Polysebacic acid 1, 3-propylene glycol ester-block-polysuccinic acid butanediol block polyester and preparation method and use thereof

A technology of polybutylene succinate block and polybutylene succinate, applied in the field of polymer materials, can solve problems such as undiscovered patent publications and the like, achieve easy control, good thermal stability, Promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

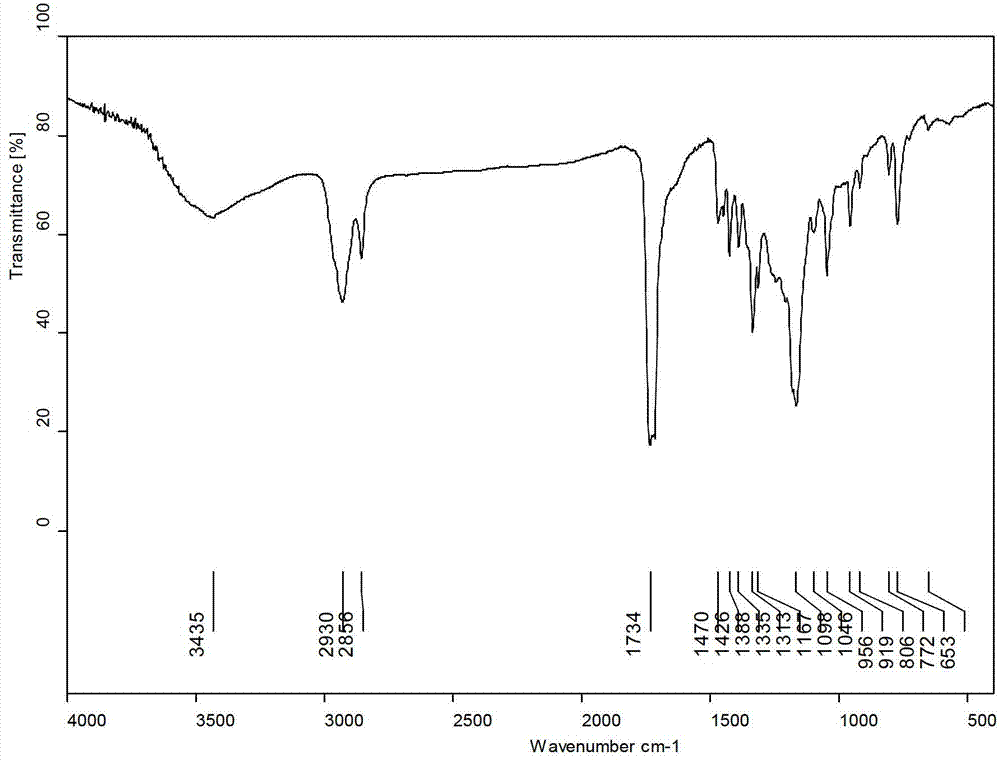

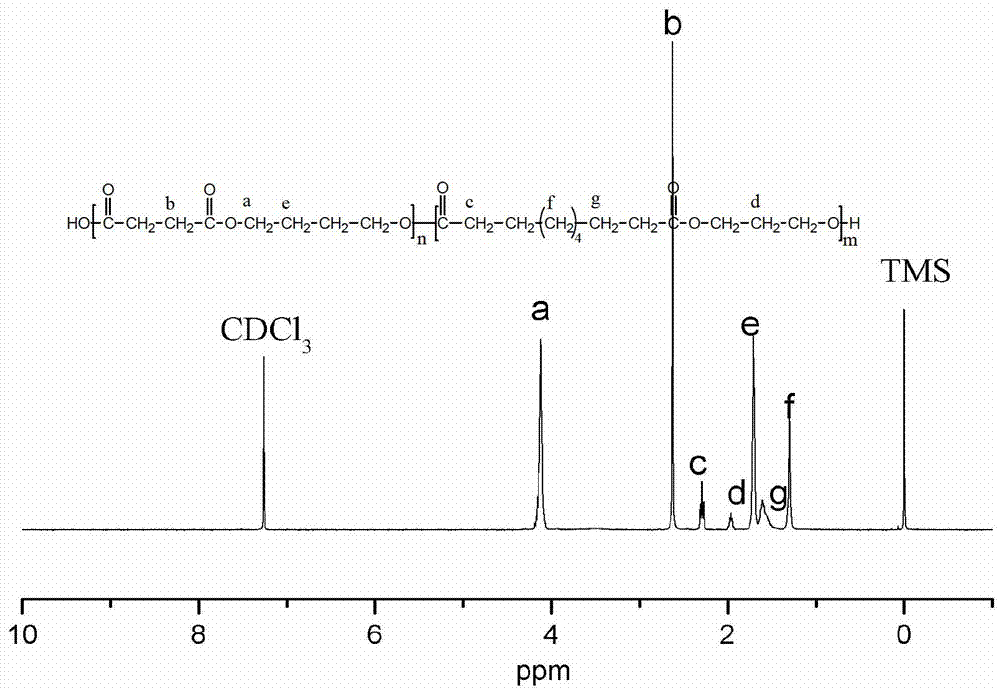

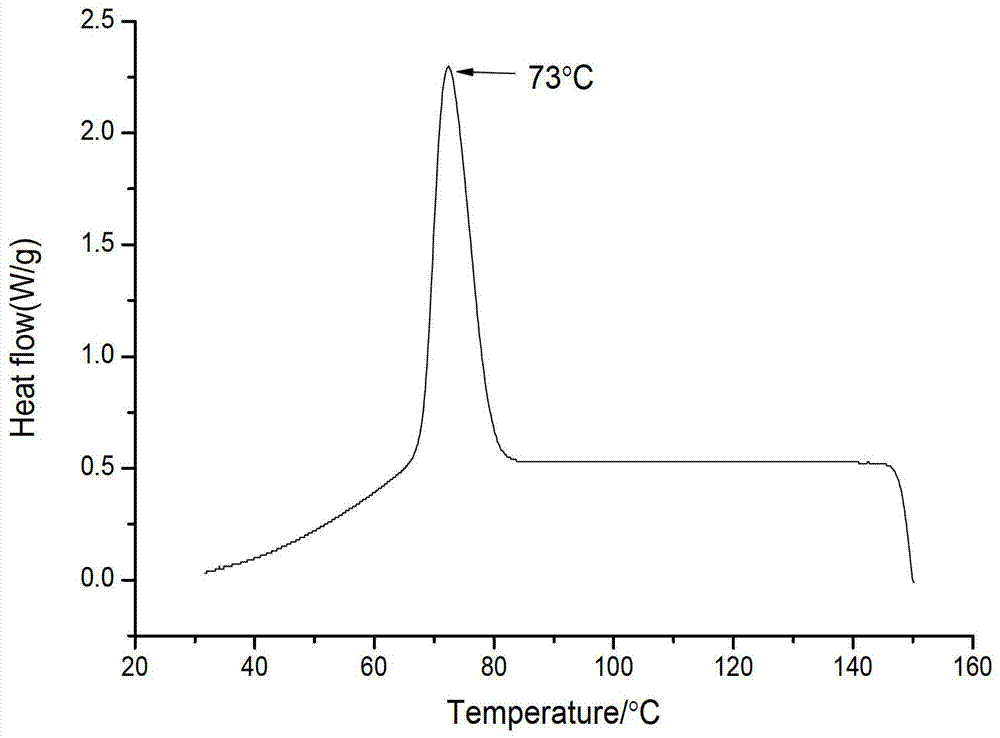

[0045] A kind of poly 1,3-propylene glycol sebacate-block-polybutylene succinate block polyester, its general formula is as follows:

[0046] , the molecular weight range is 10000-50000.

[0047] As mentioned above, the preparation method of poly-1,3-propylene sebacate (PPS)-block-polybutylene succinate (PBS) block polyester (PPS-block-PBS), the steps are as follows:

[0048] (1) Preparation of PBS prepolymer: Weigh 11.8g (0.1mol) of succinic acid and 9.9g (0.11mol) of butanediol respectively, add them to a 250mL three-necked round-bottomed flask, and inject N 2 , the flow rate is 0.05m 3 / h, raise the temperature to 160°C, after the monomer is completely melted, carry out the constant temperature stirring esterification reaction for 1h, after the end of the esterification reaction (generally control the collection amount of water generated during the collection reaction to reach 90% of the theoretical value, it is considered esterification Reaction ends), obtains PBS prep...

Embodiment 2

[0058] A kind of poly 1,3-propylene glycol sebacate-block-polybutylene succinate block polyester, its general formula is as follows:

[0059] , the molecular weight range is 10000-50000.

[0060] As mentioned above, the preparation method of poly-1,3-propylene sebacate (PPS)-block-polybutylene succinate (PBS) block polyester (PPS-block-PBS), the steps are as follows:

[0061] (1) Preparation of PBS prepolymer: Weigh 11.8g (0.1mol) of succinic acid and 10.8g (0.12mol) of butanediol, respectively, into a 250mL three-neck round bottom flask, and pass through N 2 , the flow rate is 0.08m 3 / h, raise the temperature to 160°C, after the monomer is completely melted, carry out the constant temperature stirring esterification reaction for 2h, after the end of the esterification reaction (generally control the collection amount of water generated during the collection reaction to reach 90% of the theoretical value, it is considered esterification Reaction ends), obtains PBS prepoly...

Embodiment 3

[0071] A kind of poly 1,3-propylene glycol sebacate-block-polybutylene succinate block polyester, its general formula is as follows:

[0072] , the molecular weight range is 10000-50000.

[0073] As mentioned above, the preparation method of poly-1,3-propylene sebacate (PPS)-block-polybutylene succinate (PBS) block polyester (PPS-block-PBS), the steps are as follows:

[0074] (1) Preparation of PBS prepolymer: Weigh 11.8g (0.1mol) of succinic acid and 11.7g (0.13mol) of butanediol, respectively, into a 250mL three-necked round-bottomed flask, and pass through N 2 , the flow rate is 0.1m 3 After the temperature is raised to 160°C until the monomer is completely melted, the esterification reaction is carried out with constant temperature stirring for 3 hours. The chemical reaction ends), obtains the PBS prepolymer;

[0075] The general formula of PBS prepolymer is as follows:

[0076] The molecular weight ranges from 1000 to 10000.

[0077] (2) Preparation of PPS prepol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com