High-precision adjustable auxiliary machining equipment for neodymium-iron-boron magnet

An auxiliary processing, high-precision technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc. Location movement etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

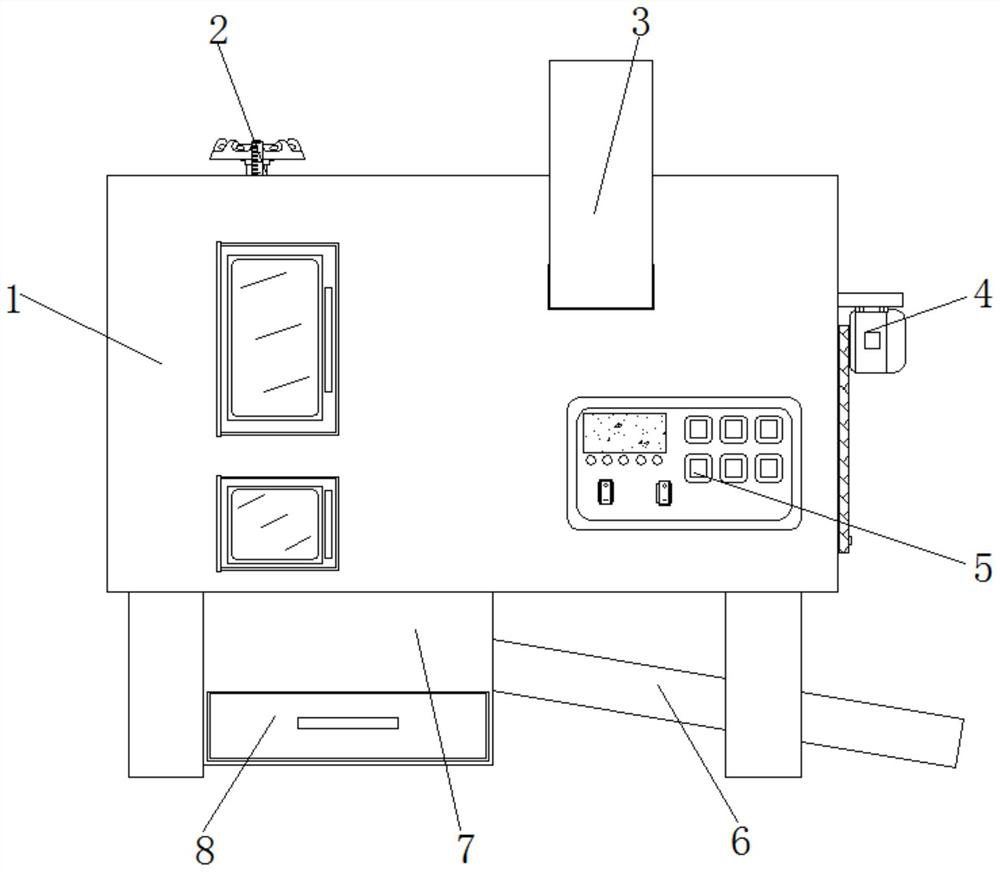

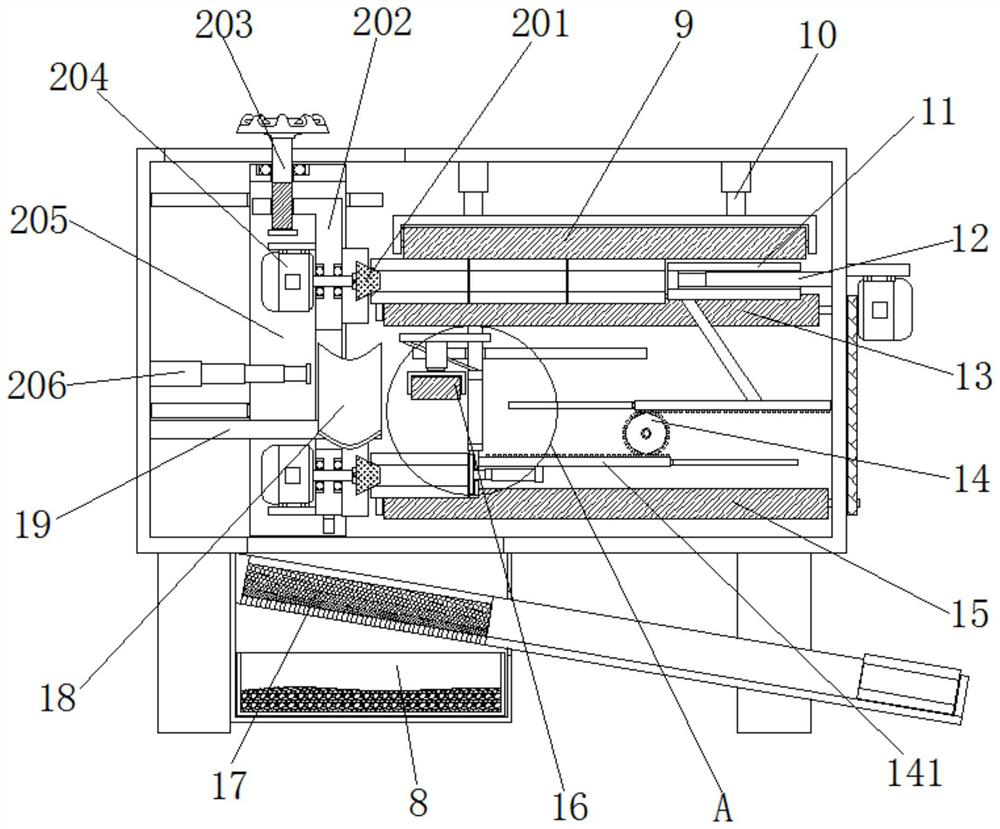

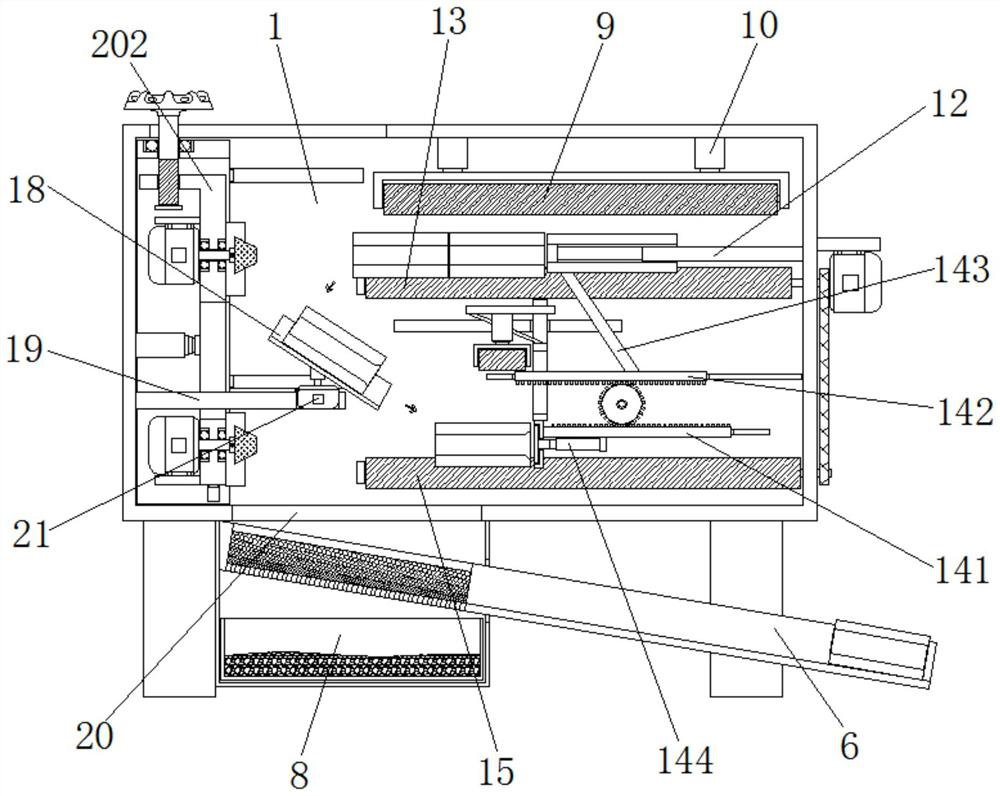

[0041] Example 1, such as figure 1 , 2 , 3, 4, 5, 8 and 10, when starting to chamfer the ring NdFeB magnet, first according to the actual diameter of the ring NdFeB magnet, compare the scale on the height scale plate 207 manually Rotate threaded rod 203, because of the effect of screw thread, force L-shaped plate 202 to rise or fall in the inside of U-shaped movable chamber 205, thereby precisely adjust the center of grinding head 201, make it and two groups of first lower installation rollers 13 circles The center of the ring NdFeB magnet is aligned, and then the operator only needs to manually place the ring NdFeB magnet horizontally into the interior of the feeding guide bin 3, and the processed ring NdFeB magnet is moved to the row The inside of the chute 6 is far away from the end of the fixed plate 19. During the whole process, the operation can easily supplement the processing raw materials to the inside of the feeding guide bin 3, and can also easily remove the proces...

Embodiment 2

[0042] Example 2, such as Figure 2-4 As shown, control the first electric lifting rod 206 to shorten, control the first electric push rod 12 to extend, and control the servo motor 21 to drive the arc-shaped material guide plate 18 to rotate counterclockwise 90°, and then the first electric push rod 12 can be controlled Elongate, use the push tube 11 to push the ring NdFeB magnets between the first two sets of lower installation rollers 13 to move to the end close to the fixed plate 19, until the first set of ring NdFeB magnets flip and fall to the arc Shaped material guide plate 18, along the guide of arc-shaped material guide plate 18, falls between two groups of second lower mounting rollers 15, and at this moment, the end of the first group of ring NdFeB magnets that is not chamfered Already facing the second group of grinding heads 201, the automatic direction adjustment of the equipment to the ring NdFeB magnets has been realized, and the ring NdFeB magnets between the t...

Embodiment 3

[0043] Example 3, such as Figure 2-5As shown, after the equipment automatically adjusts the direction of the ring NdFeB magnets, it controls the first electric push rod 12 to shorten back to the original length. At this time, the gap between the third group of ring NdFeB magnets and the push tube 11 There is a vacancy for a ring NdFeB magnet. After the inner ring NdFeB magnet of the feed guide bin 3 loses its limit by the push tube 11, a group of ring NdFeB magnets at the bottom of the feed guide bin 3 The boron magnet automatically falls into the space under the influence of gravity to realize the automatic feeding function of the equipment. When the first electric push rod 12 is extended, the first group of circular NdFeB rings between the two sets of first lower installation rollers 13 are extended. When the magnet is pushed down, due to the transmission of the lower rack plate 141, the upper rack plate 142 and the transmission gear 145, the outer pusher plate 146 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com