Transfer trolley for factory steel pipes

A technology for transfer vehicles and steel pipes, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., and can solve problems such as dragging steel pipes to the ground, difficulty in ensuring the stability of transfer vehicles, and deformation of carts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Since there must be a crane structure in the workshop of the existing steel pipe production enterprise, it is completely unnecessary to set the lifting structure on the trolley in the prior art. The present invention is mainly to ensure the carrying capacity and stability of the transfer vehicle.

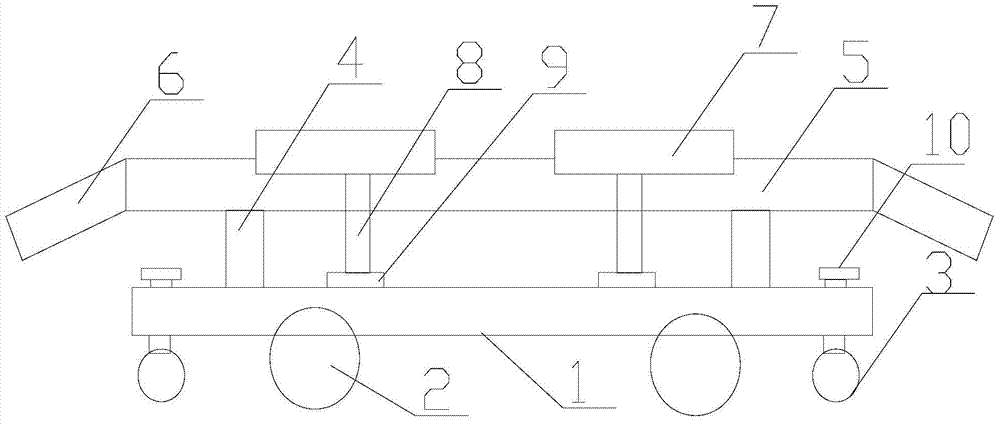

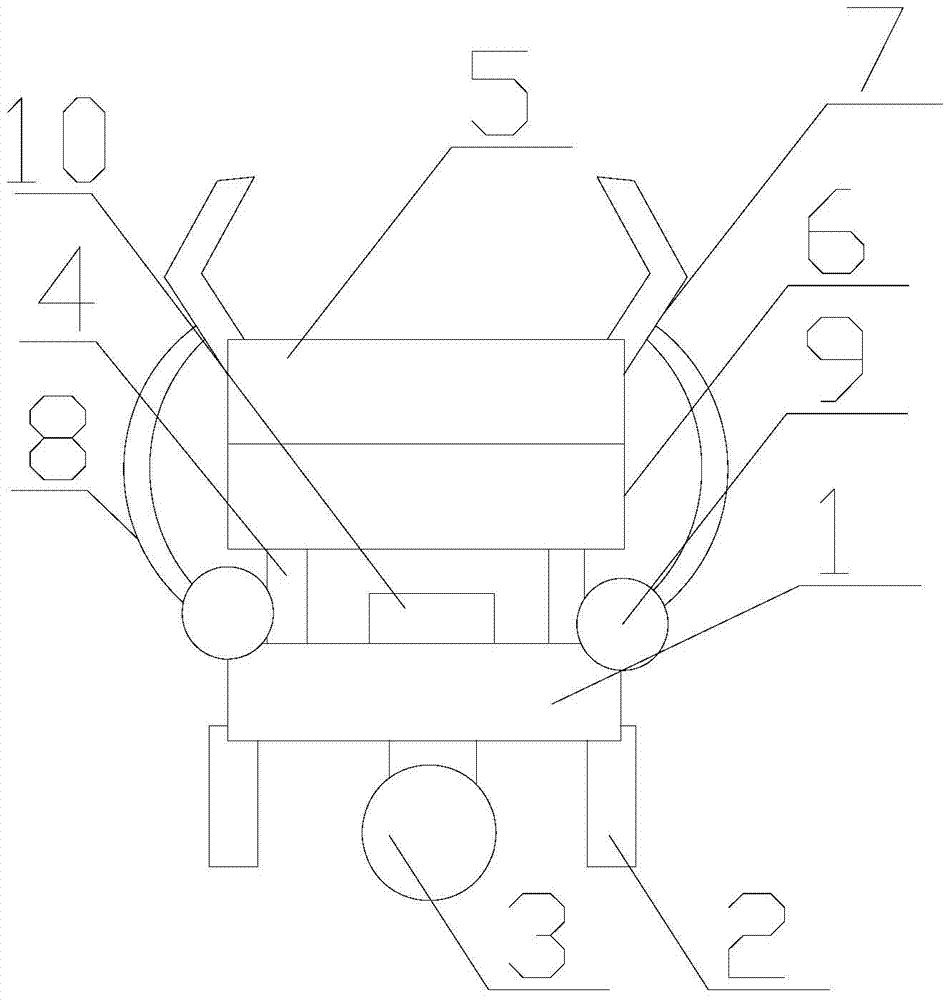

[0014] like figure 1 as well as figure 2 Shown: a factory steel pipe transfer vehicle, including a moving assembly and a carrying assembly, the moving assembly includes traveling wheels 2 fixed on both sides of the bottom plate 1 and steering wheels 3 fixed on the front and rear ends of the bottom plate 1, and the carrying assembly includes the bottom plate 1, the carrying plate 5 fixed by the shock-absorbing support column 4, the front and rear ends of the carrying plate 5 are fixed with downwardly inclined extension plates 6, and the side of the carrying plate 5 is provided with at least one set of baffles 7, the baffles 7 is fixed on the rotating roller 9 of the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com