Light and narrow series double row symmetrical spherical roller bearing with solid cage

A technology of self-aligning roller bearings and solid cages, applied in rolling contact bearings, bearing components, shafts and bearings, etc., can solve problems such as poor strength, failure to meet design requirements, thin thickness, etc., and achieve good lubrication performance and low cost Low, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention are described with reference to the accompanying drawings.

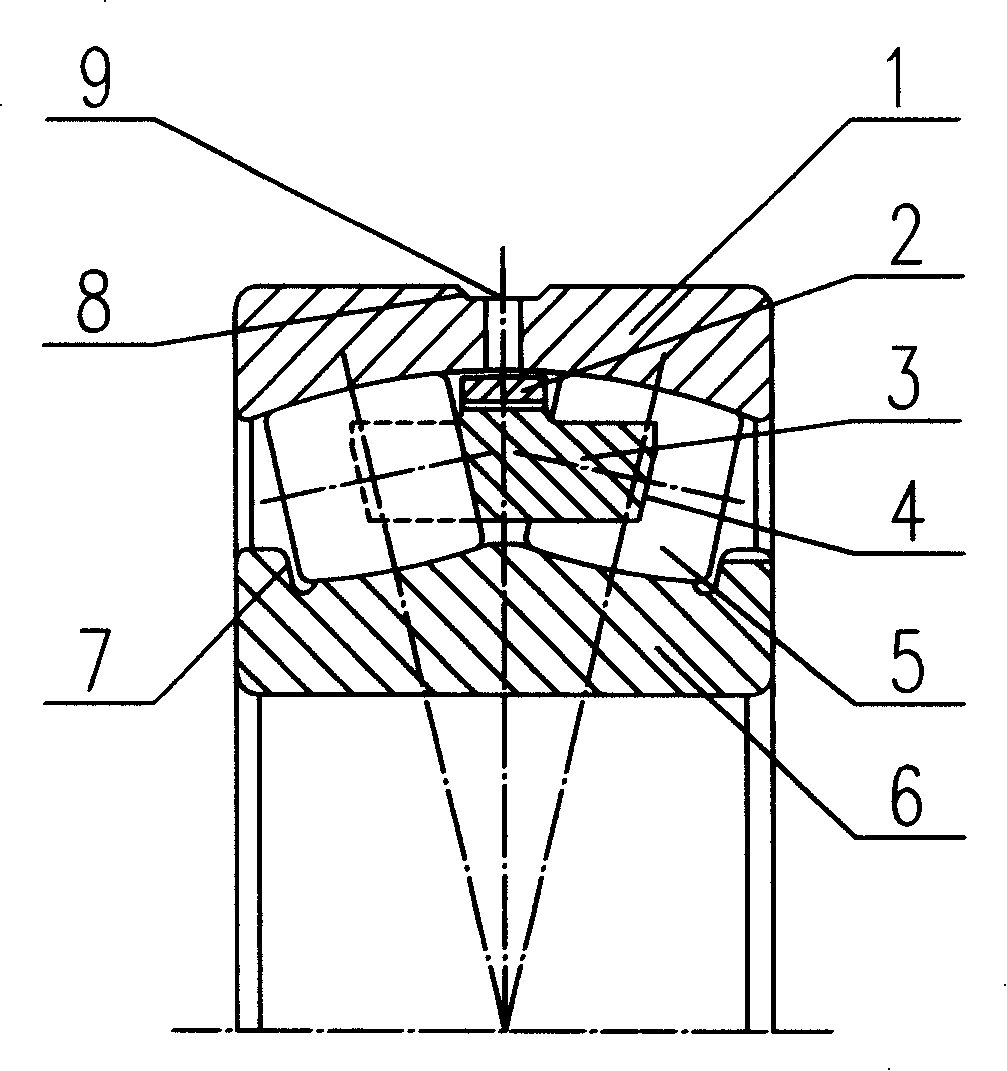

[0018] as attached figure 1 As shown, the parts of the bearing of the present invention include an outer ring 1, an inner ring 6, a moving retaining ring 2, a cage 3, and a roller 5, and the cage 3 can be a brass entity. An oil groove 8 is arranged on the center line of the outer ring 1, and six oil holes 9 are evenly distributed on the oil groove 8; the angle of the small rib 7 of the inner ring is larger than the contact angle 30' of the bearing.

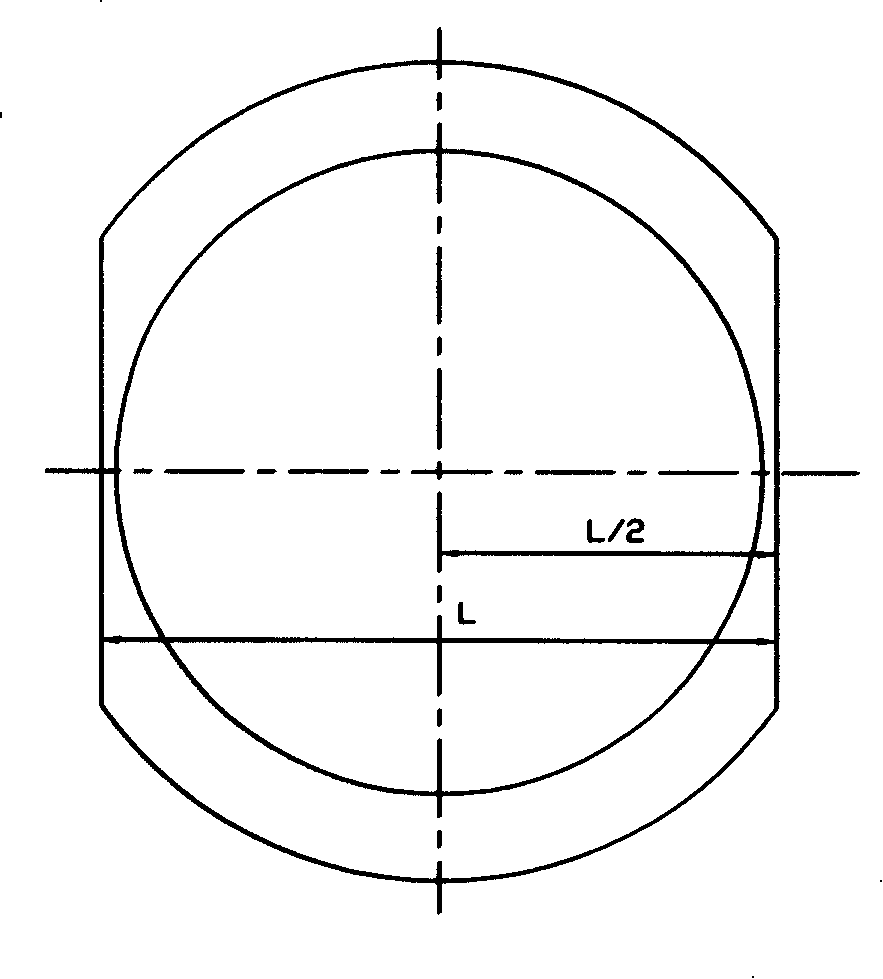

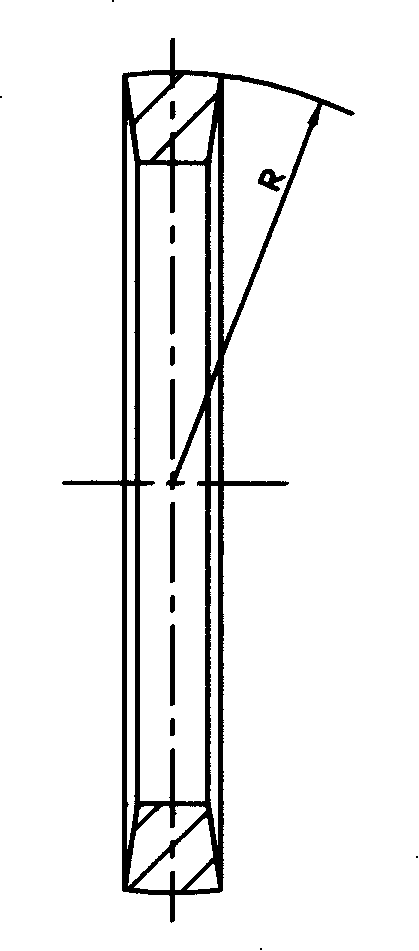

[0019] as attached figure 2 , 3 As shown, the outer diameter of the active retaining ring 2 is designed as a concentric circle smaller than the raceway diameter of the outer ring, and the dimension L between its two sides is smaller than the minimum inner diameter of the outer ring 1 . The end face of the retaining ring 2 during the activity is an oblique end face.

[0020] as attached Figure 4 As shown, the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com