Multi-layer type automatic clamp capable of conveniently and rapidly clamping flat boards

A multi-layer, flat-plate technology, applied in the direction of clamping, positioning devices, clamping devices, etc., can solve the problems of inconvenient positioning, affecting the processing accuracy of the workpiece, and slow clamping efficiency, so as to facilitate fast clamping and reduce the cost of clamping. clamping time, reducing the effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with accompanying drawing, the present invention is further elaborated.

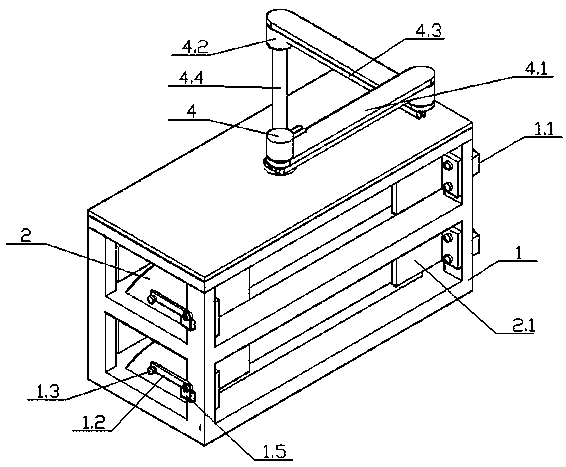

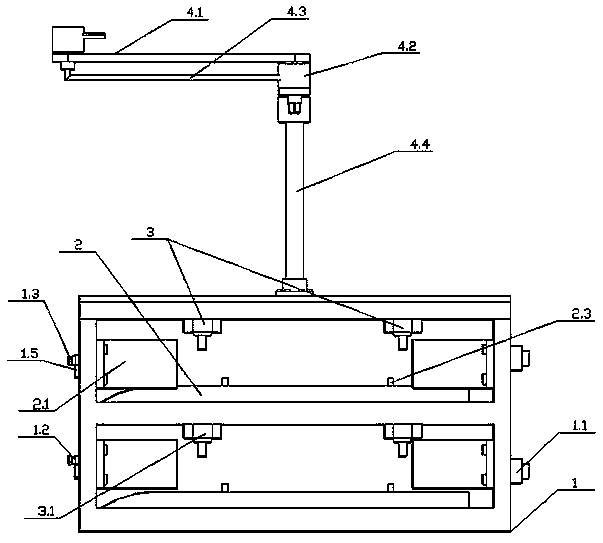

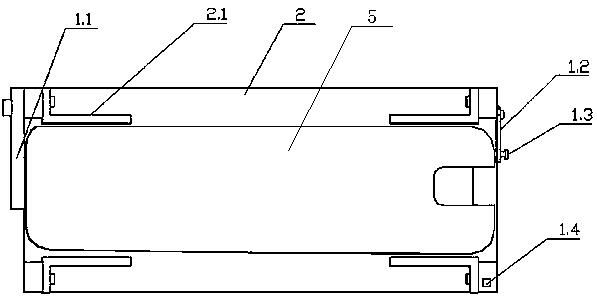

[0021] Such as Figure 1-5 As shown, a multi-layer fixture for fast clamping of a flat plate includes a multi-layer frame 1, a positioning plate 2 and a pressing mechanism 3, wherein the multi-layer frame 1 is fastened by bolts 1.3. Positioning plates 2 are arranged on the top and bottom of each block, and a pressing mechanism 3 that compresses the flat plate 5 is fixed on the top of each positioning plate 2 by bolts 1.3. Except for the pressing mechanism 3 at the top, other All the pressing mechanisms 3 are embedded in the bottom of the positioning plate 2, and the topmost pressing mechanism 3 is embedded in the inner wall of the top of the multi-layer frame 1, and each pressing mechanism 3 is connected with the same set of hydraulic oil circulation mechanism 4, Oil is supplied to the compression mechanism 3 through the hydraulic oil circulation mechanism 4, and a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com