UV hardening liquid for PET electronic membrane as well as preparation method and application thereof

A technology of hardening liquid and electronic film, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of scratch resistance, poor wear resistance, large shrinkage of coating film volume, residual UV monomer, etc., and achieve good boiling resistance , Coating film volume shrinkage is small, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

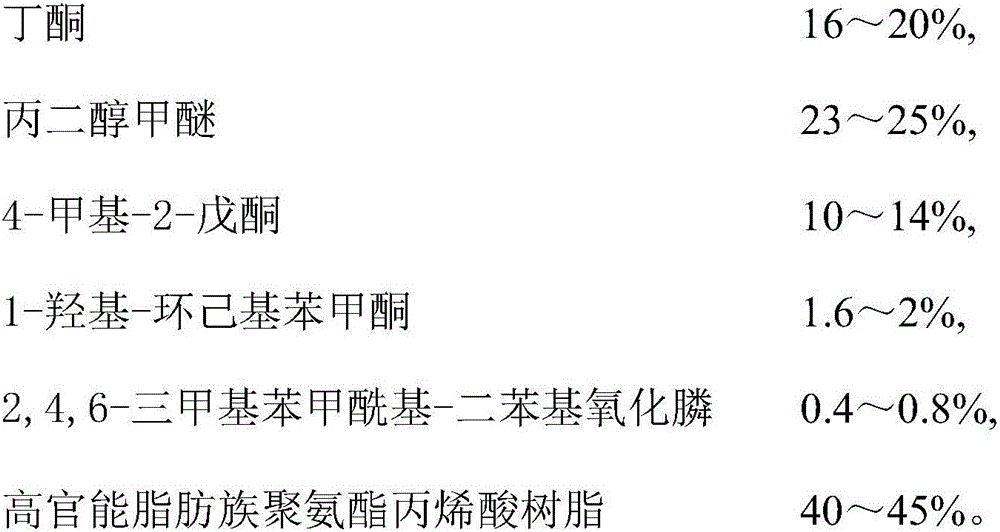

Method used

Image

Examples

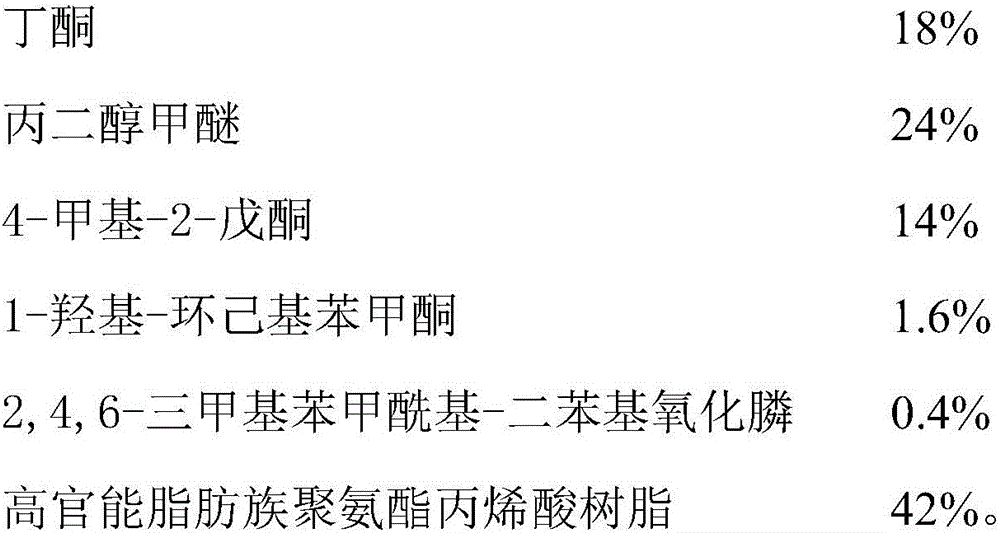

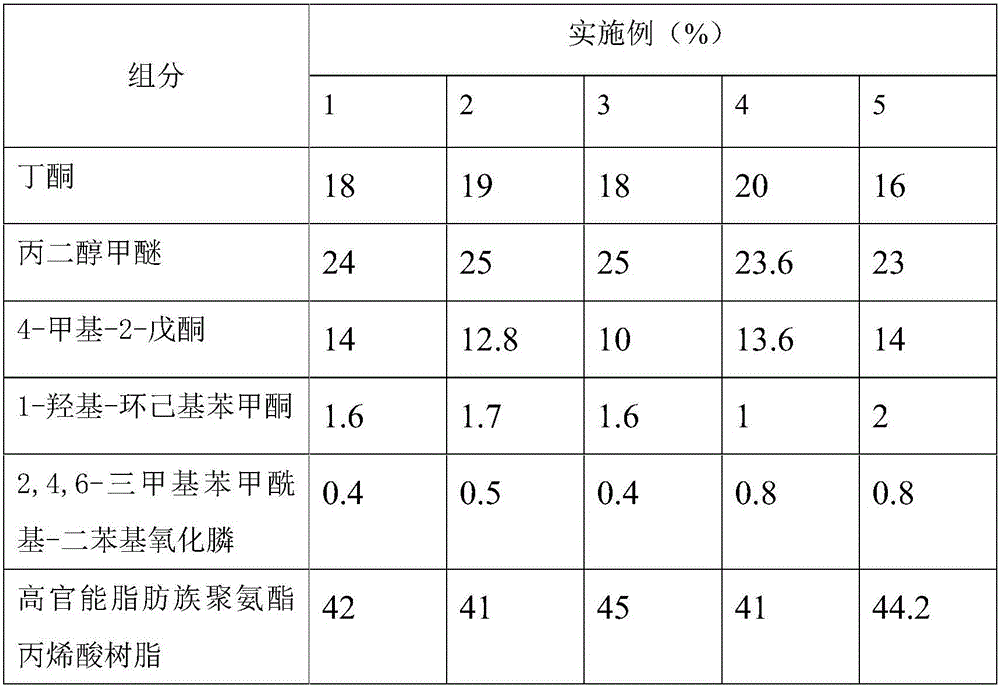

Embodiment 1-5

[0036] The preparation methods of Examples 1-5 are:

[0037] 1) Mix 1-hydroxy-cyclohexyl benzophenone and 2,4,6-trimethylbenzoyl-diphenyl phosphine oxide in a container at room temperature;

[0038] 2) Add methyl ethyl ketone, propylene glycol methyl ether and 4-methyl-2-pentanone into the container, and stir at 500r / min for 2.5h and stir evenly;

[0039] 3) Add the high-functional aliphatic urethane acrylic resin to the container, continue to stir at 500r / min for 2.5h, stir evenly, and then use a 10nm filter bag for pressure filtration to obtain the UV hardening liquid for PET electronic film.

[0040] The prepared products of Examples 1-5 were placed in a clean opaque container during storage, and sealed for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com