A processing tool for pipe fittings

A technology for processing tools and pipe fittings, which is applied in the field of processing tools for pipe fittings, can solve problems such as complex assembly of chamfering devices, and achieve the effects of stable connection, firm positioning, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

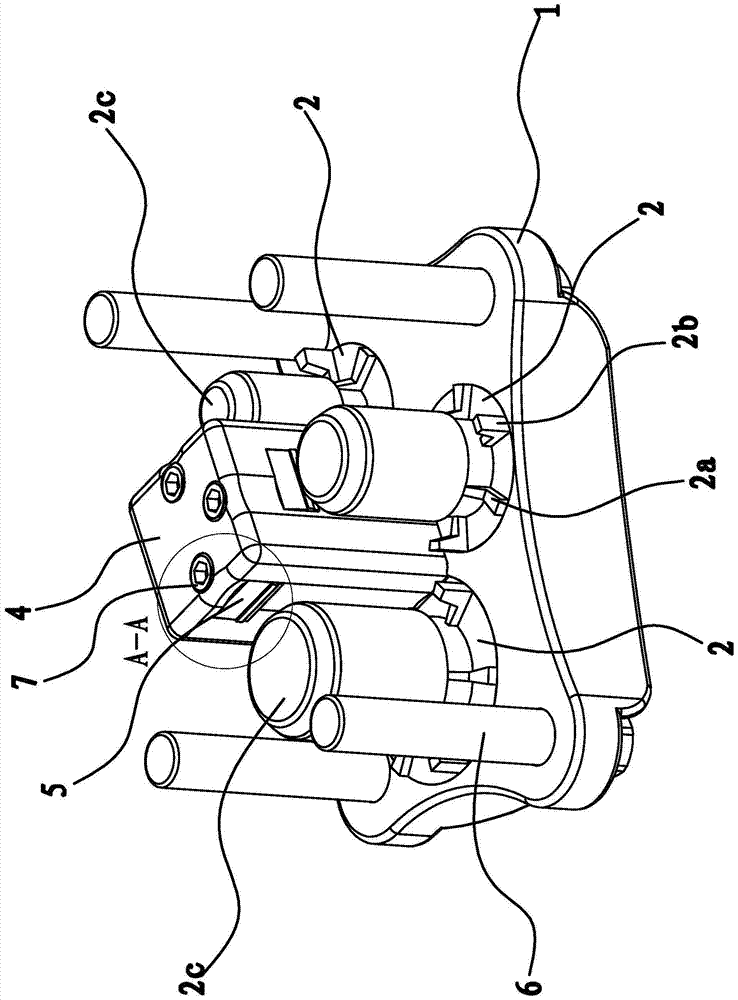

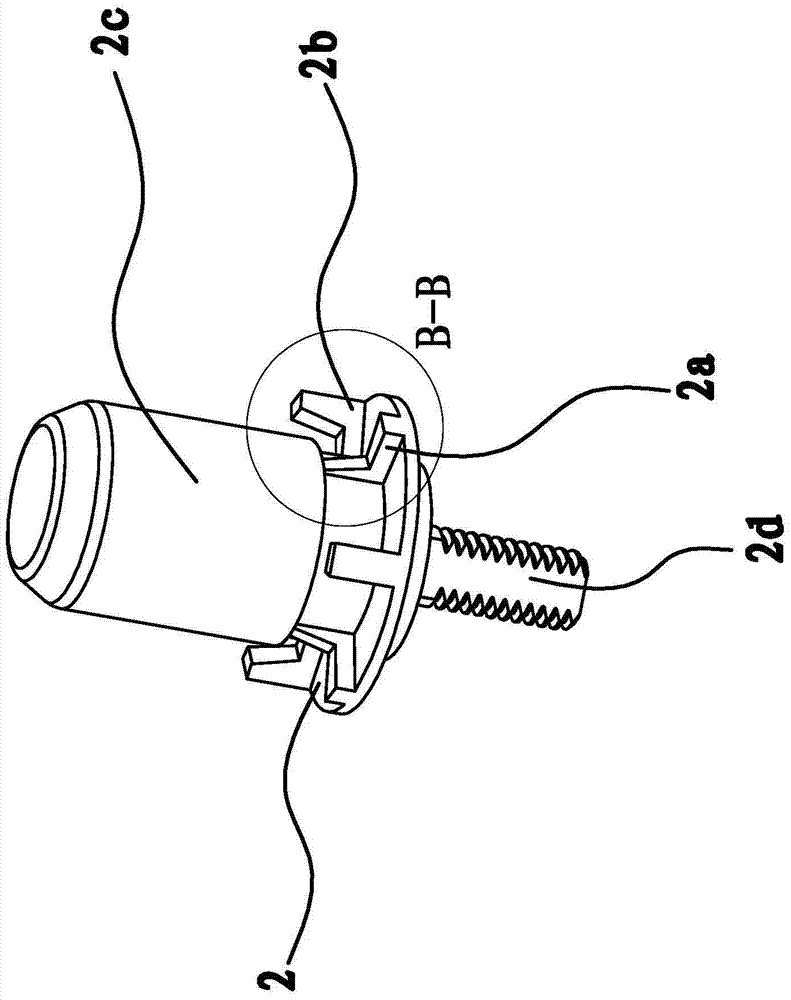

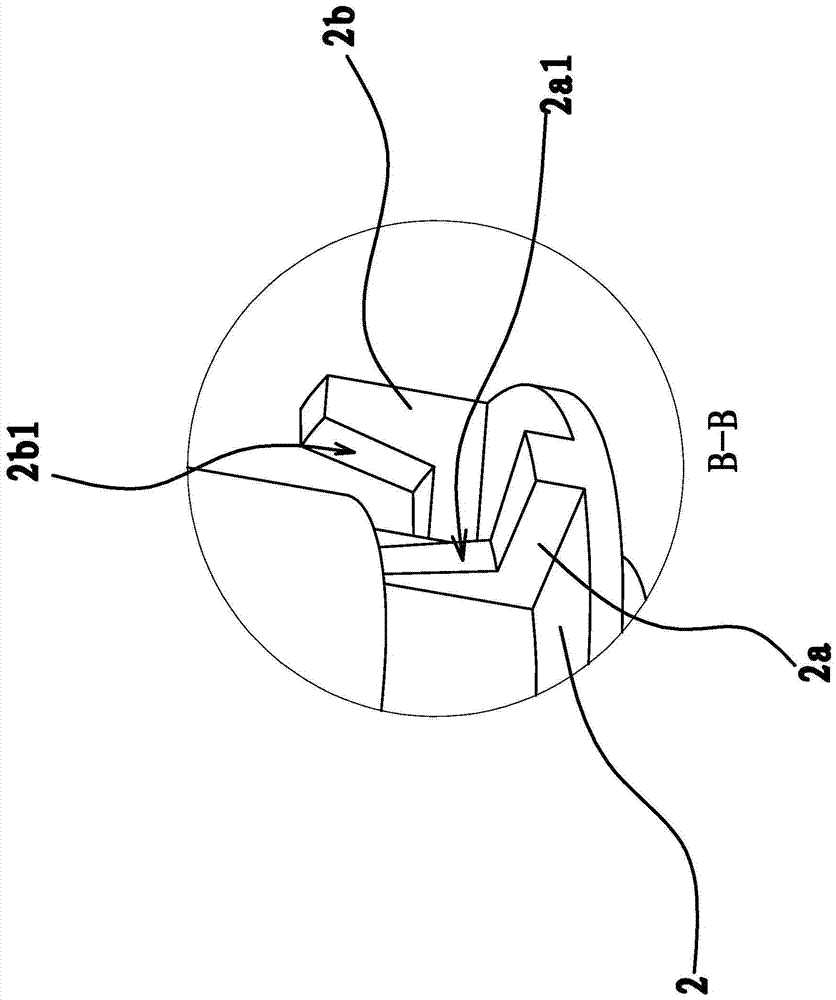

[0036] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a processing tool for pipe fittings includes a rectangular base 1 on which a connecting block 4 and 2 to 4 processing discs 2 are fixed, the connecting block 4 is in the shape of a square block, and the processing disc 2 is Disc-shaped, each processing disc 2 is distributed around the connecting block 4 . There is a positioning head 2c at the center of the processing disk 2, the positioning head 2c is cylindrical, and the end of the positioning head 2c is tapered, and the positioning head 2c and the processing disk 2 are integrally structured. A plurality of protruding inner chamfering blocks 2a and outer chamfering blocks 2b are integrally formed on the processing disk 2. The outer side of the inner chamfering block 2a has an inner chamfering cutting surface 2a1, and the inner side of the outer chamfering block 2b has an outer chamfering cutting surface. Surface 2b1, each inner chamfering block 2a and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com