An integrated middle beam frame for new energy vehicles

A new energy vehicle, forming technology, applied in the direction of vehicle components, substructure, transportation and packaging, etc., can solve the problems of small weight loss of the whole vehicle, difficulty in assembly installation, high precision requirements, etc., to achieve weight reduction, low center of mass, Improve the effect of diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

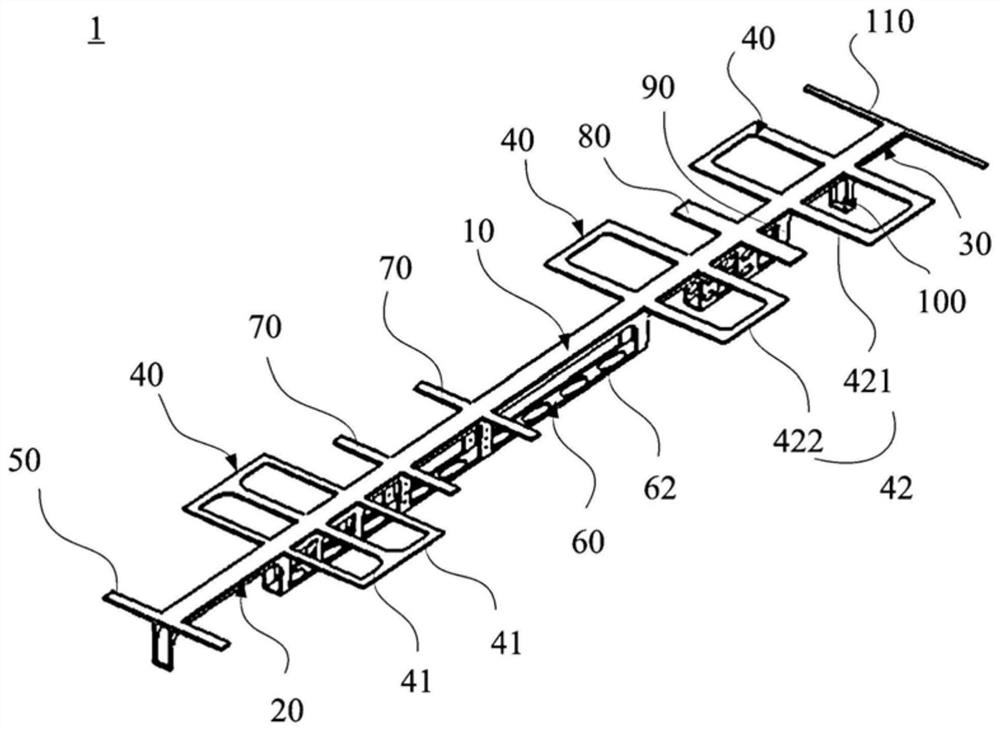

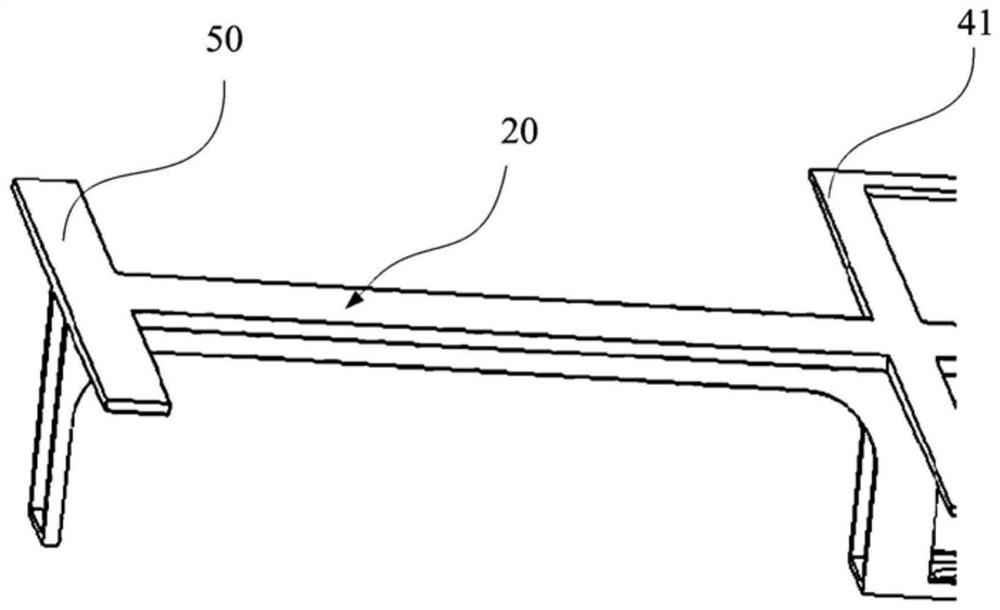

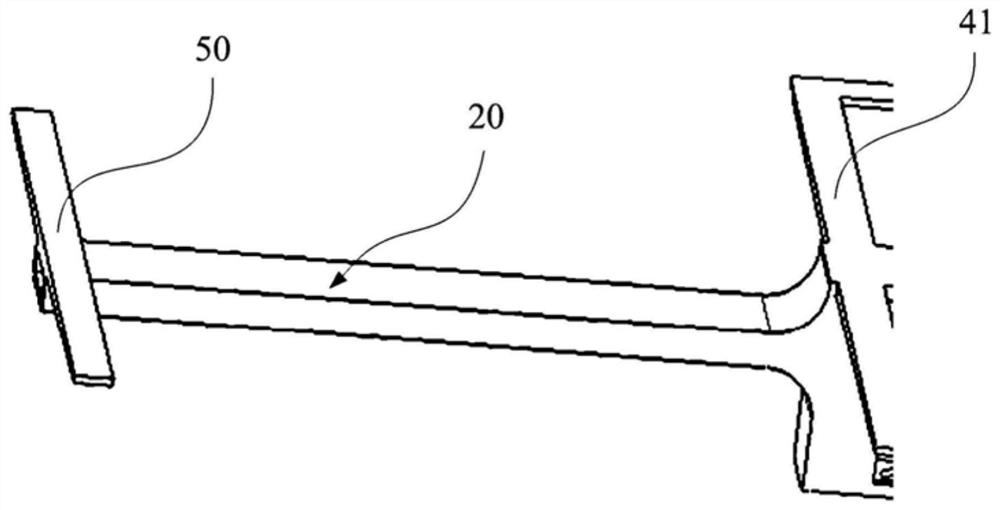

[0043] figure 1 It shows an overall schematic structural view of an integrally formed center beam frame for a new energy vehicle according to an embodiment of the present invention. The material of the integrally formed center beam frame 11 includes but not limited to steel, aluminum, magnesium alloy and non-metallic polymer materials and the like. Such as figure 1 As shown, the one-piece center beam frame 11 includes a central spine 10 , a front suspension bracket installation area 20 , a rear suspension bracket installation area 30 and a plurality of rectangular frame beams 40 . Among them, the central spine 10 extends along the length direction of the vehicle. The front suspension bracket installation area 20 and the rear suspension bracket installation area 30 are respectively located at the front and rear of the central spine 10 . A plurality of rectangular frame beams 40 are located between the front suspension bracket installation area 20 and the rear suspension brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com