A technology for rapid processing of sewing machine flat plate

A sewing machine and flat panel technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the processing accuracy of workpieces, slow clamping efficiency, and affecting work efficiency, so as to improve work efficiency and reduce clamping The effect of reducing the time and reducing the equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with accompanying drawing, the present invention is further elaborated.

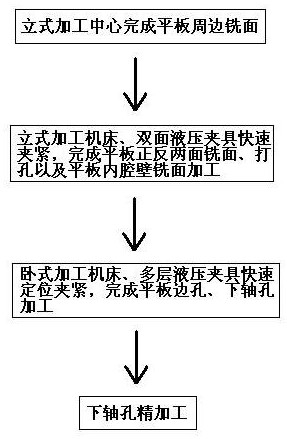

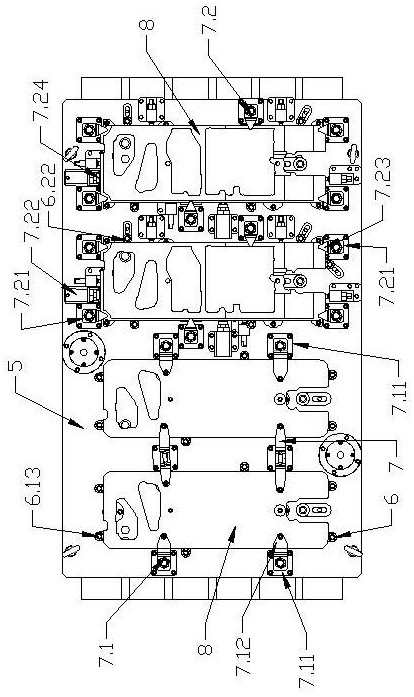

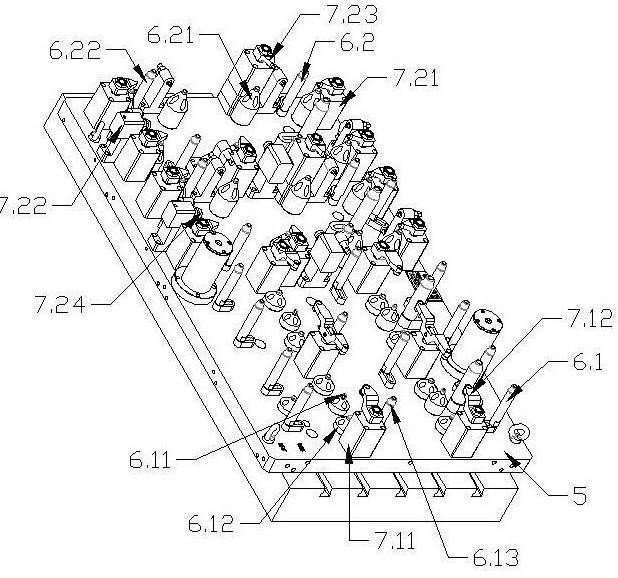

[0034] Such as Figure 1-8 Shown, the technology of fast processing sewing machine flat plate of the present invention is completed through the following operations:

[0035] (1) The vertical machining center in the prior art is used to complete the milling process around the periphery of the plate;

[0036] (2) On the vertical processing machine tool, multiple plates are quickly clamped by special double-sided hydraulic clamps (in the attached figure, two plates are processed on the front side and two plates are processed on the reverse side), and then the front and back sides of the plate are completed Milling, drilling, and milling of the inner wall of the flat plate;

[0037] (3) On the horizontal processing machine tool, multiple flat plates are quickly positioned and clamped by a special multi-layer hydraulic clamp to complete the processing of the side holes and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com