Scanning frequency method for testing large turbine generator set torsional vibration mode

A technology for torsional vibration of turbogenerator sets and shafting, which is applied in engine testing, machine/structural component testing, measuring devices, etc. It can solve problems such as inability to ensure that the test is sufficient and effective, and the operation of the unit and the power grid is damaged. Subsynchronous Oscillation Problem, Effect of Suppressing Subsynchronous Oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Through the study of the frequency sweep method for detecting the torsional vibration mode of the shafting of the turbo-generator set, the software and hardware of the torsional vibration controller of the shafting of the large-scale turbo-generator set and the torsional vibration tester have been developed. The torsional vibration moment sweep of the unit is continuously variable in frequency, and the torsional vibration response of the shafting is tested at the same time, and then the torsional vibration mode of the shafting is obtained.

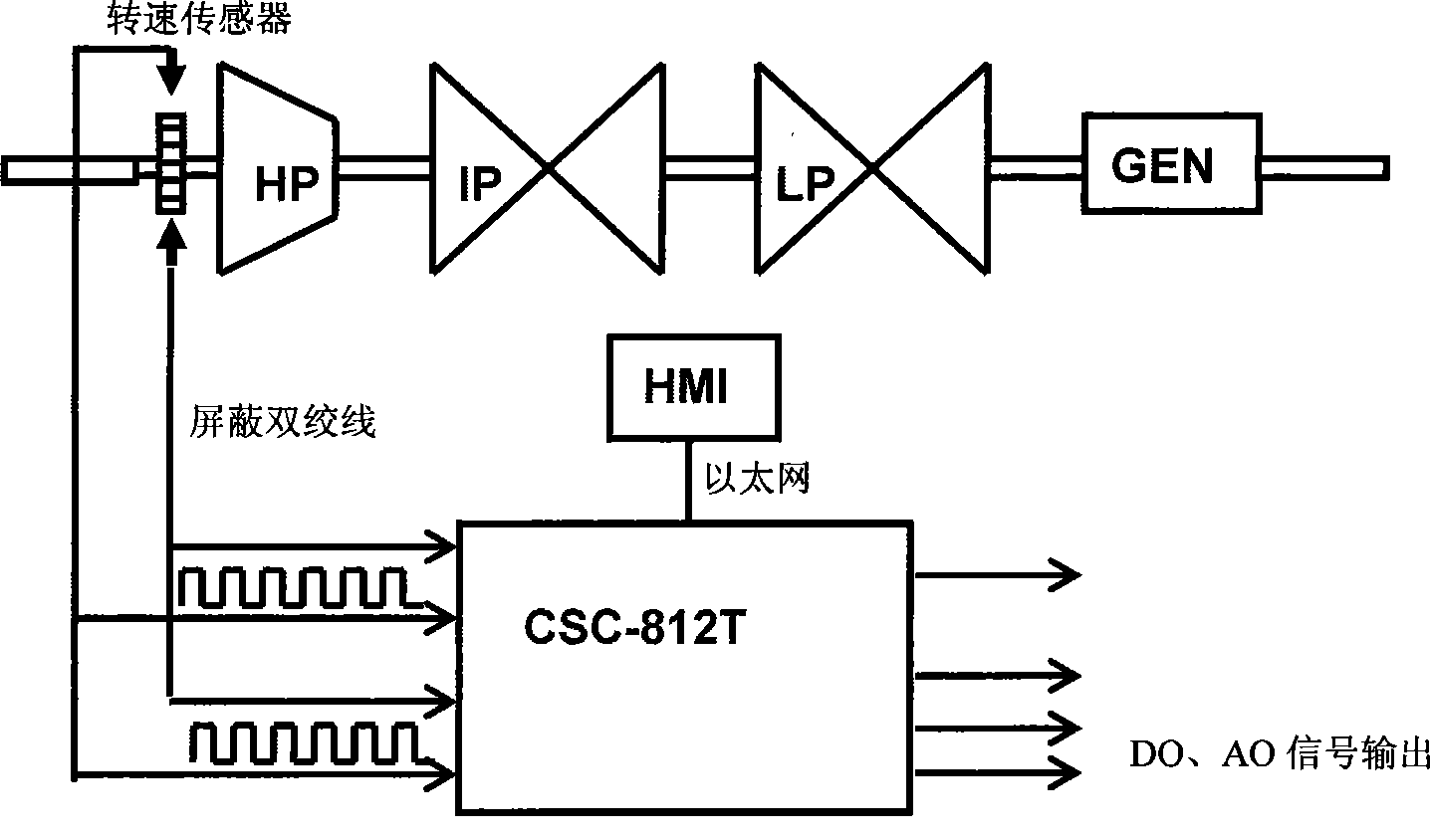

[0020] Figure 1 shows the specific wiring of the device (CSC-812T) for measuring the torsional vibration response of the shafting of the unit. The upper part of the figure shows the high-pressure cylinder (HP), medium-pressure cylinder (IP), low-pressure cylinder (LP) and generator (GEN) of the steam turbine of the unit. Install a pair of rotational speed sensors of the shaft system from the head end of the high-pressure cylinder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com