Multi-angle adjusting and clamping device for welding of special-shaped pipe fitting

A technology of special-shaped pipe fittings and clamping devices, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of limited adjustment ability, inability to realize welding, and poor welding effect, so as to avoid blocking, good fixing effect, and positioning good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

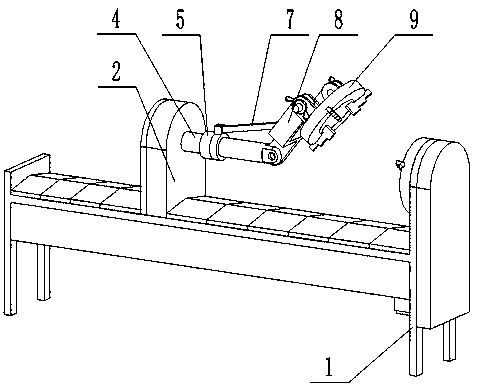

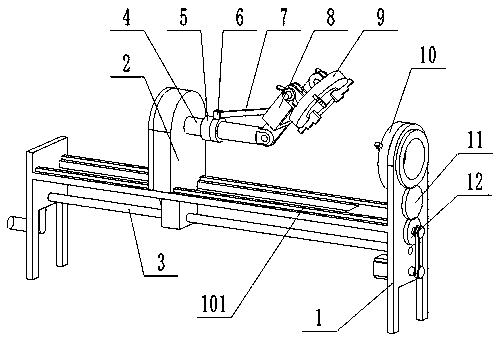

[0029] as attached figure 1 to attach Figure 8 Shown:

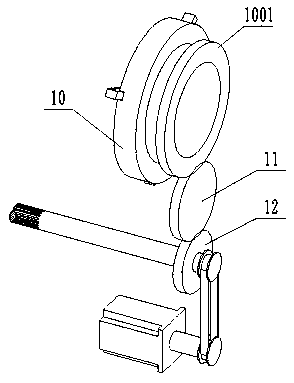

[0030] The present invention provides a multi-angle adjustable clamping device for welding special-shaped pipe fittings, including: a bracket 1, a square rail 101, a sliding support 2, a slider 201, a nut 202, a driving screw 3, a central shaft 4, and a central shaft rotation gear 401, adjusting chute 402, adjusting nut 5, adjusting pull seat 6, adjusting pull rod 7, movable chuck support 8, movable chuck 9, butterfly nut 901, fixed chuck 10, chuck rotating gear 1001, intermediate gear 11 , transmission shaft 12, spline 1201, sliding gear 1202 and fixed gear 1203; the upper end surface of support 1 is slidingly connected with a group of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com