Rubber shell rotatable wiring terminal shell pre-inserting method and device

A technology of rotary type and plastic shell, which is applied in the field of plastic shell rotary cable terminal pre-insertion method and its device, which can solve the problem of not inserting the cable terminal in place, the wire terminal is not inserted into the plastic shell, and the cable terminal plastic shell Damage and other problems, to achieve the effect of reasonable device structure design, simple and convenient equipment maintenance, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

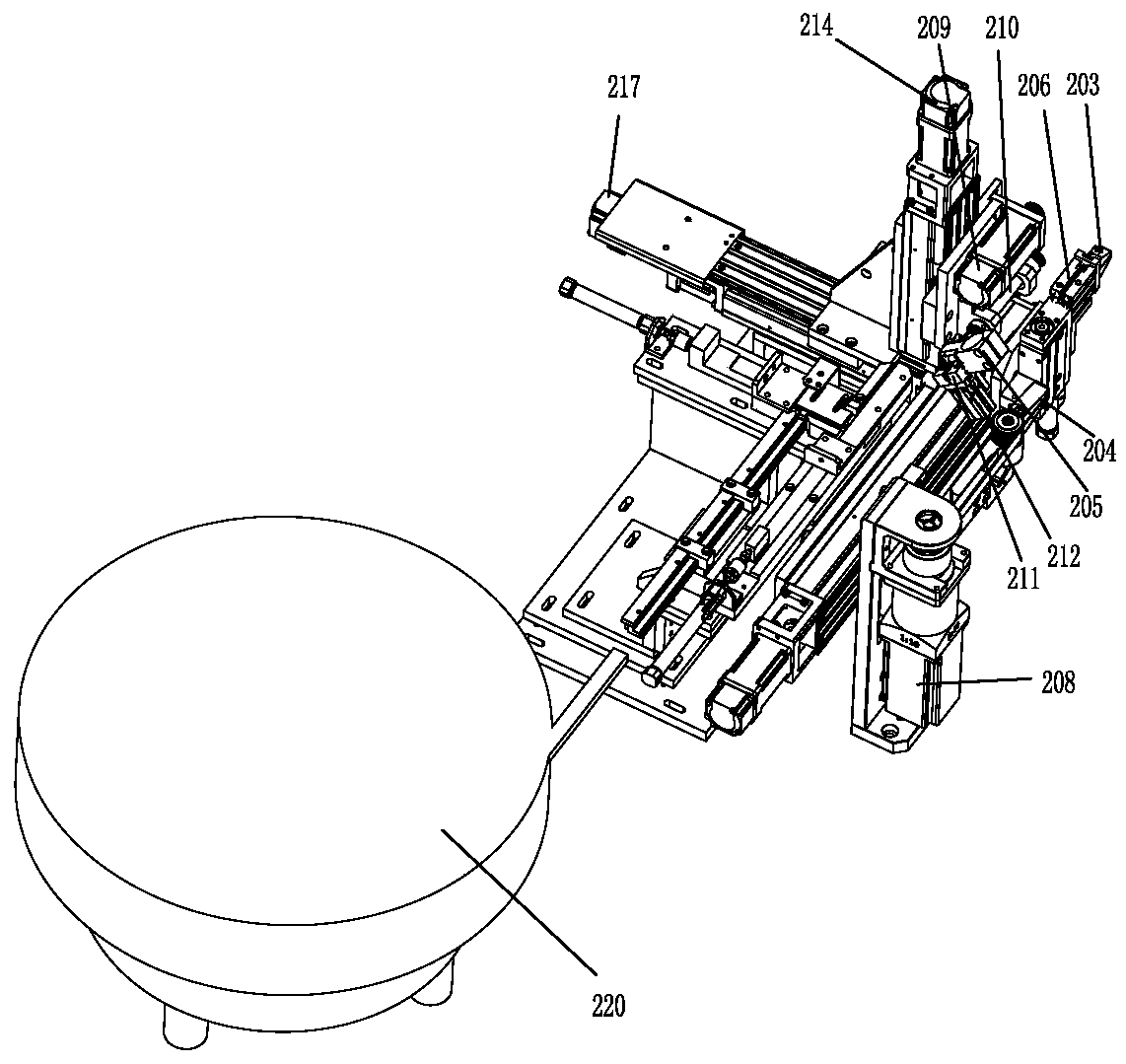

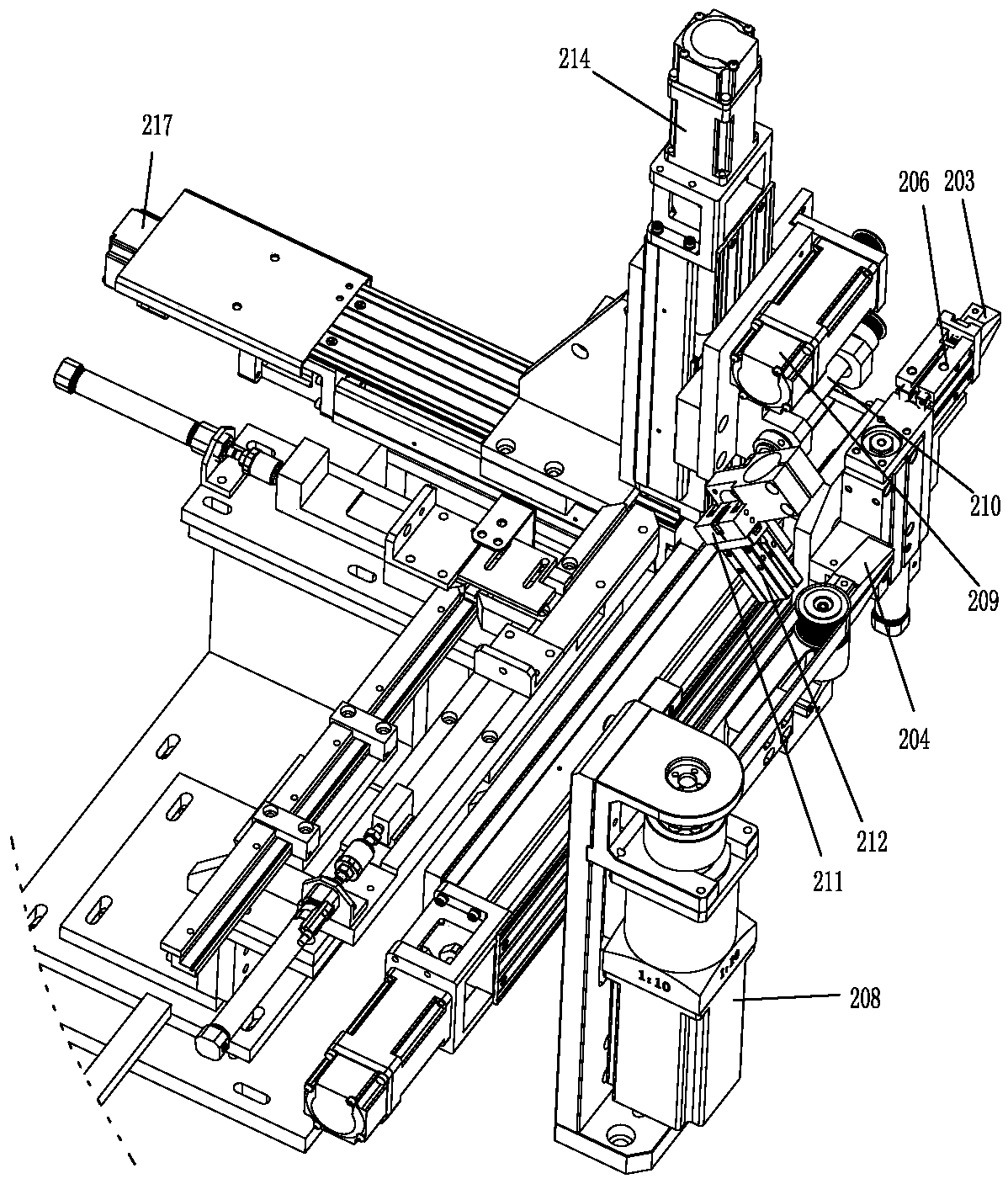

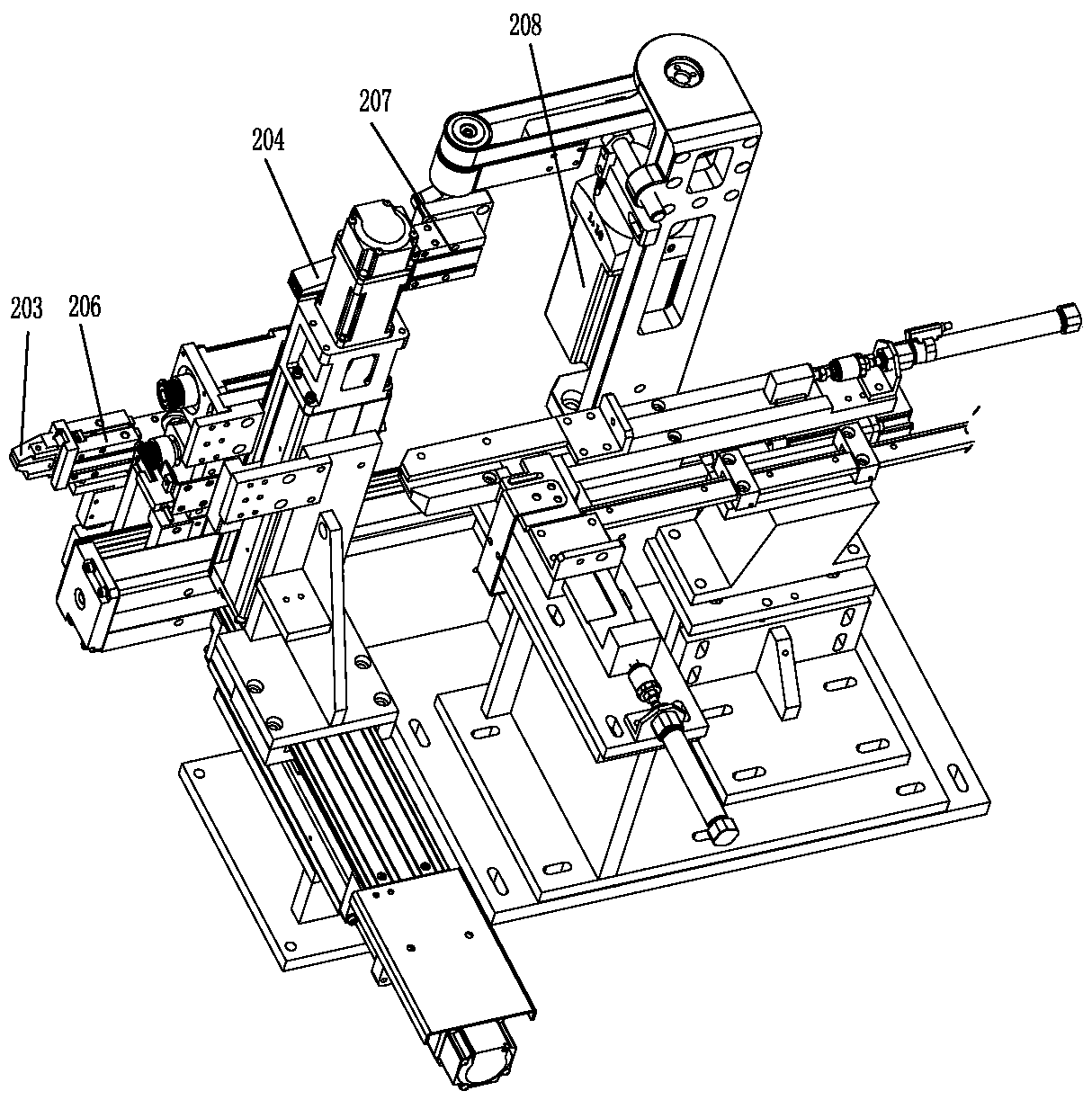

[0043] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the embodiment of the present invention.

[0044] First, please combine Figure 7 with Figure 8 As shown, it respectively shows the action change state of the pre-insertion step and the action change state diagram of the second shell insertion step in the embodiment of the present invention; before the second shell insertion action, the pre-insert shell step is performed first, and The cable terminal has a pre-positioning in the plastic shell. This pre-insertion method is realized in the way of "overlap-rotation" to ensure that the cable terminal can form a good pre-positioning in the plastic shell, which is beneficial to the subsequent shell insertion. The smooth progress of the steps; specifically (such as Figure 7 shown):

[0045] Step 1 of pre-inserting the case: place the socket at the tail of the plastic case obliquely upward; here, in the step 1 of pre-inserting the case, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com