Milling tool with multifunctional blade compensation

A multi-functional, blade technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, metal processing equipment, etc., can solve the problems of high production scrap rate, non-compliance with requirements, large workpiece errors, etc., and achieve convenient operation, easy maintenance and Maintenance, stable effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

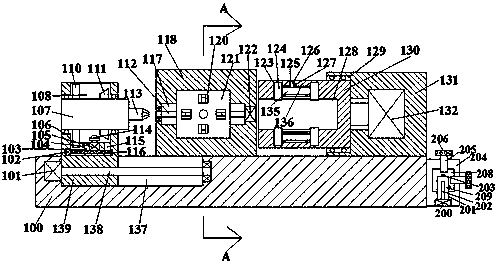

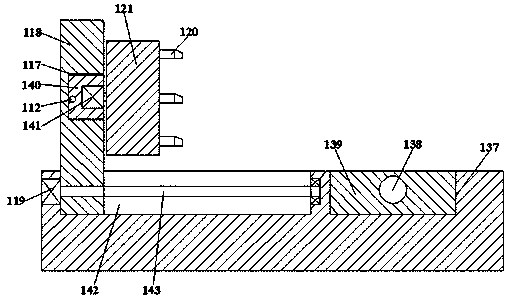

[0014] Such as figure 1 with figure 2 As shown, the milling tool with multi-function blade compensation of the present invention includes a machine tool 100 and a power machine body 131 arranged on the top end of the machine tool 100. The left end of the power machine body 131 is provided with a circular groove 129 opening to the left. , The circular groove 129 is rotatably connected with a fixing sleeve 130 extending left and right, the left end of the fixing sleeve 130 extends out of the circular groove 129, and the fixing sleeve 130 is provided with a fixing hole with a leftward opening 128. A first motor 132 is dynamically connected to the right end surface of the firmware sleeve 130. The outer surface of the first motor 132 is embedded in the inner wall of the right end of the circular groove 129 and is fixedly connected to it. A left-right symmetrical groove 123 is connected to the inner wall. An annular groove 136 is provided between the two grooves 123. The top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com