Engine power transmission output structure

A power transmission and output structure technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as difficulty in increasing power, reducing fuel consumption rate, and increasing stroke, so as to achieve power increase and manufacturing material saving , The effect of reducing the diameter of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

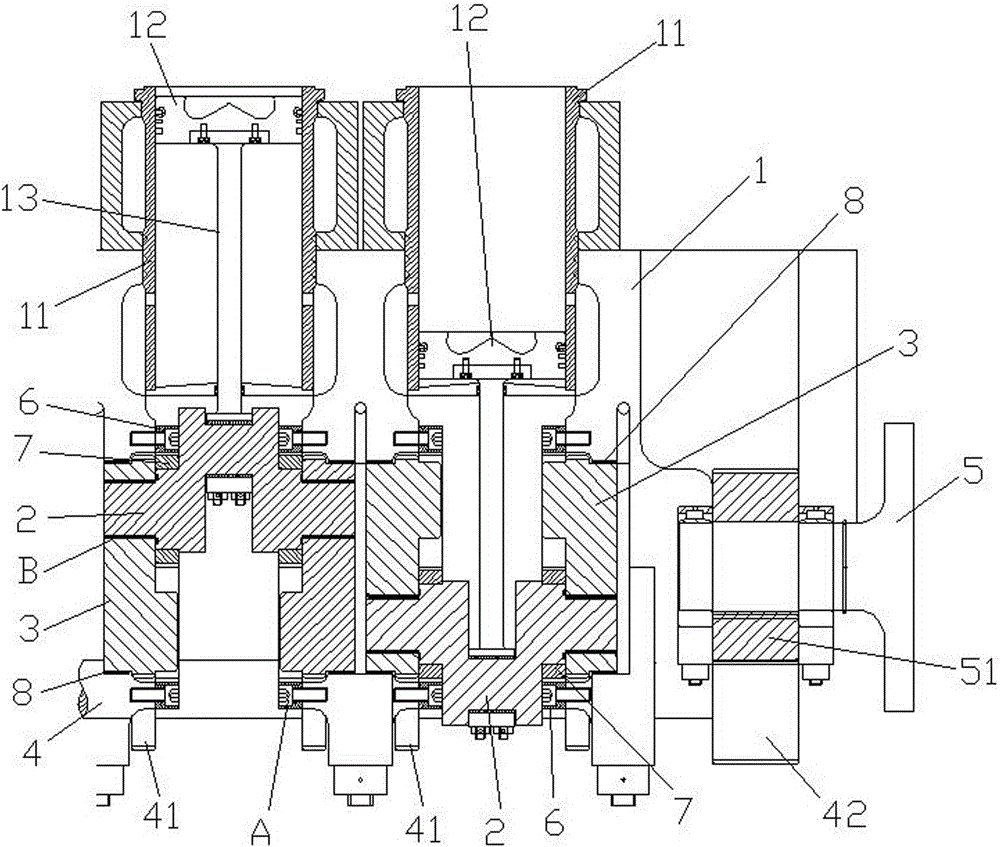

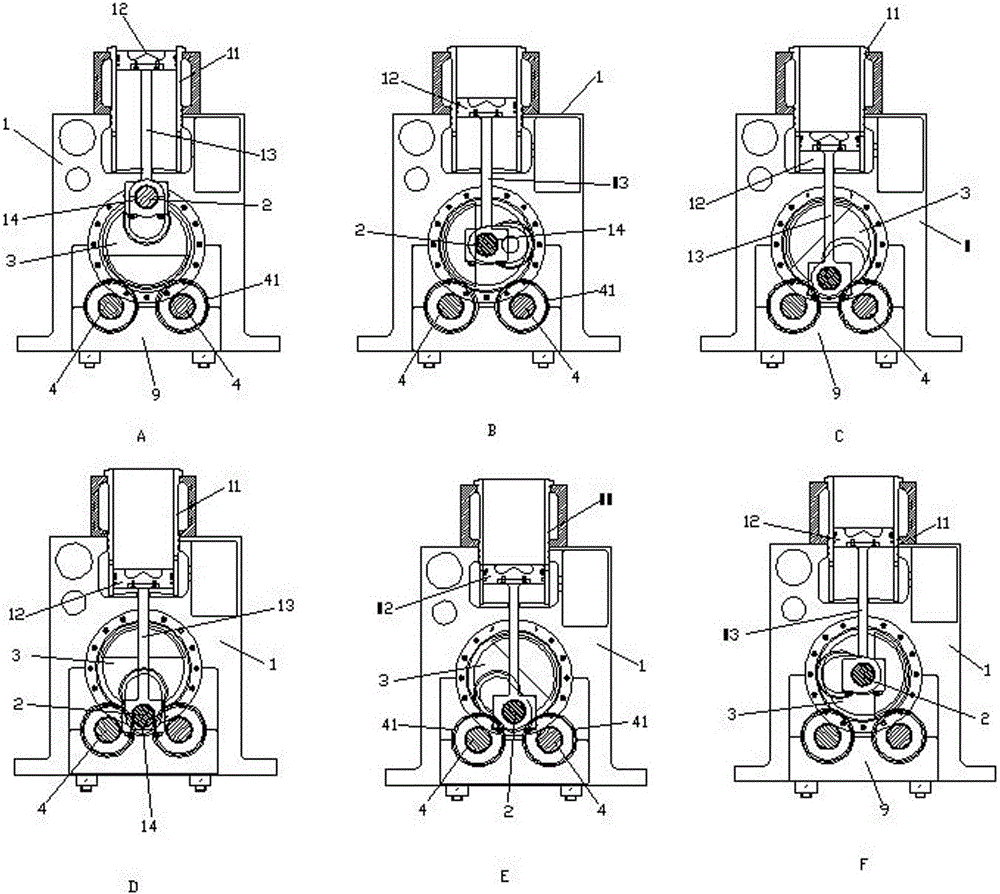

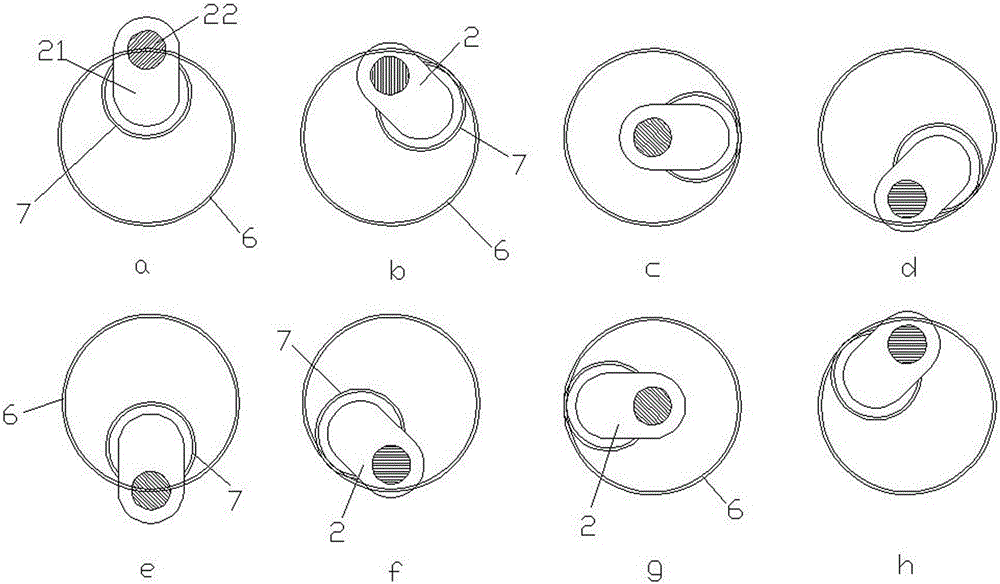

[0029] Figure 1 to Figure 10 It is a schematic diagram of the principle of the embodiment of the present invention.

[0030] The reference signs are: large gear bolt A, sliding bearing B, thrust ring C, rotation axis L, engine body 1, cylinder liner 11, piston 12, piston rod 13, connecting rod bush 14, rocker crank Pin 2, rocker crank 21, crank pin 22, output rocker gear 3, hub disc 31, transmission external gear 31a, rocker bearing hole 31b, balance weight 32, shaft section 33, torque common rail transmission shaft 4, output gear 41. Main drive gear 42, engine flywheel 5, slave drive gear 51, guide bull gear 6, inner ring teeth 61, guide pinion gear 7, outer ring teeth 71, main bearing bush 8, main bearing cap 9.

[0031] Figure 1 to Figure 10 It is the structure and transmission schematic diagram of the present invention, as shown in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com