Power line mounting assembly of fan heater and fan heater

A technology for installing components and power cords, applied in the field of power cord installation components and heaters, can solve problems such as hidden safety hazards, unfavorable efficient production of heaters, and complicated power cord installation processes, avoiding direct friction, stable and convenient installation. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiment of the power cord installation assembly of the heater:

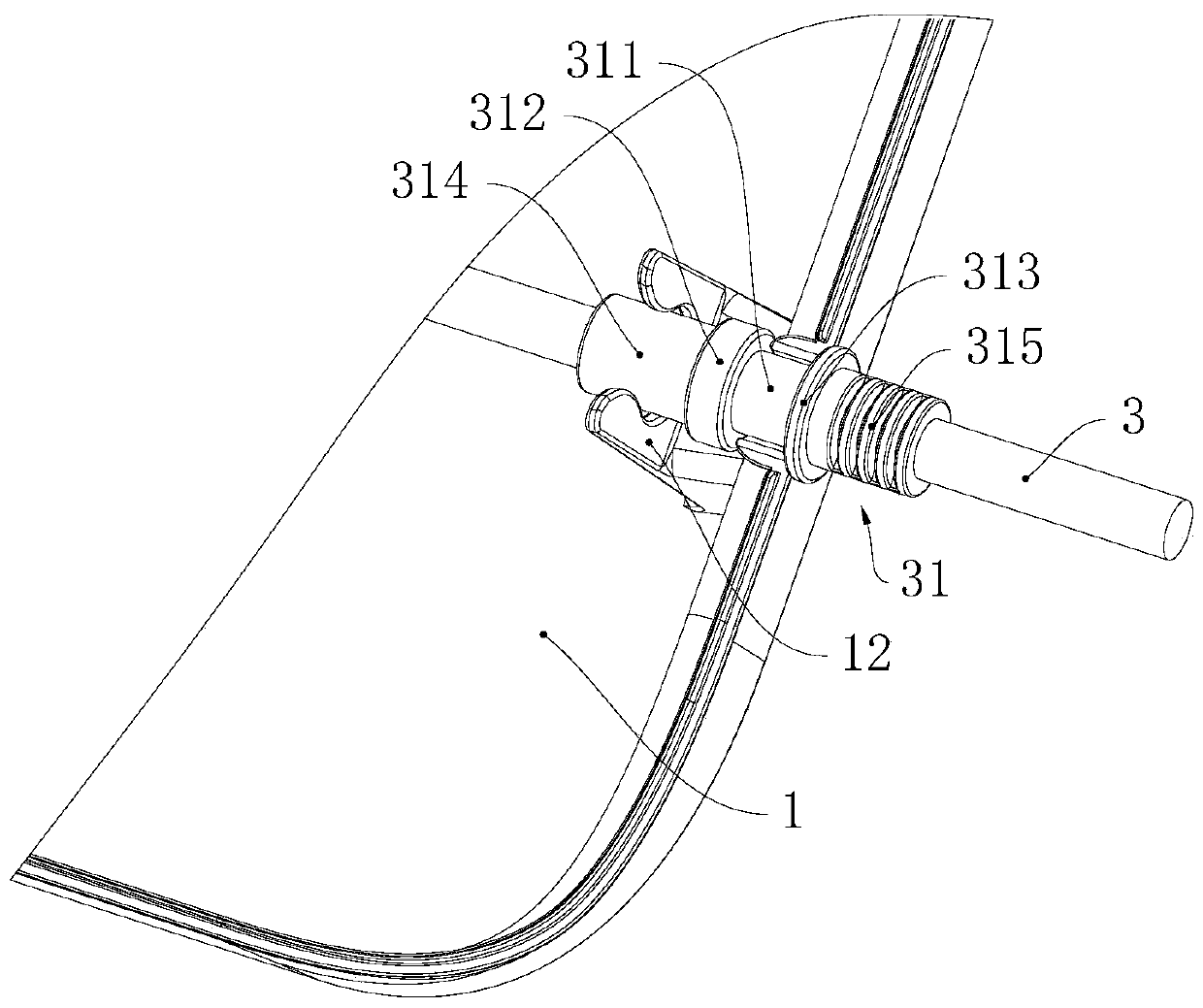

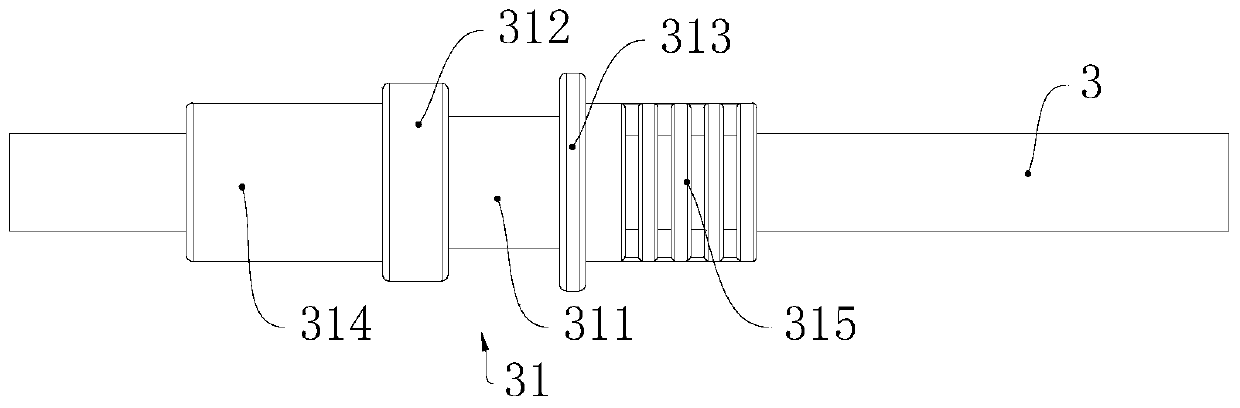

[0040] Please refer to Figure 1 to Figure 4 , this embodiment can be used for wall-mounted heaters. The power cord installation assembly of the air heater in this embodiment includes a first housing 1 , a second housing 2 and a power cord 3 .

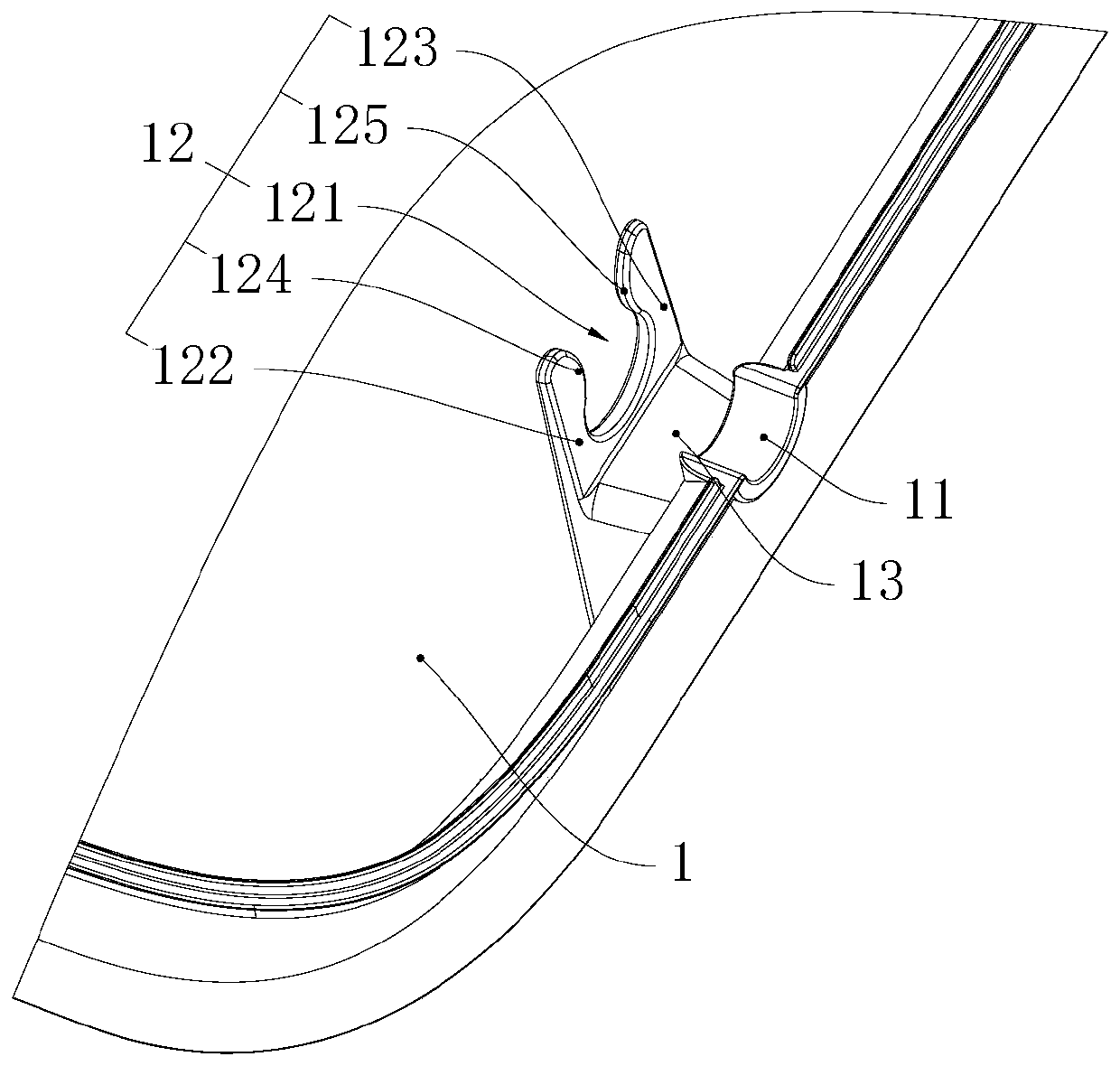

[0041] The first housing 1 is provided with a first half hole 11, a clip 12 and a first auxiliary positioning part 13 arranged between the first half hole 11 and the clip 12, the clip 12 and the first auxiliary positioning part 13 are both Located in the casing of the heater, the first auxiliary positioning part 13 is configured as a semi-circular shape, and the clips 12, the first auxiliary positioning part 13 and the first half hole 11 are distributed along a row.

[0042] The clip 12 has a first clip 122 and a second clip 123 arranged at intervals, one end of the first clip 122 is fixed to the first housing 1, the other end of the first clip 122 is a free e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com