Triple-head chamfering machine and control program thereof

A technology of a chamfering machine and an electrical control device, which is applied in the field of workpiece processing machinery and equipment, can solve the problems of high labor intensity of operators, unstable chamfering quality, and potential safety hazards, and achieves good chamfering effect, convenient implementation, and improved efficiency. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings.

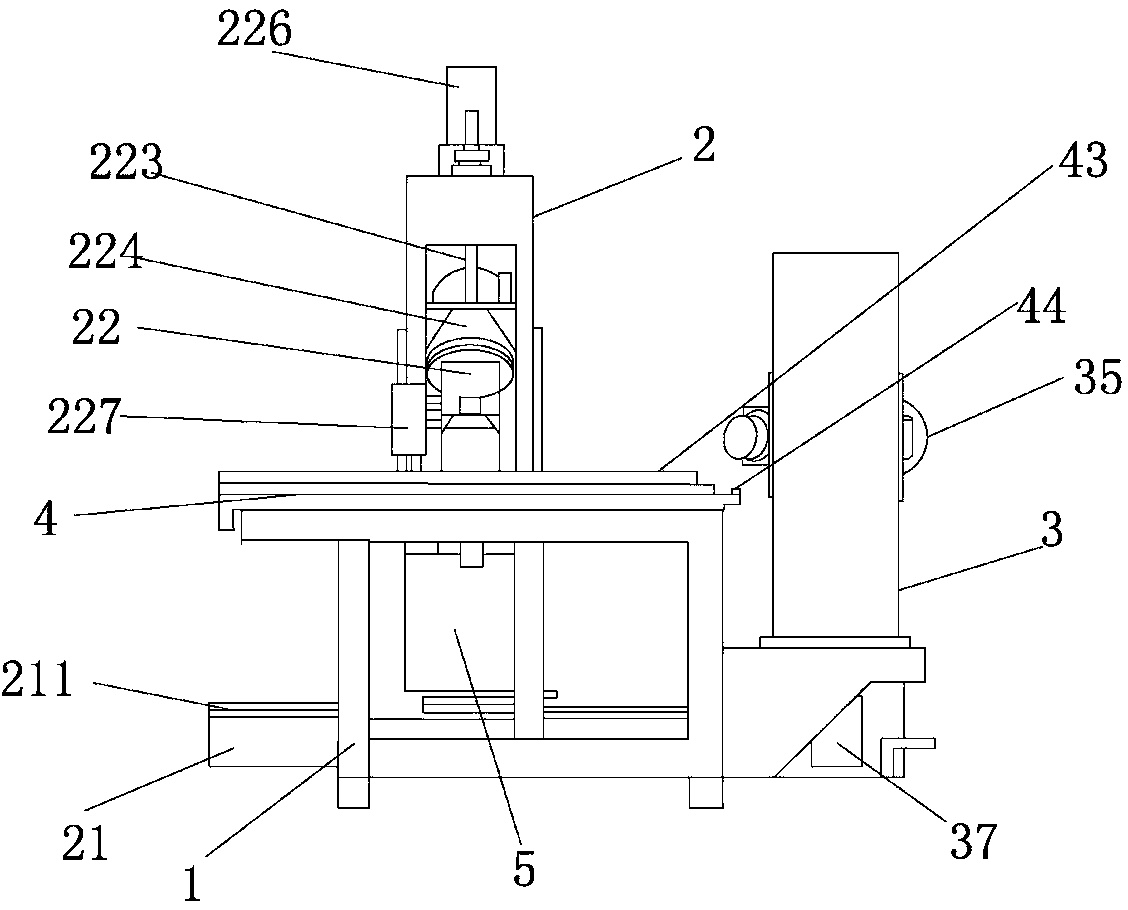

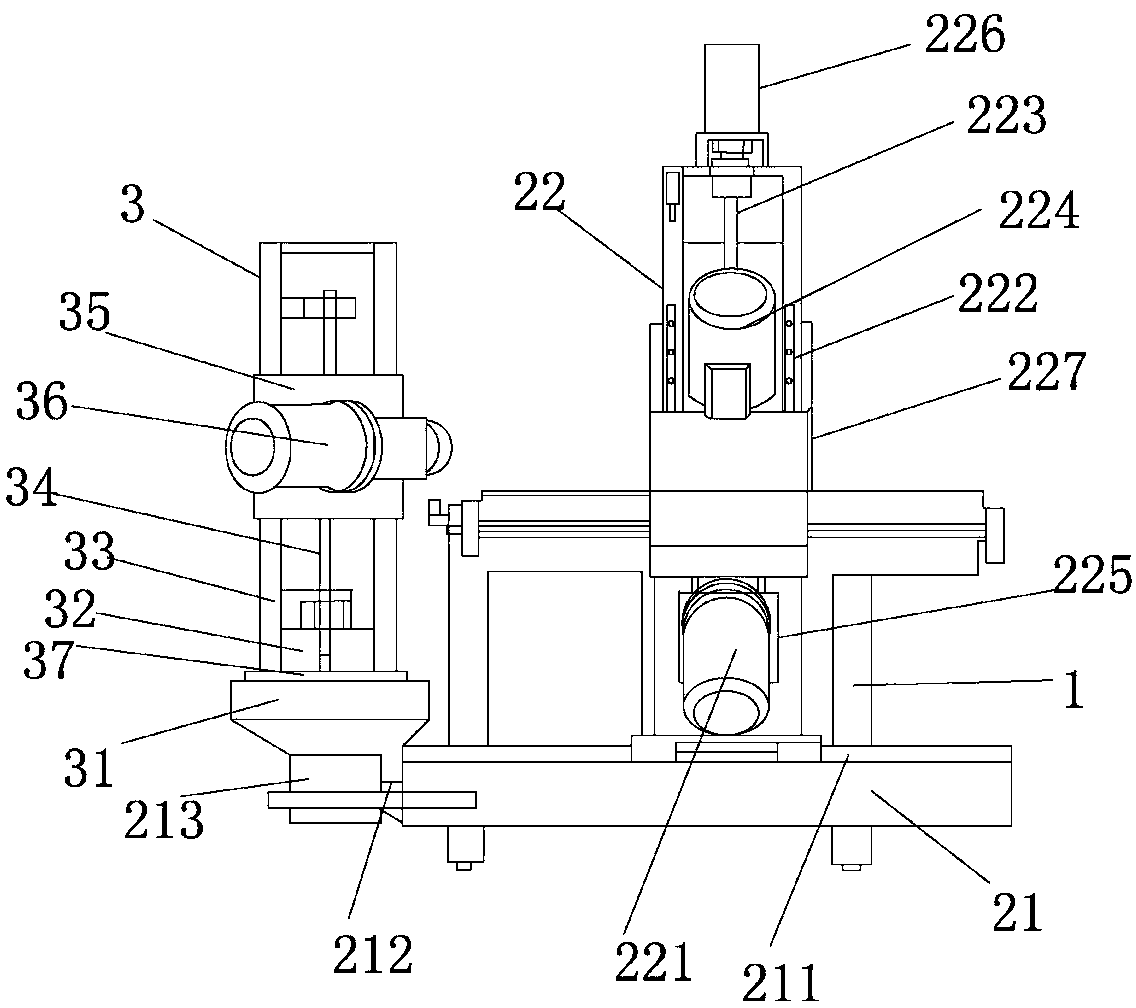

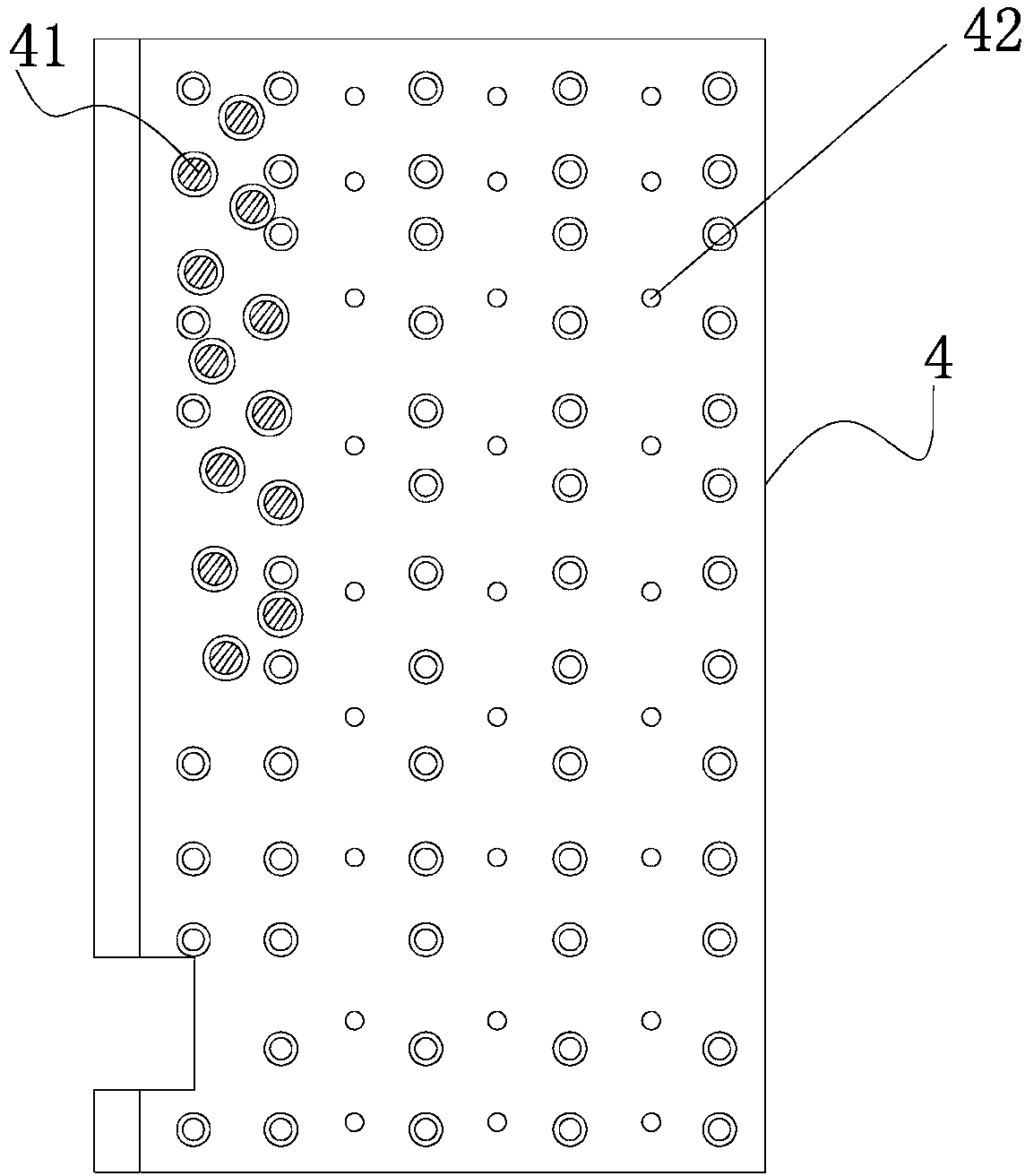

[0025] Such as figure 1 , figure 2 and image 3 As shown, a three-head chamfering machine includes a bed 1, a transverse cutting device 2 is provided at the back of the bed 1, a vertical cutting device 3 is provided on the right side of the bed 1, and a workbench 4 is provided at the front of the bed 1 , An electric control device 5 is provided below the workbench 4, and the cross-cutting device 2, the vertical cutting device 3 and the workbench 4 are all controlled by the electric control device 5. The PLC digital controller (not shown) in the electrical control device 5 controls the stepping motor 226 to work, and the displacement sensor 227 senses the signal of the position (that is, the height of the workpiece), and transmits the signal to the PLC digital controller, thereby controlling the cross-cutting upper head The position of 224; the frequency converter (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com