Planet wheel thread rolling plate and thread rolling process thereof

A technology of planetary gear and thread rolling plate, applied in the field of cold stamping processing, can solve the problems of difficult chamfering and other problems, and achieve the effect of reducing processing steps and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

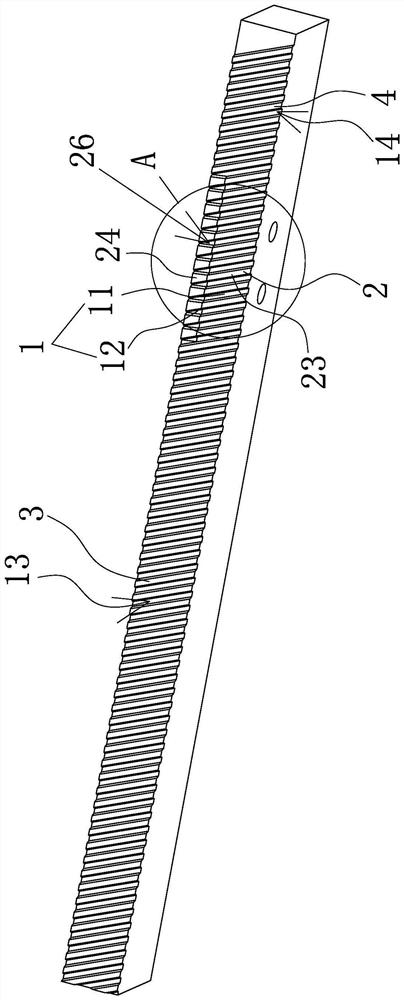

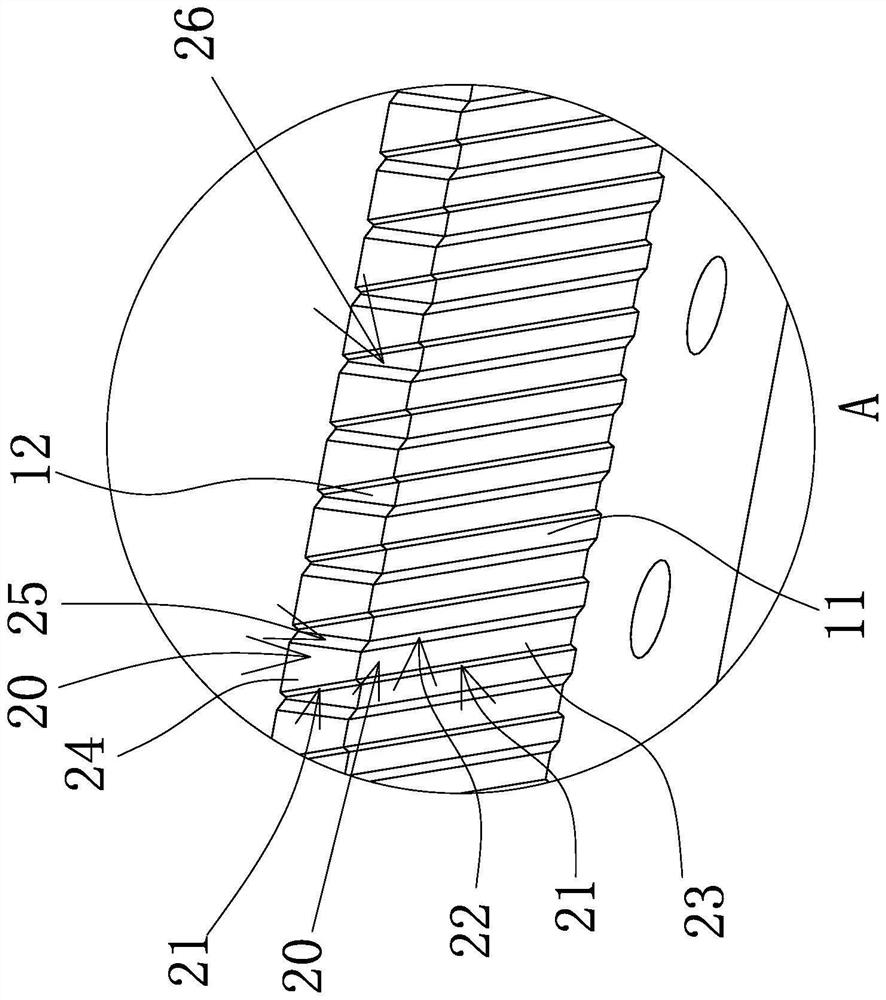

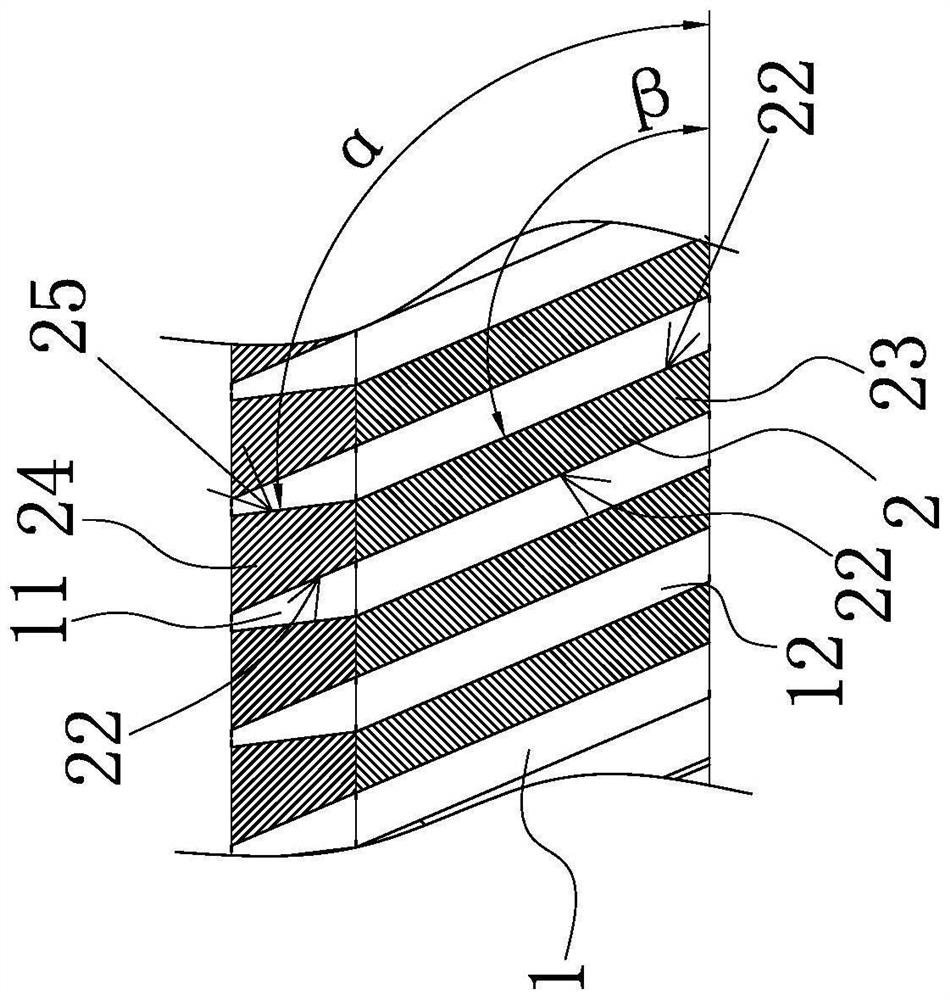

[0042] Such as Figure 1-Figure 8 A planetary thread rubbing plate shown includes a body 1 with a feed end and a discharge end. The body 1 is provided with a number of rubbing racks 2 that are inclined toward the feed end and are evenly spaced. The tooth surface 21, the reverse tooth surface 22 and the top surface 20, the oriented tooth surface 21 is located on the side of the rubbing rack 2 facing the feed end, and the reverse tooth surface 22 is located on the side of the rubbing rack 2 facing the discharge end.

[0043] This rubbing rack 2 is provided with a raised convex portion on the side of the reverse tooth surface 22, the convex portion has an inclined side and is called an inclined surface 25, and there is a clip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com