Precise chamfering device for optical component

A technology of optical components and chamfering, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machine parts, etc. How to ensure the consistent amount of chamfering of optical components and other issues, to achieve the effect of low technology and proficiency requirements, high consistency, and good chamfering consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

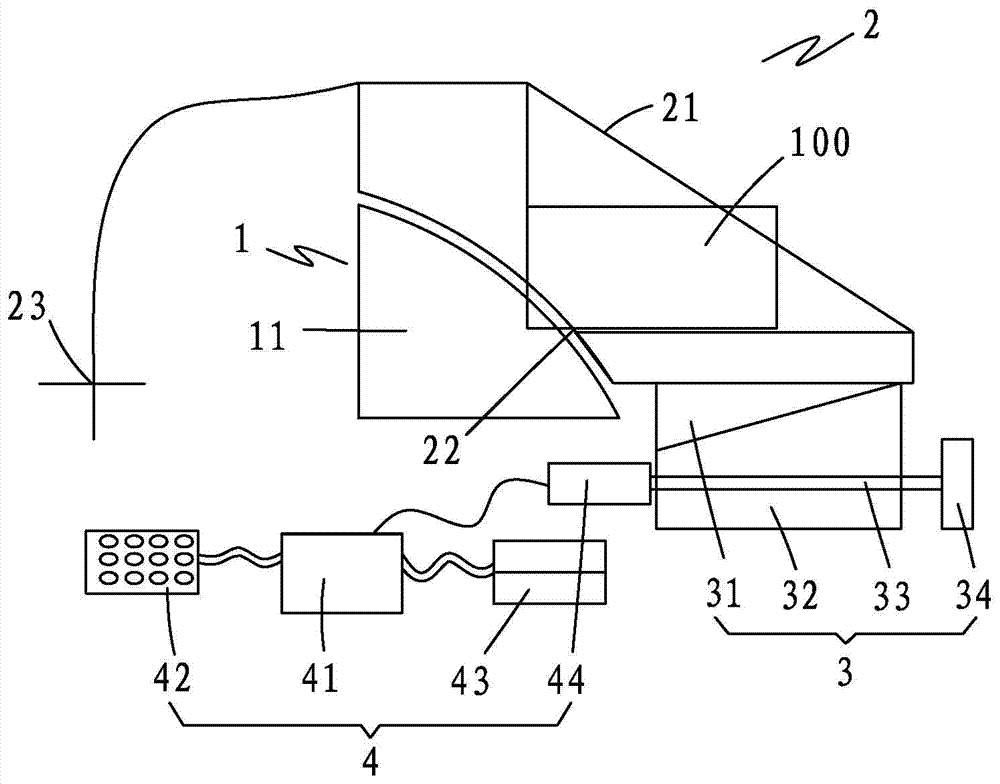

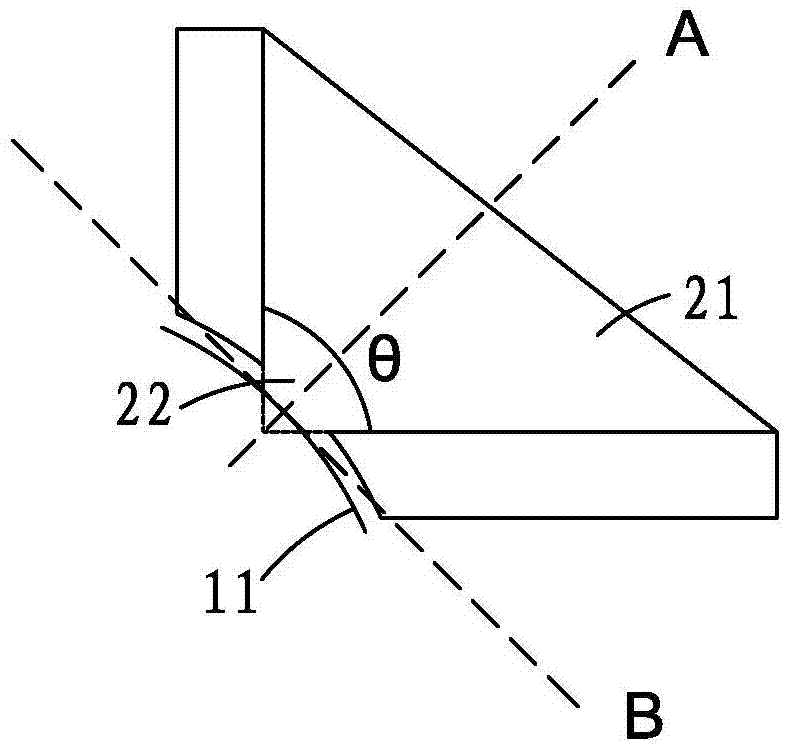

[0014] see figure 1 and figure 2 As shown, the optical element precision chamfering equipment of the present invention includes a grinding device 1, a chamfering jaw device 2, a chamfering amount adjusting device 3 and a control display device 4; the grinding device 1 includes a grinding shaft 11, The chamfering jaw device 2 has an angular clamping groove 21, a chamfering station opening 22 and a rotation center 23 deviated from the axis of the grinding shaft 11, and the chamfering station opening 22 is located in the angular clamping groove 21 The inner corner of the inner corner; the grinding shaft 11 is adjacent to the chamfering station opening 22 and is located between the angular clamp groove 21 and the center of rotation 23, and the inner corner of the angular clamp groove 21 The angle bisector A is perpendicular to the grinding shaft outer circle tangent B passing through the angle bisector; the chamfering adjustment device 3 is connected to the chamfering jaw device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com