High-speed gauze folding machine

A folding machine and folding mechanism technology, applied in the direction of folding thin materials, thin material processing, transportation and packaging, etc., can solve the problems of unfavorable packaging process, disordered gauze, machine damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

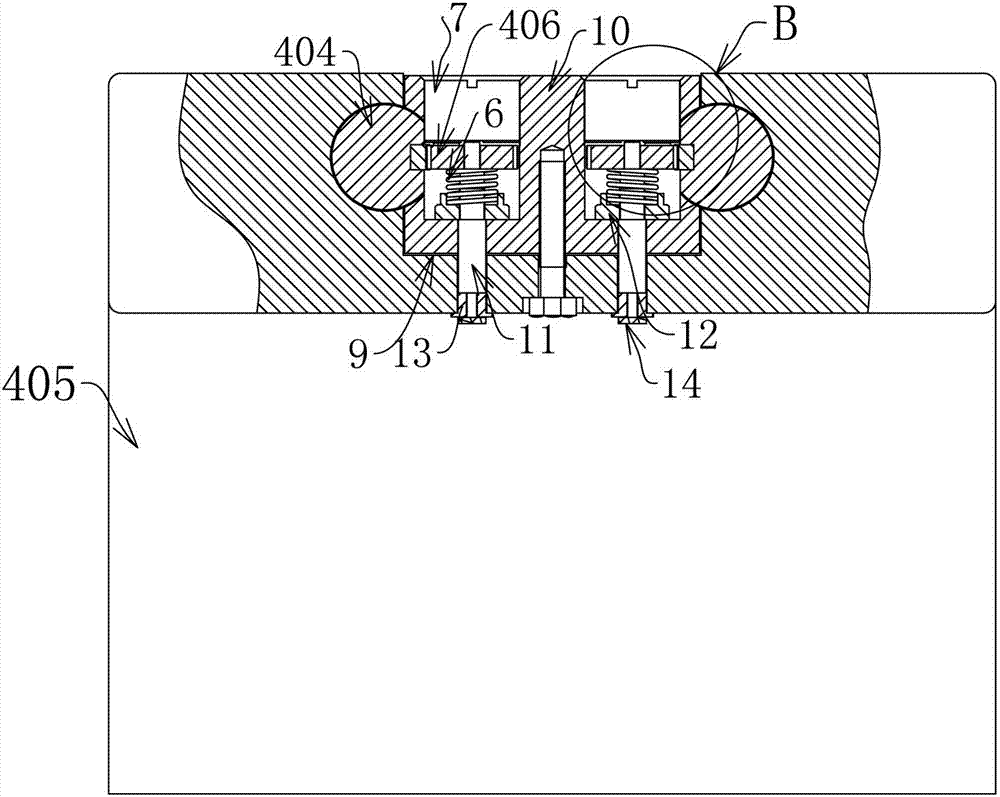

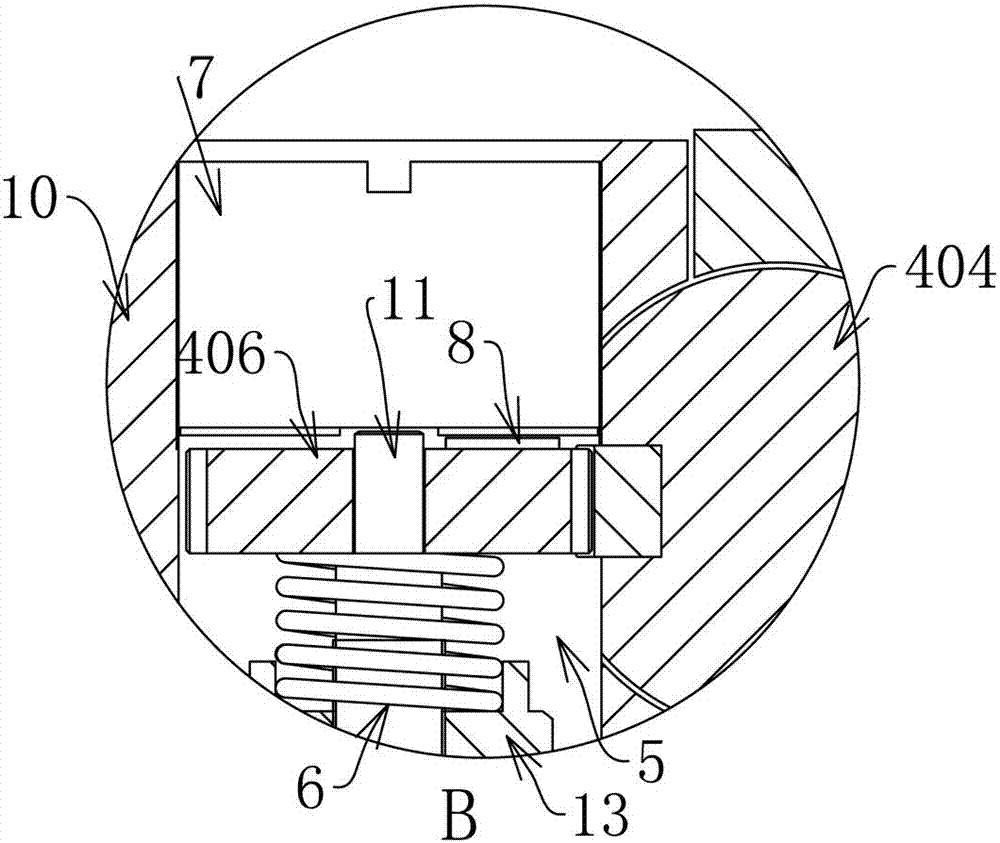

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

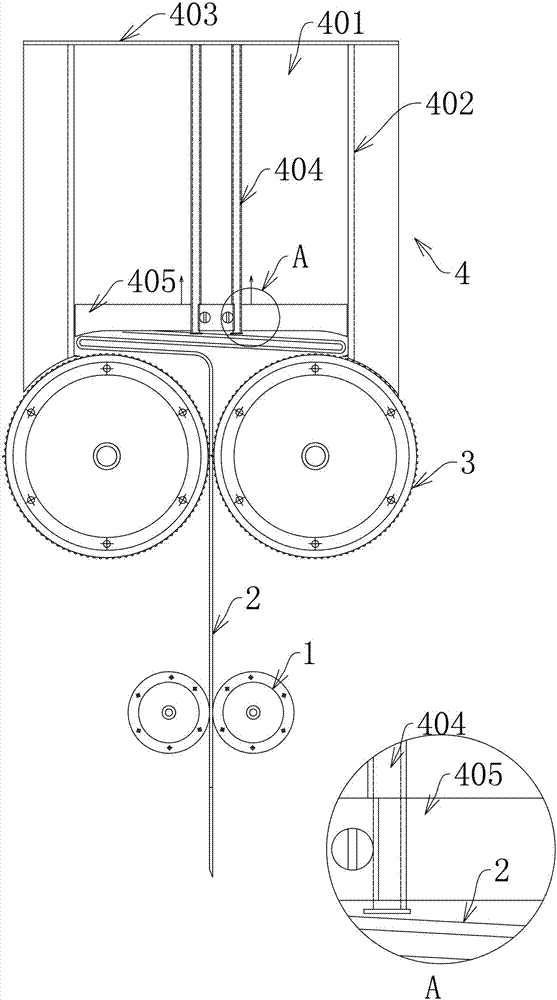

[0015] Such as figure 1 As shown, the roller pair 1 is included, and the roller pair 1 is relatively installed and forms a gap through which the gauze 2 passes. Each roller pair 1 maintains the same linear speed, so that the gauze 2 is conveyed at the same speed. Between 2 and two folding rollers 3, the folding rollers 3 may have slots and inserting knives at intervals. Groove, when rotating, the slotting knives of two folding rollers 3 are inserted into the slots of the other side in turn, so that the flexible strips passing between the two folding rolls 3, such as gauze 2, are inserted into the slots of another folding roll 3 by slotting knives , to realize the bending of the gauze 2, the folding roller 3 continues to rotate, and continues to rotate with the part inserted into the slot as the pulling point, then the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com