A large pyrolysis device

A pyrolysis, large-scale technology, applied in the direction of indirect heating dry distillation, special form dry distillation, coke oven, etc., can solve the problems of large differences in motion trajectories, large differences in heat exchange efficiency, and low overall thermal efficiency, and achieve high energy utilization. , the effect of high space utilization and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

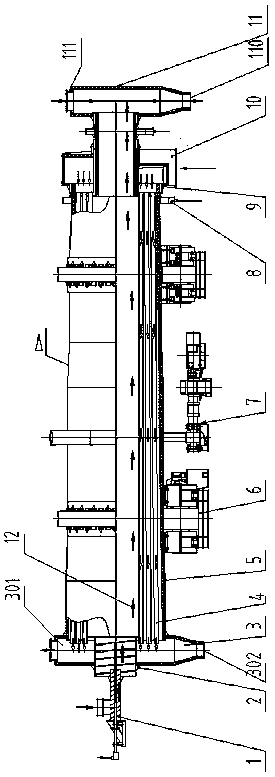

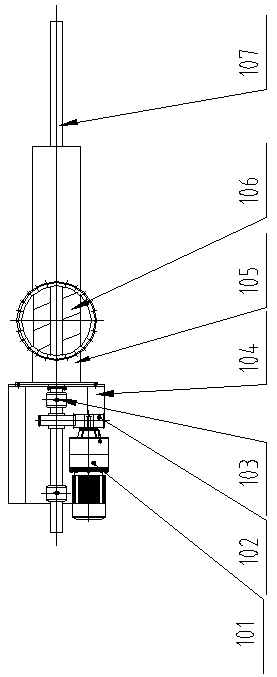

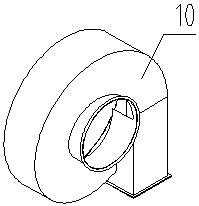

[0020] Such as Figure 1~7 As shown, the large-scale pyrolysis device includes a cylinder body 5, a heat exchange tube 4, a feeding device 1, a feed end flue gas hood 3, a discharge end flue gas hood 10 and a discharge hood 11, and the innermost exchanging The heat pipe 4 forms a material channel 12, and the distance between adjacent heat exchange tubes 4 gradually decreases from the feed end to the discharge end to form a tapered material channel 12 whose aperture gradually increases from the feed end to the discharge end; The feeding device 1 is a sleeve-type screw feeding device with a hollow shaft 107 , and the hollow shaft 107 communicates with the inner cavity of the cylinder body 5 .

[0021] The flue gas hood 3 at the feed end is connected to the heat exchange tube 4 and then connected to the flue gas hood 10 at the discharge end to form a heating air flow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com