Ionic intermediate membrane raw material modification method and manipulator applied to sterile production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for modifying an ionic intermediate membrane raw material, comprising the steps of:

[0052] Step 1. Stir the sarin base material with a certain proportion of KH550 and ECH additives;

[0053] Step 2, adding a silane coupling agent to the mixture in the above step 1, and stirring at a high speed; adding monomer glycidyl methacrylate in the step 2.

[0054] Step 3: Add the mixture of the above step 2 into a granulator, and granulate and modify it at a temperature of 170° C. in the granulator.

[0055] Adding a silane coupling agent to the raw material improves the adhesion between the material and the glass, and at the same time, due to the effect of the coupling agent, the water boiling resistance of the material is improved; The introduction of epoxy groups into the material chain improves the boiling resistance of the material without affecting the transparency and haze of the material.

[0056] The modified ionic interlayer material of the present inventio...

Embodiment 2

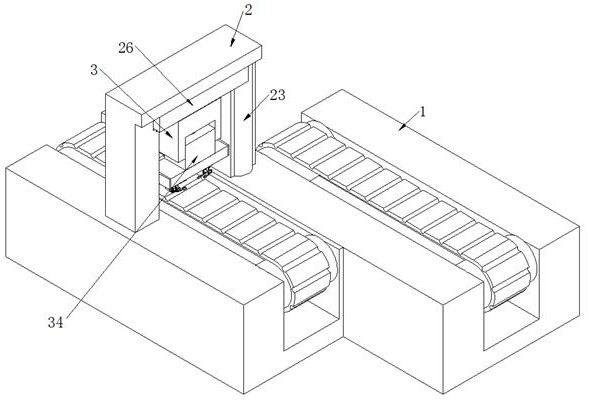

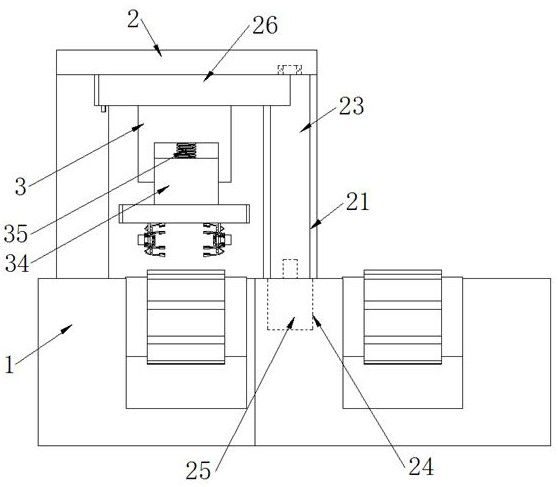

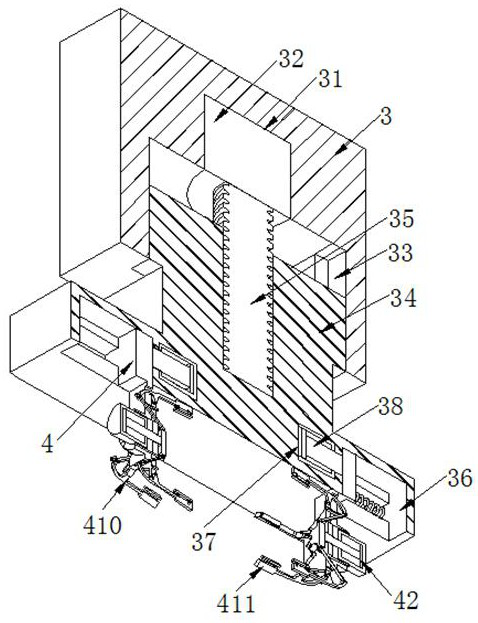

[0058] refer to Figure 1-10 , a manipulator for the aseptic production of ionic interlayer raw materials, including a transmission part 1, a transfer device, a lifting device and a gripping device, the inner walls of both sides of the transfer part 1 are provided with photoelectric contrast switches, and the transfer device is fixedly installed on the transfer On the upper surface of part 1, the lifting device is fixedly installed on the lower surface of the transfer device, the clamping device is arranged inside the lower end of the lifting device, and the lifting device controls the clamping device to descend and slide left and right;

[0059] Such as Figure 1-2 and Figure 4 As shown, the transfer device includes a connection frame 2, the lower surface of one side of the connection frame 2 is provided with an arc-shaped slot 21, and the inner wall of one side of the arc-shaped slot 21 penetrates and extends to the outer surface of the connection frame 2;

[0060] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com