Yarn winding device and yarn winding process

A winding device and yarn technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problem of yarn unraveling, reduce the precision of yarn winding operation, and affect yarn processing Efficiency and other issues to achieve the effect of ensuring tightness, ensuring that it will not scatter, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

[0029] In addition, the following terms are defined based on the functions in the present invention, and may be different according to the user's or operator's intention or practice. Therefore, these terms are defined based on the entire content of this specification.

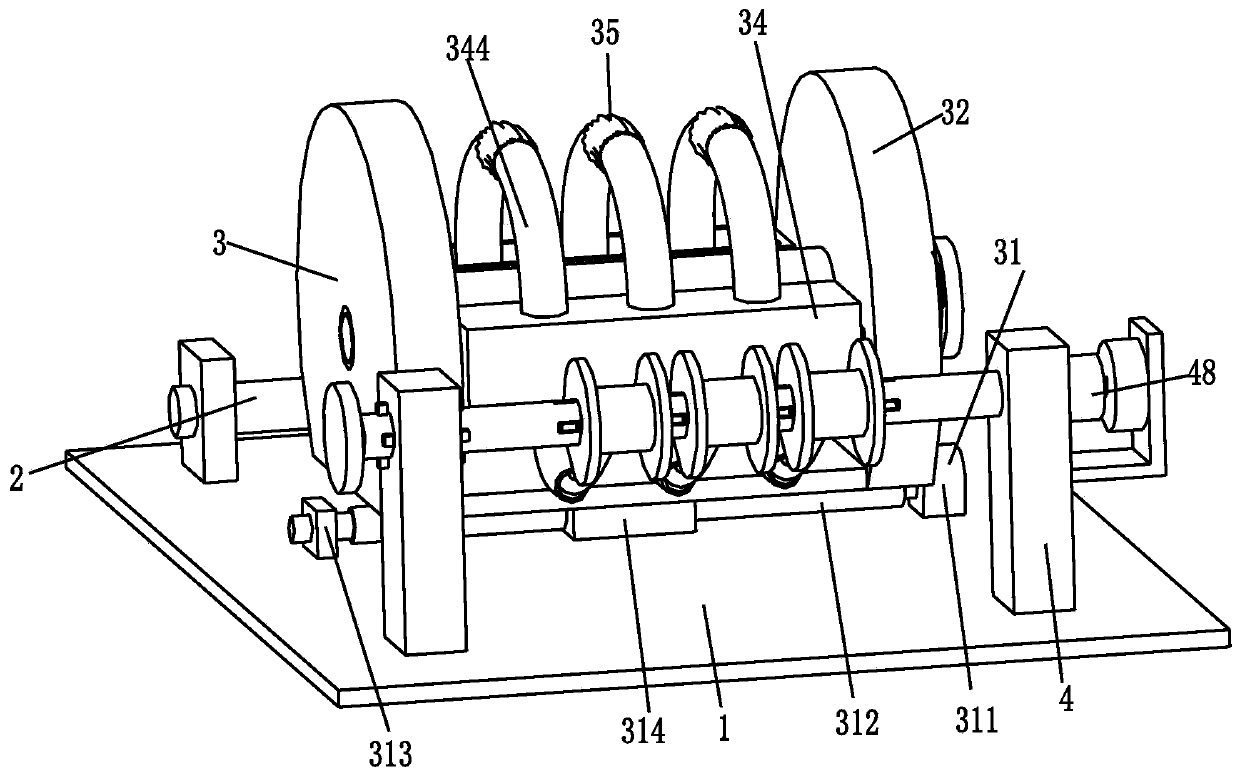

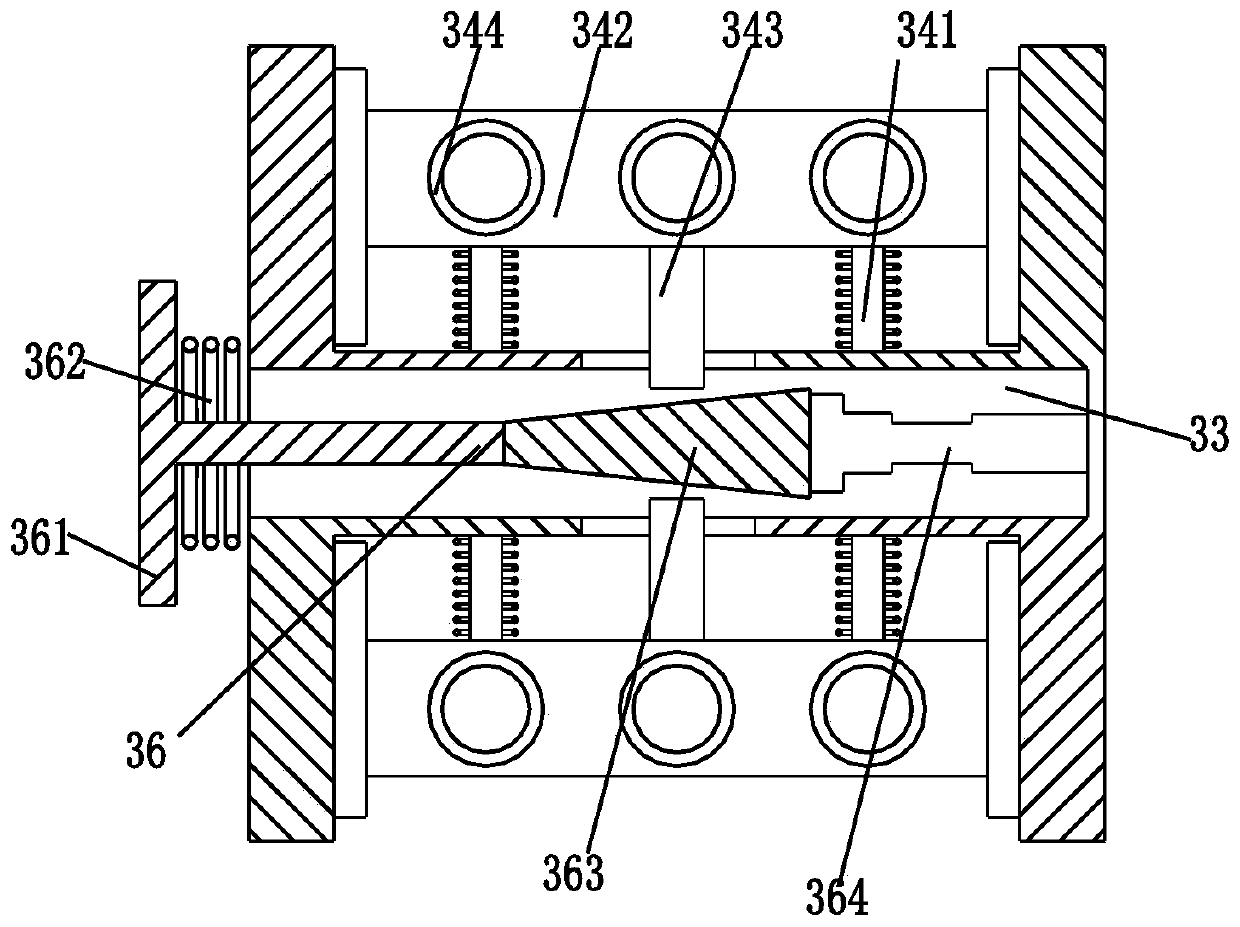

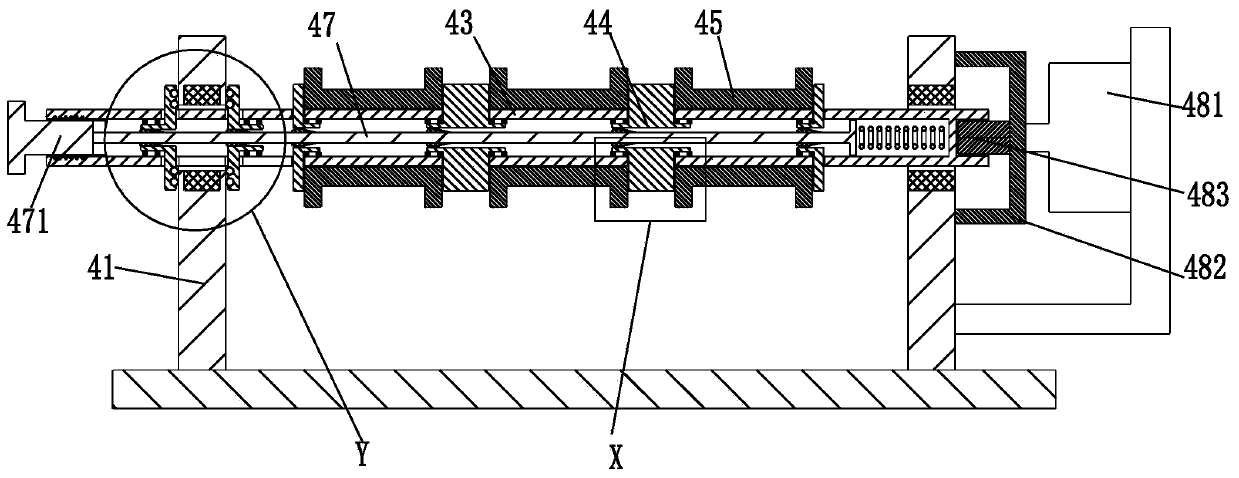

[0030] Such as Figure 1 to Figure 5 As shown, a yarn winding device includes a bottom plate 1, on which a winding roller 2, a tensioning device 3 and a winding device 4 are sequentially arranged from back to front;

[0031] The yarn goes around the winding roller 2 and is connected to the tensioning device 3 , and the yarn is wound on the winding device 4 after being stretched by the tensioning device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com