An Electric Drive Hydraulic Independent Suspension Coiled Tubing Chassis

An independent suspension and electric drive technology, applied in suspension, elastic suspension, motor vehicles, etc., can solve problems such as inability to adapt to desert area operations, large turning diameter, and difficult turning, and achieve high off-road performance and ride comfort. Effects of increased usable space and small turning diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

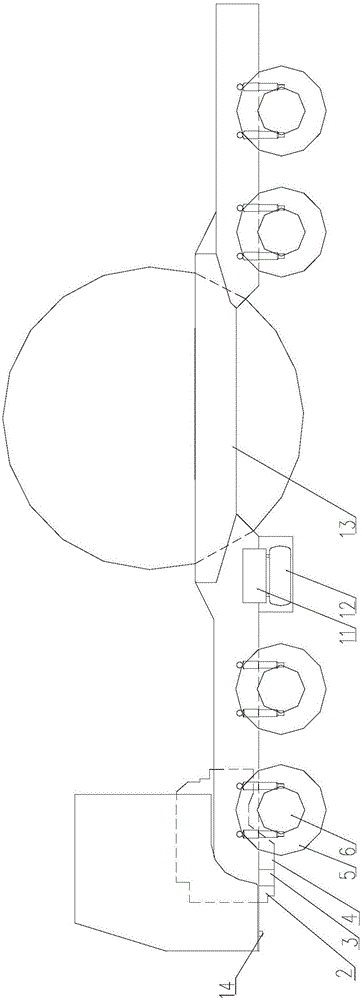

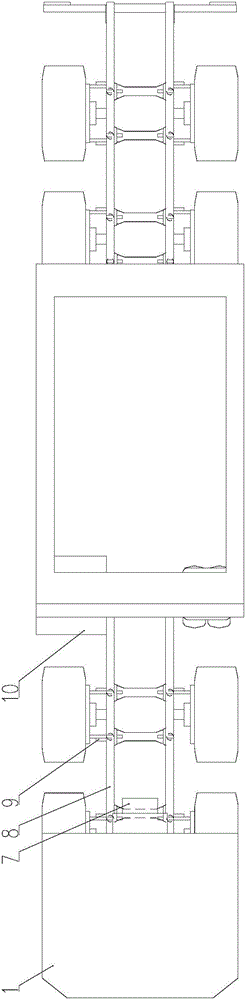

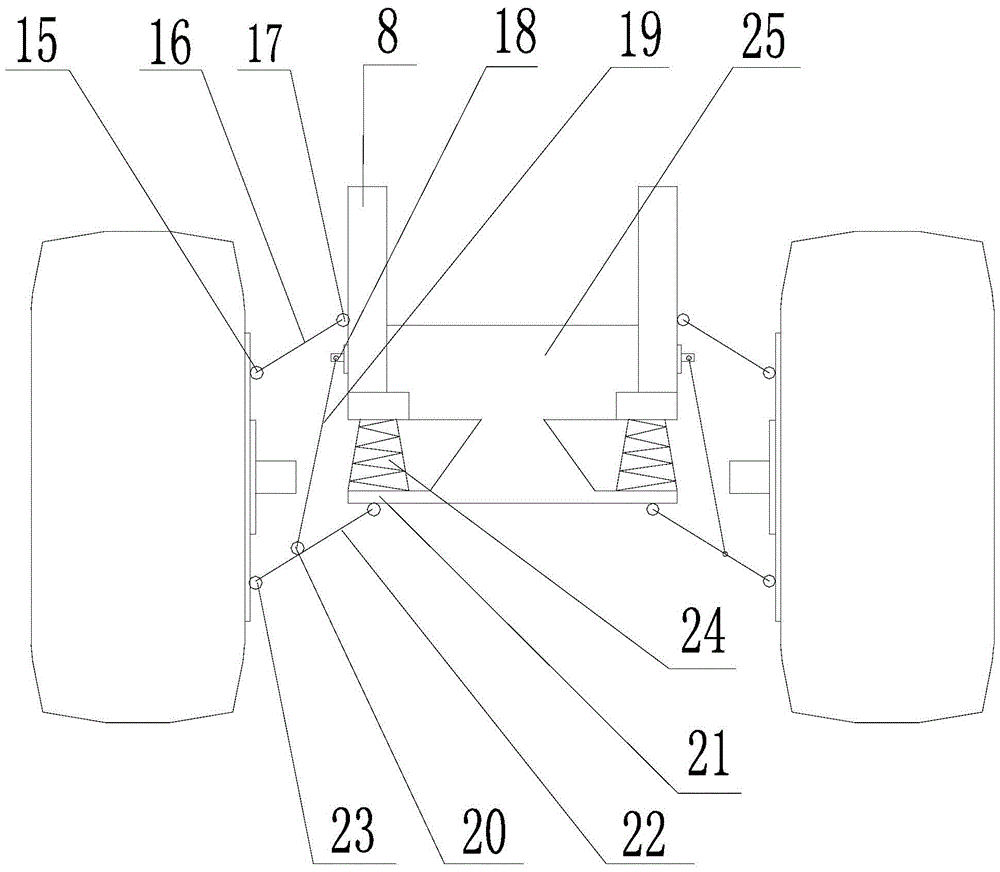

[0030] Such as Figure 1-2 As shown, an electrically driven hydraulic independent suspension coiled tubing chassis according to an embodiment of the present invention includes: a vehicle frame, which includes a longitudinal beam 8, a plurality of beams 28, a hollow frame beam 13 and a plurality of composite Crossbeam 25; the front end of the vehicle frame is equipped with a cab 1, the longitudinal beam 8 is connected with the hydraulic independent suspension system 9, and the hydraulic independent suspension system 9 is connected with the electric wheel 6, and the electric wheel 6 is installed There are tires 5; a generator set 2, a cooling system 3, and an exhaust system 4 are installed on the inner side of the front part of the vehicle frame; the generator set 2 includes an engine, a DC generator and an alternator; The power take-off 7 connected to the engine in the generator set 2, an electronic control system 11 and a braking system 12 are also installed on the vehicle fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com