Hydraulic supporting control mechanism of roller connecting shaft and relevant puncher and relevant pipe milling machine

A technology of hydraulic support and control mechanism, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of the sinking of the roll joint shaft, the large rotation diameter of the roll joint shaft, and the reduction of the force on the roll joint 107, etc. Achieve the effect of prolonging the life, reducing the diameter of rotation and improving the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

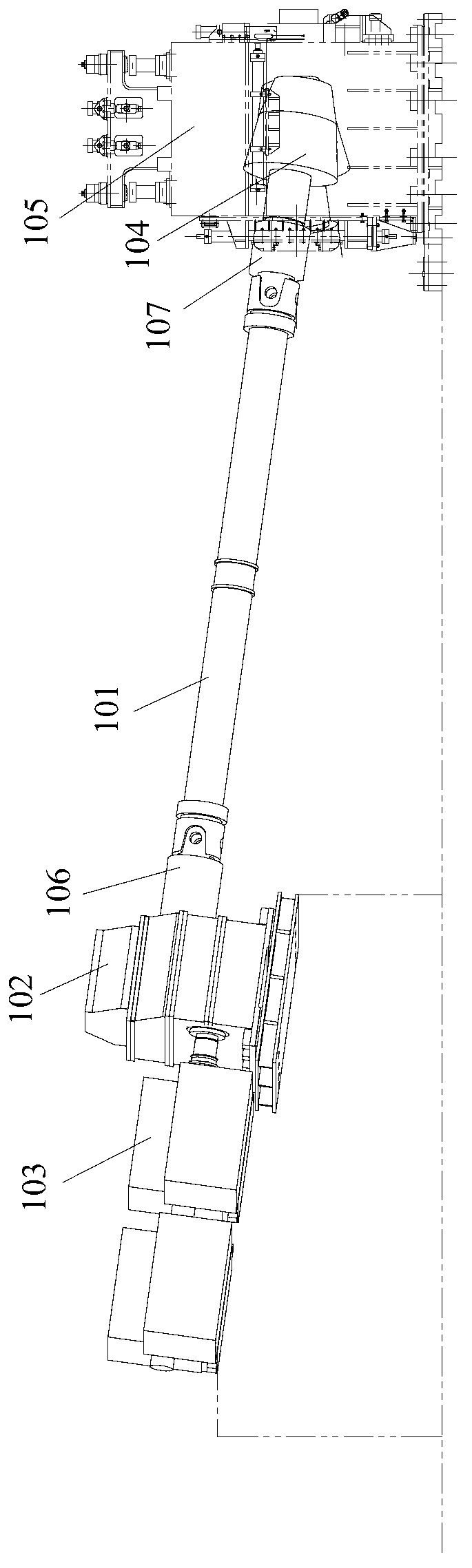

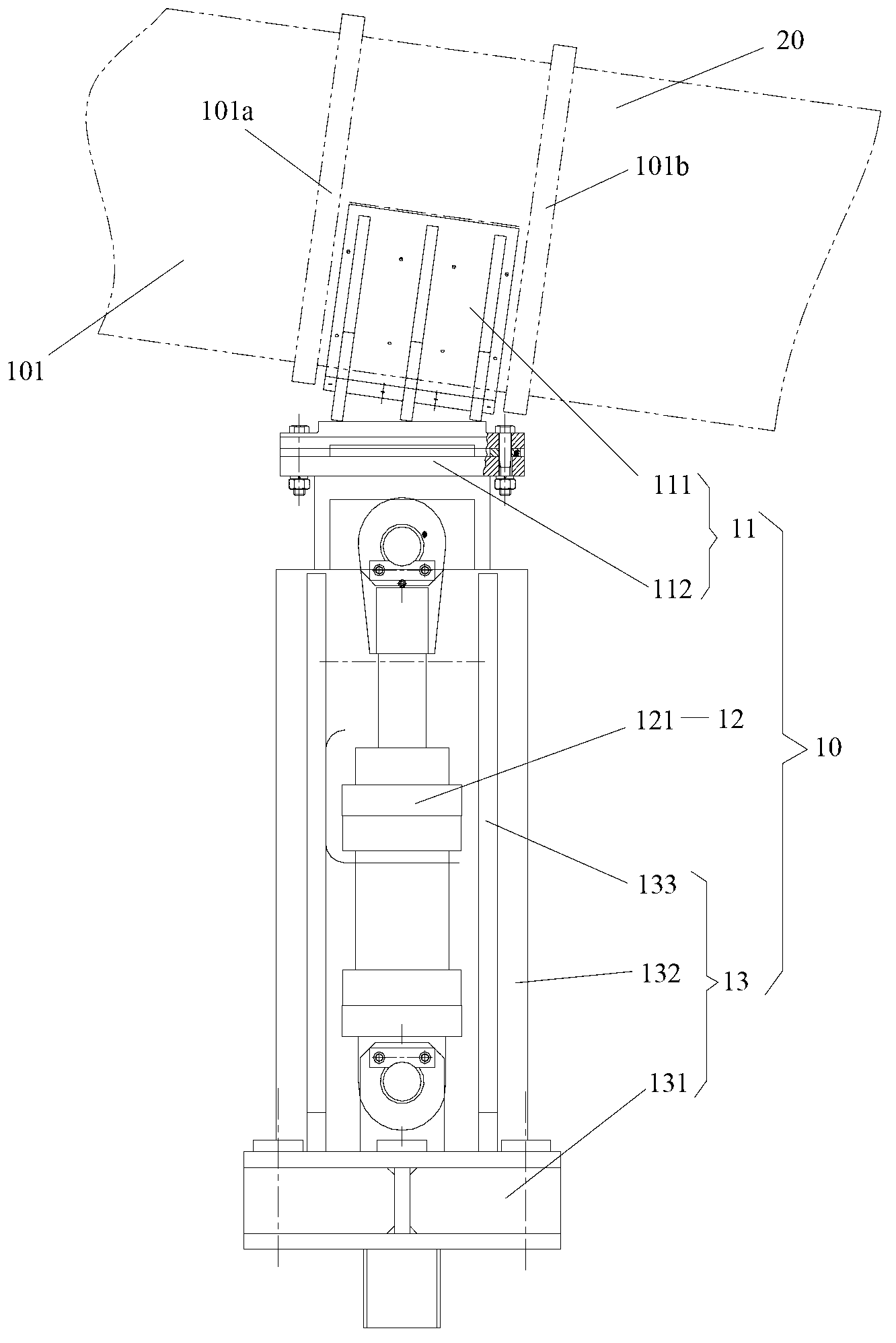

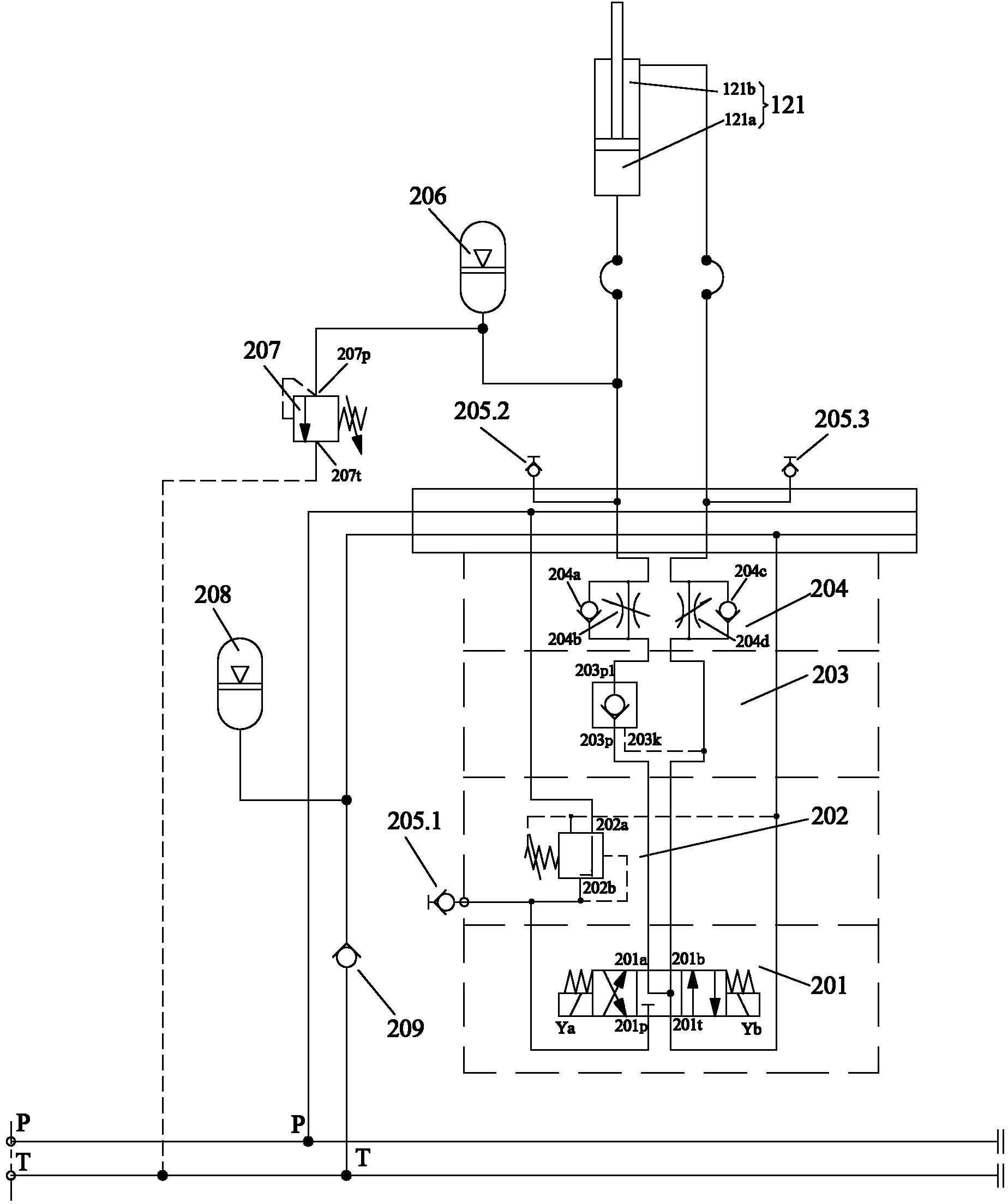

[0018] figure 2 Shown is a schematic diagram of the hydraulic support control mechanism of the roll joint shaft according to an embodiment of the present invention. Such as figure 2 As shown, the present invention is provided with a hydraulic control support mechanism 10 for supporting the roll connection shaft 20 below the roll connection shaft 20. The hydraulic control support mechanism 10 includes a connection shaft support seat 11 that contacts and supports the roll connection shaft 20, a hydraulic support Control system 12 and hydraulic cylinder mount 13.

[0019] The shaft connection support seat 11 supports the roll connection shaft 20 upwards from the lower middle part of the roll connection shaft 20 , and the shaft connection support seat 11 and the roll connection shaft 20 are in sliding contact with the bearing bush. The hydraulic cylinder 121 of the hydraulic support control system 12 is arranged in the hydraulic cylinder installation seat 13, and the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com