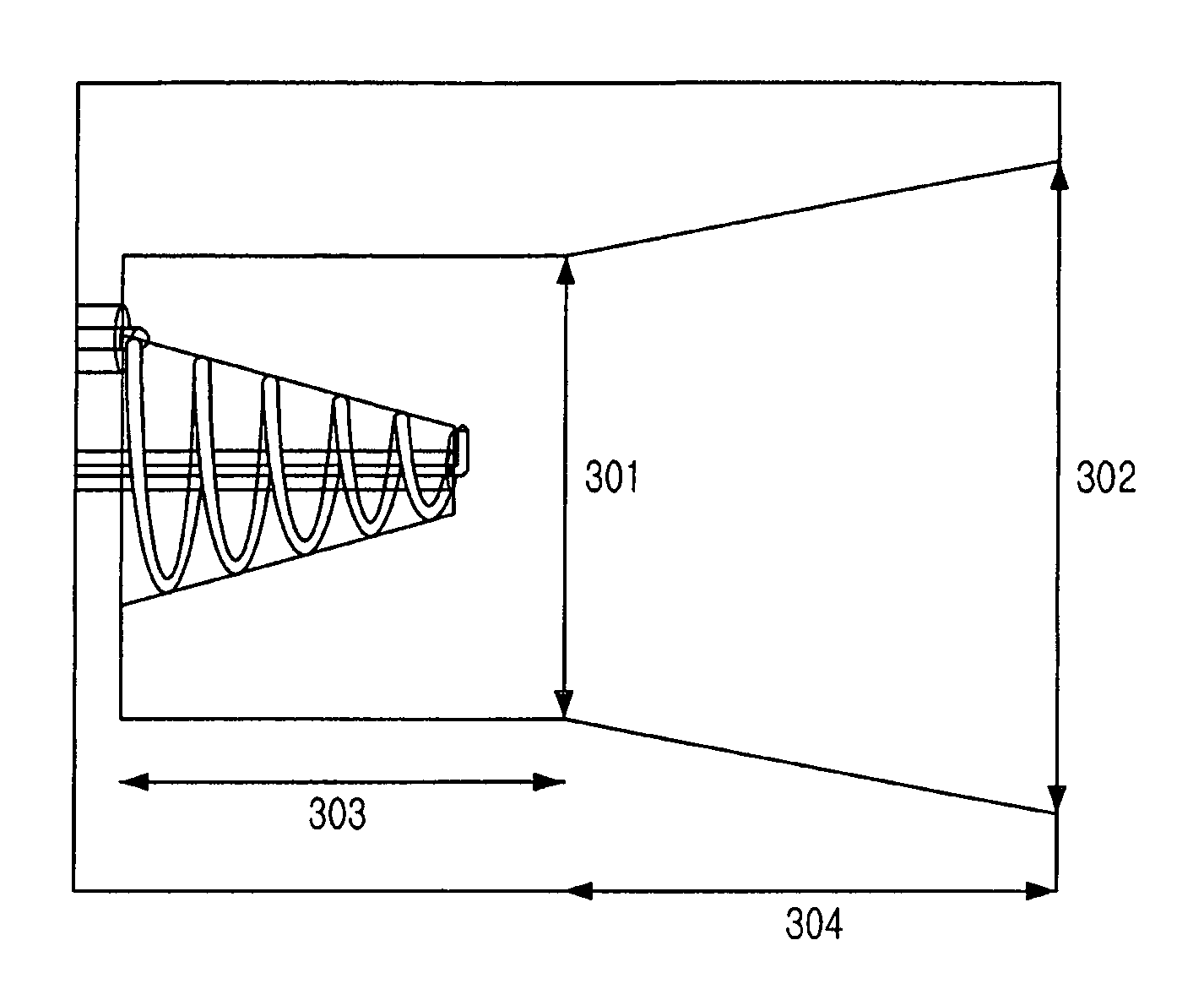

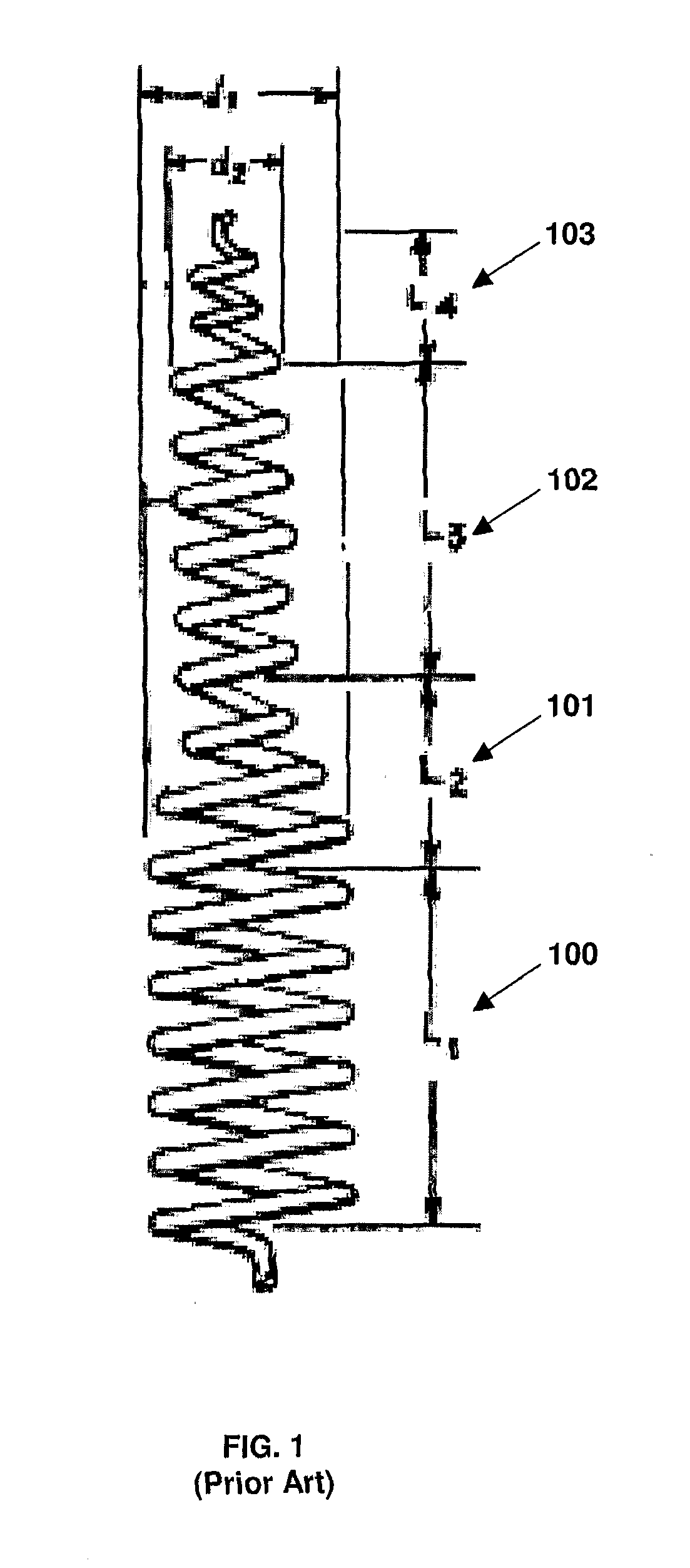

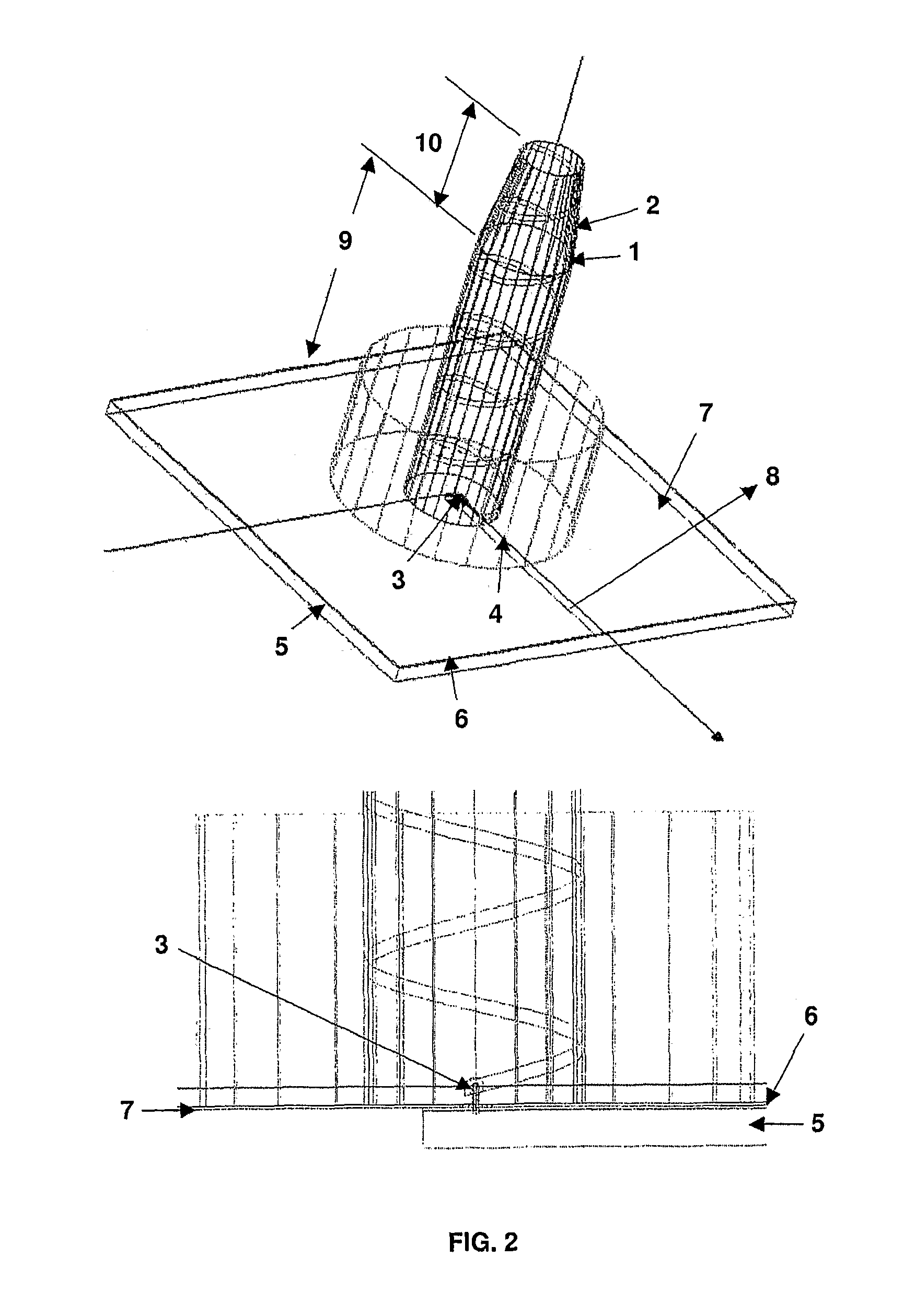

Printed quasi-tapered tape helical array antenna

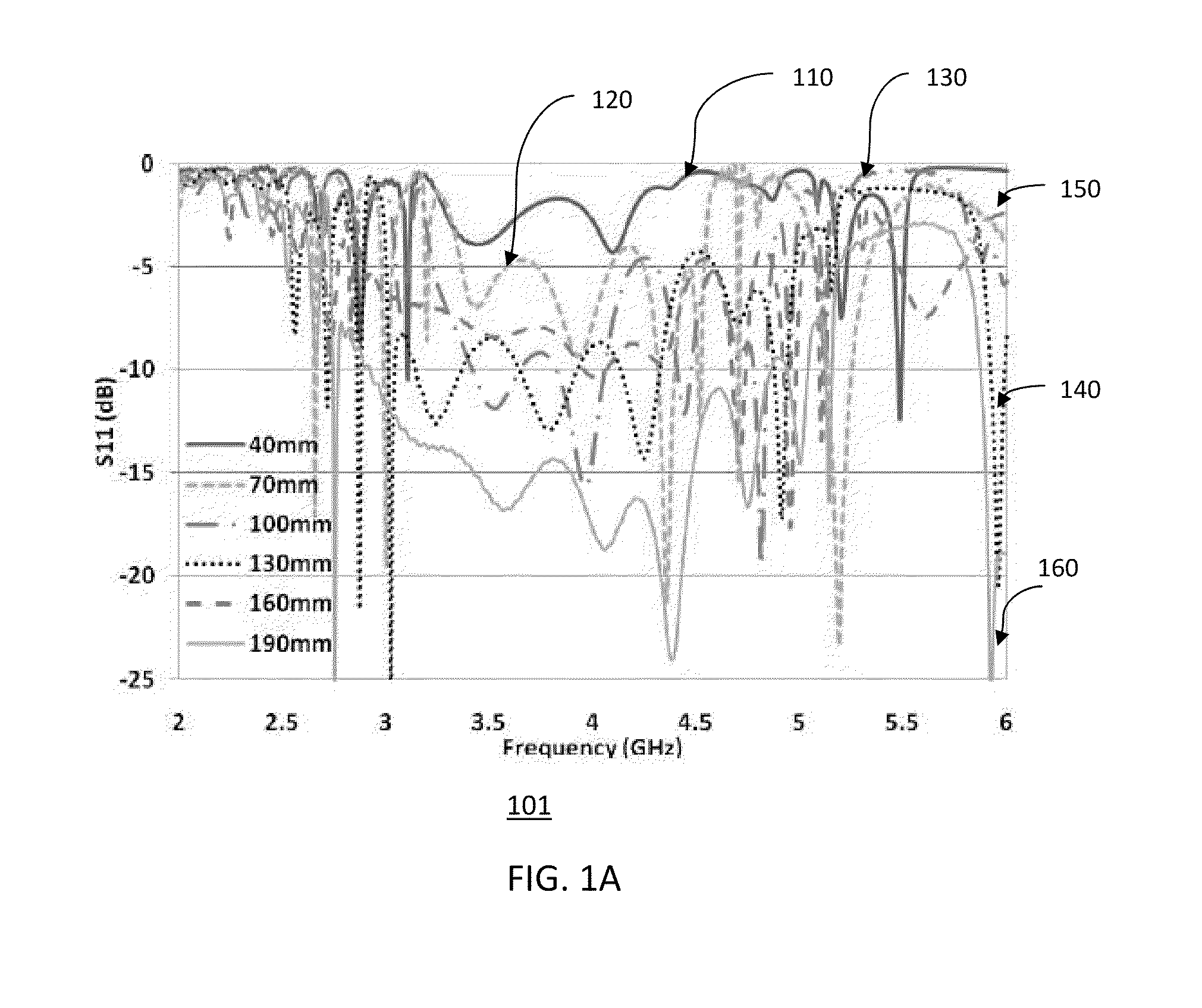

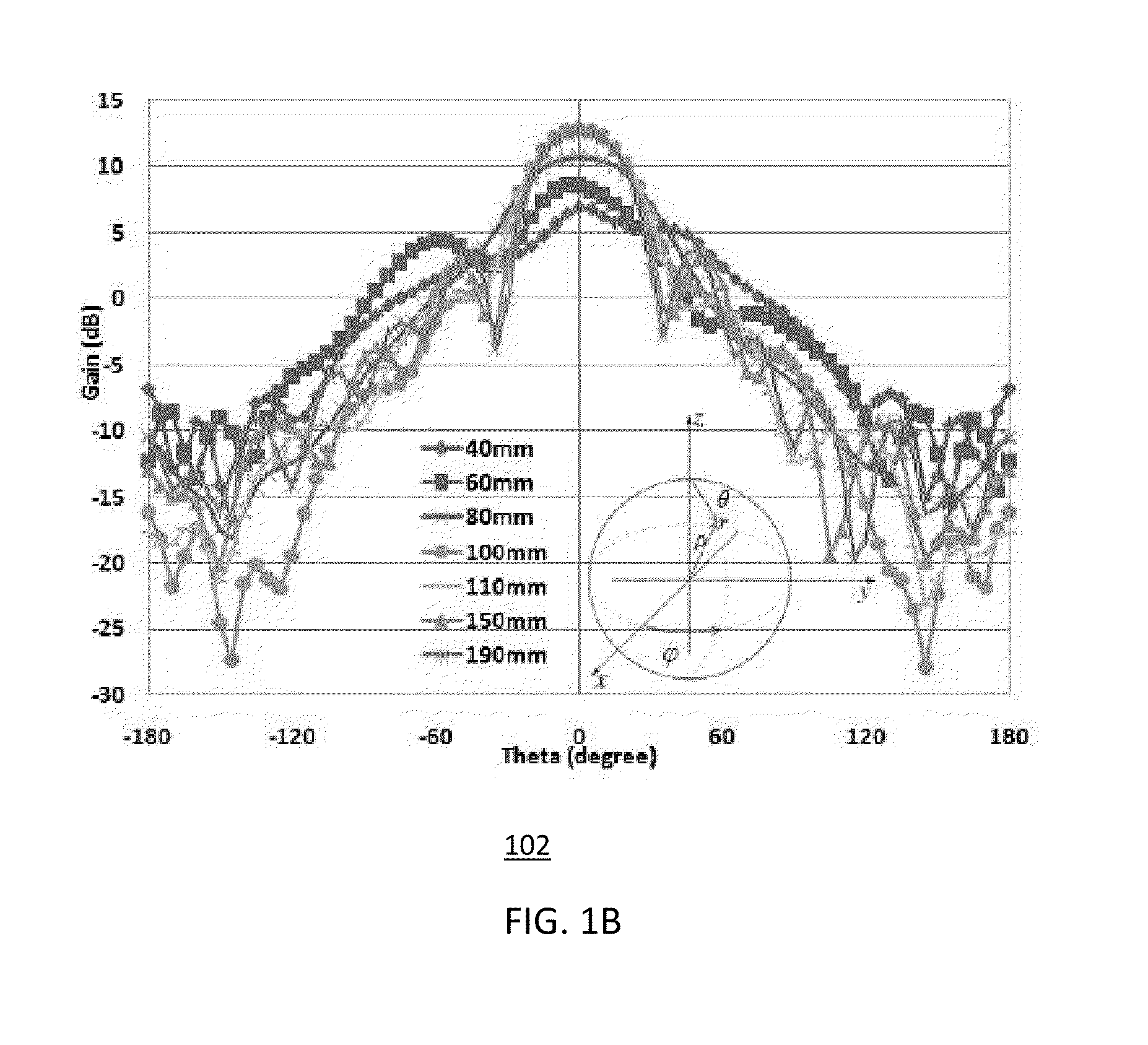

ActiveUS20120188142A1Reduce decreaseMinimize couplingAntenna arraysElectrically long antennasCopper conductorAxial ratio

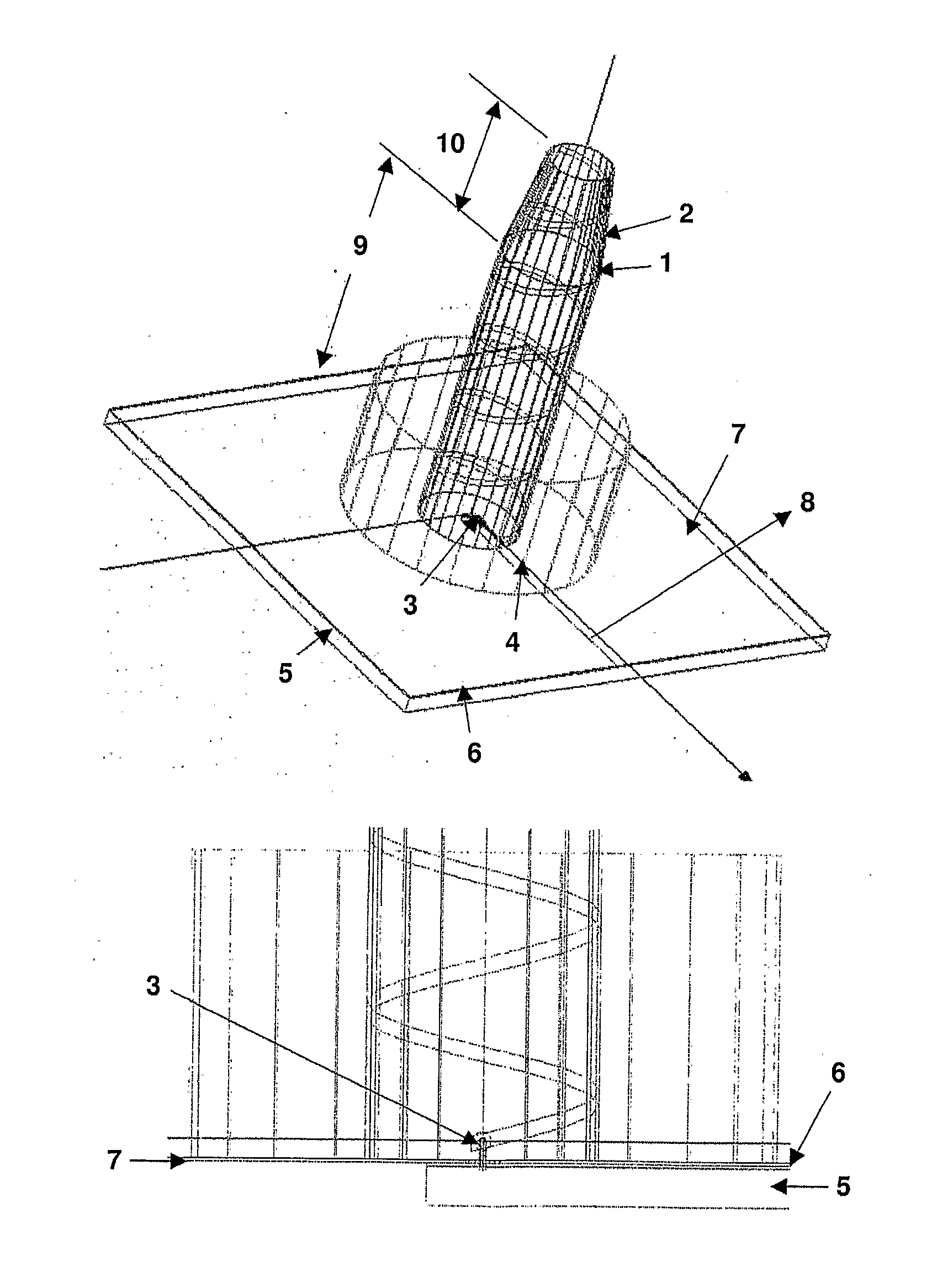

A printed quasi-tapered tape helical element and printed helical array antenna arc disclosed. The helical element comprises a thin helix conductor having a uniform section associated with a tapered section. The helix conductor can be printed on a thin dielectric sheet and bonded to a hollow composite dielectric support. A solid copper conductor is configured to provide electrical connection between a feeding point of the helix conductor and a microstrip line of a microstrip feed network. The uniform and tapered helix turns are respectively wrapped around the uniform and tapered sections, which enables impedance matching, axial mode excitation, gain and radiation patterns, and damping out of standing waves generated in current distribution over the helix conductor. Conductive composite cups surrounding each helical element reduces mutual coupling in array environment. Thus, the helical element and the array antenna achieve low on-axis and off-axis axial ratio performance over the wideband for global coverage.

Owner:INDIAN SPACE RES ORG OF ISRO

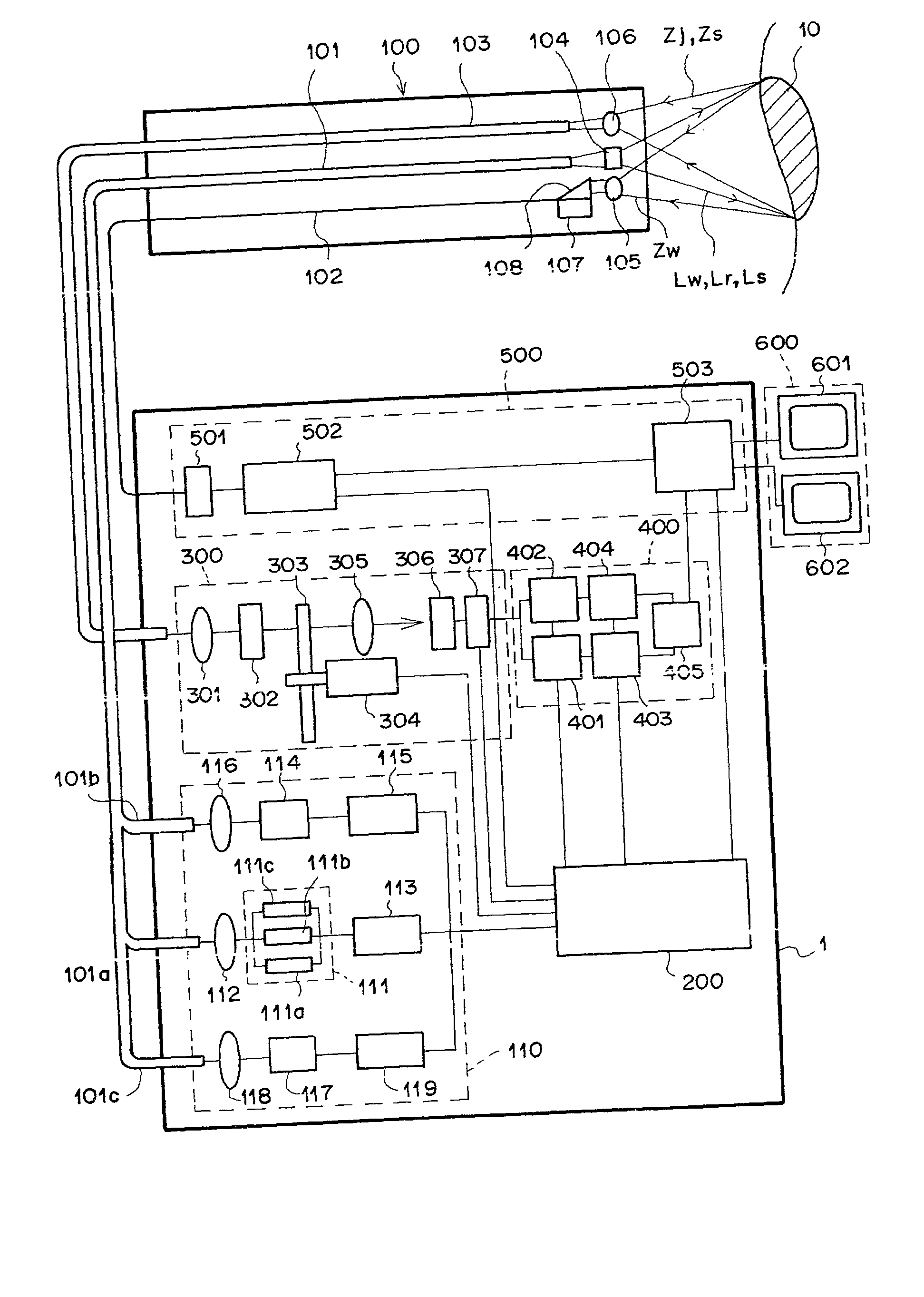

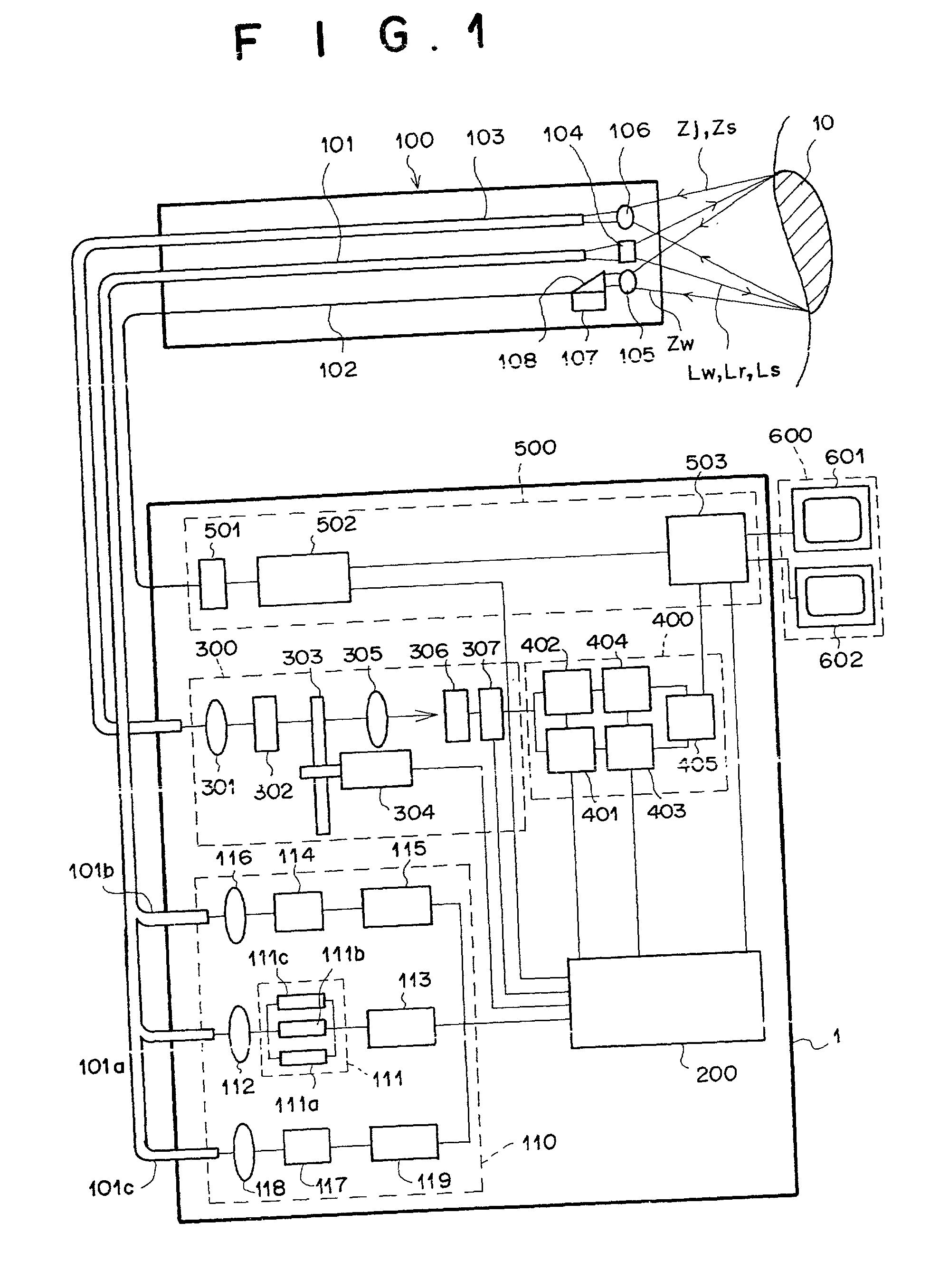

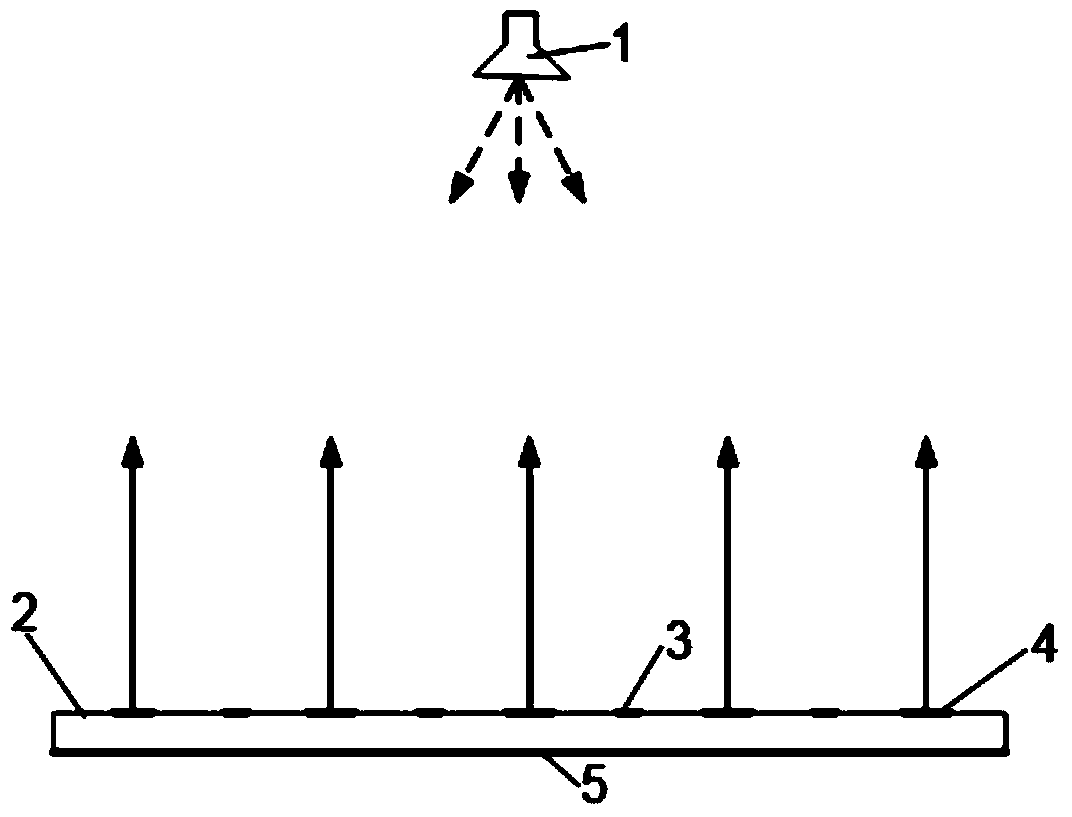

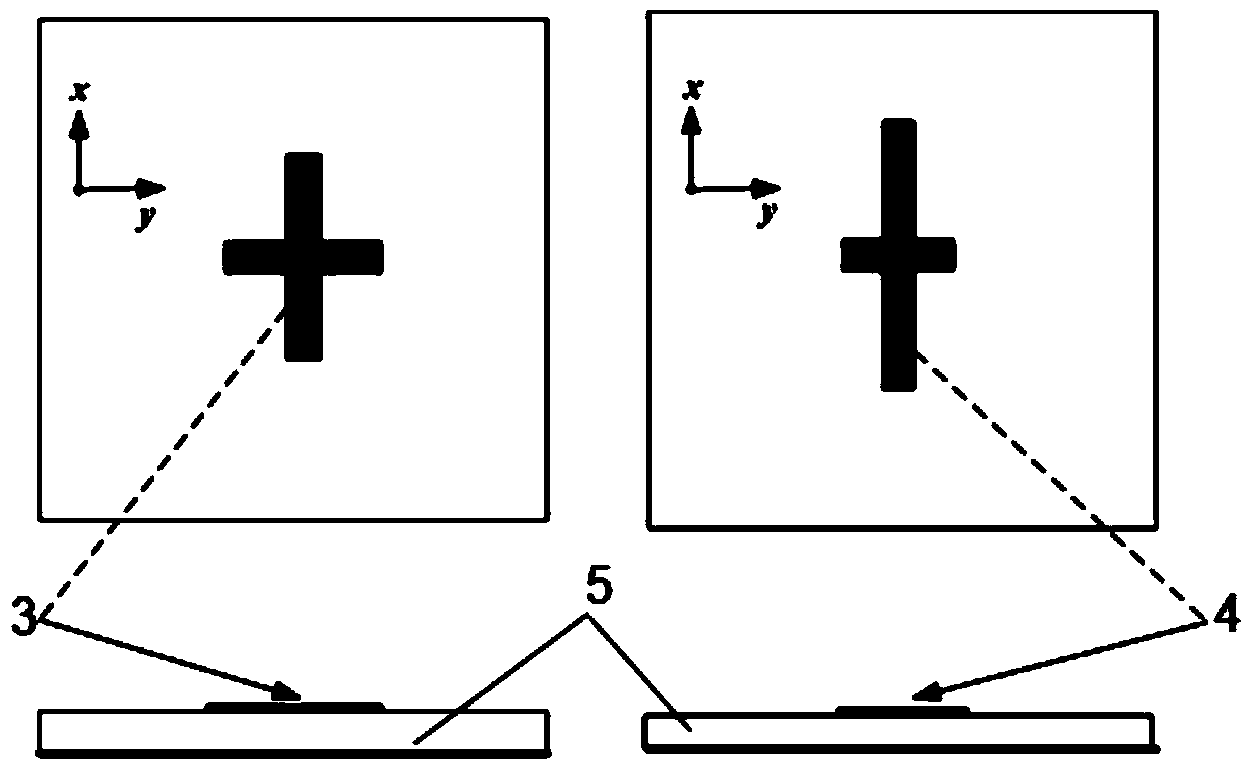

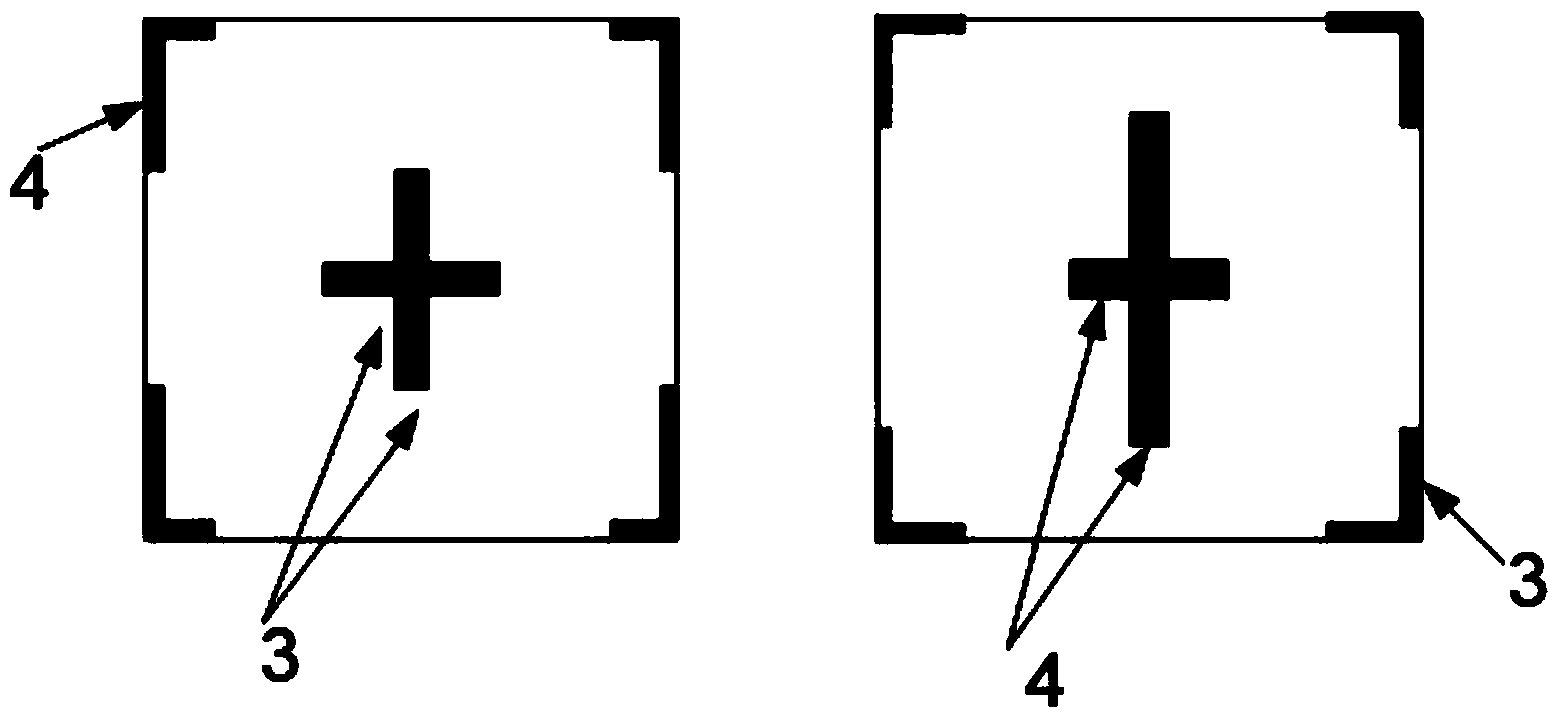

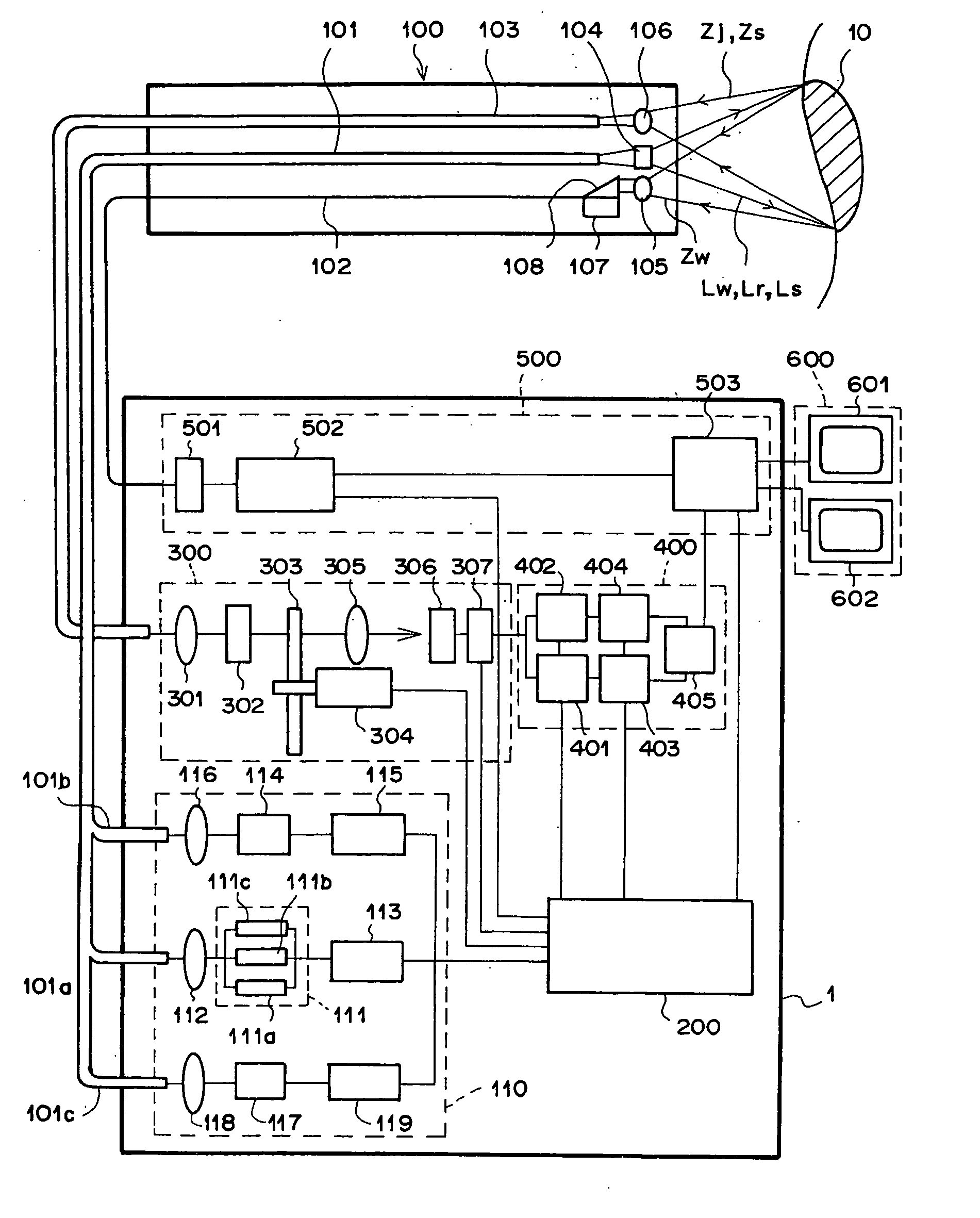

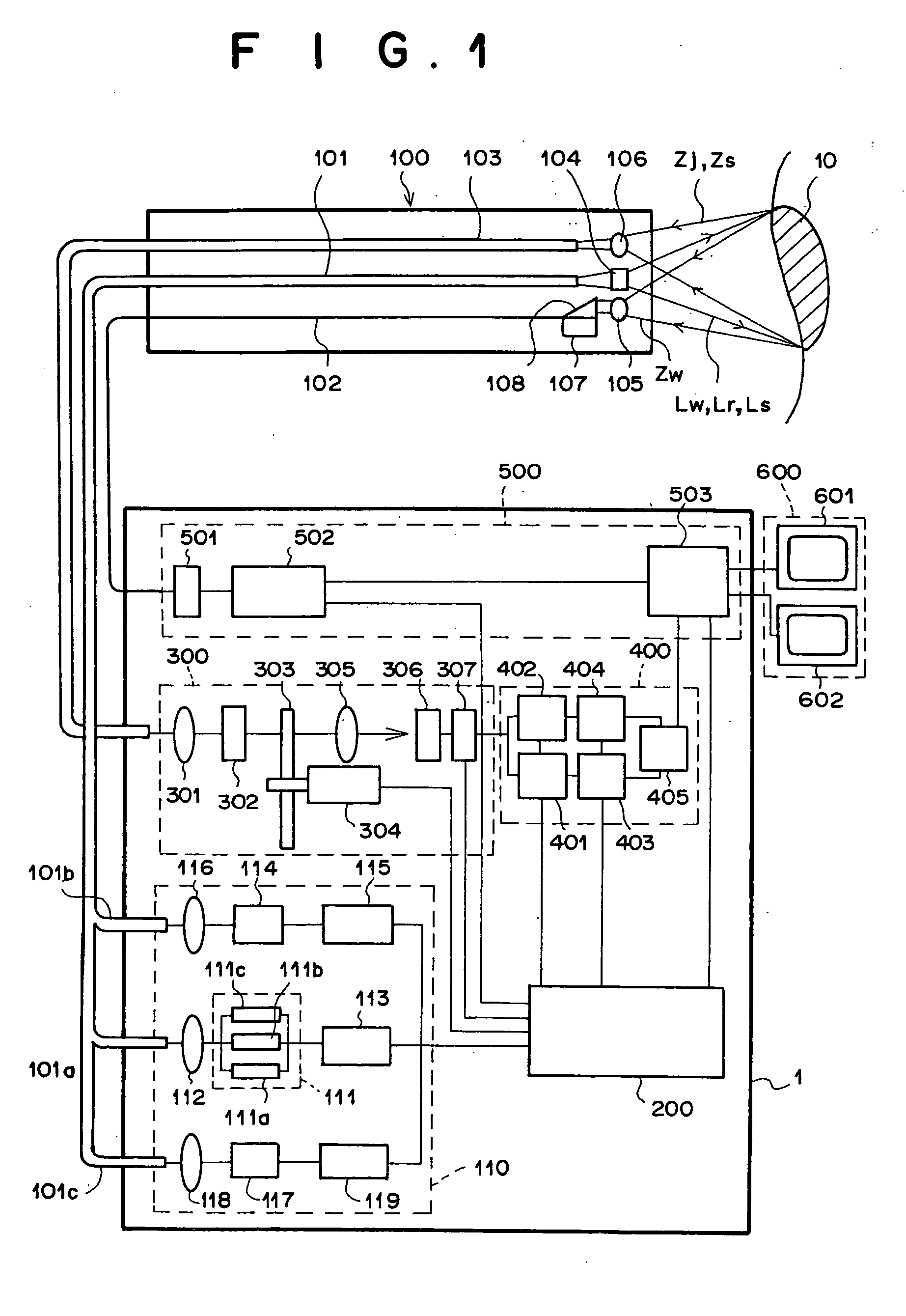

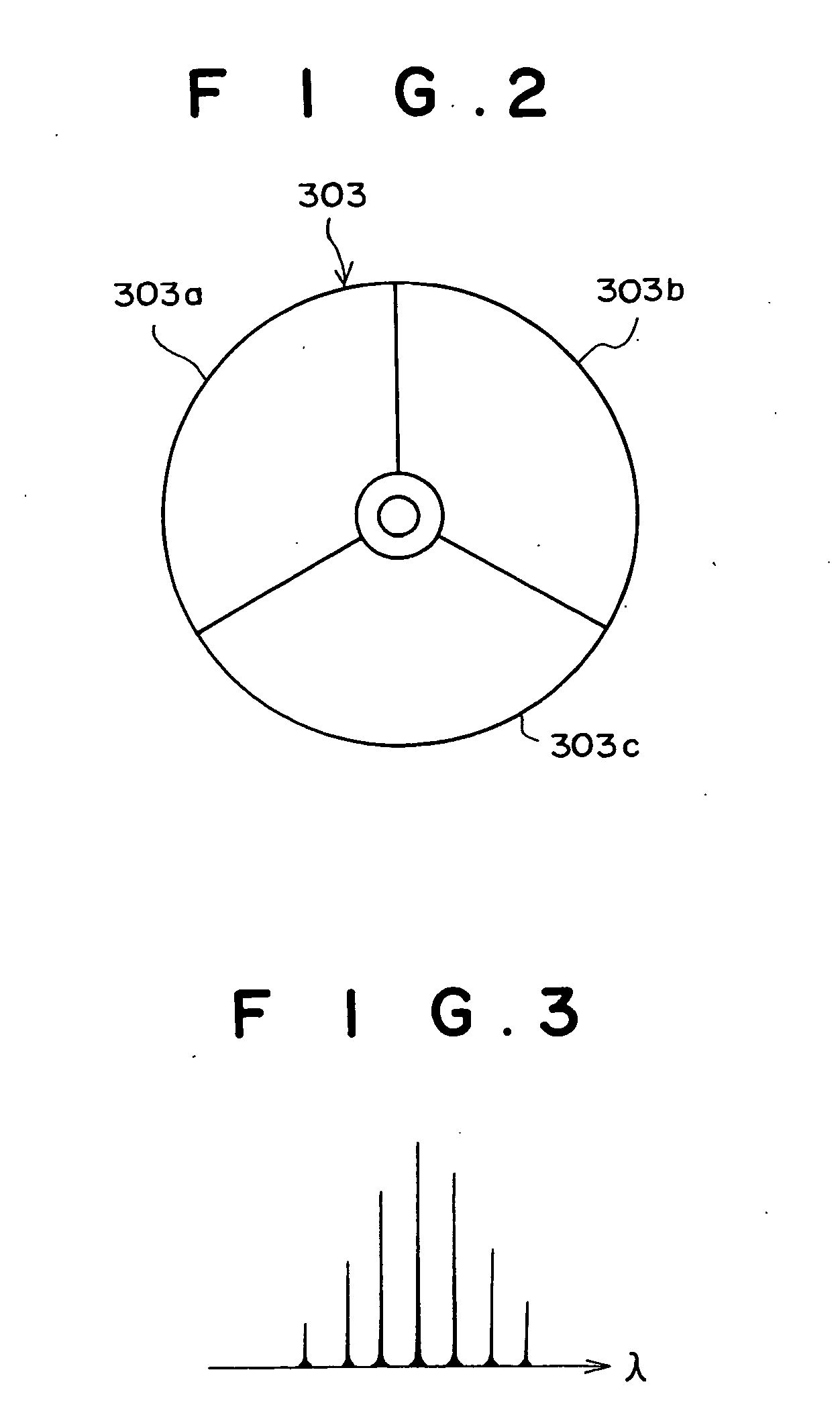

Endoscope system having multiaxial-mode laser-light source or substantially producing multiaxial-mode laser light from single-axial-mode laser light

InactiveUS20020038074A1Clearer diagnostic imageSmall sizeLaser detailsSurgeryDriving currentFluorescence

In an endoscope system including: a light emission unit emits laser light as illumination light or excitation light; a light guide unit guides the illumination light or the excitation light to an object; and an image pickup unit picks up a normal image formed with reflection light generated by reflection of the illumination light from the object or a fluorescence image emitted from the object in response to the excitation light. The laser light is multiaxial-mode laser light, or the light emission unit includes a plurality of laser-light sources which emit single-axial-mode laser beams having different wavelengths or phases. Alternatively, a vibration unit which vibrates the light guide unit is provided, or a high-frequency signal is superimposed on a driving current of the light emission unit, so that the wavelength of the laser light is shifted among a plurality of values.

Owner:FUJIFILM HLDG CORP +1

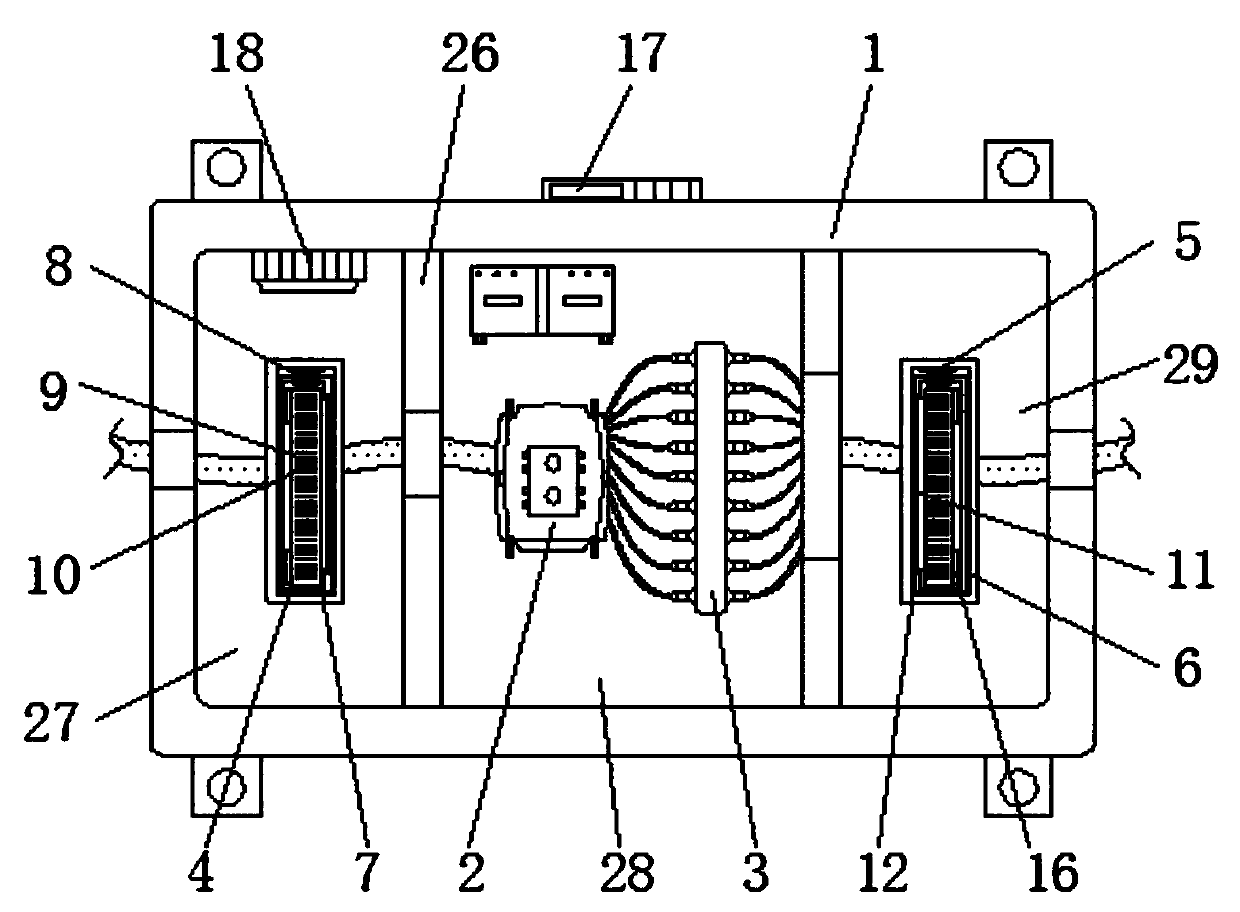

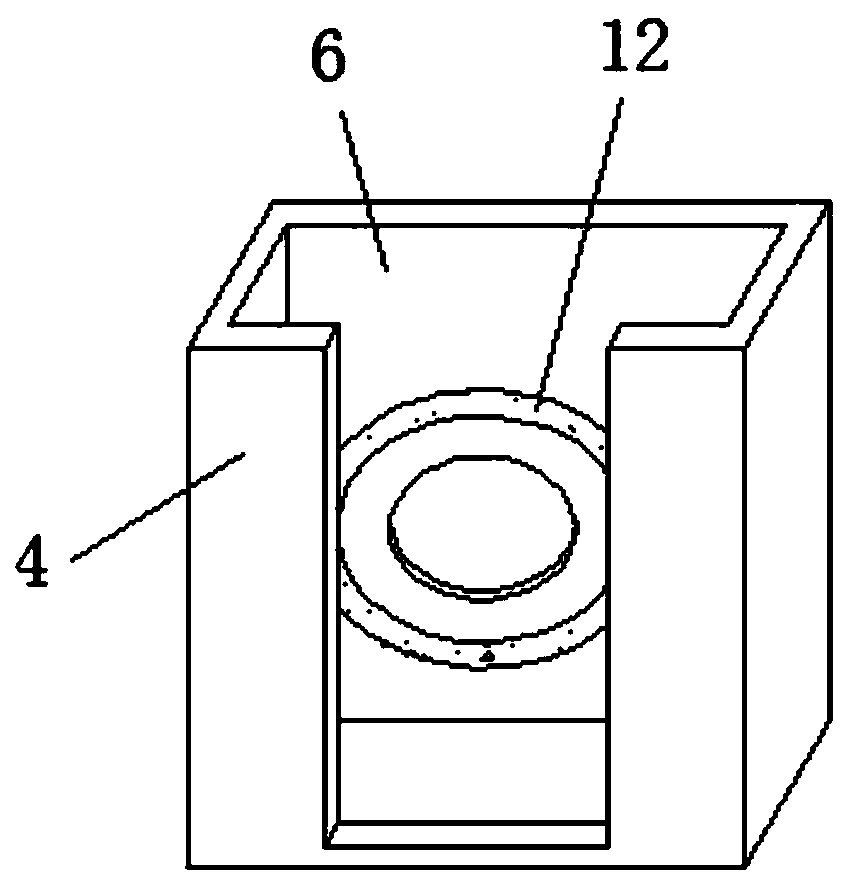

Rotating unit type double-frequency circular polarization reflective array antenna

InactiveCN103730739ASimple structureLight structurePolarised antenna unit combinationsAntenna couplingsCouplingOptoelectronics

The invention discloses a rotating unit type double-frequency circular polarization reflective array antenna which comprises a circular polarization feed source and a reflective array. The circular polarization feed source comprises an axial mode spiral antenna. The reflective array is formed by a high band unit and a low band unit in an alternating-arraying mode. The high band unit and the low band unit carry out phase compensation in a rotating-band-unit mode, and accordingly the fact that after feed source irradiation, the reflective array can emit identical-phase circular polarization wave beams at the two bands can be guaranteed. A rotating technology is introduced to the units at the two bands on the same layer of array face, and cross coupling between the two bands is effectively lowered. The reflective array is of a single-layer structure, so that the array structure is simple and light.

Owner:XIDIAN UNIV

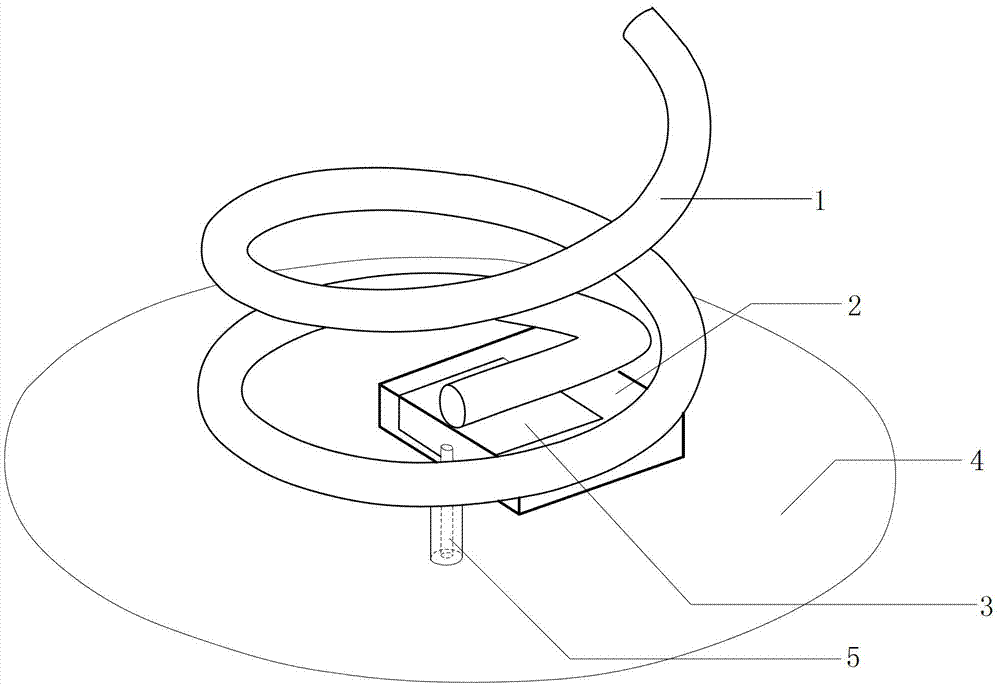

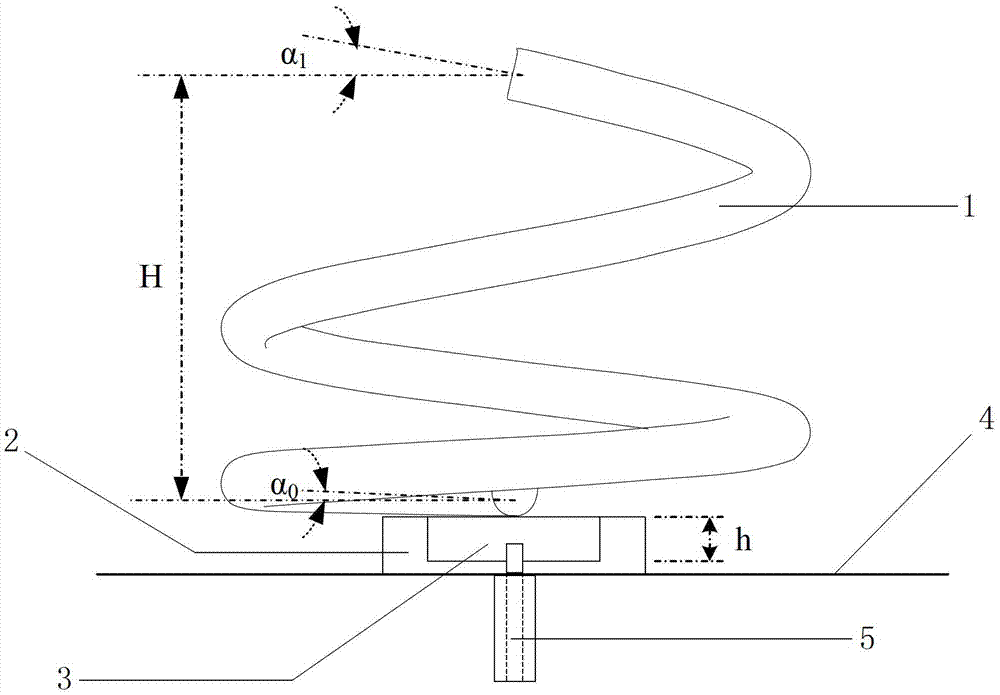

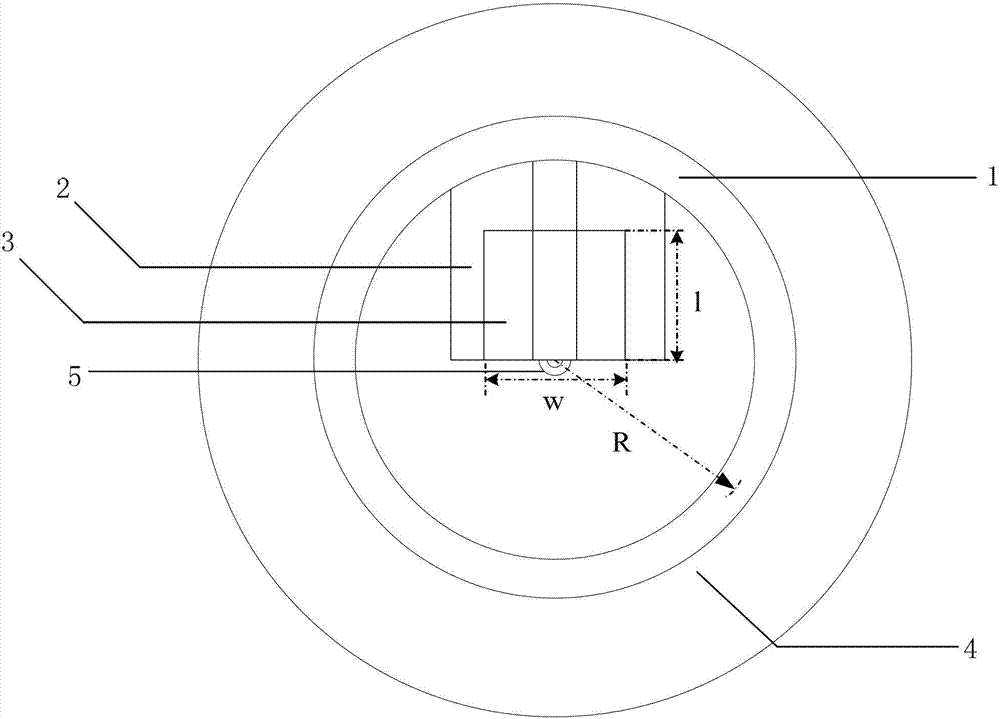

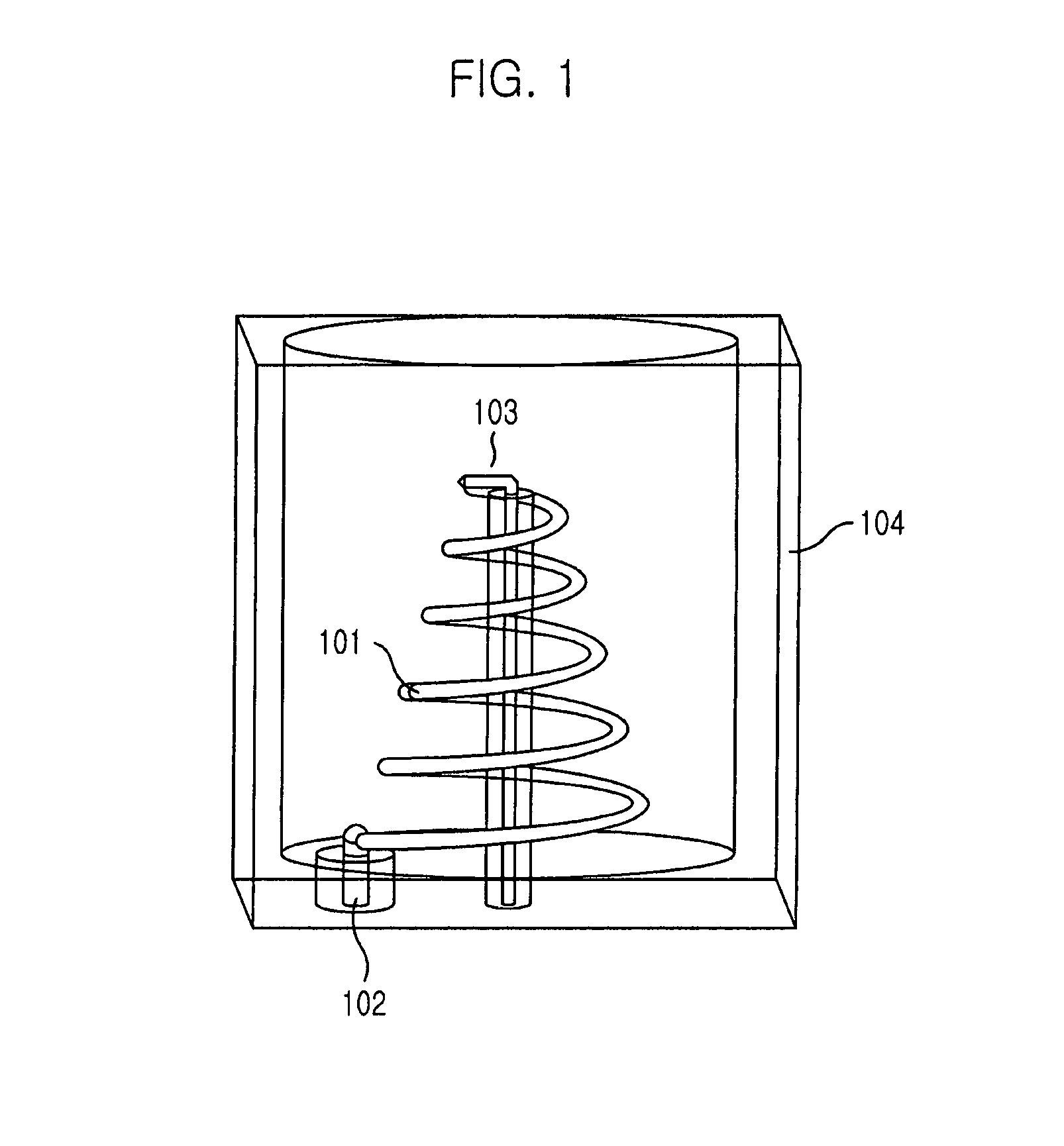

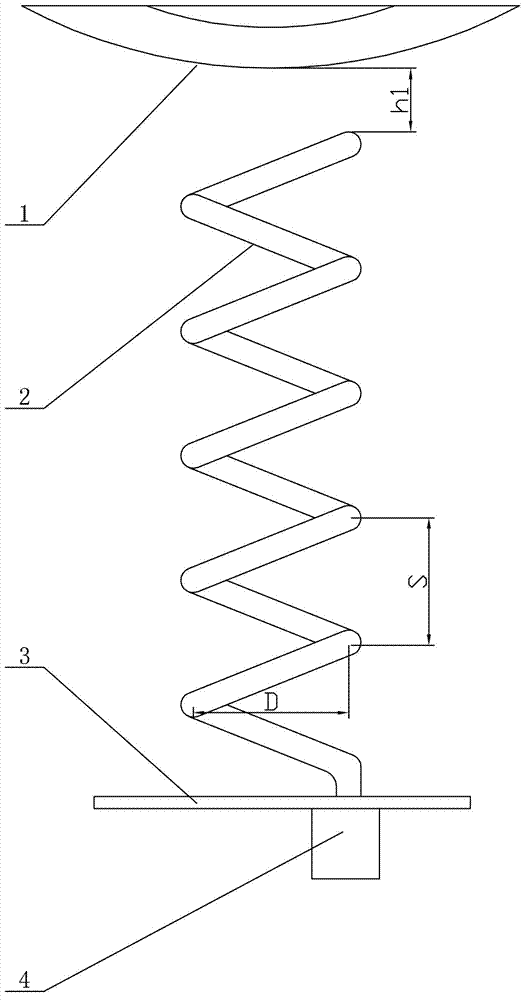

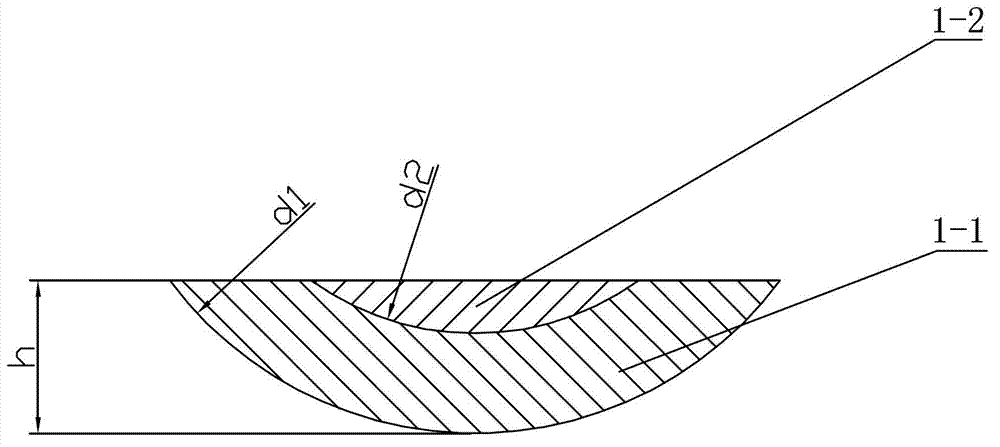

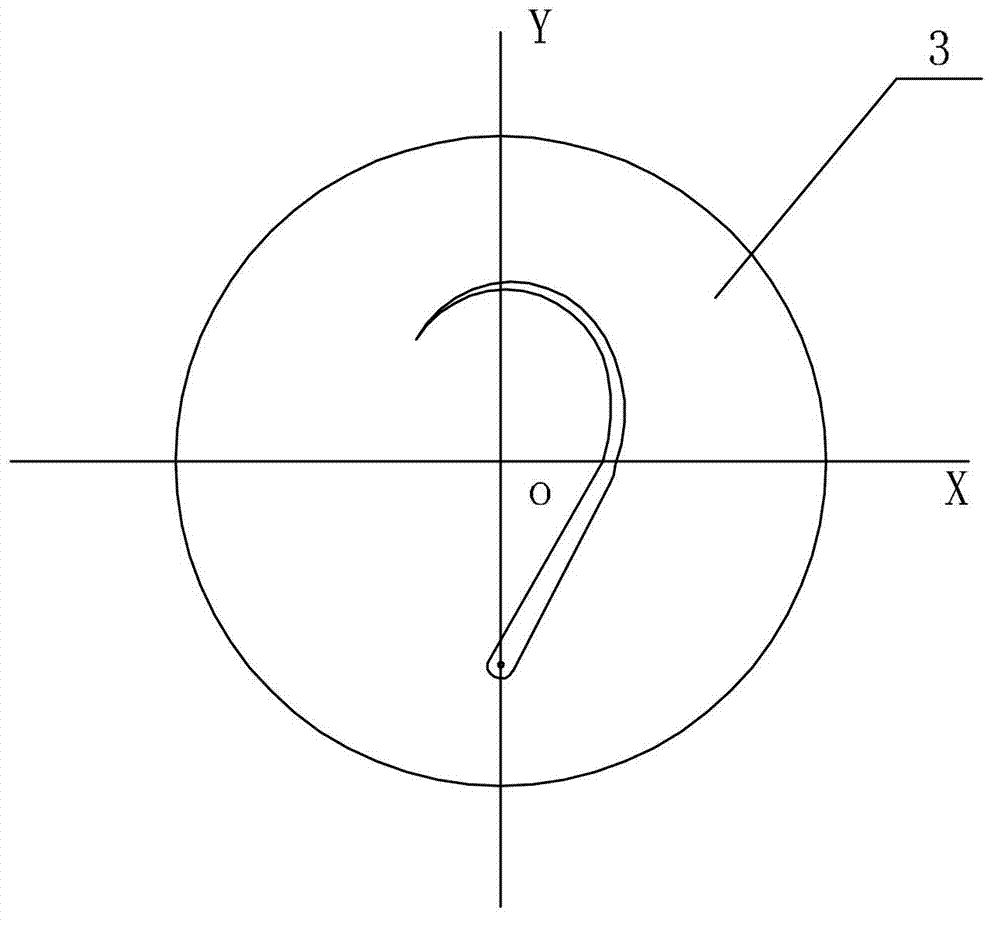

Axial-mode cylindrical helical antenna

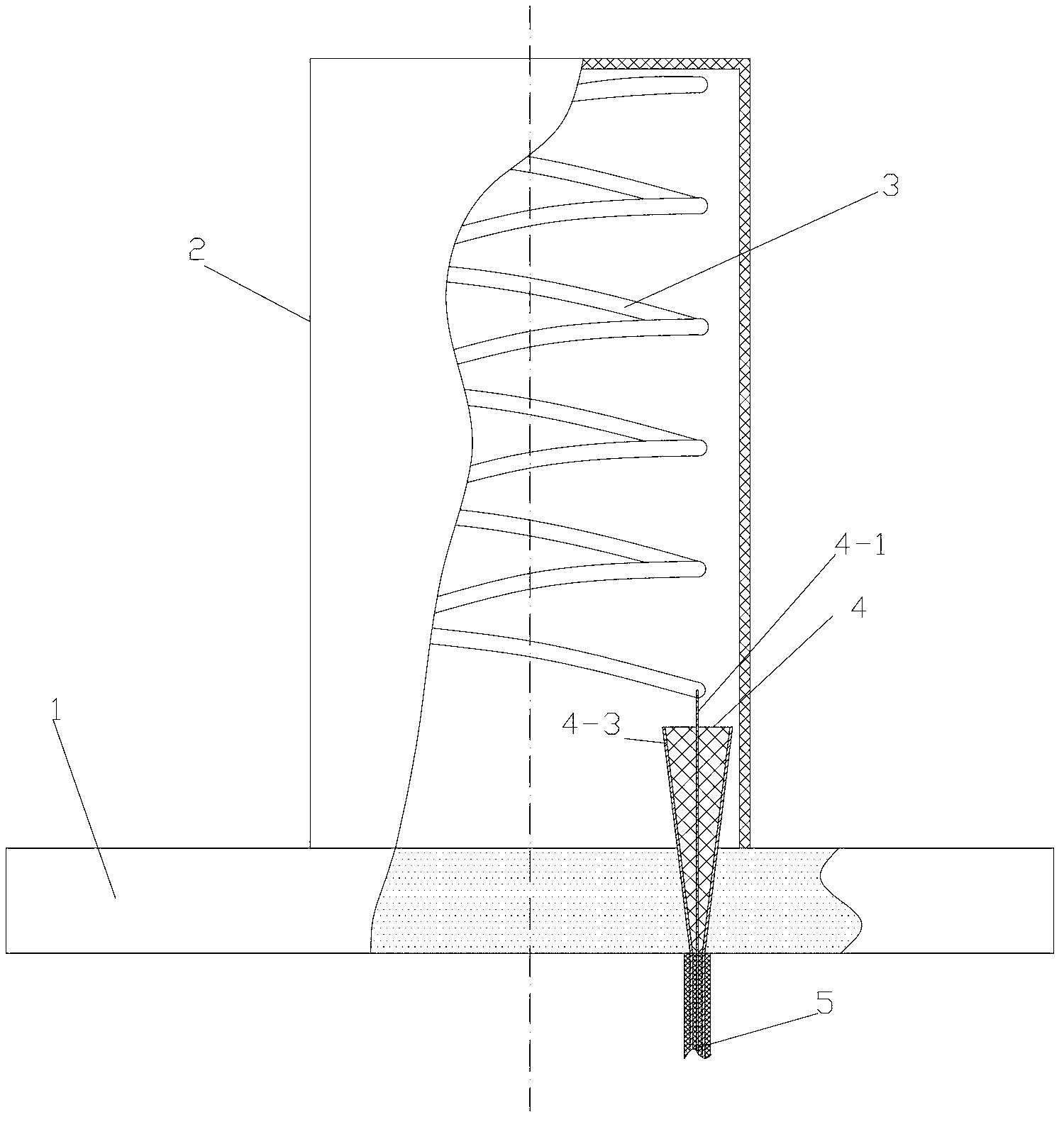

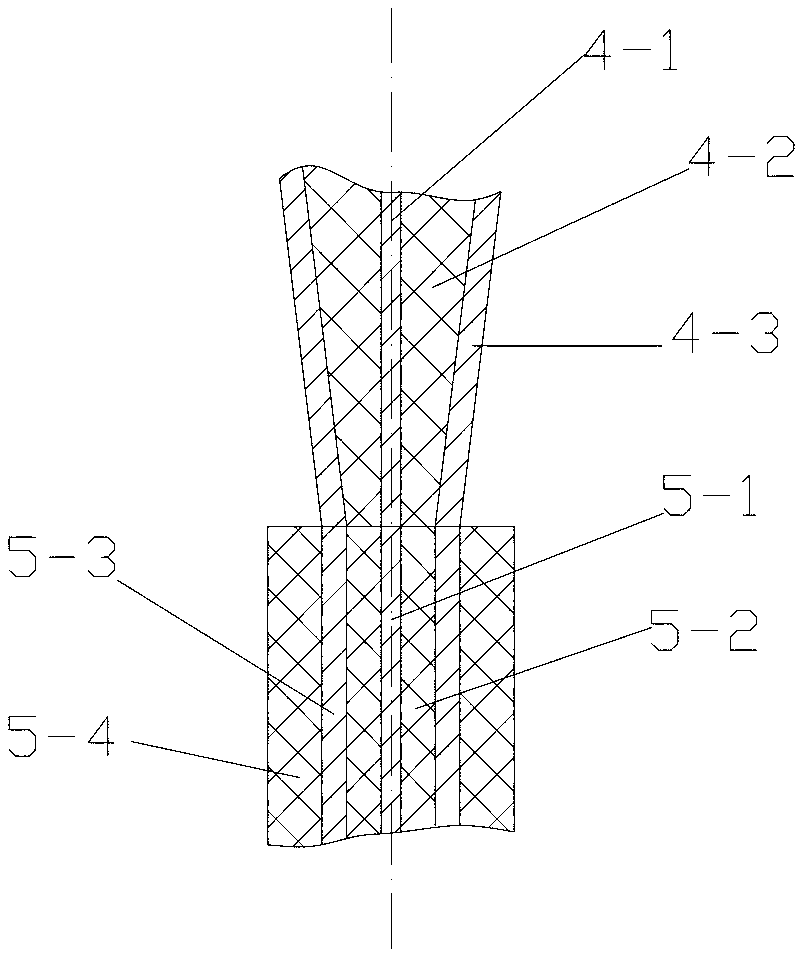

InactiveCN102931490AExcellent circular polarization radiation performanceImprove matchAntenna feed intermediatesElectrical conductorEngineering

The invention discloses an axial-mode cylindrical helical antenna. The axial-mode cylindrical helical antenna comprises a helical radiator, a medium supporter, a feed matcher, a grounding board and a radio-frequency (RF) coaxial connector, wherein the helical radiator is of a cylindrical shape which is formed in a manner that a copper pipe is sequentially and helically encircled rightwards, and a variable-lift-angle helical structure is formed in a manner that the helical radiator extends to the circumference of a cylindrical bottom face from the circle center of the bottom face along the radial direction and then extends along the axial direction in a rising manner; the medium supporter is fixedly arranged on the grounding board; the feed matcher is of an inverted-L-shaped microstrip structure and divided into a horizontal part and a vertical part; the starting end of the helical radiator is arranged on the horizontal part which is stuck to the upper surface of the medium supporter and supported by the medium supporter; the RF coaxial connector is vertically arranged on the grounding board, and the top end of an inner conductor of the RF coaxial connector is connected with the vertical part; and an outer conductor of the RF coaxial connector is connected with the grounding board. The axial-mode cylindrical helical antenna has the advantages of flexible design, simple physical structure, excellent antenna performance and wide application.

Owner:DALIAN MARITIME UNIVERSITY

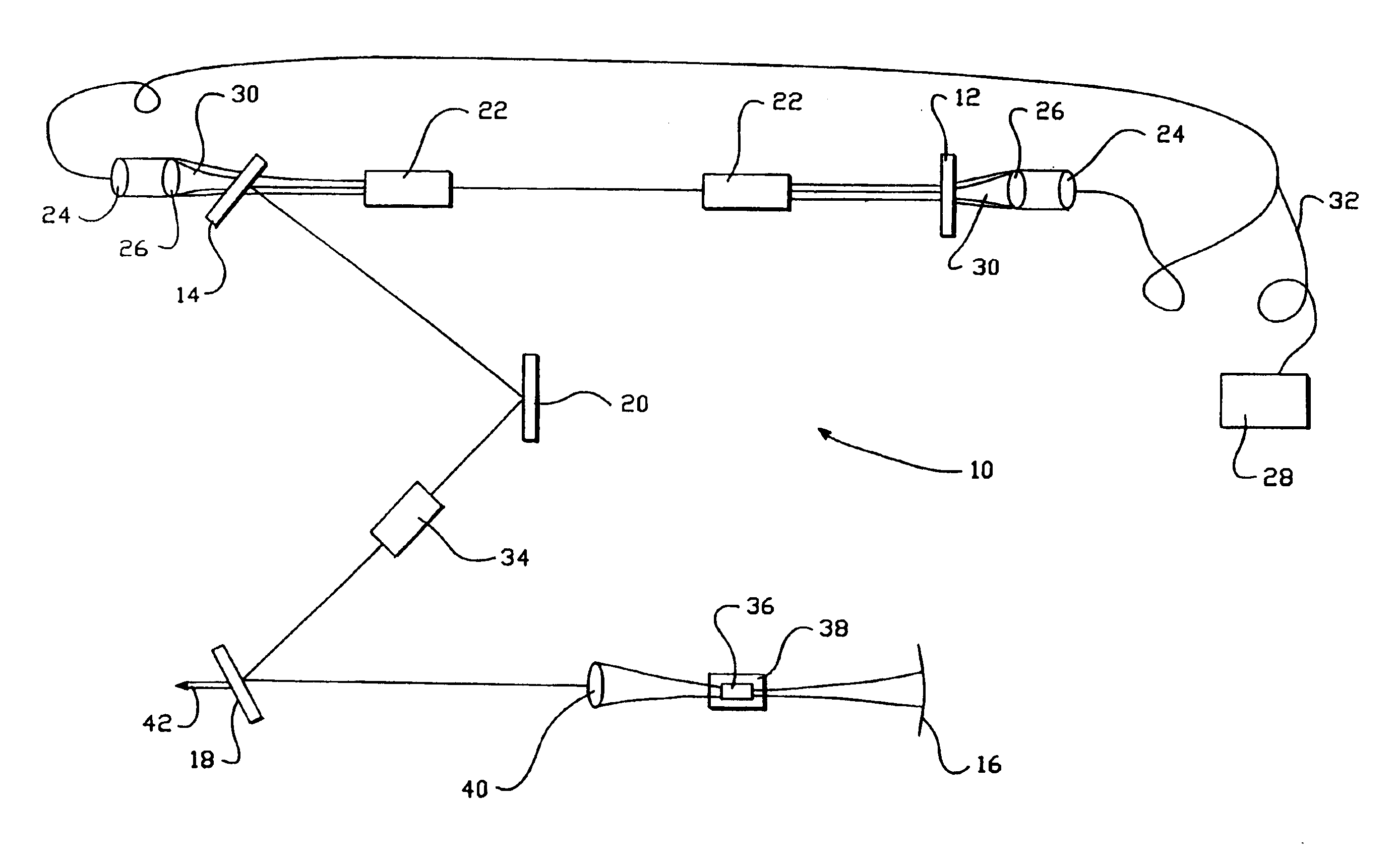

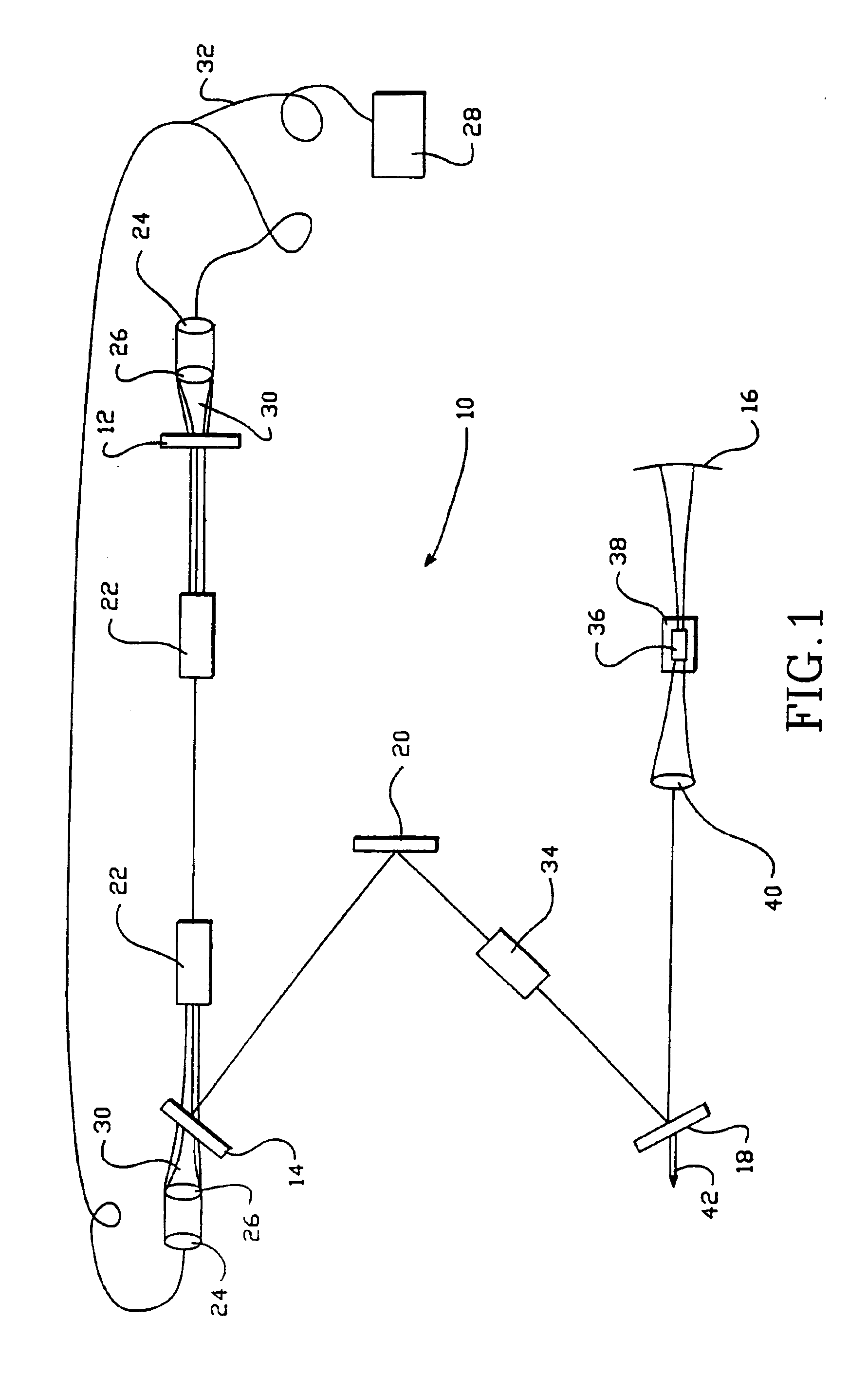

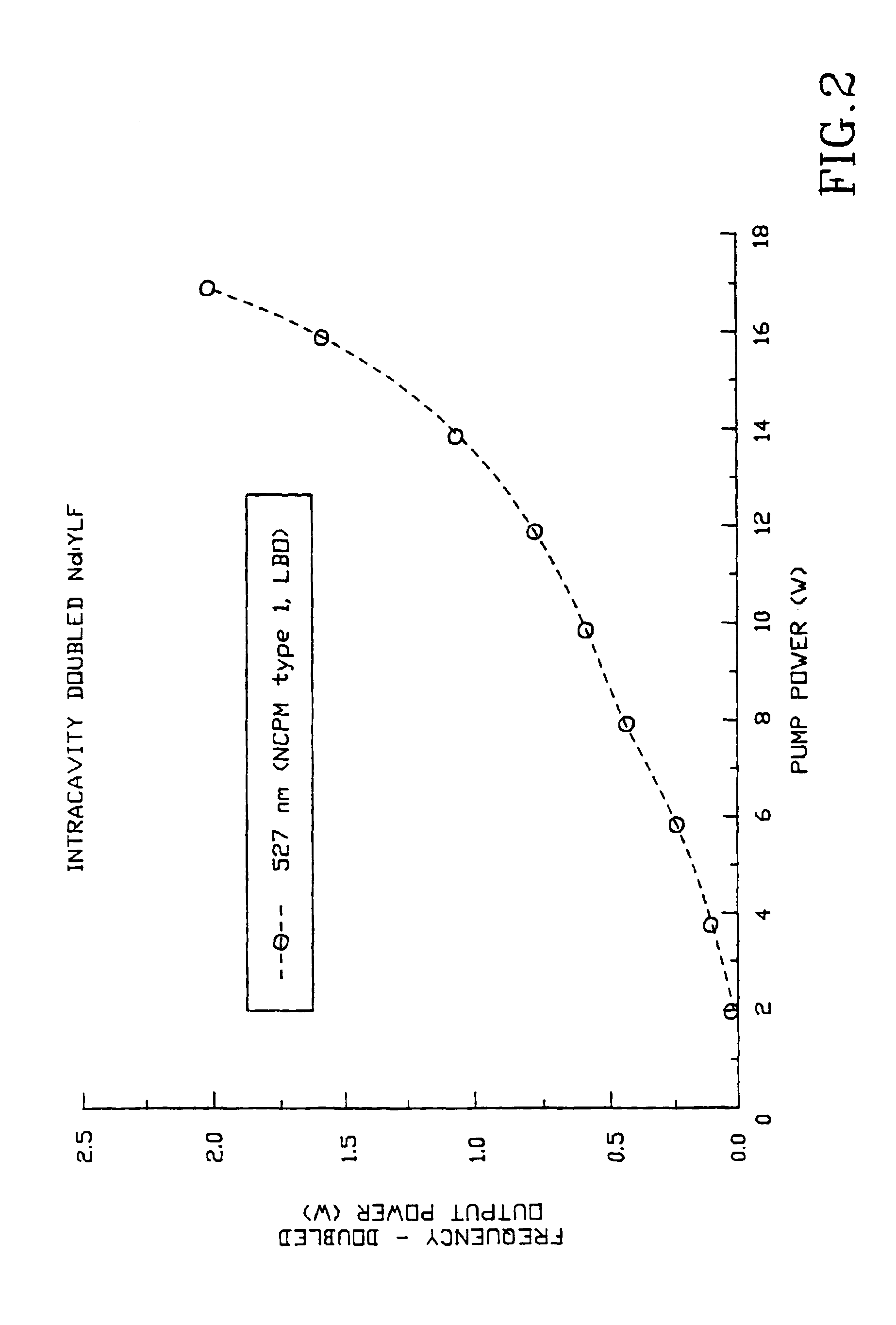

Diode pumped, multi axial mode intracavity doubled laser

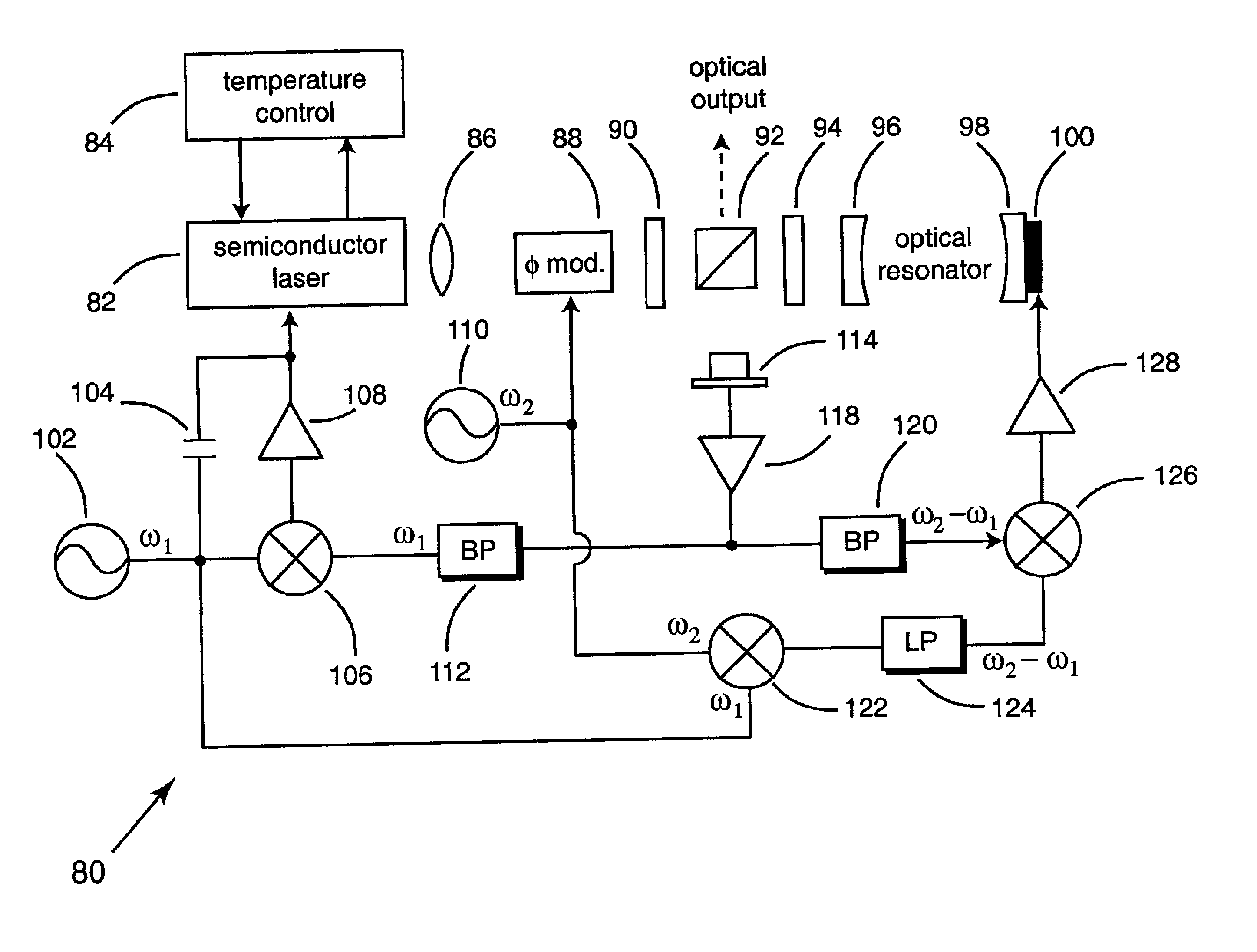

InactiveUS6931037B2Reduce noiseImprove stabilityExcitation process/apparatusOptical resonator shape and constructionResonant cavityLight beam

A diode pumped, multi axial mode, intracavity doubled, intracavity tripled laser, includes at least two resonator mirrors defining a resonator cavity. A laser crystal and a doubling crystal are positioned in the resonator cavity. A tripling crystal is also positioned in the resonator cavity. A diode pump source supplies a pump beam to the laser crystal and produces a laser crystal beam with a plurality of axial modes that are incident on the doubling crystal. This produces a frequency doubled output beam. Further, a diode pumped, multi axial mode, intracavity nonlinearly-converted laser is provided and includes at least two resonator mirrors defining a resonator cavity, a laser crystal and a nonlinear conversion apparatus positioned in the resonator cavity. A nonlinear conversion apparatus is also positioned in the resonator cavity. A diode pump source supplying a pump beam to the laser crystal and produces a laser crystal beam with a plurality of axial modes that are incident on the nonlinear conversion apparatus. The result is a nonlinearly converted output beam that has a % RMS noise of less than 3%.

Owner:NEWPORT CORP

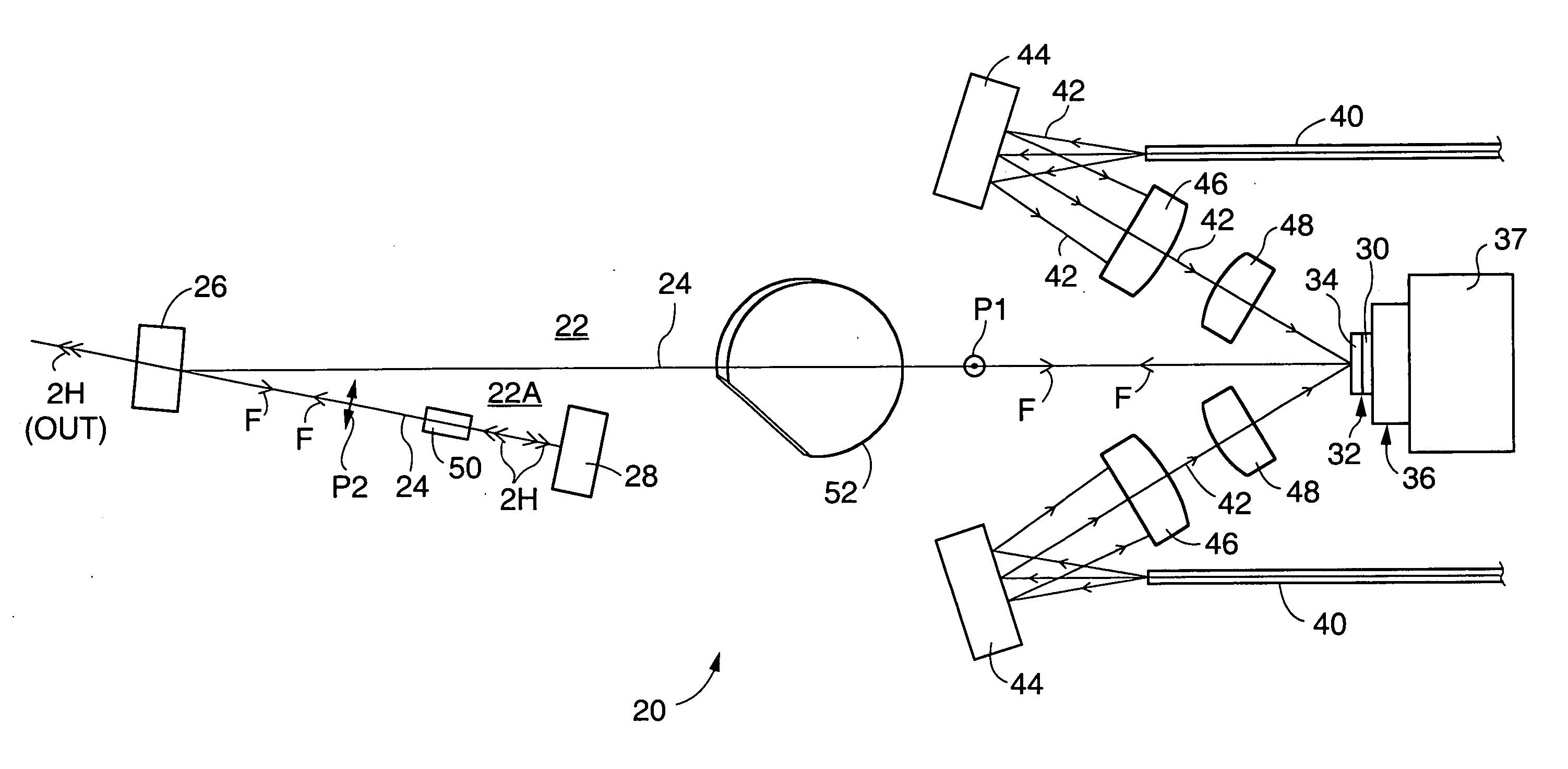

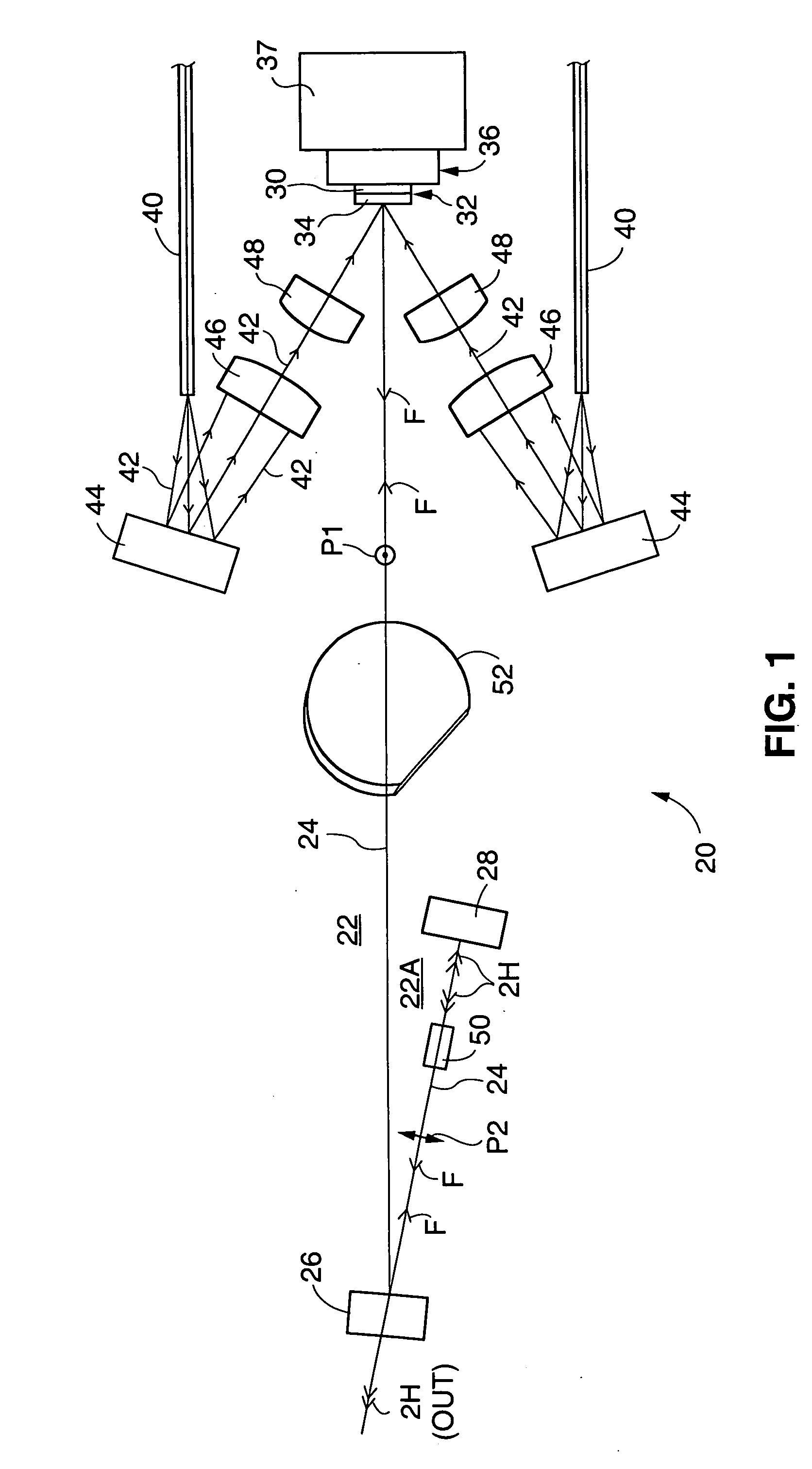

High-power external-cavity optically-pumped semiconductor lasers

InactiveUS20050220165A1Temperature safetyLarge fundamental mode-sizeLaser optical resonator constructionExcitation process/apparatusFourth harmonicWavelength

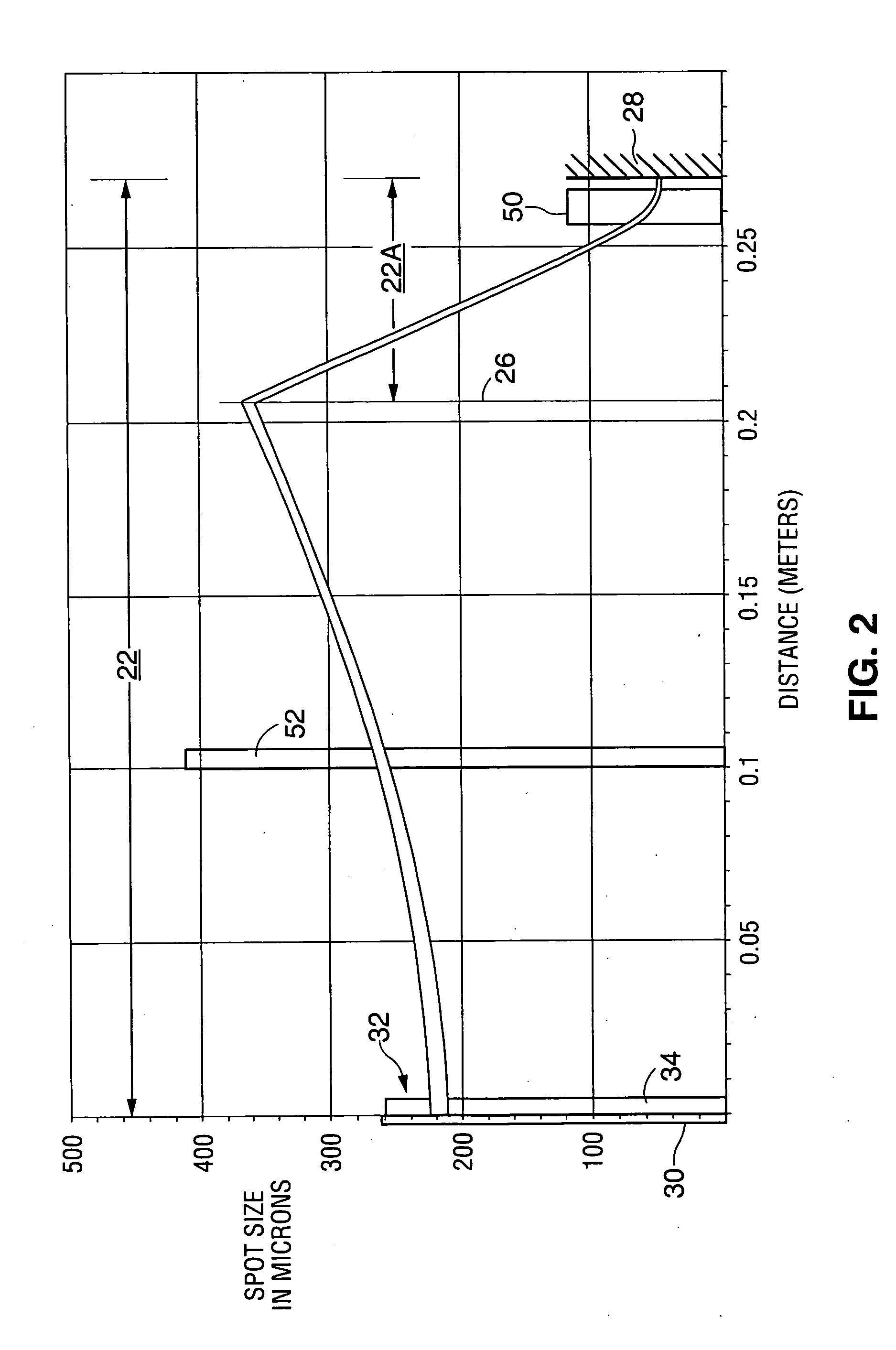

External-cavity optically-pumped semiconductor lasers (OPS-lasers) including an OPS-structure having a mirror-structure surmounted by a surface-emitting, semiconductor multilayer (periodic) gain-structure are disclosed. The gain-structure is pumped by light from diode-lasers. The OPS-lasers can provide fundamental laser output-power of about two Watts (2.0 W) or greater. Intracavity frequency-converted arrangements of the OPS-lasers can provide harmonic laser output-power of about one-hundred milliwatts (100 mW) or greater, even at wavelengths in the ultraviolet region of the electromagnetic spectrum. These high output powers can be provided even in single axial-mode operation. Particular features of the OPS-lasers include a heat sink-assembly for cooling the OPS-structure, a folded resonator concept for providing optimum beam size at optically-nonlinear crystals used for frequency conversion, preferred selection of optically-nonlinear materials for frequency-conversion, and compound resonator designs for amplifying second harmonic-radiation for subsequent conversion to third or fourth harmonic radiation.

Owner:COHERENT INC

Method and apparatus for measuring a frequency of an optical signal

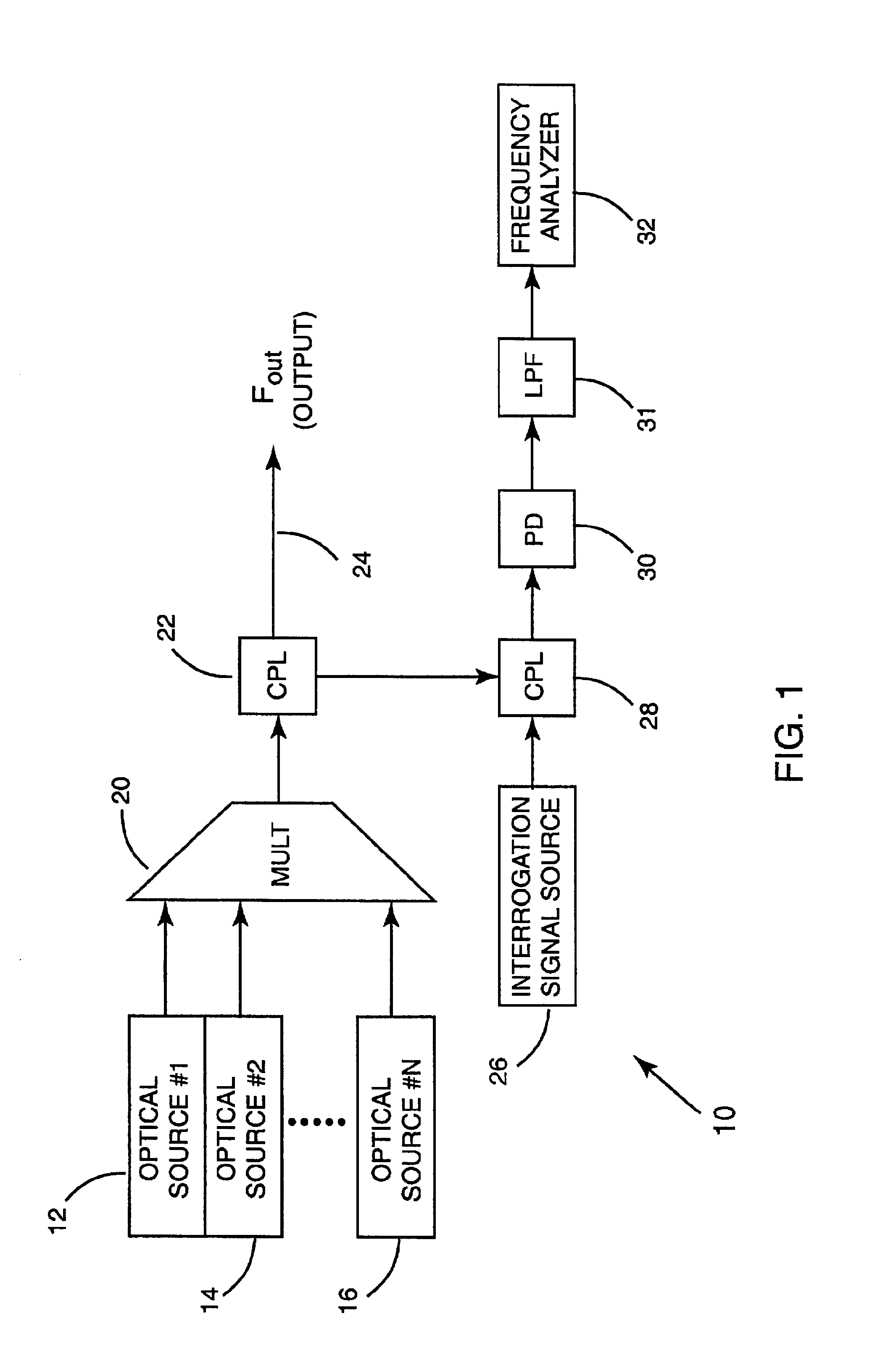

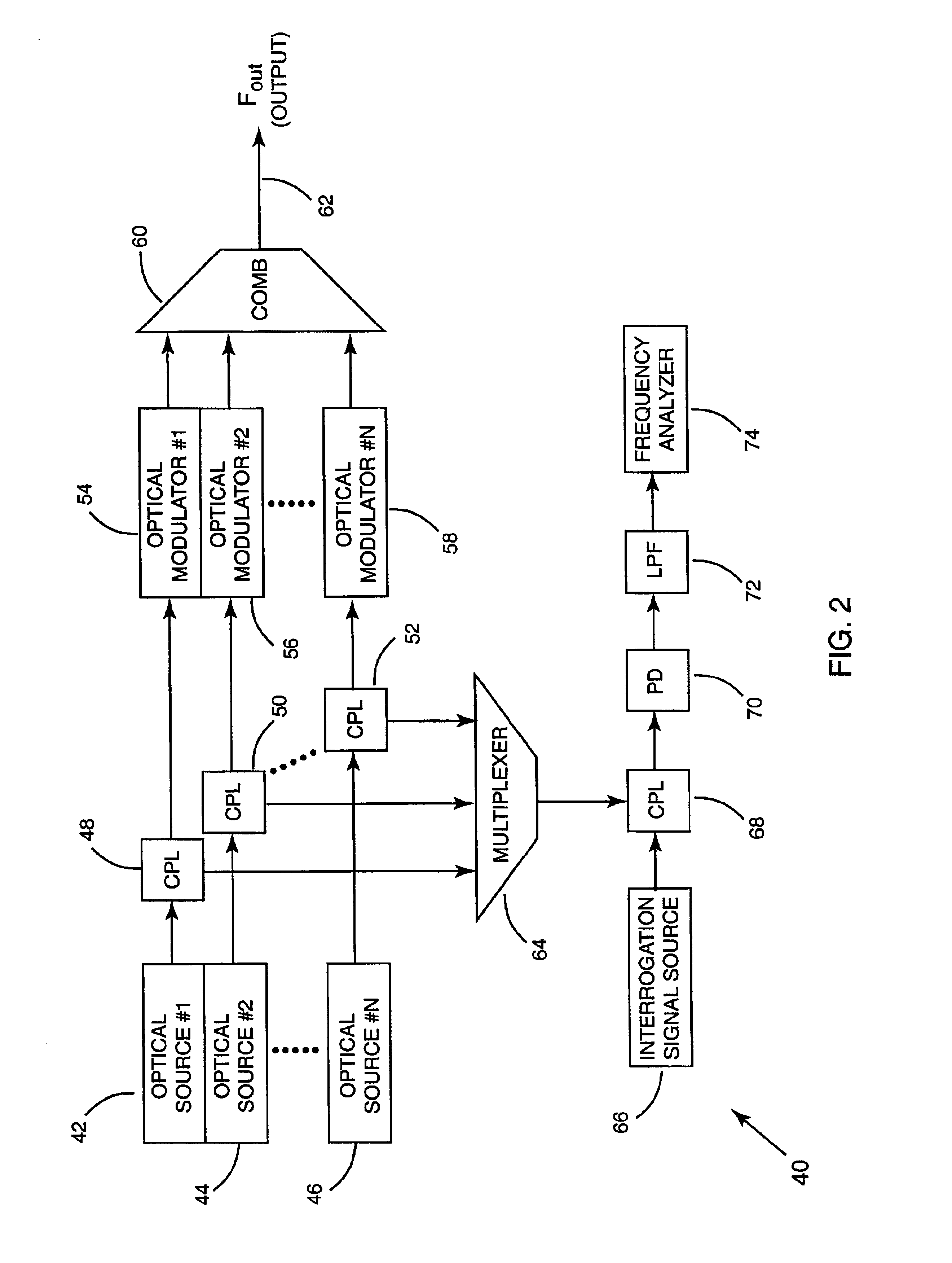

InactiveUS6853456B2Optical measurementsRadiation pyrometryCarrier frequency offsetFree spectral range

A method and apparatus are provided for detecting a frequency of an optical signal within a communications channel having a plurality of optical carriers separated by a predetermined frequency spacing. The method includes the steps of locking an optical carrier frequency to an axial mode of an optical resonator of known free spectral range; providing an additional optical resonator as a reference having a known free spectral range that differs from that of the first optical resonator; locking an optical reference signal to a closest axial mode of a reference optical resonator producing an optical reference signal that is spectrally offset from said optical carrier frequency by a spectral quantity less than the known free spectral range; mixing the optical carrier frequency with the reference optical signal frequency thus generating a difference signal as a beat frequency; and measuring a frequency of a difference signal.

Owner:FIBERSPACE

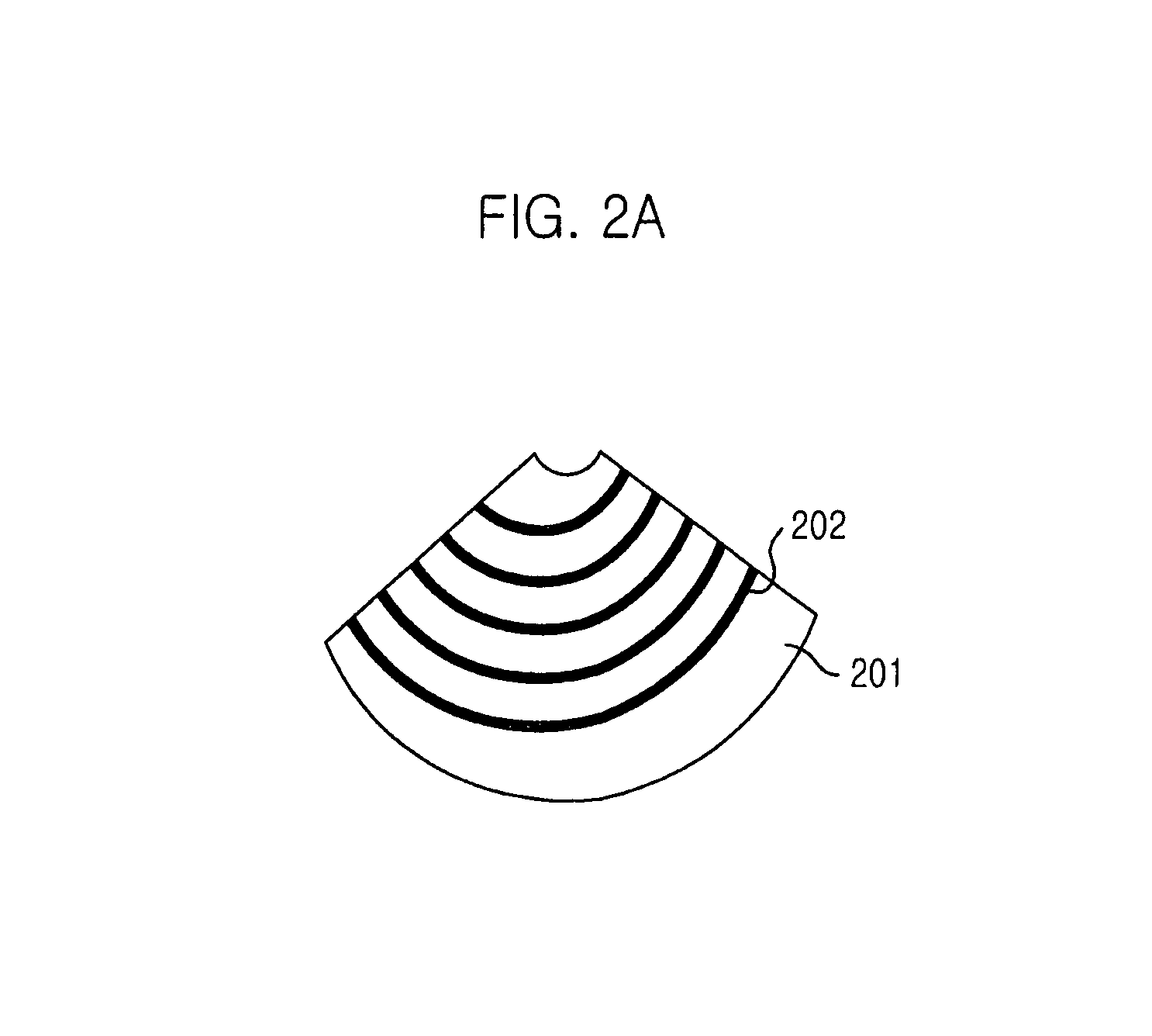

Circular polarized helical radiation element and its array antenna operable in TX/RX band

InactiveUS7944404B2Improve radiation efficiencyWaveguide hornsRadiating elements structural formsWave bandRadiating element

Provided are Circular Polarized Helical Radiation element and its Array Antenna operable in TX band and RX band. The circular polarized helical radiation element and its array antenna and the antenna with double reflection boards using that array can operate at TX / RX dual band which is high frequency such as Ka band by operating the helical antenna in axial mode and implementing dual feeding structure. The array antenna having a number of radiation elements operable in the both of TX band and RX band, wherein the radiation elements are arrayed on predetermined column lines, each radiation element comprising: a helix for radiating orthogonal circular polarized waves in the different frequency bands wherein the helix is fed at its beginning point and its terminating point; and a wave guide for accommodating the helix.

Owner:ELECTRONICS & TELECOMM RES INST

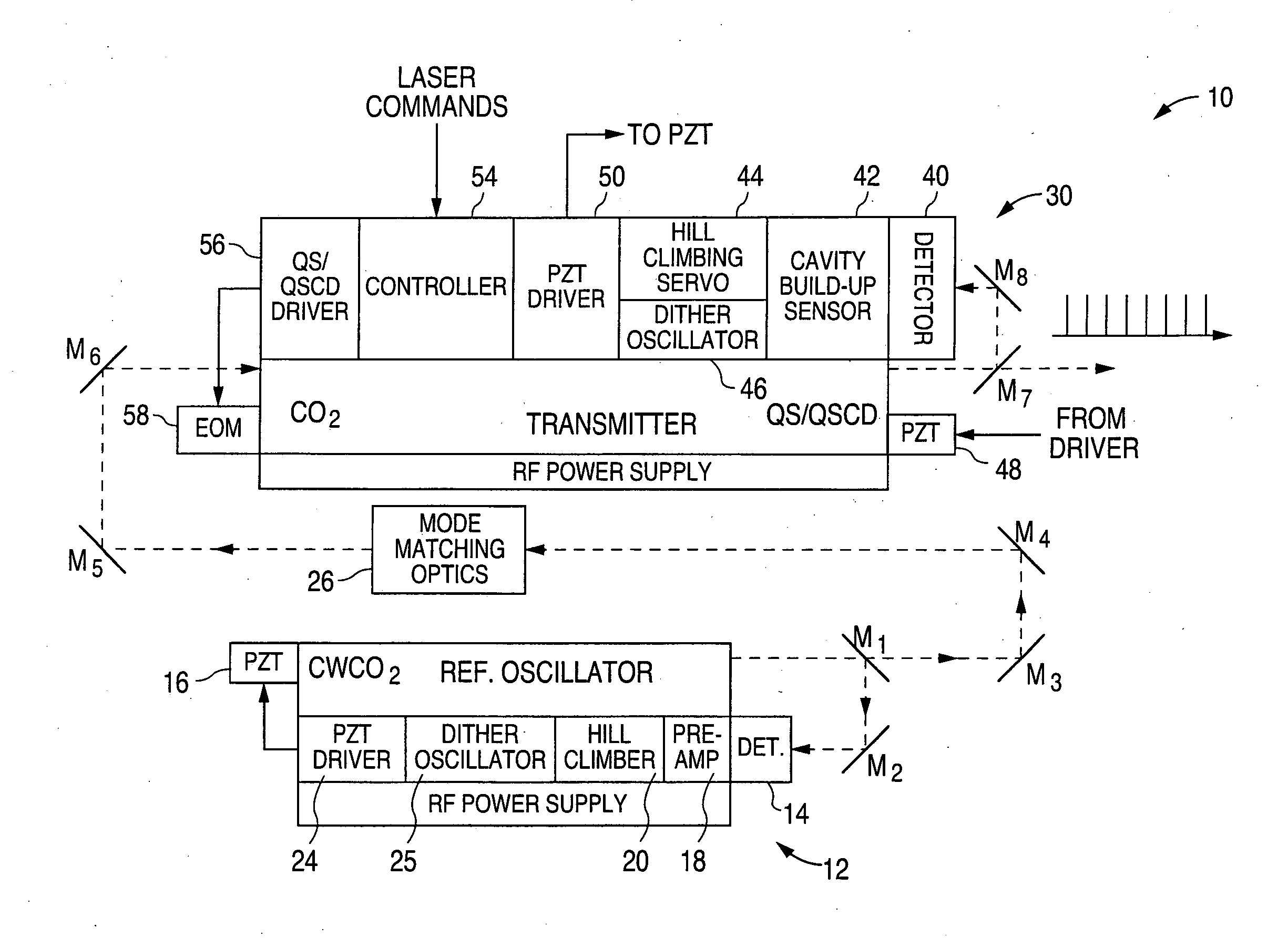

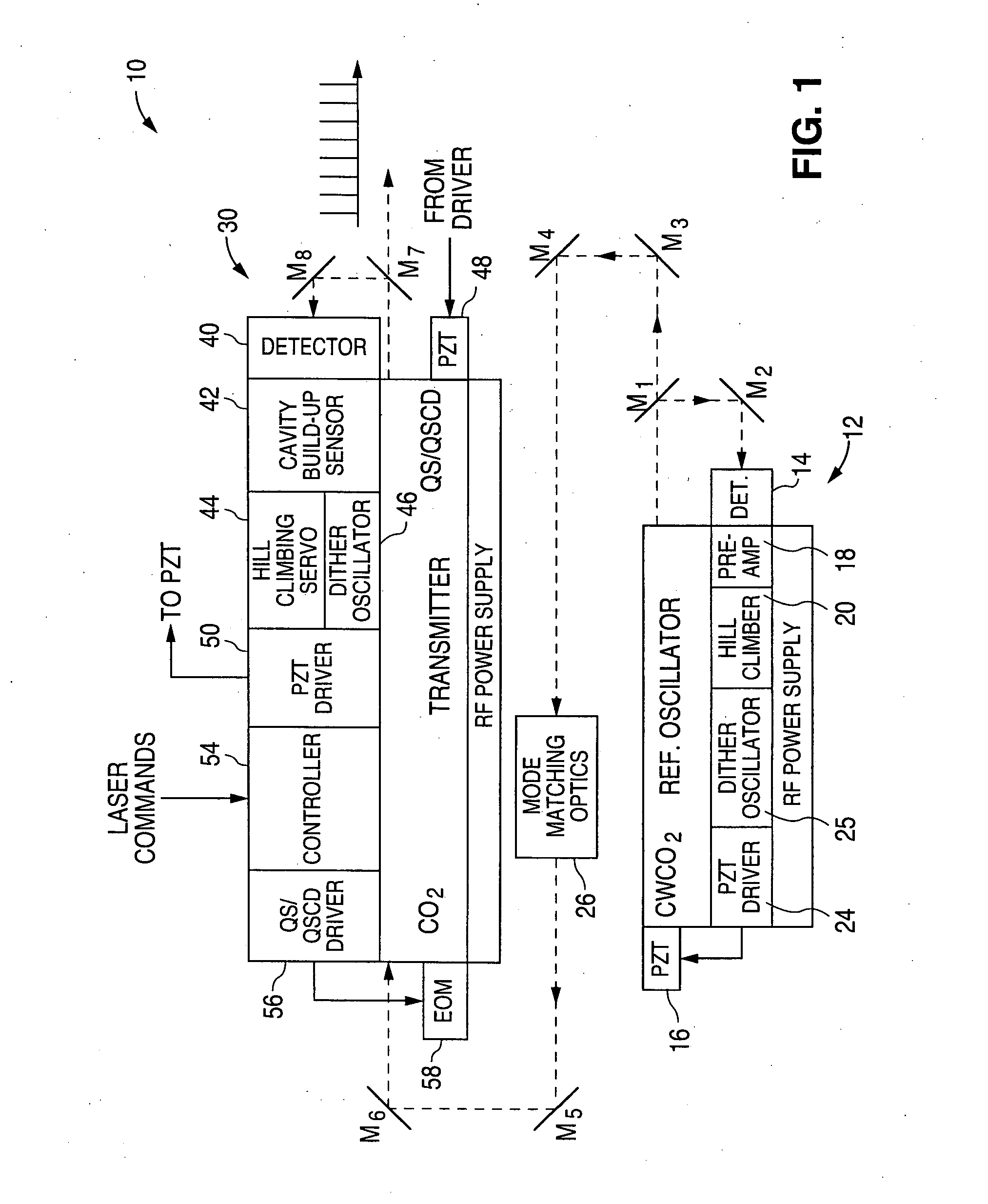

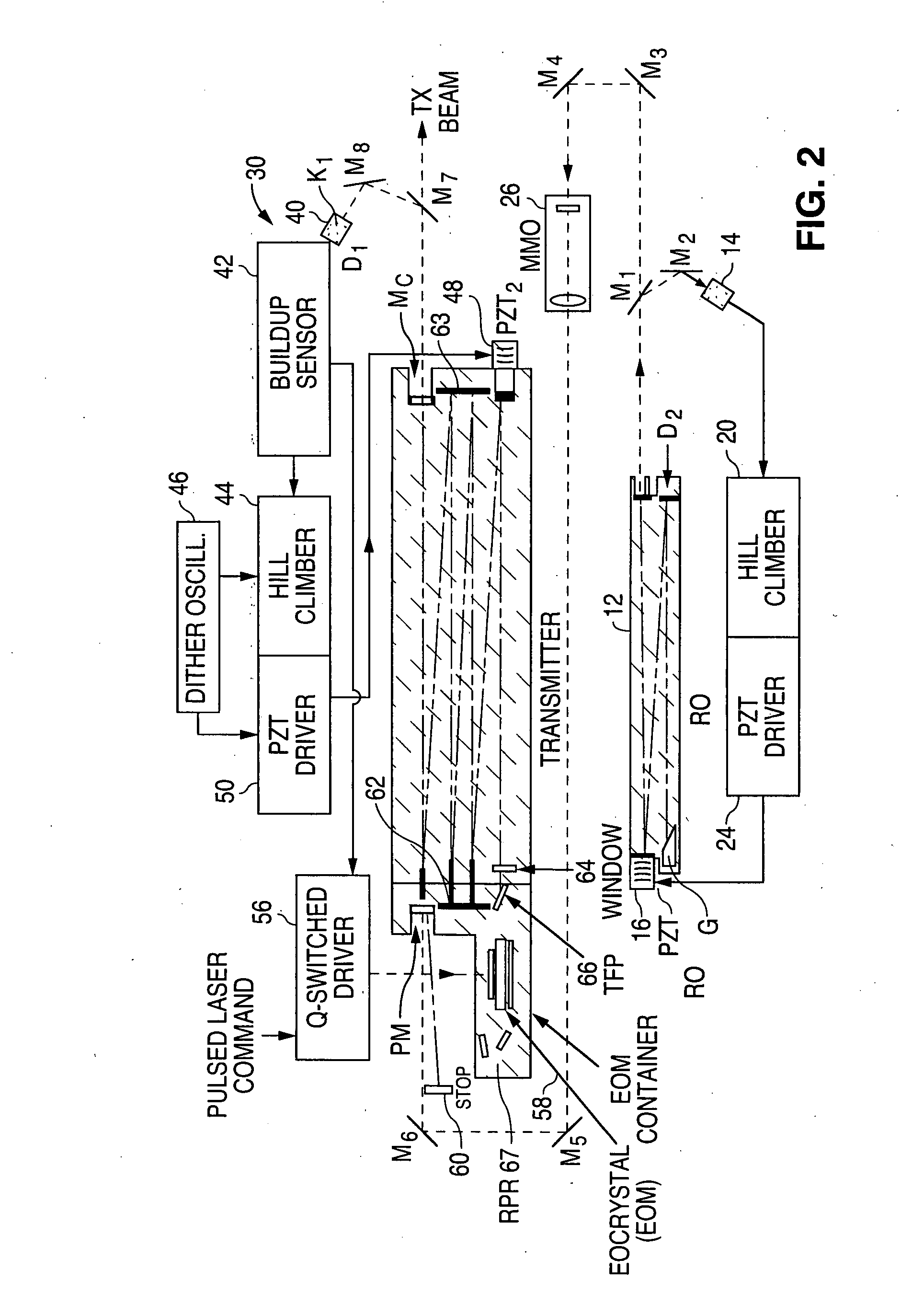

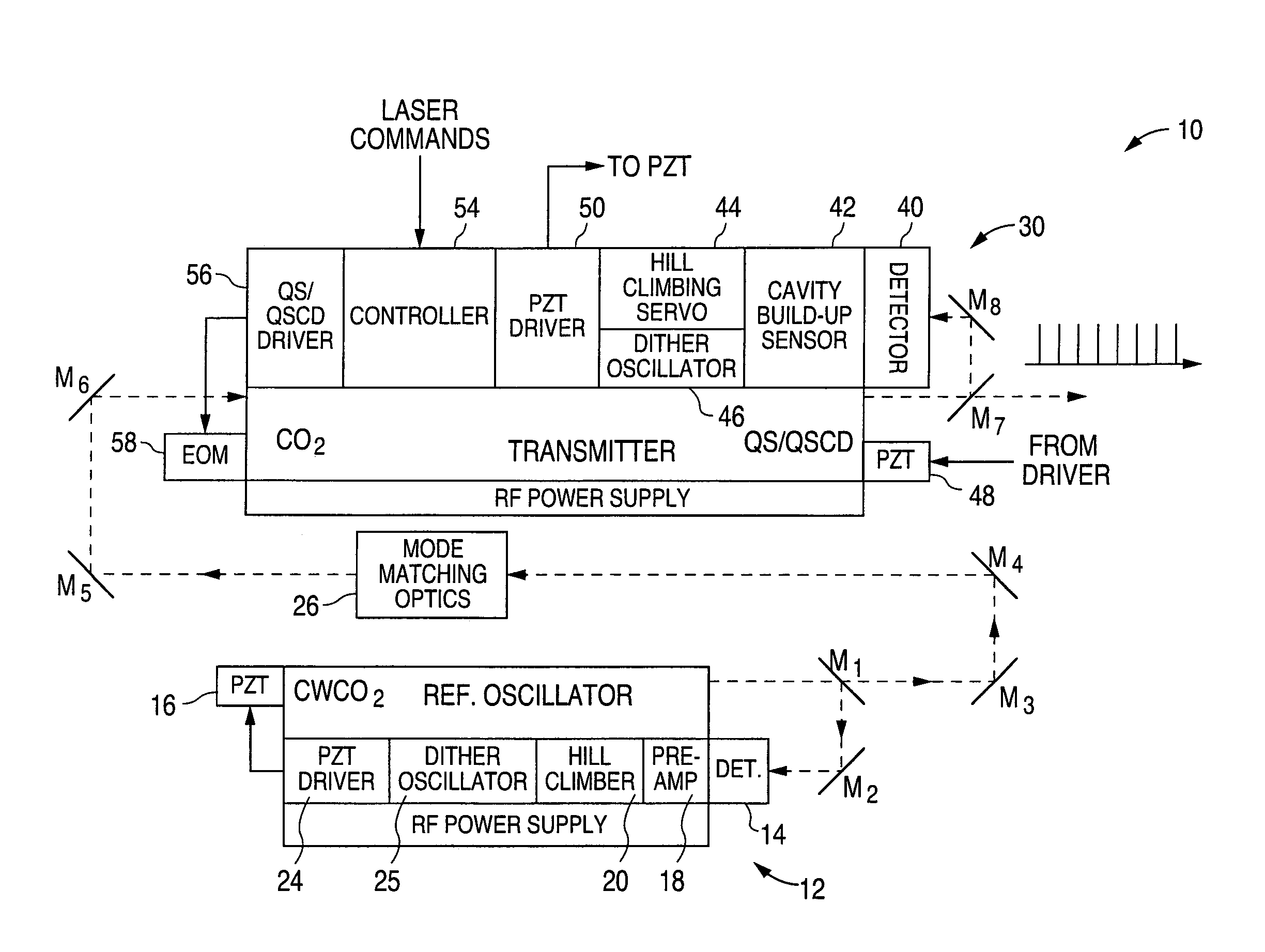

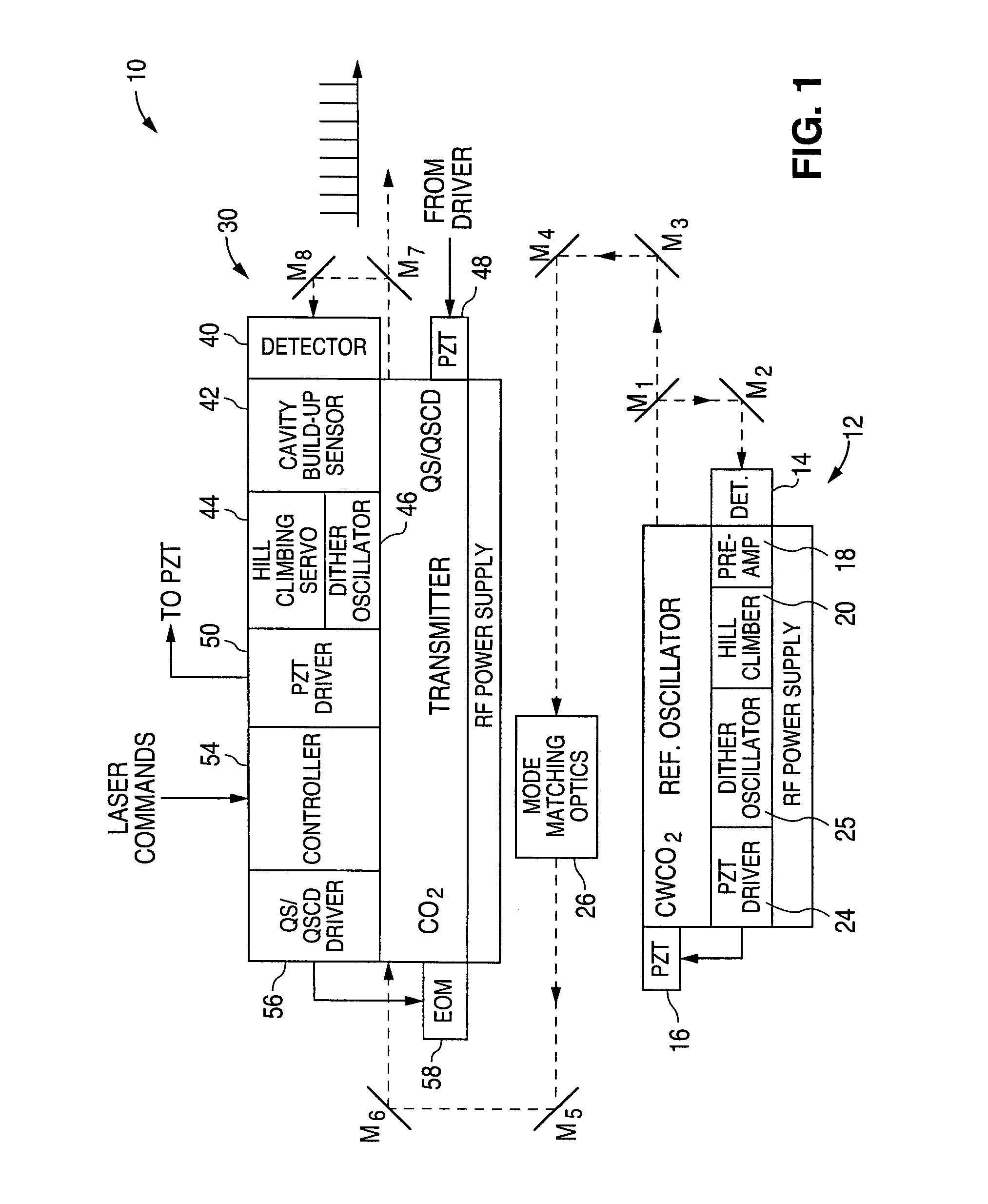

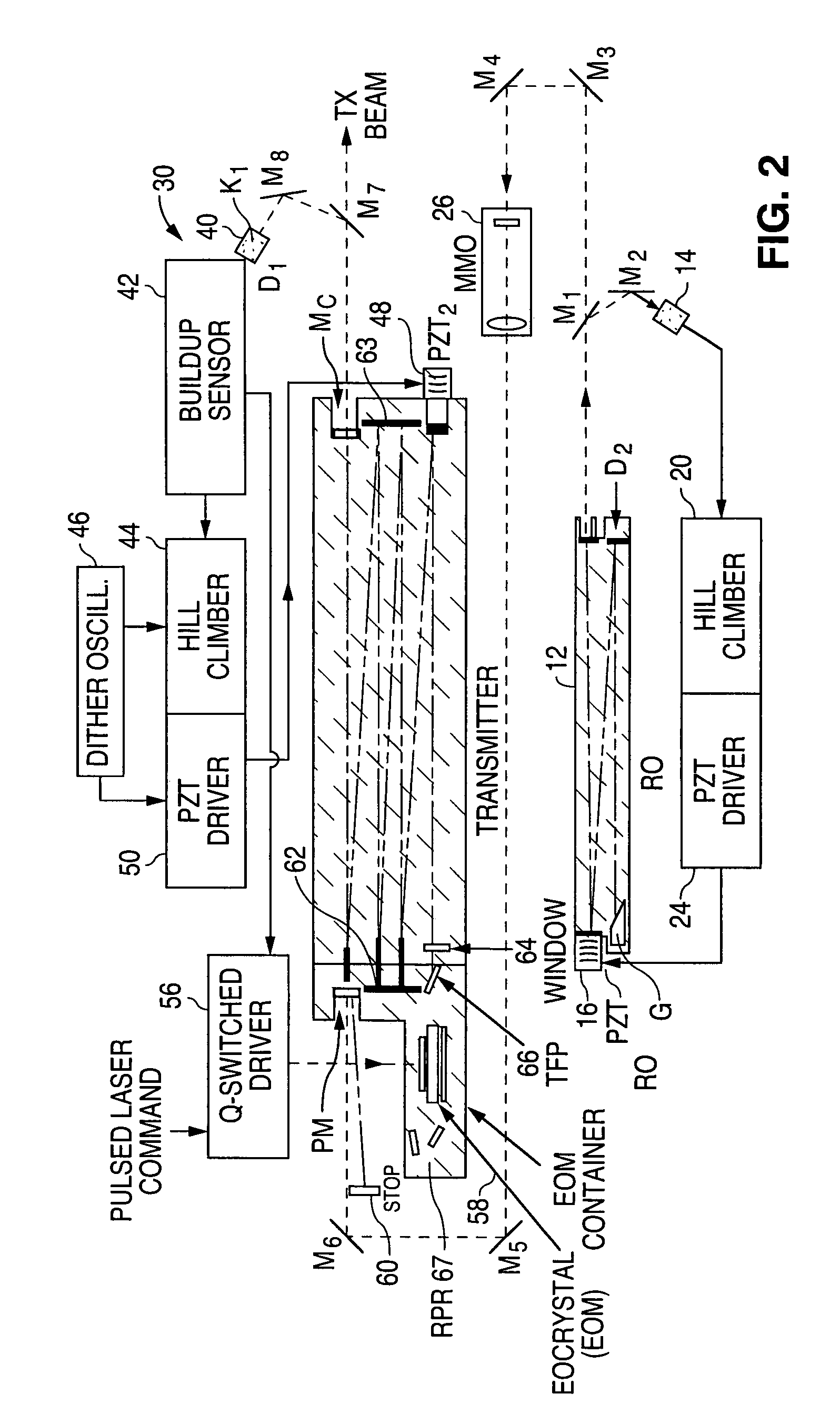

Injection locking Q-switched and Q-switched cavity dumped CO2 lasers for extreme UV generation

ActiveUS20070091973A1High repetition rateOptical resonator shape and constructionOptical devices for laserUltravioletPeak value

A CO2 laser reference oscillator (RO) can provide injection seeding to a Q-switched (QS) or Q-switched cavity dumped (QSCD) CO2 laser, where the output frequency of the RO laser is locked to the peak of the laser line by the use of appropriate electronics to dither one of the resonator mirrors of the reference oscillator. This injected radiation seeds the radiation building up within the Q-switched laser cavity, such that the oscillating frequency favors the wavelength of the injected radiation. An electronic feedback control circuit can be used to lock an axial mode of the Q-switched laser to line center. The change in build-up time of the pulses within the QS laser can be used to maintain cavity length at a value that enables oscillating at the peak of the same laser line that is injected into QS laser.

Owner:COHERENT INC

Endoscope system having multiaxial-mode laser-light source or substantially producing multiaxial-mode laser light from single-axial-mode laser light

In an endoscope system including: a light emission unit emits laser light as illumination light or excitation light; a light guide unit guides the illumination light or the excitation light to an object; and an image pickup unit picks up a normal image formed with reflection light generated by reflection of the illumination light from the object or a fluorescence image emitted from the object in response to the excitation light. The laser light is multiaxial-mode laser light, or the light emission unit includes a plurality of laser-light sources which emit single-axial-mode laser beams having different wavelengths or phases. Alternatively, a vibration unit which vibrates the light guide unit is provided, or a high-frequency signal is superimposed on a driving current of the light emission unit, so that the wavelength of the laser light is shifted among a plurality of values.

Owner:FUJIFILM CORP

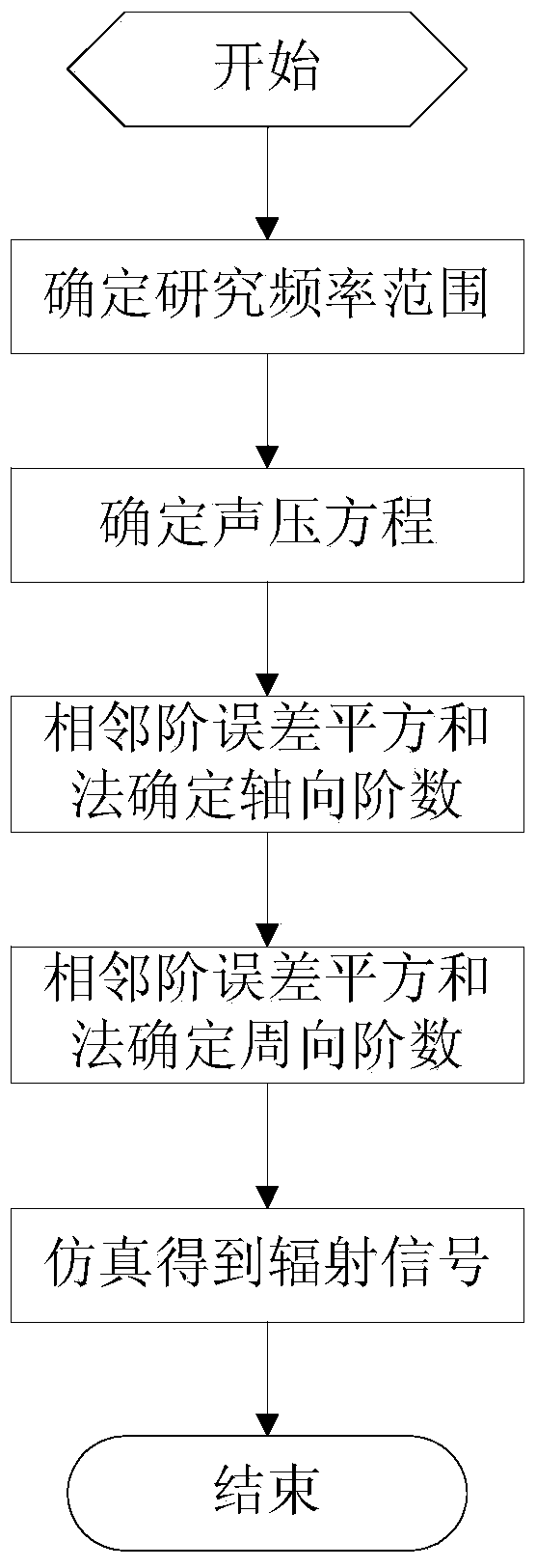

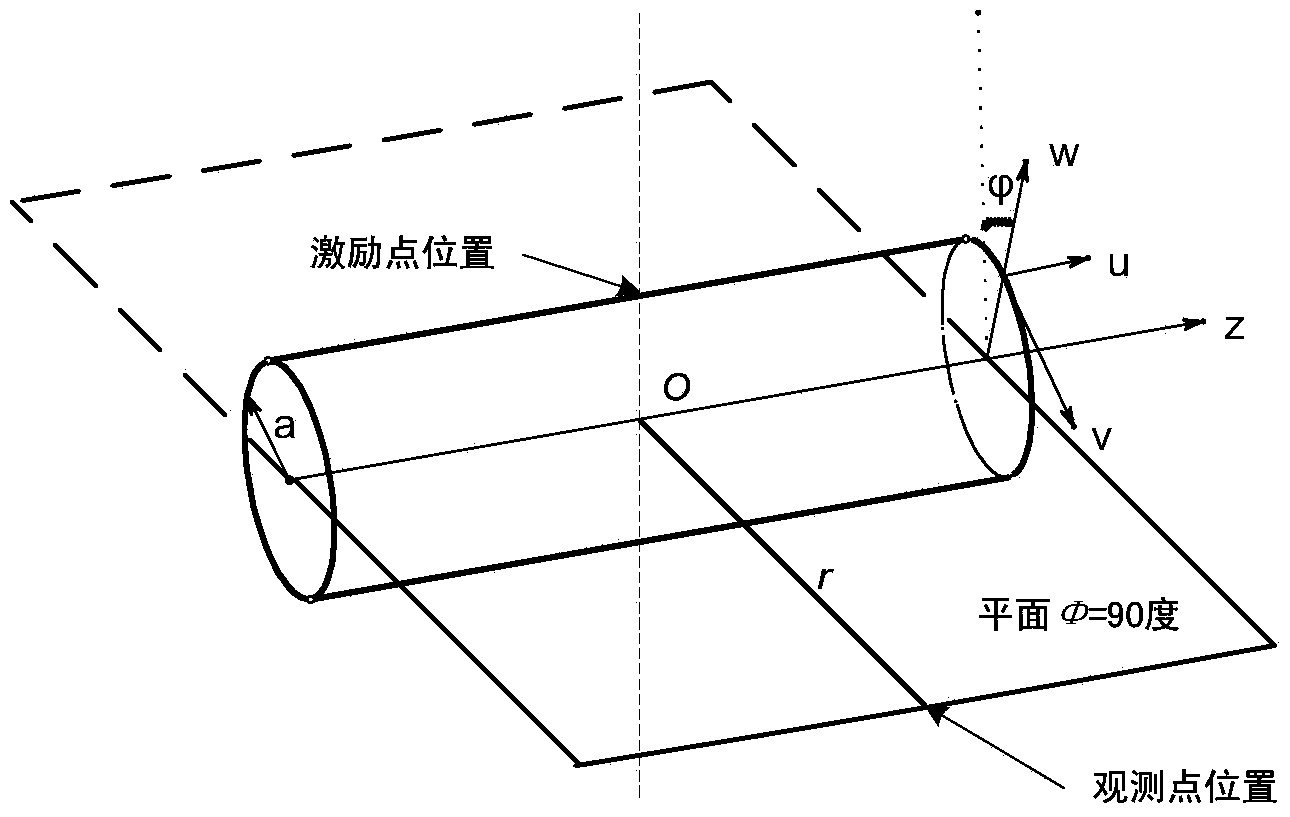

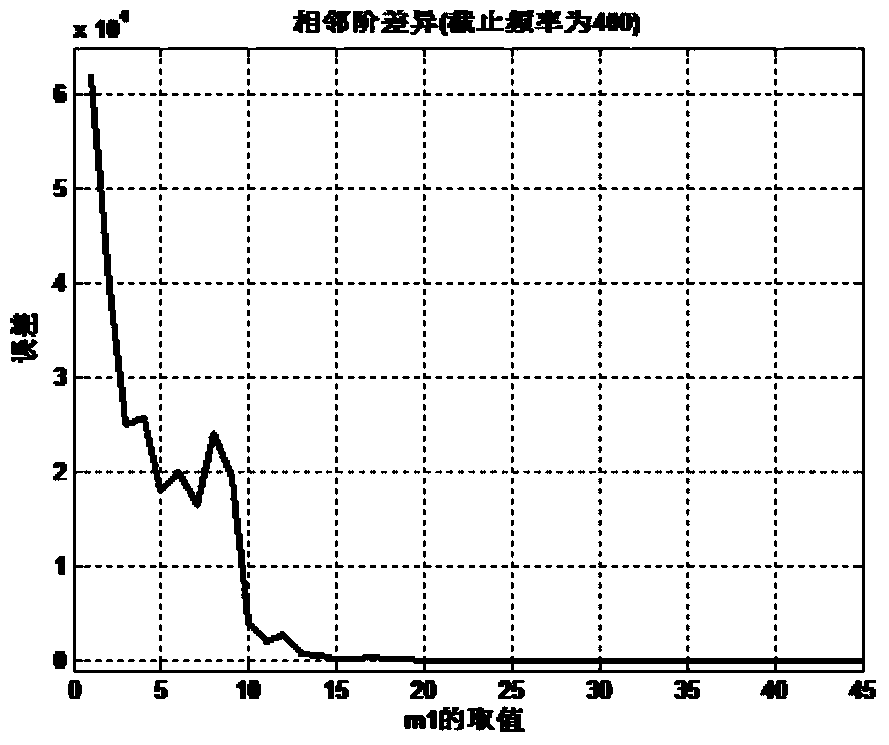

Method for quickly estimating underwater target shell radial vibration low-frequency sound radiation signals based on mode decomposition

ActiveCN103593571ASimulation is accurateModerate amount of calculationSpecial data processing applicationsQR decompositionComputation complexity

The invention discloses a method for quickly estimating underwater target shell radial vibration low-frequency sound radiation signals based on mode decomposition, and belongs to the technical field of underwater target sound radiation. The method includes the following steps that firstly, based on uncertainty of a researched object, the range of researched frequency bands is determined; secondly, based on a mode decomposition theory and different model structures, a simulation sound pressure equation is determined; thirdly, based on a mode truncation theory, an appropriate lower order axial mode order is calculated by adopting a higher circumferential mode order; fourthly, an appropriate lower order circumferential mode order is calculated by adopting a higher axial mode order; eventually the radiation signals through simulating calculation are acquired through calculation, and then the underwater target sound radiation condition is analyzed. According to the technical scheme, the underwater target sound radiation signals generated by radial vibration are accurately simulated through the few mode orders, and therefore calculation complexity is low and accuracy is high.

Owner:SOUTHEAST UNIV

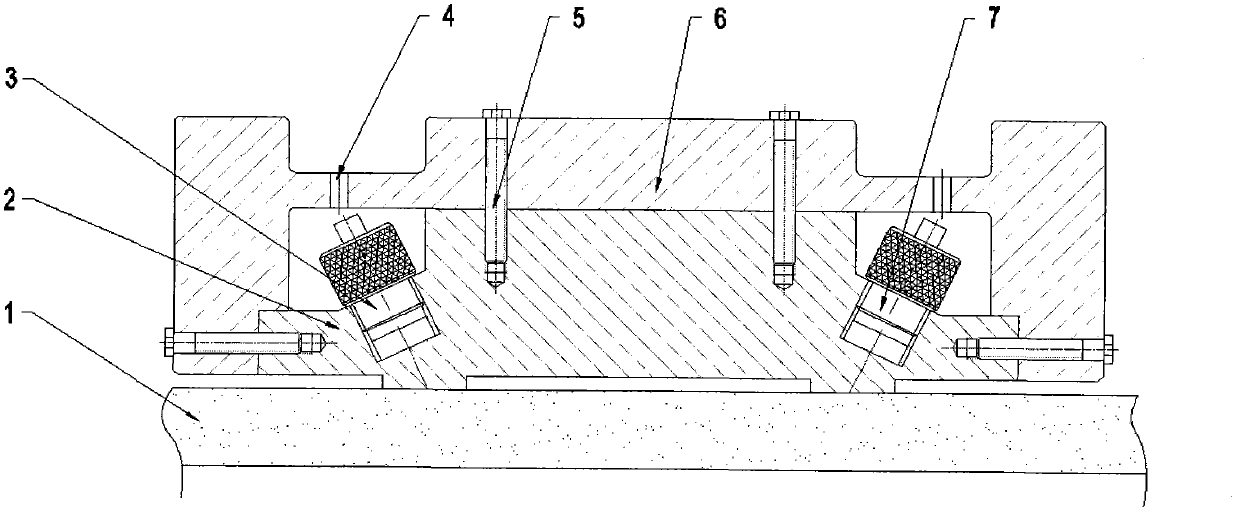

Annular array energy transducer for pipeline axial residual stress detection based on critically refracted longitudinal wave method

The invention relates to an annular array energy transducer for pipeline axial residual stress detection based on a critically refracted longitudinal wave method. A critically refracted longitudinal wave method is utilized to realize axial residual stress detection of a circumferential array of an annular pipeline; and a plurality of organic glass wedges are uniformly assembled and distributed at an inner ring of a fixed flexible sleeve. When the annular array energy transducer works, the fixed flexible sleeve is wound the circumference of the annular pipeline and is fastened; and a certain pretightening force is added according to the radius of the pipeline. Besides, a plurality of pairs of piezoelectric transducers are assembled in each of the organic glass wedge, so that an axial mode of one sending and one receiving is formed, wherein the mode has a property of equipartition with 360 degrees; and moreover, a first critical angle is formed between each of the energy transducer and a contact tangent plane of each of the organic glass wedge. According to the invention, on-line detection on annular pipelines with different radiuses is realized; and the annular array energy transducer has characteristics of high sensitivity and convenience for using and the like; besides, the annular array energy transducer is especially suitable for detection on some large petroleum transmission pipelines.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

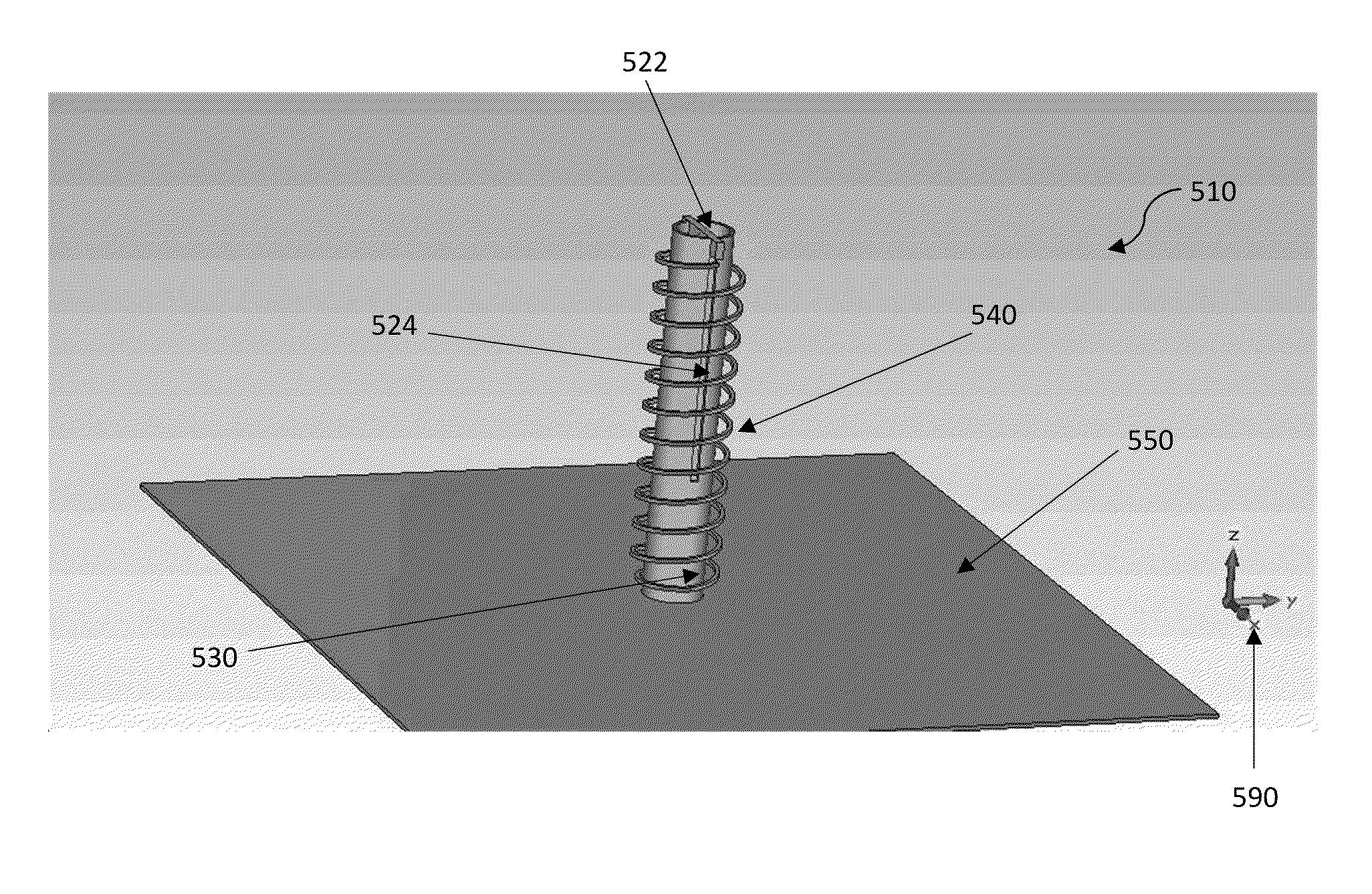

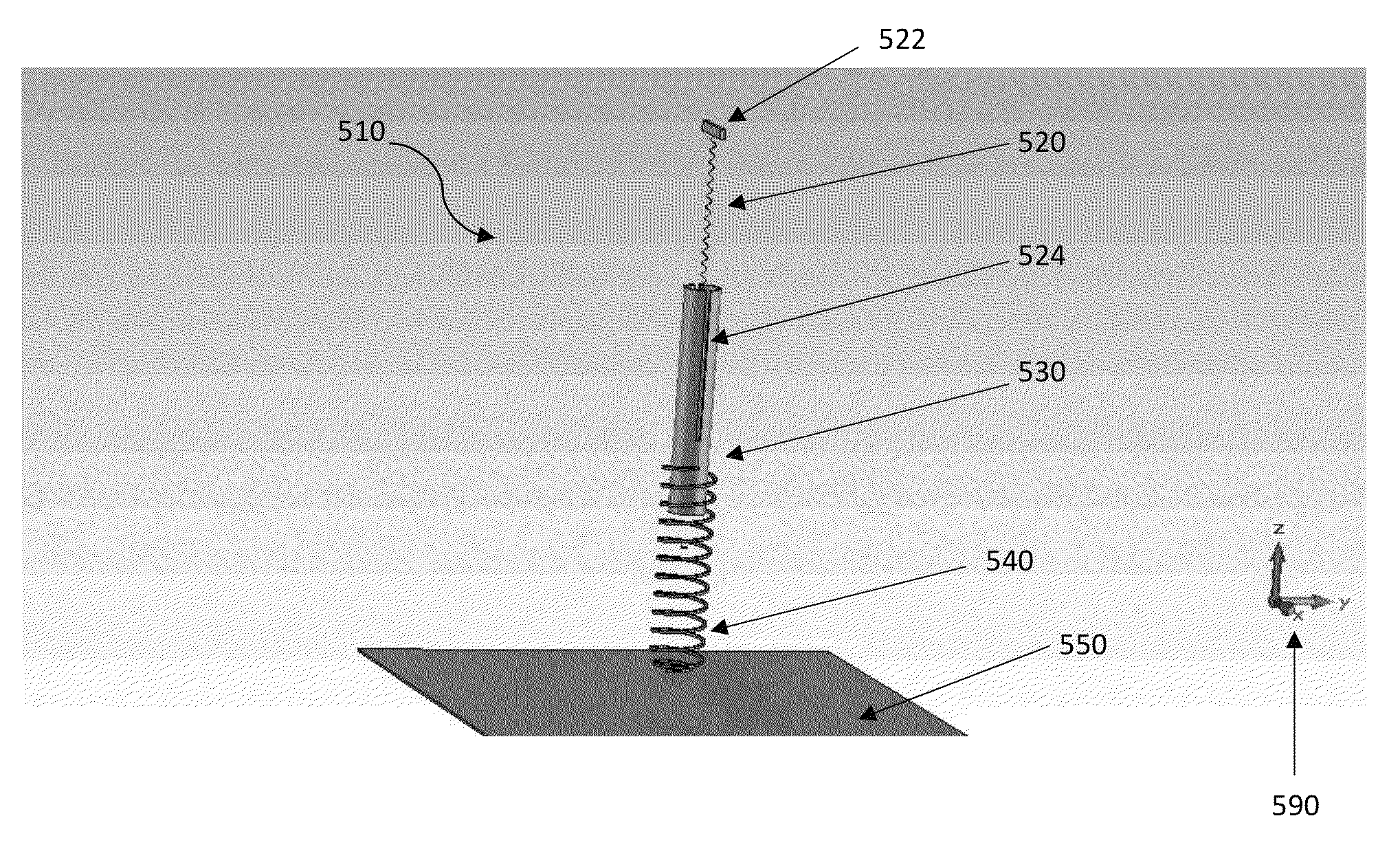

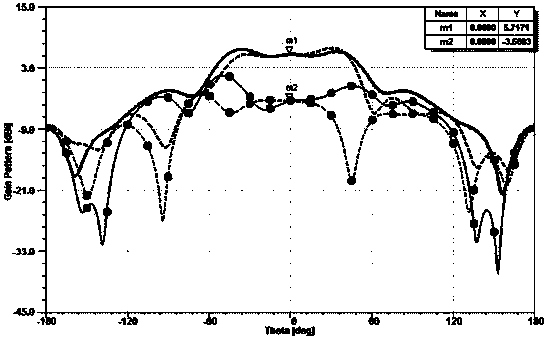

Reconfigurable axial-mode helical antenna

InactiveUS20110298688A1Smooth transitionRadiating elements structural formsResonant antenna detailsReconfigurable antennaFar field radiation pattern

Novel reconfigurable antennas are provided which may be used to accommodate the requirements for wideband multi-standard handheld communication devices. It is shown that using a shape memory alloy spring actuator, the height of a helical antenna and therefore the pitch spacing and angle can be varied. This can in turn tune the far-field radiation pattern and gain of the antenna dynamically to adjust to new operating conditions. The radiation pattern can further be directed using a two-helix array. Finally, a helical antenna embodiment is implemented and measured using a shape memory alloy actuator. Measurement results confirm that while keeping the centre frequency constant, gain tunability can be attained using this structure.

Owner:SIMON FRASER UNIVERSITY

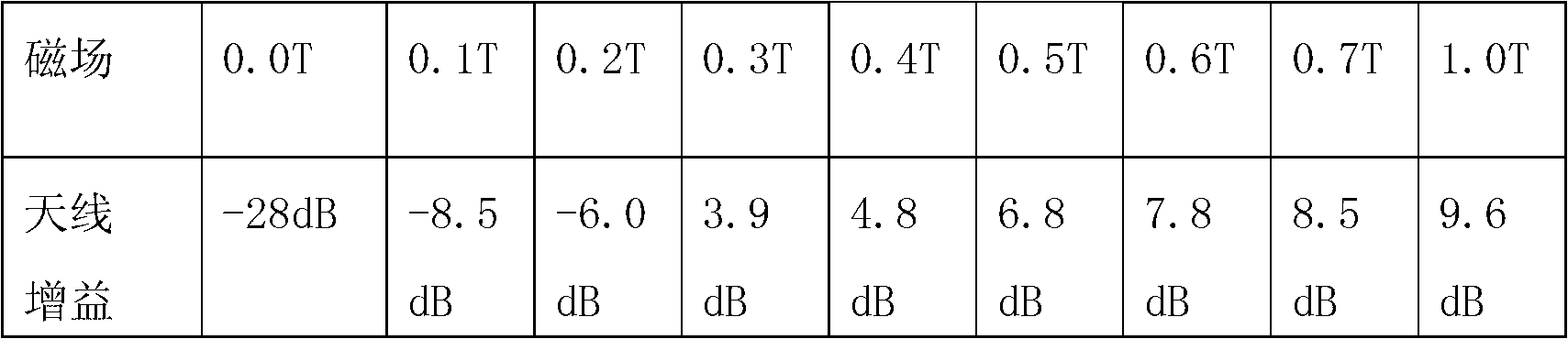

Magnetic antenna for improving penetrability of electromagnetic wave in plasma

InactiveCN102709670AStrong penetrating powerBroaden the bandwidth of the frequency bandAntenna supports/mountingsRadiating element housingsUltrasound attenuationSurface plasmon

The invention belongs to a magnetic antenna for high-speed aircraft navigation and communication, which comprises a columnar spiral antenna, a closed antenna cover, a strong magnet ground plate and a conical coaxial feeding wire column. In the magnetic antenna, the spiral antenna of an axial mode is adopted, the antenna and a strong permanent magnet are integrated, the magnet serves as a magnetic field generator to generate a high permanent field and also serves as the antenna ground plate, when magnetic field intensity B is more than or equal to 0.5T, signal emitted by the spiral antenna can effectively penetrate a plasma, when the magnetic field of the permanent magnet is increased to 1.0T, antenna gain is increased to 9.6dB and approaches 10.6dB of the antenna gain in air, and the attenuation of electromagnetic wave during transmission in the plasma is reduced by 30dB. Therefore, the magnetic antenna has the characteristics of frequency bandwidth, circular polarization bandwidth, low attenuation amplitude of the electromagnetic wave of the antenna and the like, the antenna gain and the penetrability of the plasma are effectively improved, and the defect of communication interrupt caused by the existence of a surface plasma sheath in a background technology is overcome.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

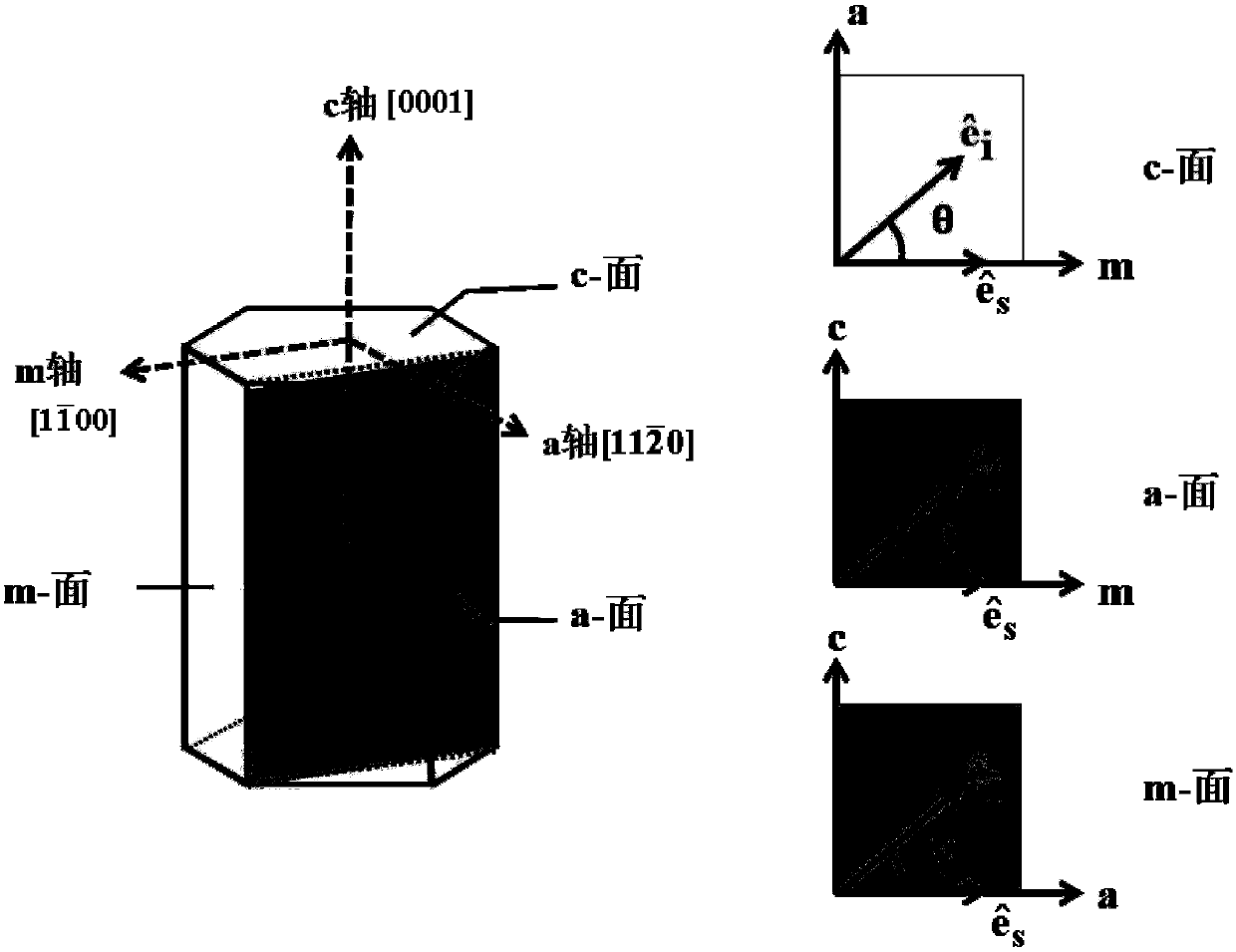

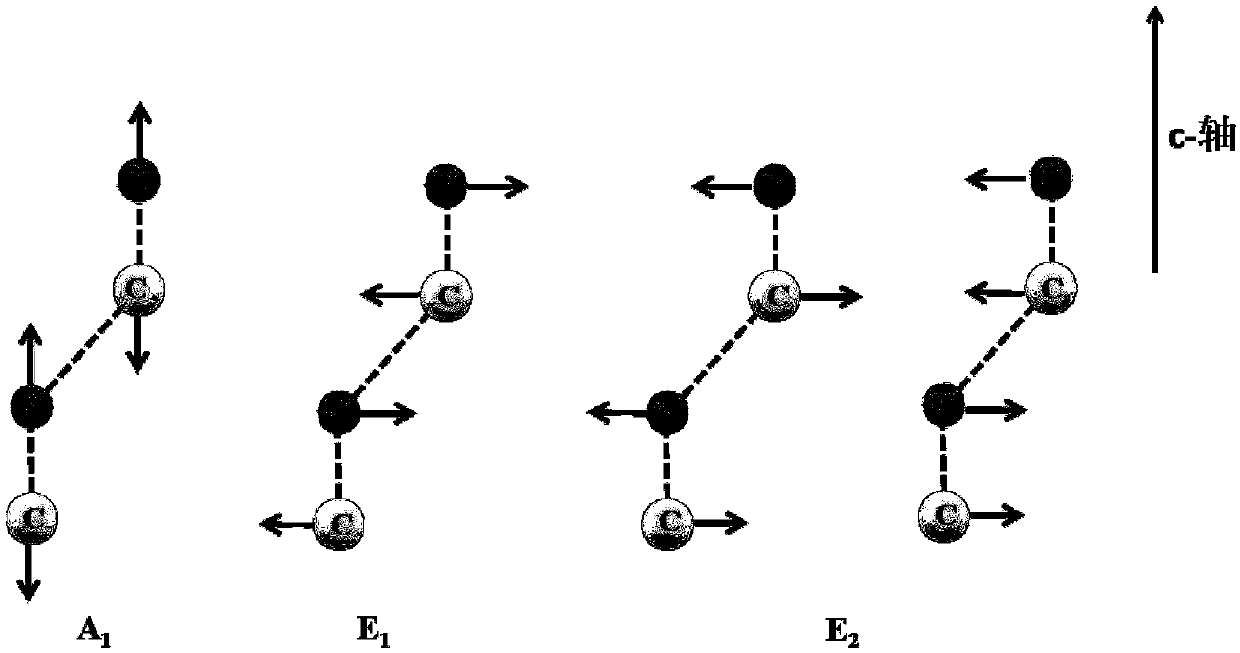

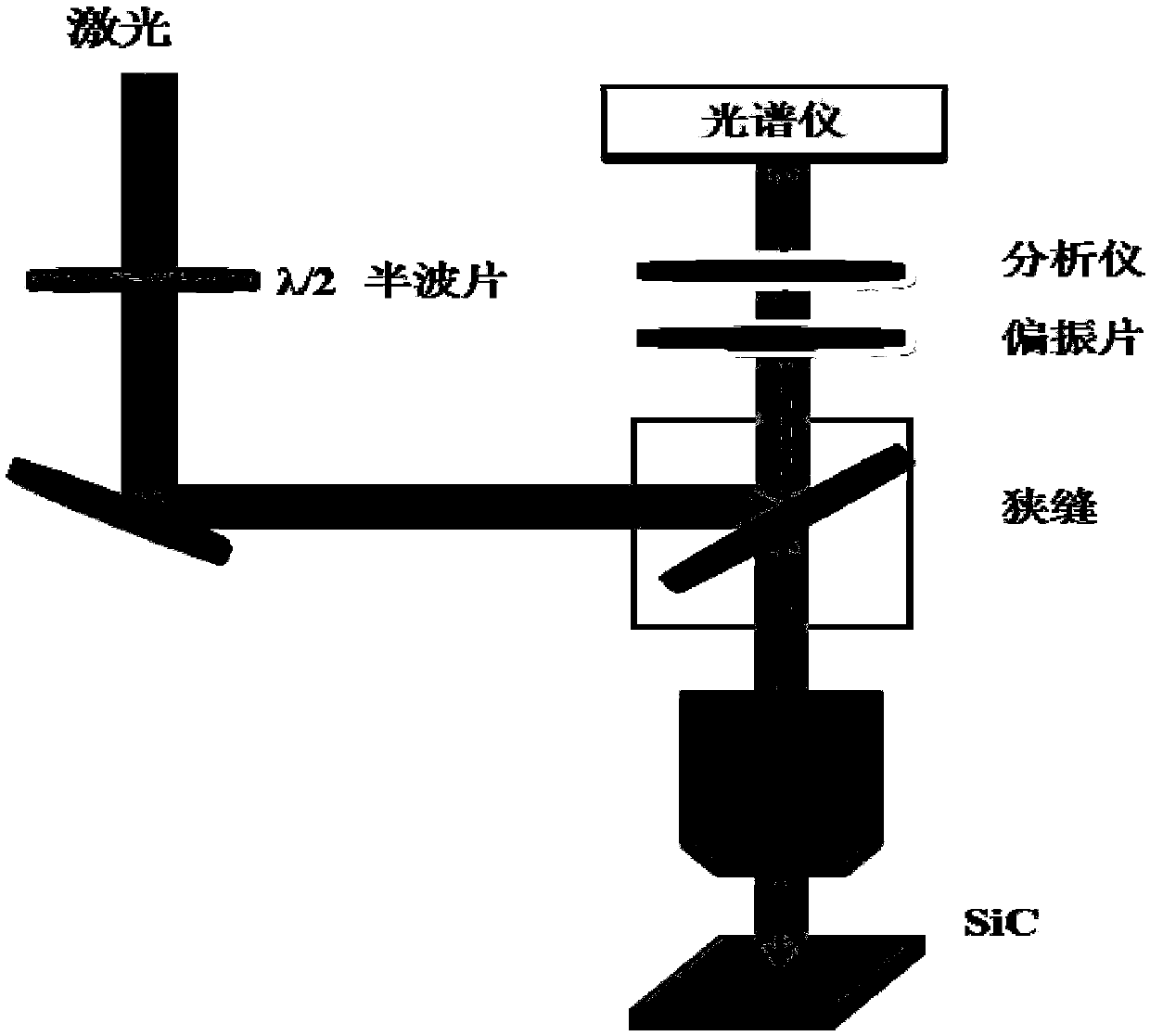

Test method of SiC crystal phonon anisotropy based on polarized Raman spectroscopy

ActiveCN108680557AAnisotropy is effectiveEffective anisotropy exists that cannot be directly observedRaman scatteringPolarizerPhonon

The invention relates to a test method of SiC crystal phonon anisotropy based on polarized Raman spectroscopy, wherein the test method includes the following steps: (1) processing SiC crystals respectively, to obtain a-face, c-face and m-face samples, and polishing; (2) adding a semi-wave sheet in an incident light path of a Raman spectrometer, and adding a polarizing sheet in a back scattering light path; (3) fixing the direction of the polarizing sheet, rotating the semi-wave sheet to change the relative direction of the incident polarized light to the scattering polarized light, and testinga polarized Raman spectrum; (4) fitting peaks of different phonon modes, to obtain the Raman intensities of a plane mode E1, a plane mode E2 and an axial mode A1; (5) carrying out normalization treatment law of the Raman peak intensities of the plane mode E1, the plane mode E2 and the axial mode A1; and (6) obtaining anisotropy of different anisotropic phonon modes. By optimizing the test parameters, the anisotropy of the phonons in different polarity faces of the SiC crystals is effectively characterized.

Owner:SHANDONG UNIV

Reconfigurable axial-mode helical antenna

InactiveUS8436784B2Smooth transitionRadiating elements structural formsResonant antenna detailsReconfigurable antennaFar field radiation pattern

Novel reconfigurable antennas are provided which may be used to accommodate the requirements for wideband multi-standard handheld communication devices. It is shown that using a shape memory alloy spring actuator, the height of a helical antenna and therefore the pitch spacing and angle can be varied. This can in turn tune the far-field radiation pattern and gain of the antenna dynamically to adjust to new operating conditions. The radiation pattern can further be directed using a two-helix array. Finally, a helical antenna embodiment is implemented and measured using a shape memory alloy actuator. Measurement results confirm that while keeping the centre frequency constant, gain tunability can be attained using this structure.

Owner:SIMON FRASER UNIVERSITY

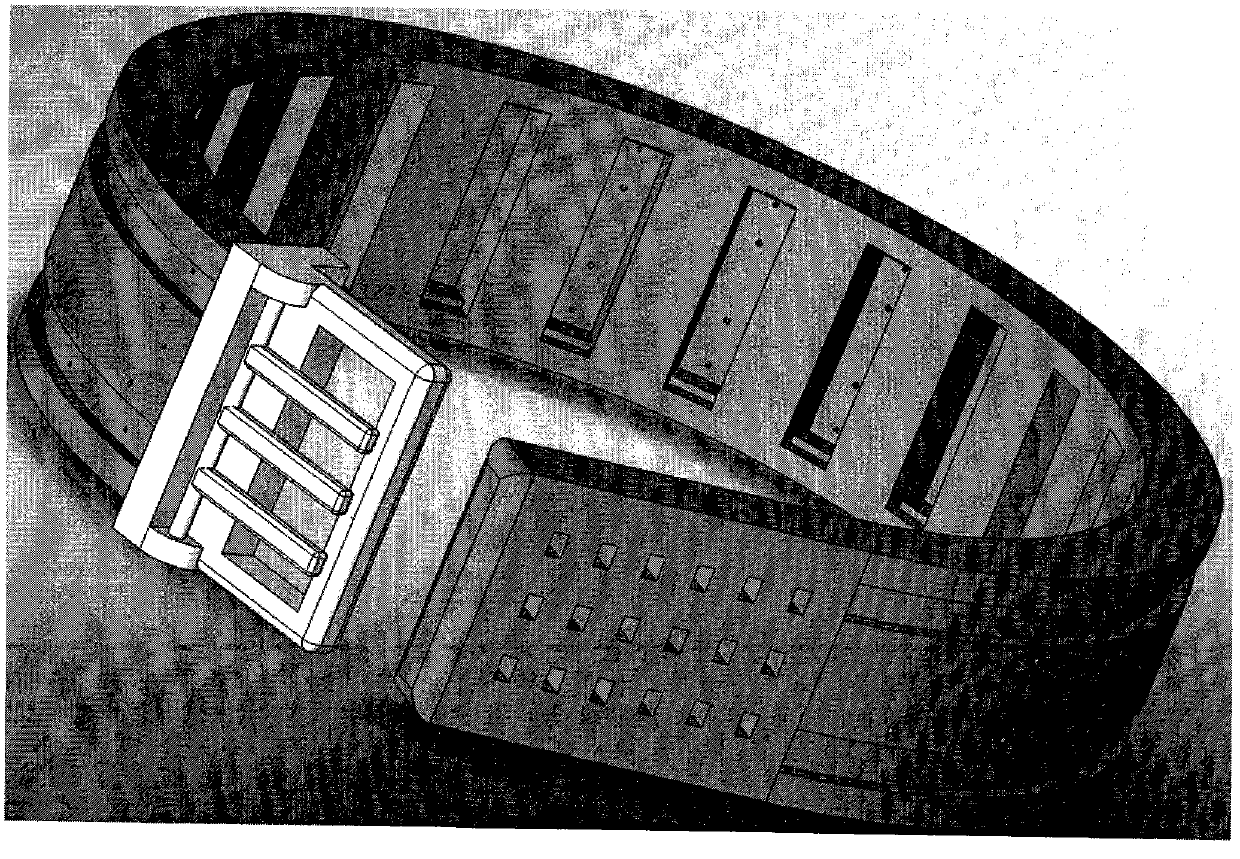

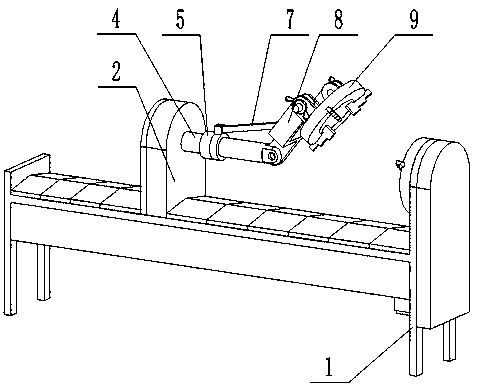

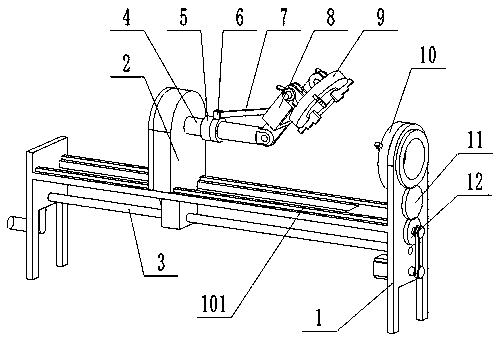

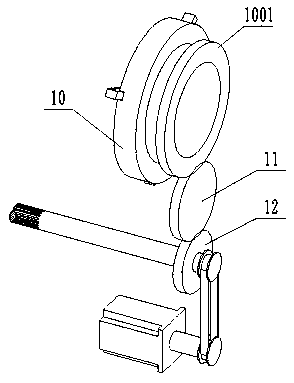

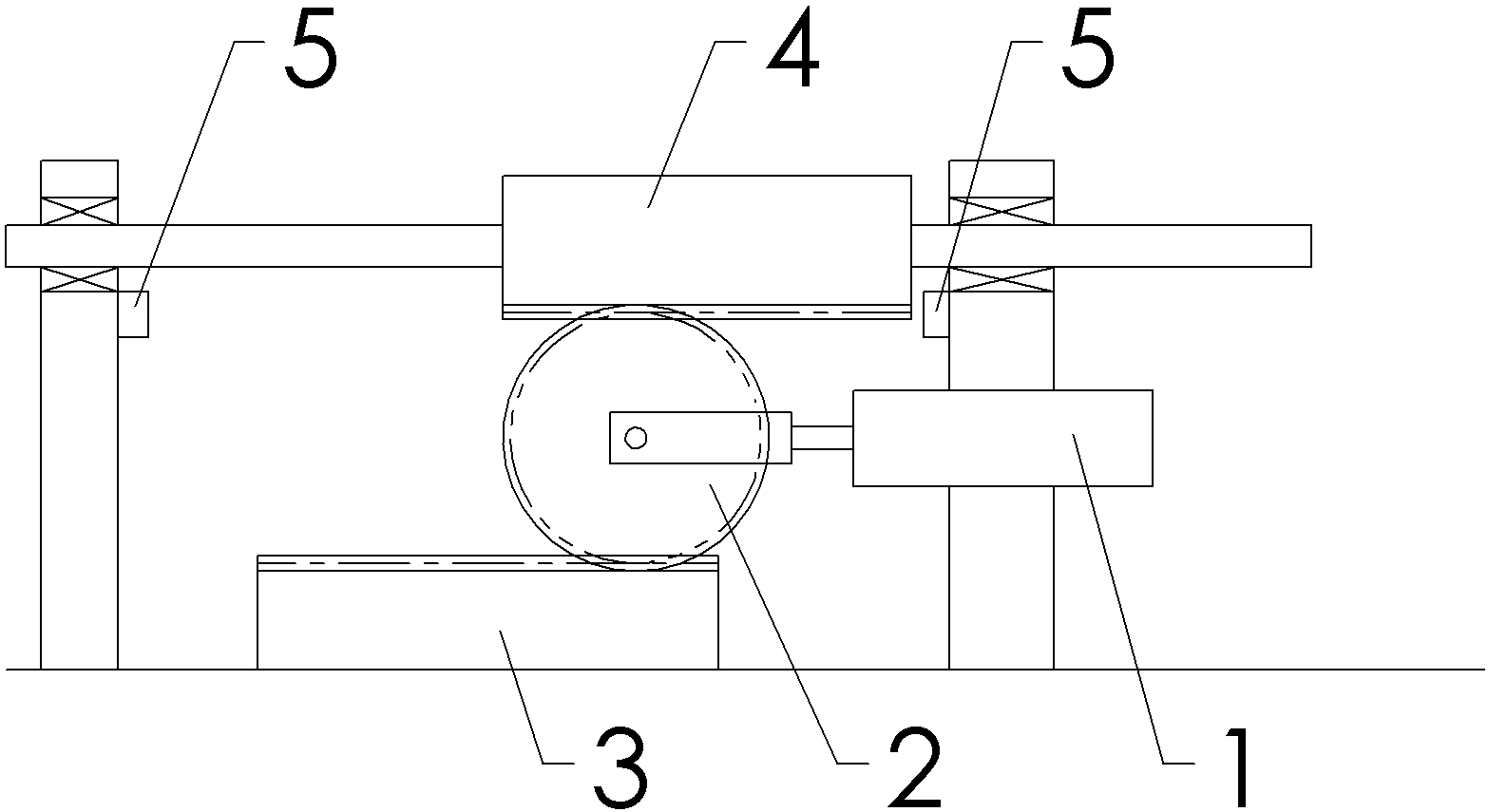

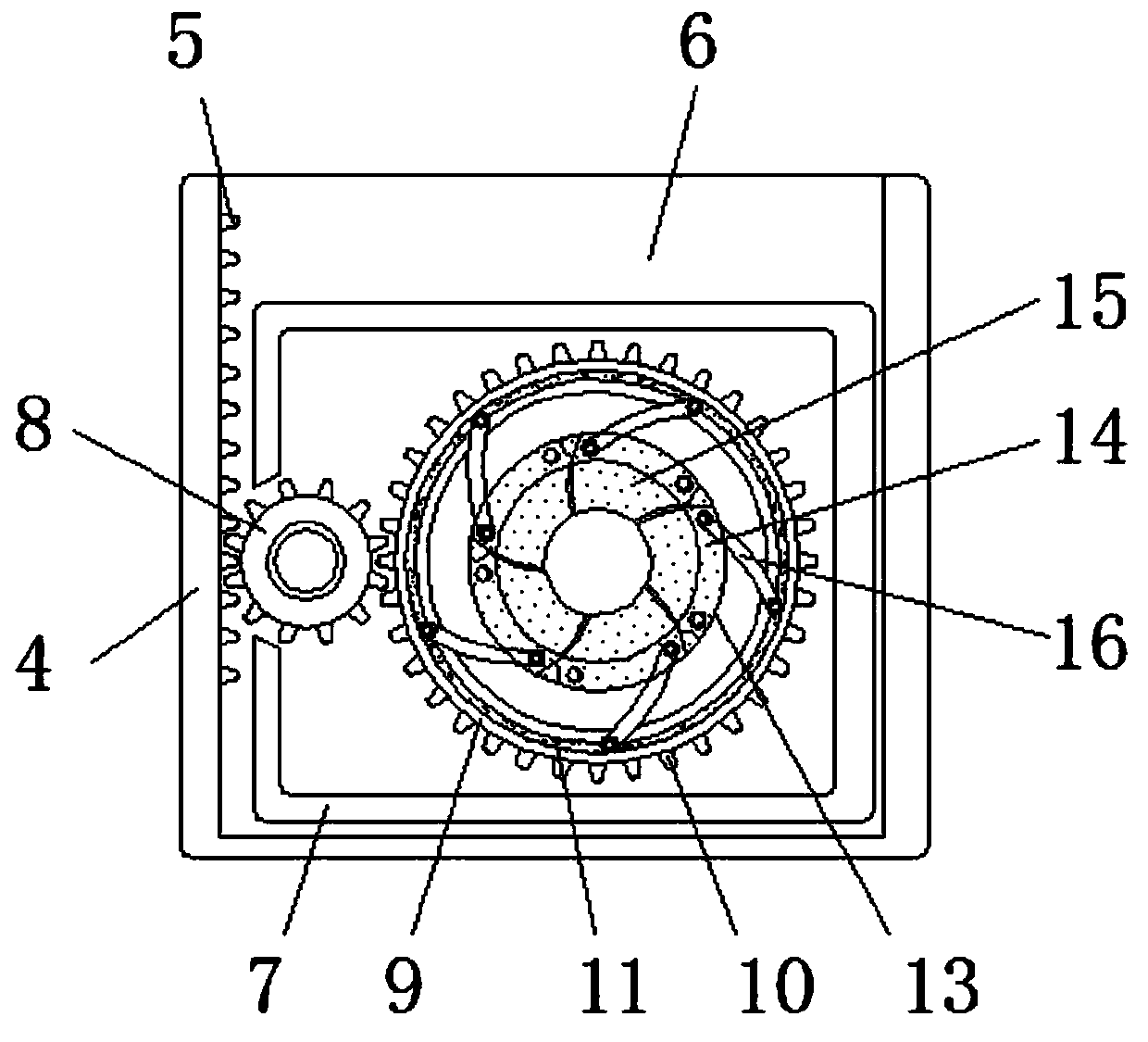

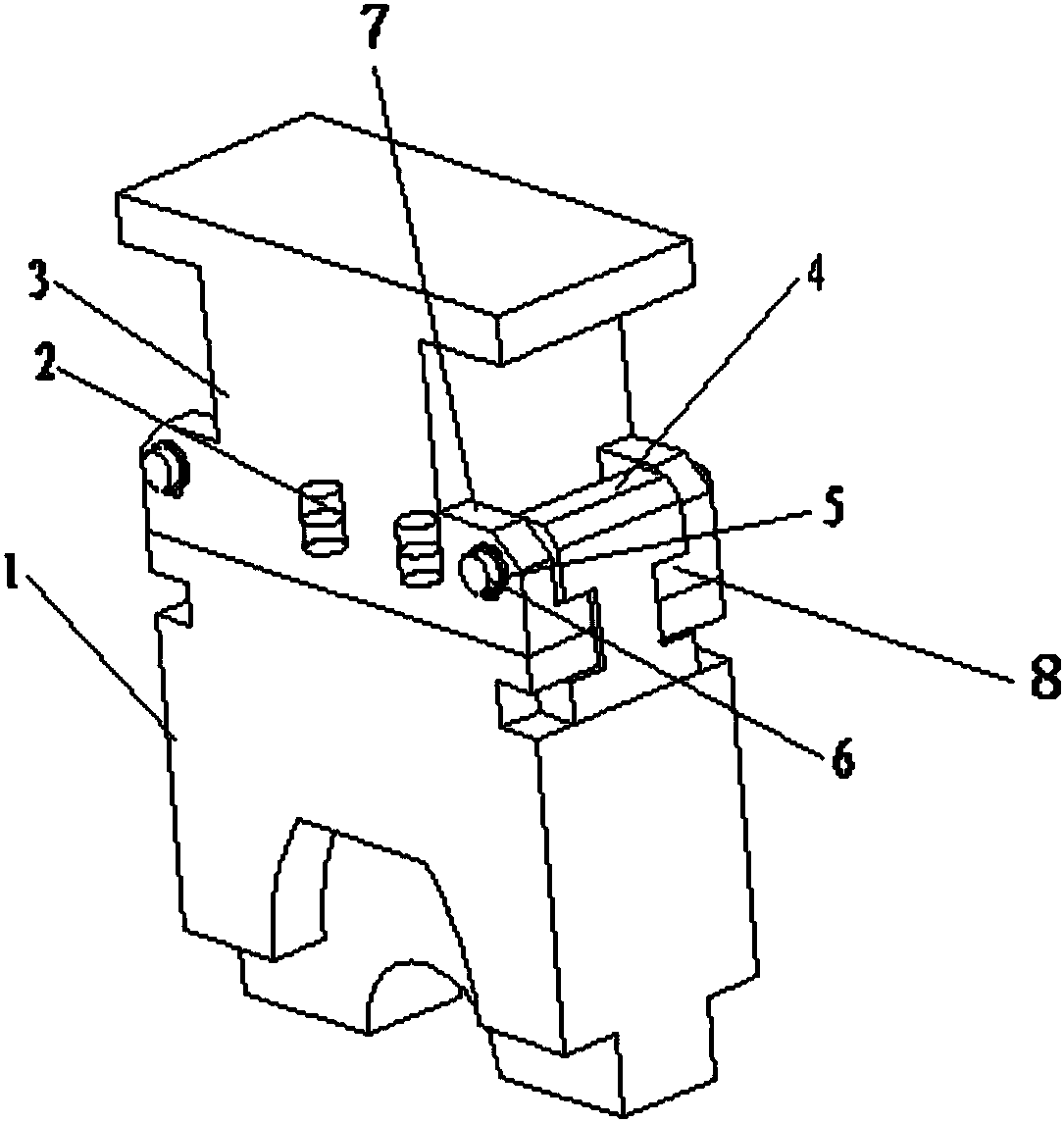

Multi-angle adjusting and clamping device for welding of special-shaped pipe fitting

ActiveCN110052766AAdaptableAvoid blockingWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention provides a multi-angle adjusting and clamping device for welding of a special-shaped pipe fitting. The multi-angle adjusting and clamping device comprises a bracket, a square rail and afixed gear, a set of sliding supporting seat is slidably connected with the upper end face of the bracket, a set of fixed chucks is connected with the right end face of the bracket in an axial mode, aset of middle gears is connected with the right end face of the bracket in an axial mode, a set of middle gears is connected with the left end face of each sliding supporting seat in an axial mode, aset of center rotating shafts is connected with the upper part of each sliding supporting seat in an axial mode, a set of adjusting pulling seats is slidably connected with each center rotating shaft, and a set of adjusting nuts is connected with the left end face of each adjusting pulling seat in an axial mode. Movable chucks and the fixed chucks are arranged to rotate synchronously, the fact that the welding seam cannot change is ensured, and the welding quality is improved; and by adapting rotating of the pipe fitting, welding is achieved through a overall non-rotating manner, blocking dueto the clamping device is avoided, secondary welding is avoided, one-time welding molding is achieved, and the welding quality is improved.

Owner:山东军钛金属材料有限公司

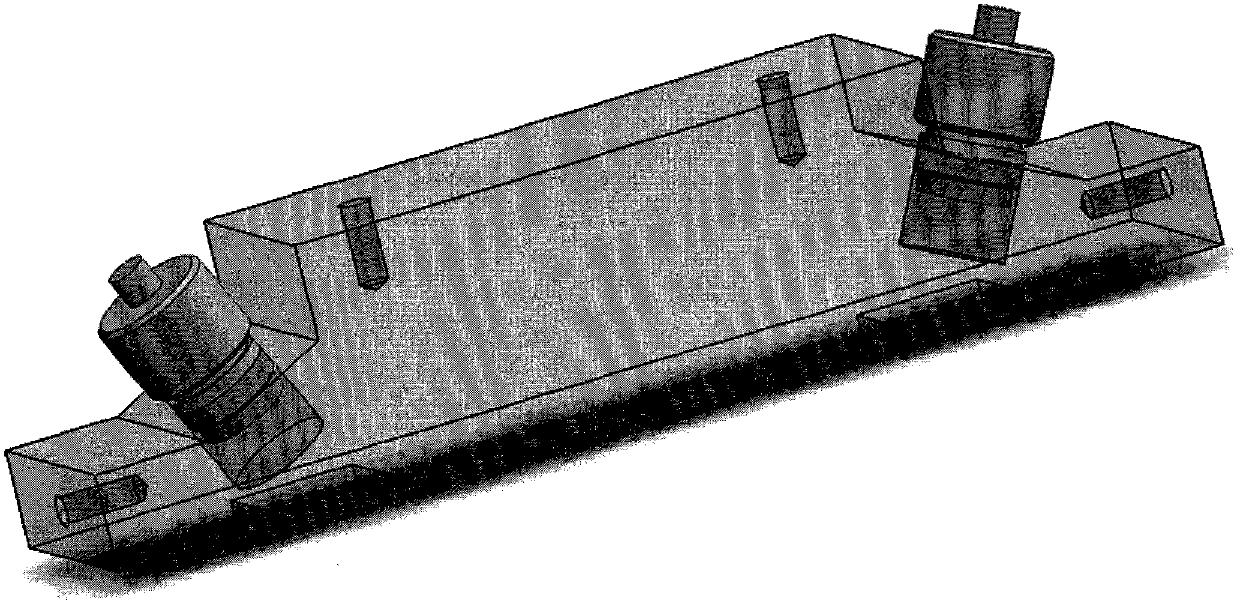

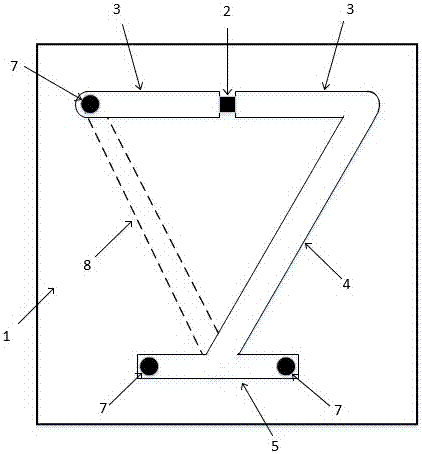

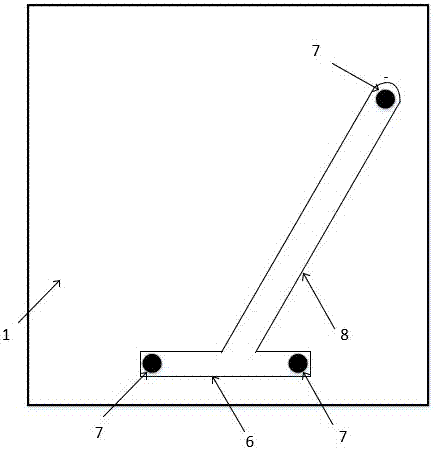

Cylinder stroke amplification mechanism

InactiveCN103644167ASolve the problem that the stroke is difficult to increaseFluid-pressure actuatorsEngineeringLubrication

The invention discloses a cylinder stroke amplification mechanism which aims at solving the problem that the cylinder stroke is difficult to be increased in the prior art. The cylinder stroke amplification mechanism comprises a frame and a cylinder which are fixed together; the cylinder stroke amplification mechanism also comprises a gear, a fixed rack and a movable rack; the fixed rack is fixed on the frame; the movable rack can move in a linear axial mode; an original lever of the cylinder is in rotating connection and vertical intersection with a center shaft of the gear; the upper edge and the lower edge of the gear, which are opposite to each other, are meshed with the fixed rack and the movable rack respectively; a material pushing rod which is used for outputting the motion outward is fixedly connected onto the movable rack; the fixed rack and the movable rack are provided with automatic lubrication devices. According to the cylinder stroke amplification mechanism, the gear is driven by the original lever of the cylinder to move, the gear rotates under the constraints of the fixed rack, and the movable rack is driven to move, and the push work of workpieces is executed by the material pushing rod.

Owner:CHONGQING BISHAN AIHUA

Fractal miniaturization method for axial mode cylinder helical antenna

ActiveCN103943949AIncrease girthReduce operating frequencyRadiating elements structural formsAntenna earthingsHelical lineImpedance transformer

The invention discloses a fractal miniaturization method for an axial mode cylinder helical antenna. The method includes the first step of constructing a fractal curve, the second step of constructing a longer periodic fractal curve, the third step of drawing a cylinder, the fourth step of counterclockwise rotating the periodic fractal curve constructed in the second step along the starting point of the periodic fractal curve by the angle alpha or the angle of pi-alpha, the fifth step of forming a circle of dextrorotation or levorotation cylinder helix, the sixth step of combining M circles of fractal helixes to form a fractal helix strip, the seventh step of turning the M circles of the fractal helixes in the sixth step into a metal conduction band with the thickness of T, the eighth step of placing concentric round copper plates, and the ninth step of adding a lambda / 4 impedance transformer at the initial end of a fractal helical line. According to the method, operating frequency of an axial mode of the helical antenna is lowered, so that size miniaturization is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Injection locking Q-switched and Q-switched cavity dumped CO2 lasers for extreme UV generation

Owner:COHERENT INC

Planar two-arm axial-mode helix antenna suitable for radio-frequency identification label

InactiveCN106961002AGood end-fire characteristicsImprove matchAntenna supports/mountingsRadiating elements structural formsCouplingDielectric plate

The invention discloses a planar two-arm axial-mode helix antenna suitable for a radio-frequency identification label. The planar two-arm axial-mode helix antenna comprises a dielectric plate, a planar two-arm axial-mode helical structure having an end-fire characteristic and an RFID label chip; a first microstrip line, a second microstrip line and a third microstrip line on the front side of the RFID label, and a fourth microstrip line and a fifth microstrip line on the back side of the RFID label form the planar two-arm axial-mode helical structure having the end-fire characteristic in a helical surrounding manner through three corresponding metalized through holes. The planar two-arm axial-mode helix antenna has a good end-fire characteristic, and can be matched with the RFID label chip easily, and is compact in structure and simple in production process, and the mutual coupling interference is small when multiple RFID labels are arranged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

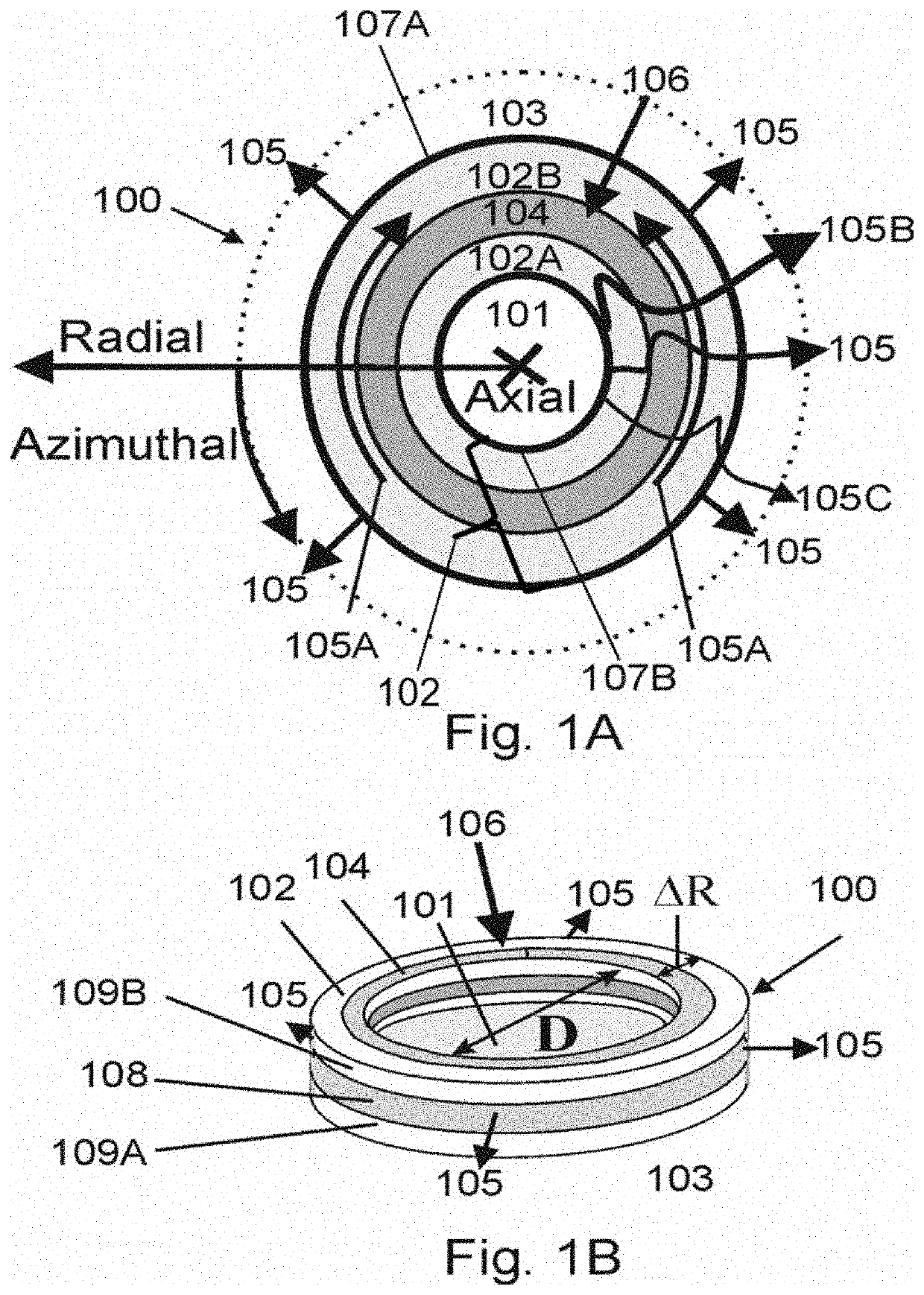

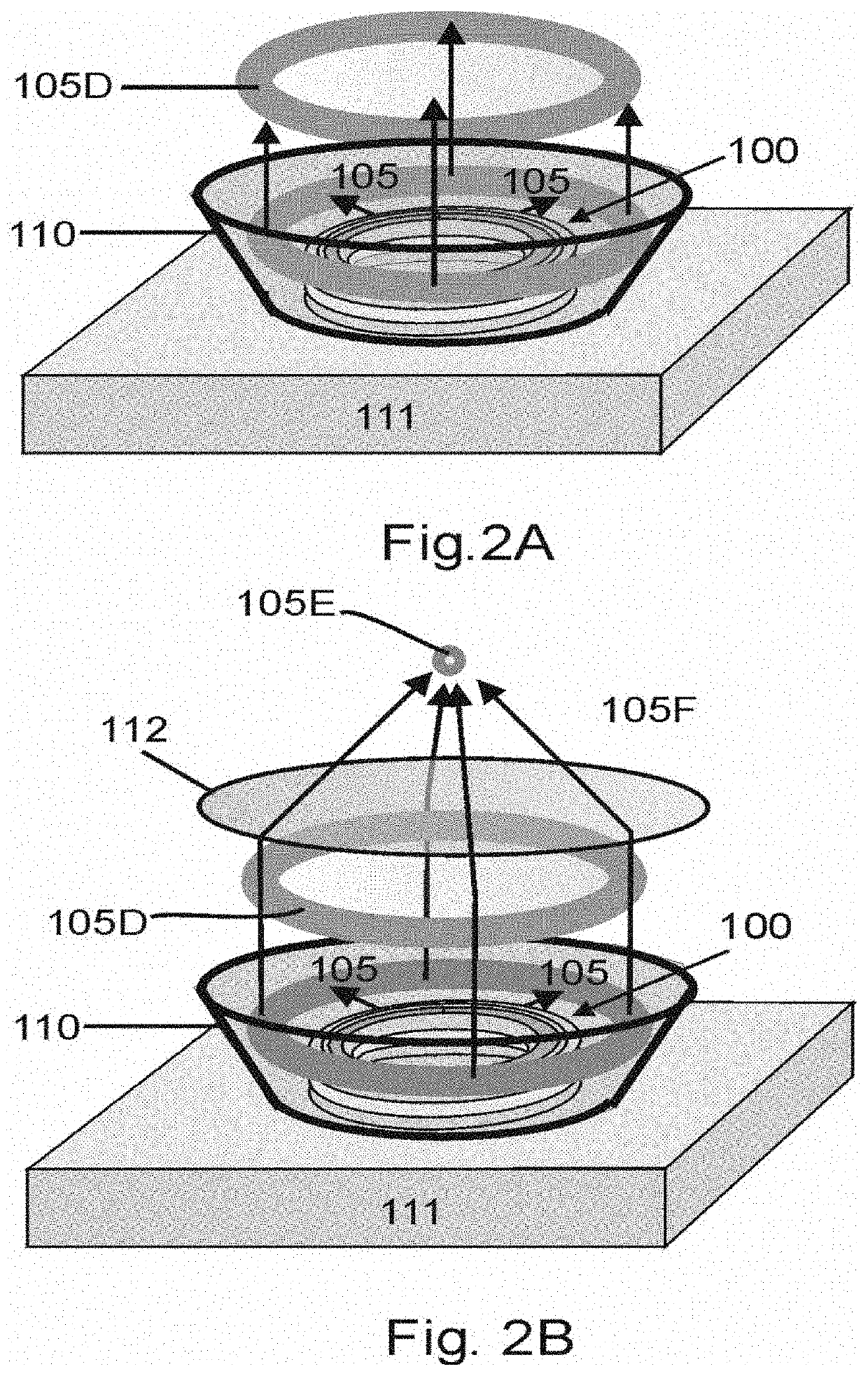

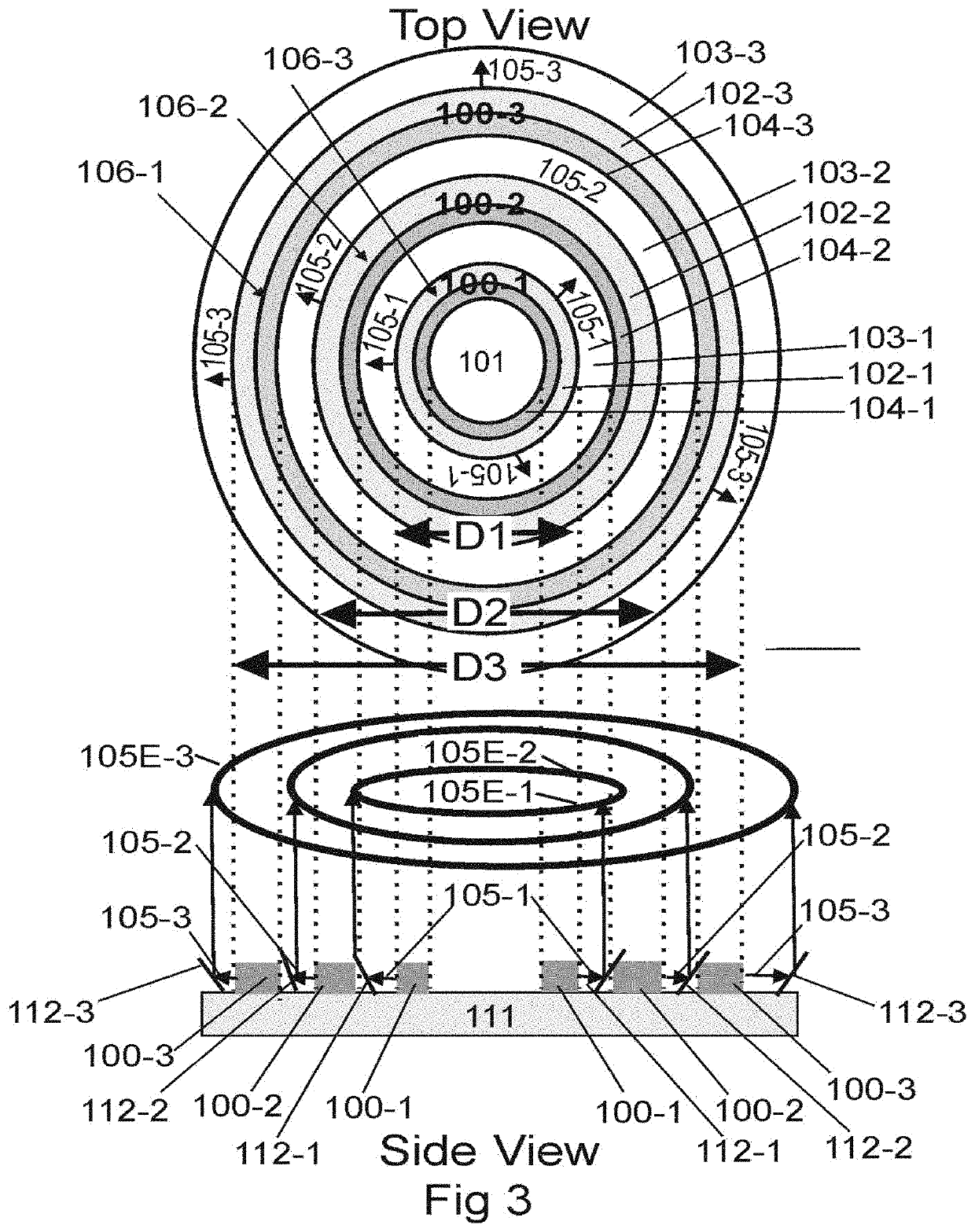

Concentric cylindrical circumferential laser

ActiveUS20210104861A1Laser optical resonator constructionActive medium shape and constructionModal gainOptical limiting

The present disclosure relates to a three-dimensional cylindrical cavity-type laser system capable of supporting circumferential radial emission. A cylindrical ring waveguide provides optical confinement in the radial and axial dimensions thereby supporting a plurality of radial modes, one of a plurality of axial modes and a plurality of degenerate azimuthal modes. These modes constitute a set of traveling wave modes which propagate around the cylindrical ring waveguide possessing various degrees of optical confinement as quantified by their respective Q-factors. Index tailoring is used to tailor the radial refractive index profile and geometry of the waveguide to support radial modes possessing Q-factors capable of producing efficient radial emission, while gain tailoring is used to define a gain confining region which offsets modal gain factors of the modal constituency to favor a preferred set of modes supporting efficient radial emission out of the total modal constituency supported by the resonator. Under appropriate pump actuation the selected modes produce circumferential laser radiation with the output surface comprising of the entire outer perimeter of the cylindrical ring waveguide. The design is applicable toward both micro-resonators and resonators much larger than the optical wavelength, enabling high output powers and scalability. The circumferential radial laser emission can be concentrated by positioning the cylindrical ring laser inside a three-dimensional conical mirror thereby forming a laser ring of light propagating in the axial dimension away from the surface of the laser, which can be subsequently collimated for focused using conventional optics.

Owner:LACOMB RONALD +1

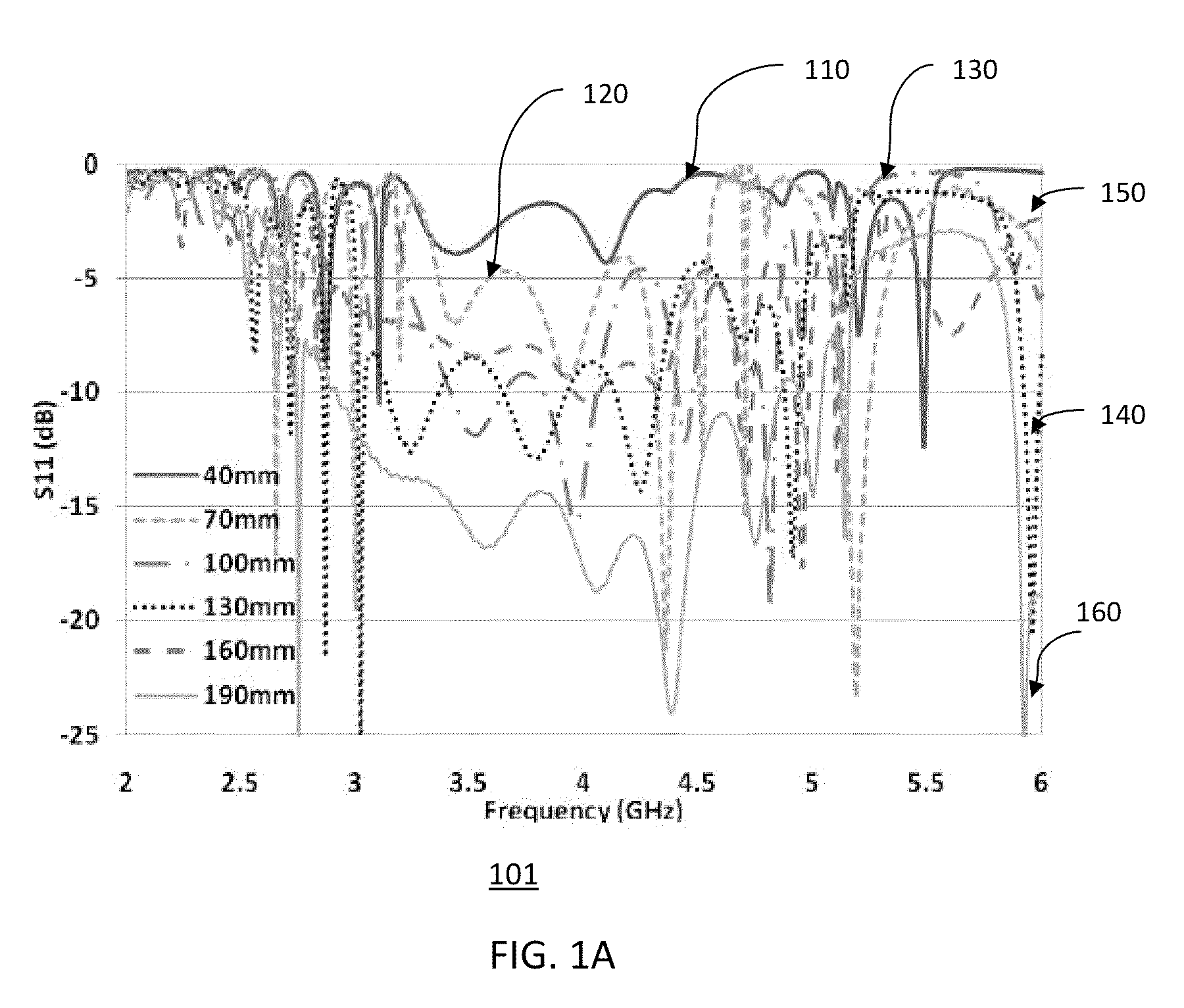

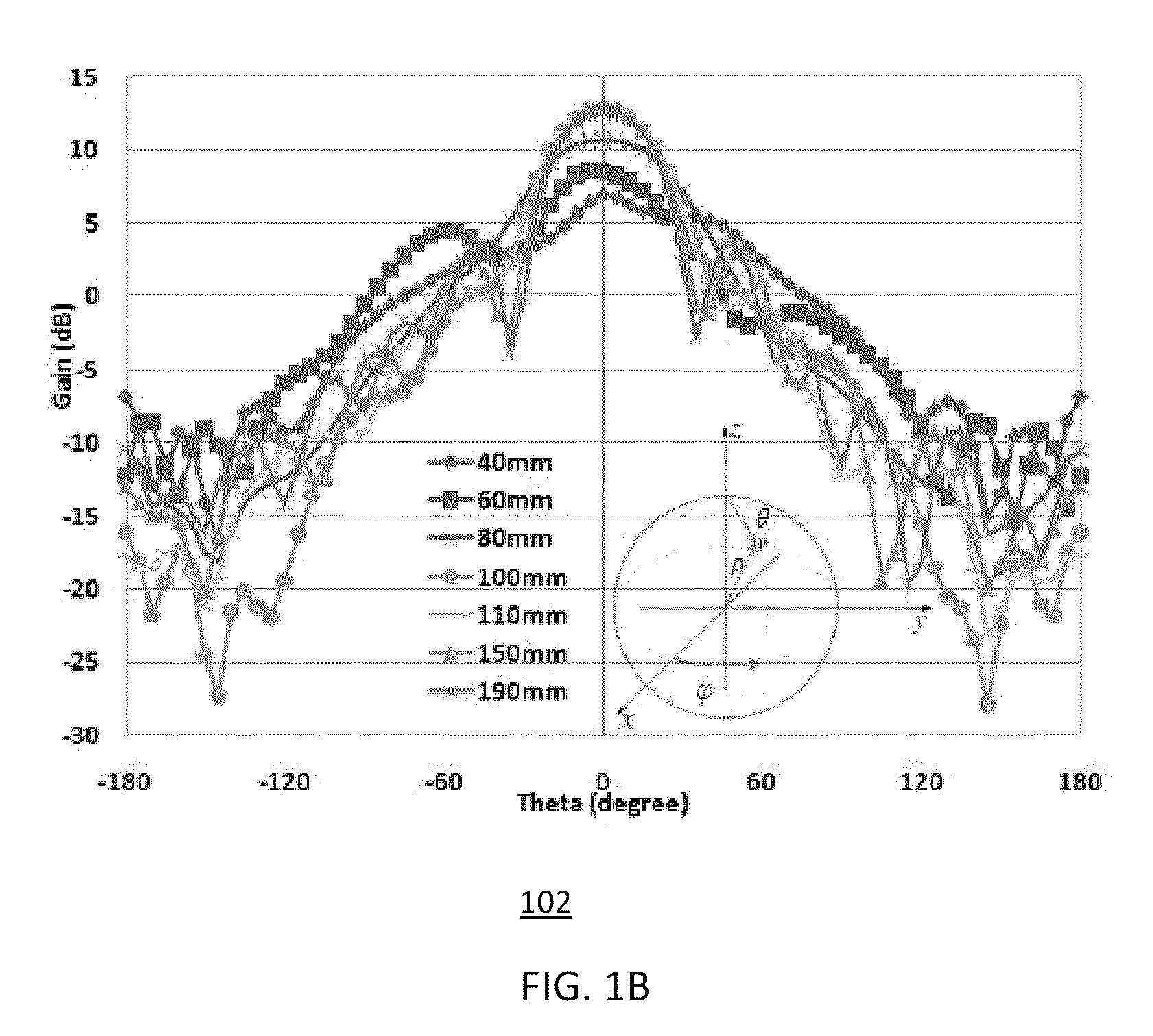

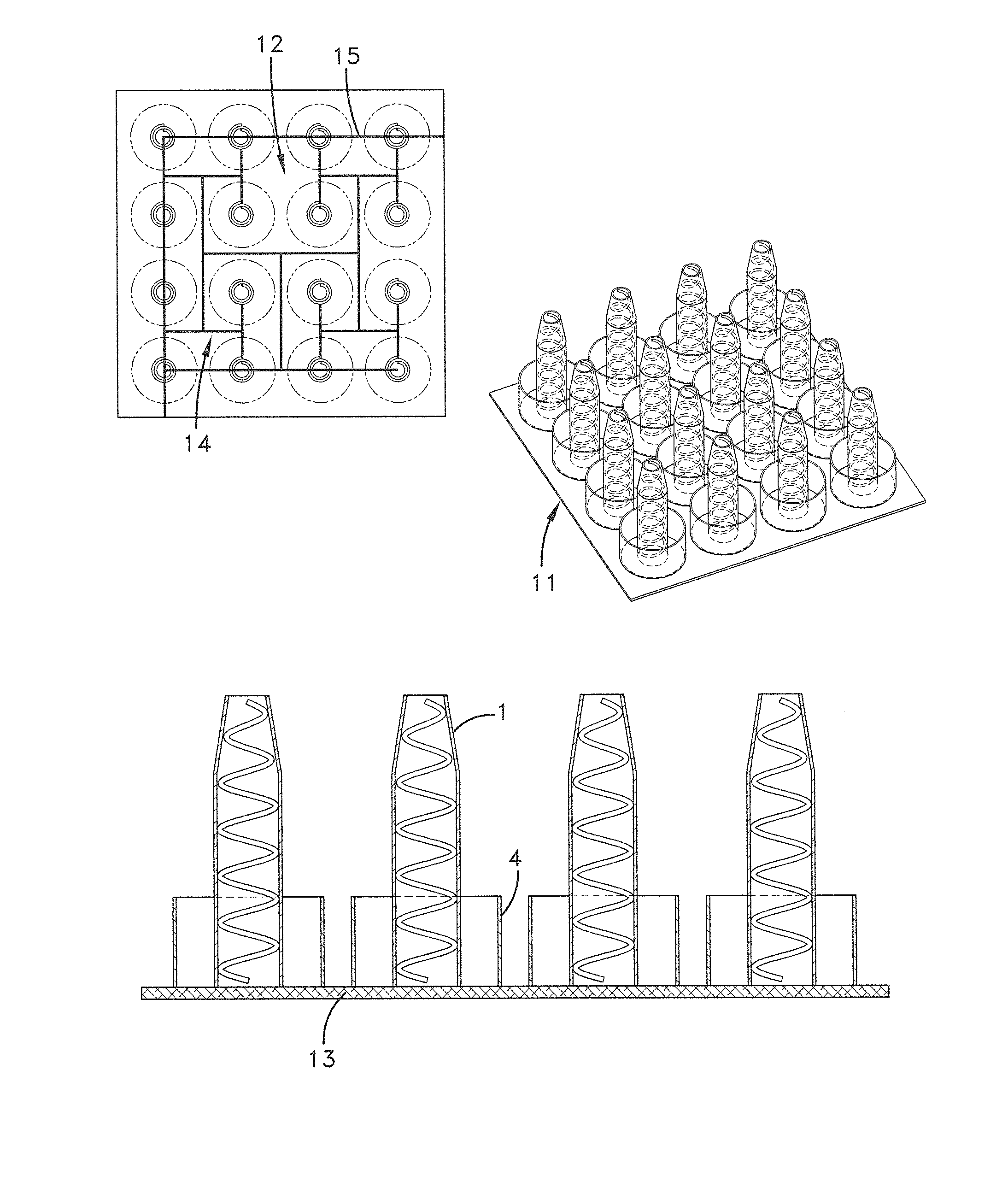

Printed quasi-tapered tape helical array antenna

ActiveUS9444148B2Reduce performanceImprove RF performanceLogperiodic antennasRadiating elements structural formsCopper conductorAxial ratio

A printed quasi-tapered tape helical element and printed helical array antenna. The helical element comprises a thin helix conductor having a uniform section associated with a tapered section. The helix conductor can be printed on a thin dielectric sheet and bonded to a hollow composite dielectric support. A solid copper conductor is configured to provide electrical connection between a feeding point of the helix conductor and a microstrip line of a microstrip feed network. The uniform and tapered helix turns are respectively wrapped around the uniform and tapered sections, which enables impedance matching, axial mode excitation, gain and radiation patterns, and damping out of standing waves generated in current distribution over the helix conductor. Conductive composite cups surrounding each helical element reduces mutual coupling in array environment. Thus, the helical element and the array antenna achieve low on-axis and off-axis axial ratio performance over the wideband for global coverage.

Owner:INDIAN SPACE RES ORG OF ISRO

Distribution box with automatic cable bundling function

ActiveCN109884761AIt has the function of automatically closing the cableEasy to closeFibre mechanical structuresButt jointFixed frame

The invention discloses a distribution box with an automatic cable bundling function, which comprises a box body, a humidity sensor, a single chip microcomputer and an electric push rod, wherein a partition plate is welded on the inner wall of the box body, an incoming line cavity, an installation cavity and an outgoing line cavity are respectively arranged in the box body from left to right through the partition plate, a welding plate and an optical fiber splitting assembly are connected in the installation cavity, fixed frames are installed on the inner walls of the incoming line cavity andthe outgoing line cavity, an installation frame is connected in a movable groove, a first gear is connected to the side shaft of the installation frame, a heat dissipation plate is connected to the inner wall of an inner frame in an axial mode, one end of the heat dissipation plate penetrates through the inner frame and is connected with a second gear, the second gear is located in a positioning groove, a positioning plate is located in the positioning groove, and the upper end of the positioning plate is fixed with a butt joint block. The distribution box with an automatic cable bundling function can carry out automatic cable bundling and avoid mixed and disorderly circuit, and in the meantime, the distribution box with an automatic cable bundling function has heat dissipation and water-proof effects and protects internal electrical components.

Owner:HUNAN UNIV OF ARTS & SCI

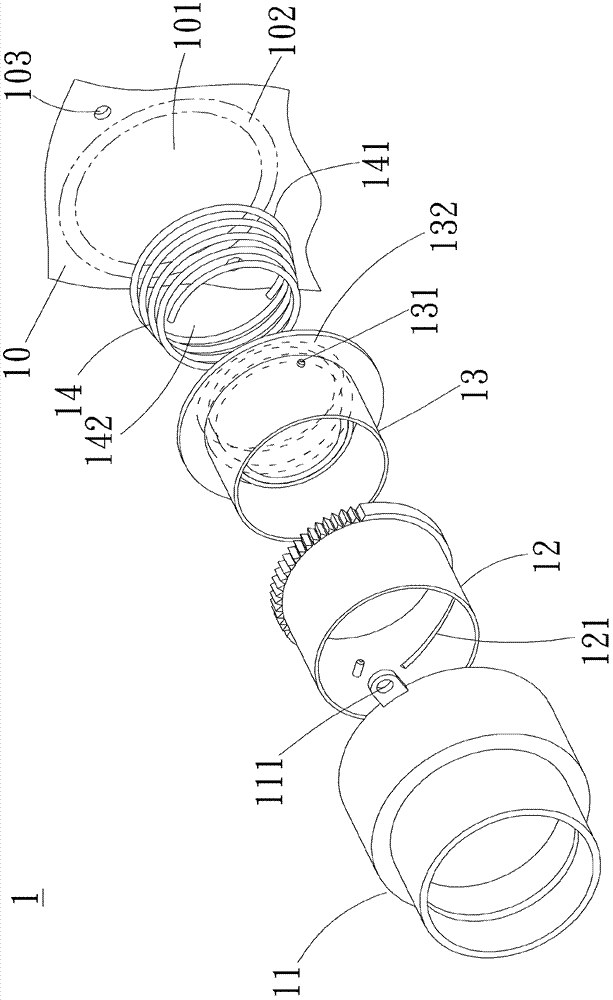

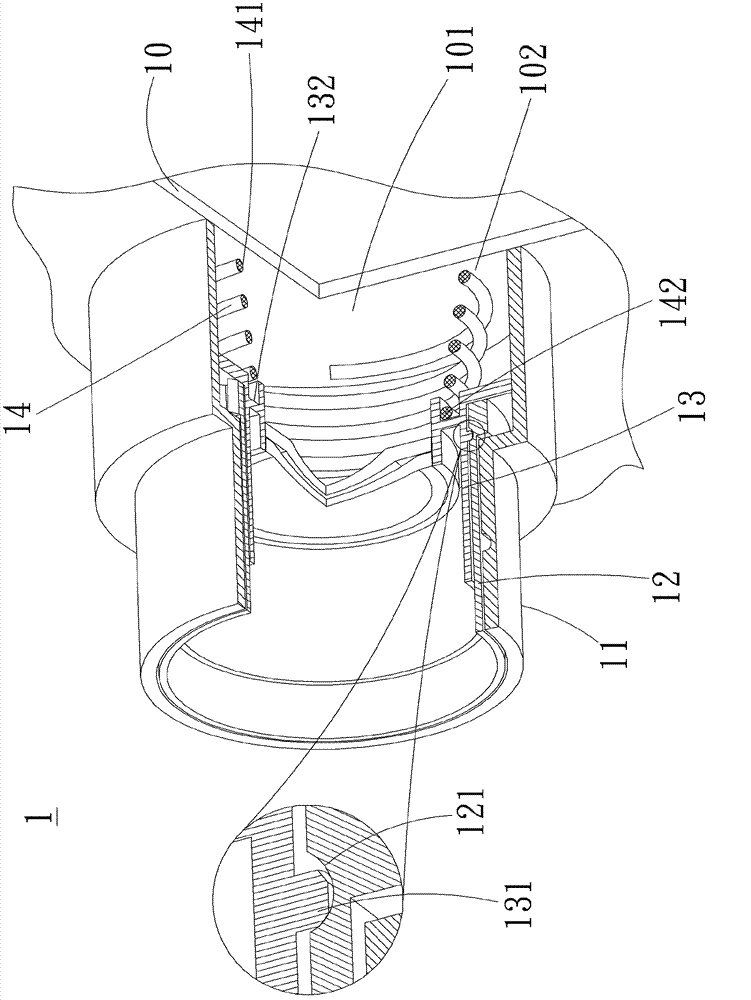

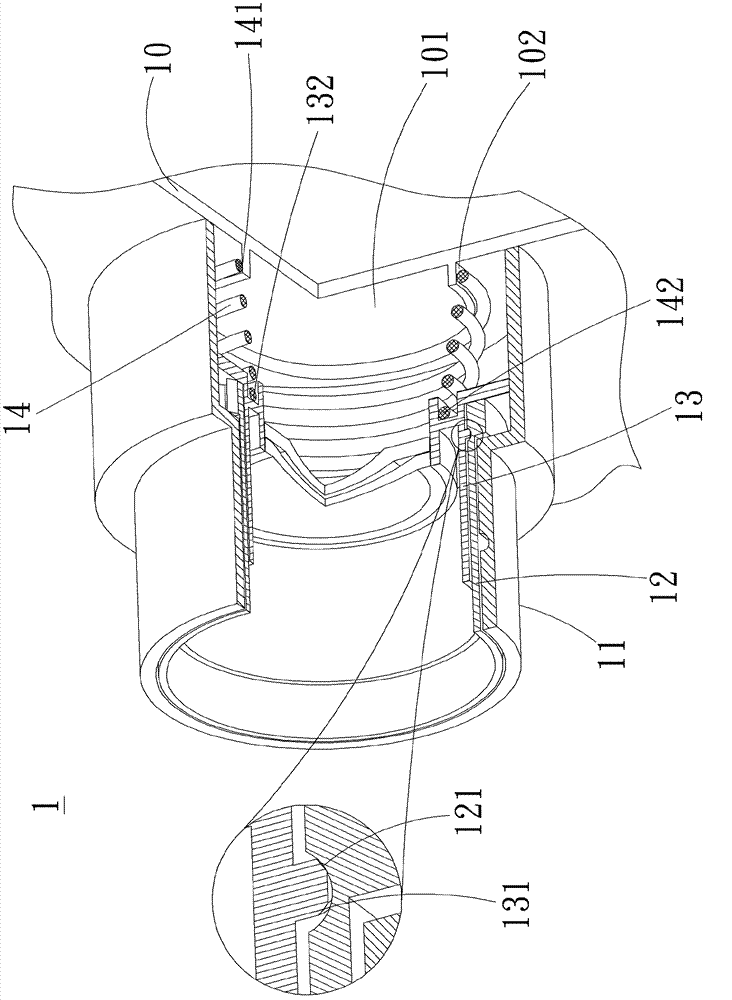

Lens of improving focusing accuracy rates and photographic device thereof

InactiveCN103091812ASolve the problem of focusing accuracyImprove focus accuracyMountingsFocusing aidsElastic componentEngineering

The invention provides a lens of improving focusing accuracy rates. The lens of improving the focusing accuracy rates comprises a lens cone fixing seat, a driving canister and an elastic component, wherein the lens cone fixing seat is provided with a hollow out part, and the hollow out part is provided with a first top abutted part, the first abutted part is provided with a connecting part. The driving canister is provided with a canister groove and a pair of focusing lens cones on the inner edge of the circumference wall, and a guiding part is arranged on the out edge of the circumference wall, and the guiding part is embedded into the canister groove so that the focusing lens cones can be arranged inside the driving canister in an axial movement and containing mode. A second top abutted part is arranged on the inner edge of the circumference wall. The elastic part is in a hollow ring-shaped structure and can be capable of stretching in an axial mode, and the elastic part is arranged between the lens cone fixing seat and the pair of the focusing lens cones. One end of the elastic part is abutted against the first top abutted part of the lens cone connecting seat, and the other end of the elastic part is abutted against the second top abutted part. The lens of improving the focusing accuracy rates and a photographic device thereof have the advantages of being capable of improving the focusing accuracy rates, reducing the phenomenon of shining, meanwhile simplifying assembly technological process.

Owner:ALTEK CORP

Axial mode helical antenna with double-layer segmental medium lens

InactiveCN103117449ASimple structureEase of mass productionRadiating elements structural formsAntenna earthingsHelical lineElectrical conductor

The invention relates to an axial mode helical antenna, particularly to an axial mode helical antenna with a double-layer segmental medium lens. The axial mode helical antenna with the double-layer segmental medium lens aims at solving the problem that when the coil number of an existing helical antenna is large, the enhancement effect of the gain is obvious, and the manufacture of the antenna can be complex. The double-layer segmental medium lens is arranged above the upper end of the helical antenna, and the lower surface of the double-layer segmental medium lens is a downward-convex spherical surface. The distance between the vertex of the lower surface of the double-layer segmental medium lens and the upper end surface of the helical antenna is 12mm, the lower end of the helical antenna is connected with the terminals of micro-strip line metal straps on a micro-strip impedance transformer floor, the tops of the micro-strip line metal straps on the micro-strip impedance transformer floor are connected with an inner conductor of a coaxial feeder line, the central axis of the helical antenna is perpendicular to the upper surface of the micro-strip impedance transformer floor, and the micro-strip metal straps are arranged on the micro-strip impedance transformer floor in a question mark shape. The axial mode helical antenna with the double-layer segmental medium lens is applicable to the radio field.

Owner:HARBIN INST OF TECH

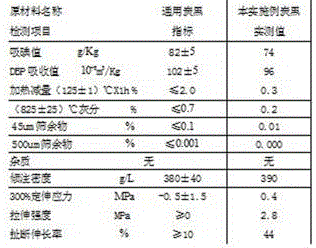

N330 carbon black production method

ActiveCN106189377AImprove compression heat generationIncrease resistancePigmenting treatmentProcess engineeringUnit/Kilogram

The invention provides an N330 carbon black production method. The process is simple and practical, and produced carbon black is better in performance. A hard carbon black reaction furnace is used for production, and the volume ratio of air to natural gas entering the reaction furnace is (18-19):1, so that more redundant air is generated to take participation in secondary combustion in a reaction chamber; raw oil enters the reaction chamber according to the spray amount of 440 kg / h; each kilogram of raw oil needs 2-3 m<3> of mixed gas composed of air and natural gas; the temperature of secondary combustion in the reaction chamber is controlled to be 1500-1600 DEG C; a plurality of gas inlets are evenly formed in a spray burner in the radial direction, and natural gas enters the gas inlets in a radial surrounding and axial mode so as to improve combustion efficiency; a first quenching section and a second quenching section are arranged at an outlet of the reaction furnace, the temperature of the first quenching section is controlled to be 900-950 DEG C, the temperature of the second quenching section is controlled to be 700-950 DEG C, and accordingly reaction time is prolonged; after carbon black is subjected to wet granulation, mixed gas composed of tail gas generated after carbon black production and air is introduced to dry the carbon black at the temperature of 300 DEG C; the tail gas and the air are mixed according to the volume ratio of (1.5-1.6):1.

Owner:山西永东化工股份有限公司

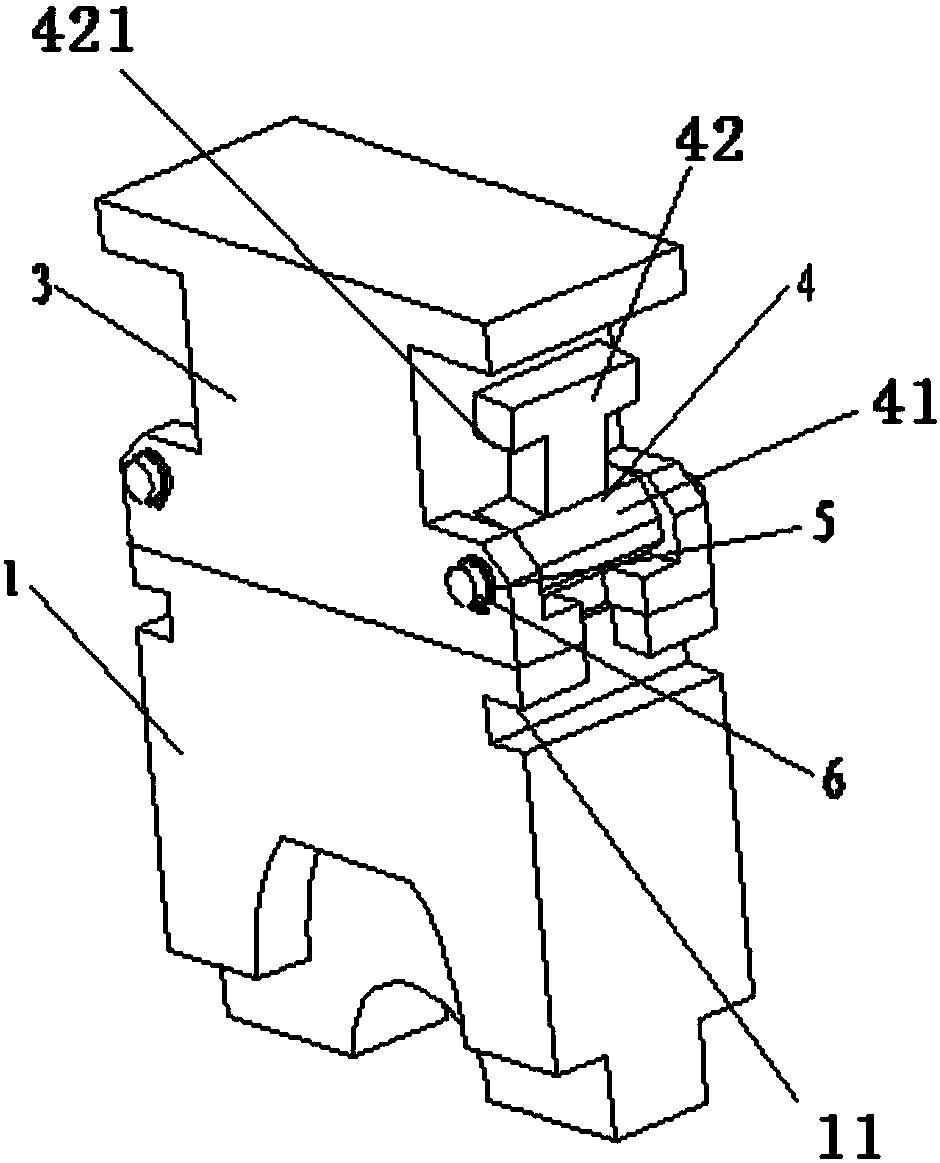

Connecting device suitable for forging die for large upsetting forging crankshaft and using method thereof

ActiveCN108067577AImprove job stabilityIncrease job securityForging/hammering/pressing machinesCirclipMechanical engineering

The invention discloses a connecting device suitable for a forging die for a large upsetting forging crankshaft and a using method thereof. The connecting device comprises a connector, wherein the connector is I-shaped, and the upper end of the connector is fixed on a sliding block of a press; a pair of shaft tables are arranged at the lower end of the connector, and shaft holes are formed in theshaft tables; connecting shafts penetrate through the shaft holes in a penetrating mode, and elastic check rings are arranged at the two ends of the connecting shafts; bosses with the position corresponding to the that of the connector is further arranged at the lower end of the connector; connecting pieces are also in an I-shaped shape and each comprise an upper cross arm and a lower cross arm, wherein through holes are formed in the upper cross arms, and the through holes are connected with the connecting shafts in an axial mode, and the lower parts of the upper cross arms are planes and arematched with the upper surfaces of the bosses; the upper parts of the lower cross arms are matched with the upper side surfaces of grooves arranged on the die; and pin holes are formed in the upper surface of the die and the lower surface of the connector correspondingly, and positioning keys are inserted into the pin holes. The connecting device and the using method thereof have the advantages that a traditional structure utilizing bolt conduction force can be changed into a large-scale rectangular cross section conduction structure with the connecting pieces, so that the connecting strengthis high, structure is simple, operation is convenient, and working stability and the safety of the die are high.

Owner:LIAONING 518 INTERNAL COMBUSTION ENGINE FITTINGS

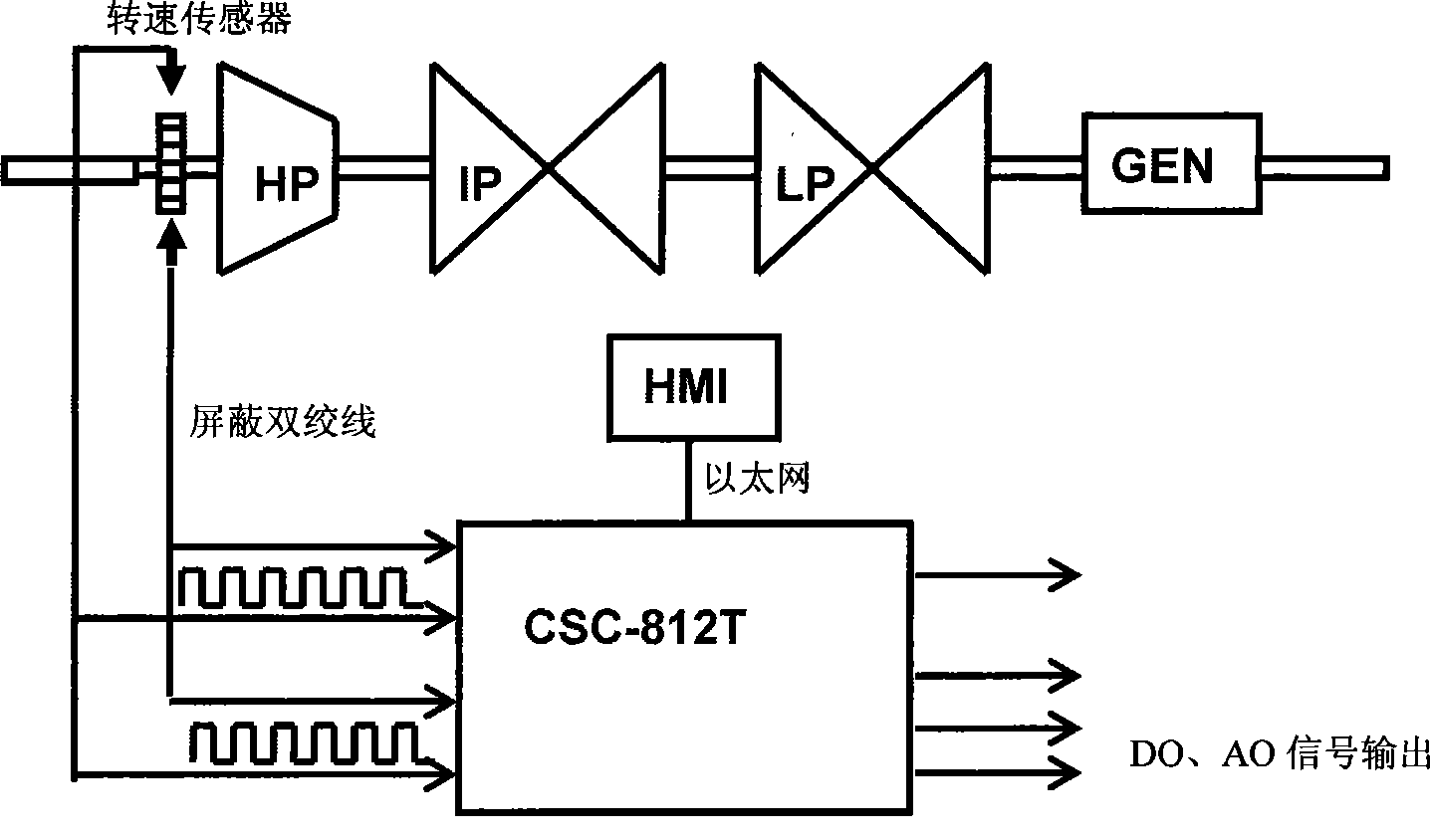

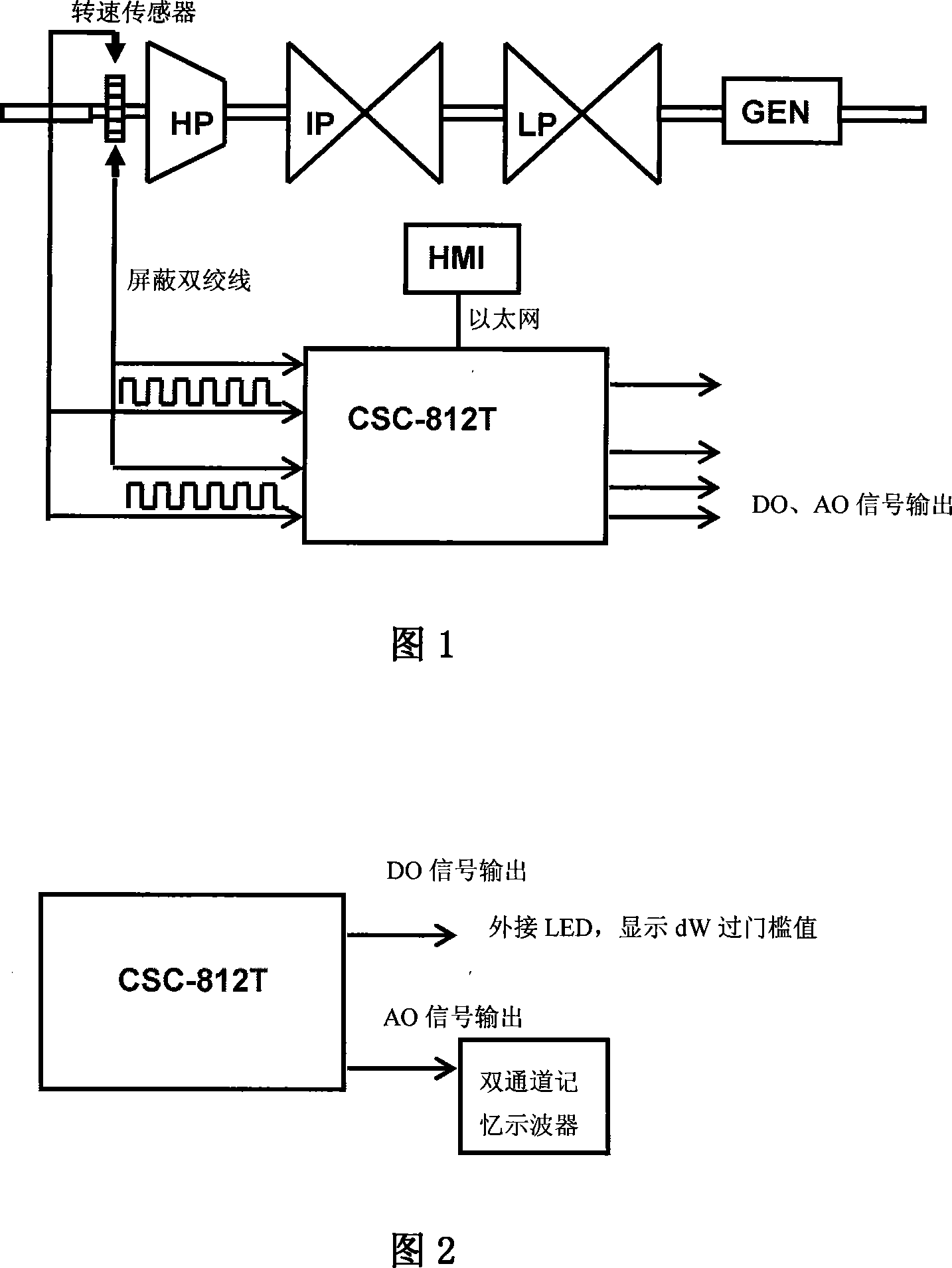

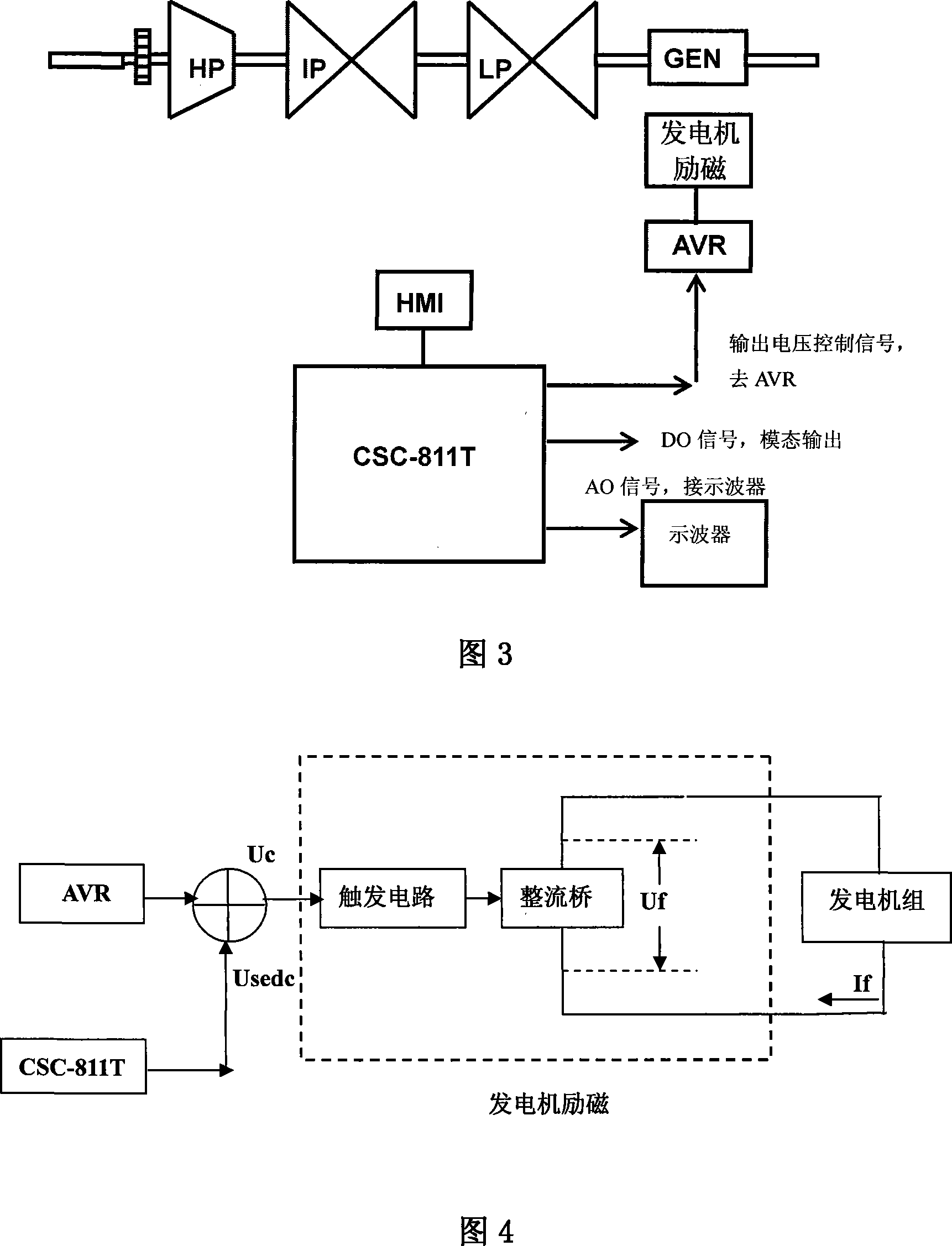

Scanning frequency method for testing large turbine generator set torsional vibration mode

ActiveCN101169352BProtect operational safetySuppression of subsynchronous oscillationsEngine testingSignal onBasic research

The invention relates to a measurement and test method for an axial torsional vibration mode of 300MW, 600MW, 1000MW turbine-generator set in a large-scale thermal power plant, and discloses a detecting method for an on-line dynamical frequency sweeping the axial torsional vibration mode by working a pumping signal on the excitation of power generator and combing the closed-circuit test which obtains the optimized response by a dynamically and continuously adjusting the pumping signal. The pumping signal with the mode characteristic is outputted through a method of dynamically on-line frequency sweeping. The excitation system of the turbine-generator set produces a controllable electric torque in the turbine-generator set through the excitation system so as to excite the axial torsional vibration of the turbine-generator set. Besides, the intensity of the axial vibration is measured to assure the fixed axial mode of the turbine-generator set. The method can measure the mechanical fixed frequency that is the axial torsional vibration mode of the turbine-generator set accurately, and is the basic research for solving the secondary in-phase vibration harm of the turbine-generator set. The invention is used for preventing, restraining and protecting the generator set and the power network from producing secondary in-phase vibration.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com