Conveying reversing device for assembly line

A reversing device and assembly line technology, applied in the direction of conveyor objects, transportation and packaging, metal processing, etc., can solve the problems of high labor cost, laborious, low production efficiency, etc., to reduce labor intensity, improve production efficiency and production safety Sexuality and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

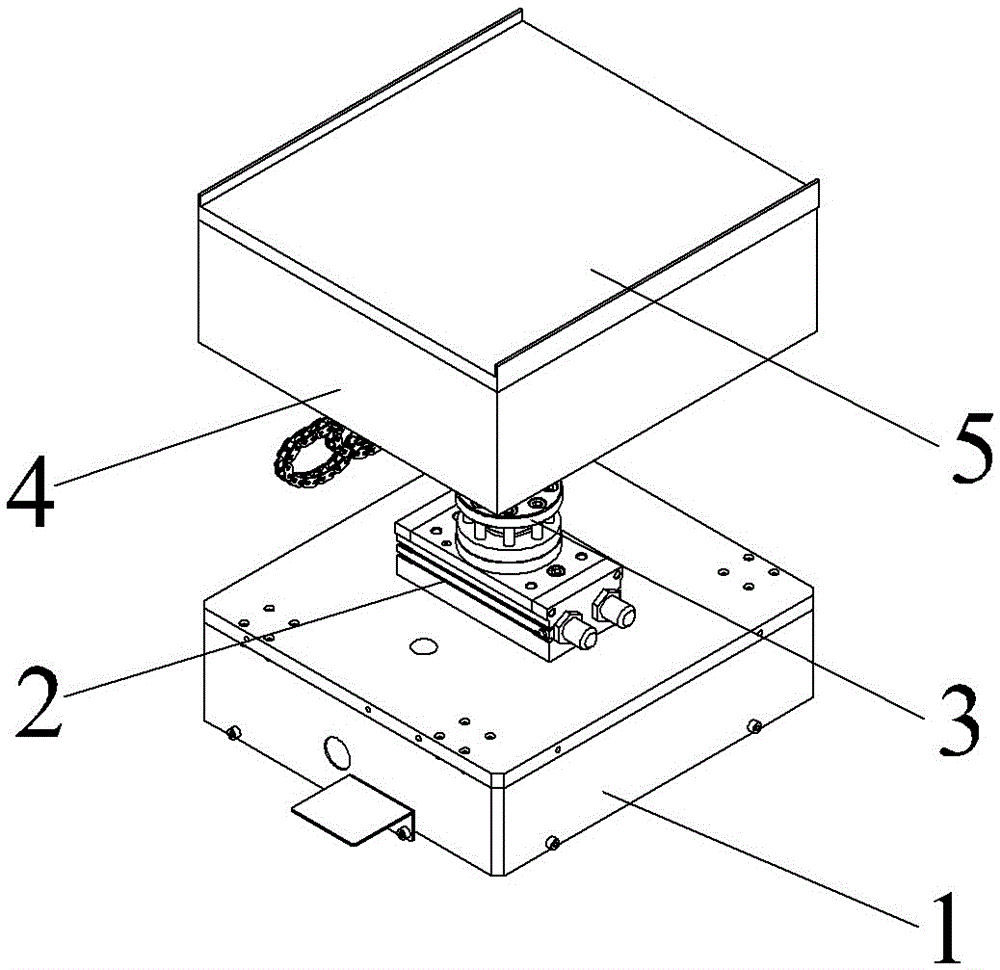

[0008] Such as figure 1 As shown, the present invention includes a base 1, a rotary cylinder 2 is arranged on the base 1, a rotary power connection is carried out between a turntable 3 and the rotary cylinder 2, a hollow workbench 4 is fixed on the turntable 3, and a U-shaped The conveying plate 5 prevents the parts on the conveying plate 5 from falling. The workbench 4 located at the starting end of the conveying direction is equipped with a driving cylinder (not shown in the figure), and the piston rod of the driving cylinder passes through the workbench 4 and the bottom of the conveying plate 5 The conveyor plate 5 can be easily lifted to automatically slide off the parts; the workbench 4 is provided with a positioning hole, and the bottom of the conveyor plate 5 corresponding to the positioning hole is provided with a positioning block, and the conveyor plate 5 is positioned on the working surface through the positioning block. On the platform 4, the positioning hole and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com