Connecting device suitable for forging die for large upsetting forging crankshaft and using method thereof

A technology of connecting devices and molds, applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc., can solve problems such as potential safety hazards, mold tilting, crankshaft damage, etc., and achieve work stability and The effect of high safety, high connection strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

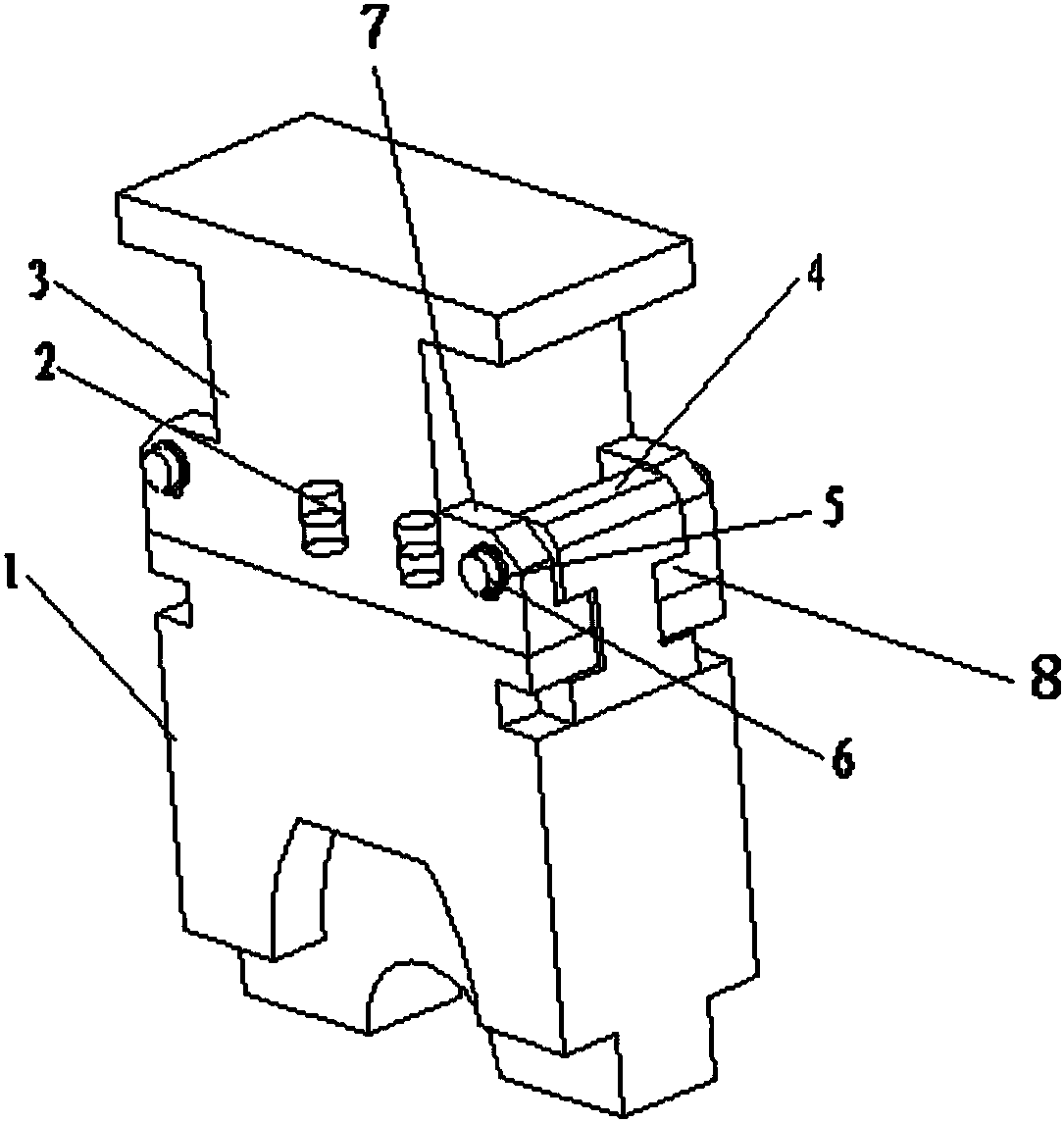

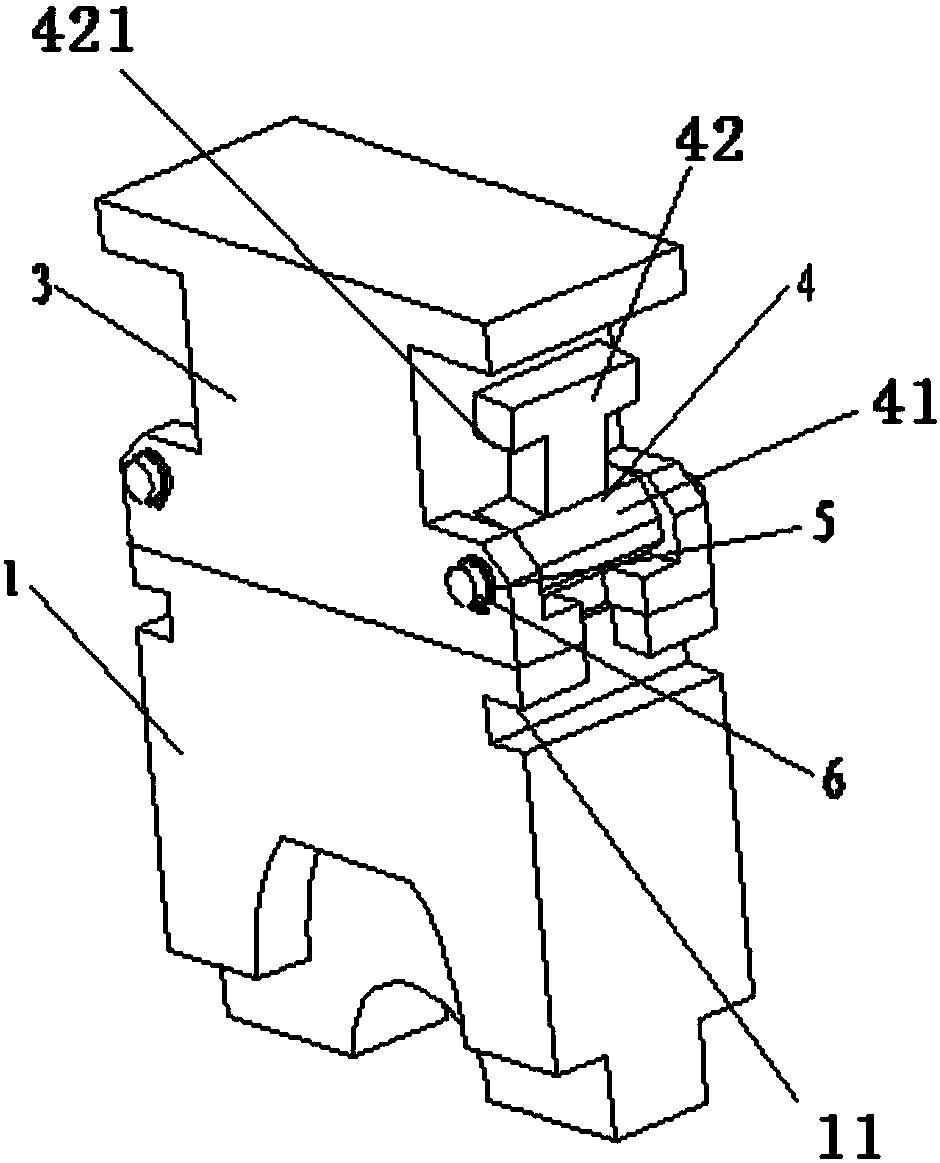

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The main contents of the present invention include: 1) a coupling device for a large-scale upsetting crankshaft forging die; 2) a method for using the coupling device for a large-scale upsetting crankshaft forging die. The invention is used for the connection of molds in the forging process of large-scale upsetting crankshafts, and has high connection strength, simple structure, convenient operation, and high working stability and safety of the molds.

[0015] Such as figure 1 As shown, the specific structure of the present invention is as follows: a coupling 3 is included, the coupling 3 is I-shaped, the upper end of the coupling is fixed on the slider of the press, and a pair of pillow blocks are arranged at the lower end of the coupling 7. A shaft hole is provided on the pillow block 7, and the coupling shaft 6 is inserted through the shaft hole 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com