Patents

Literature

48results about How to "Guaranteed dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

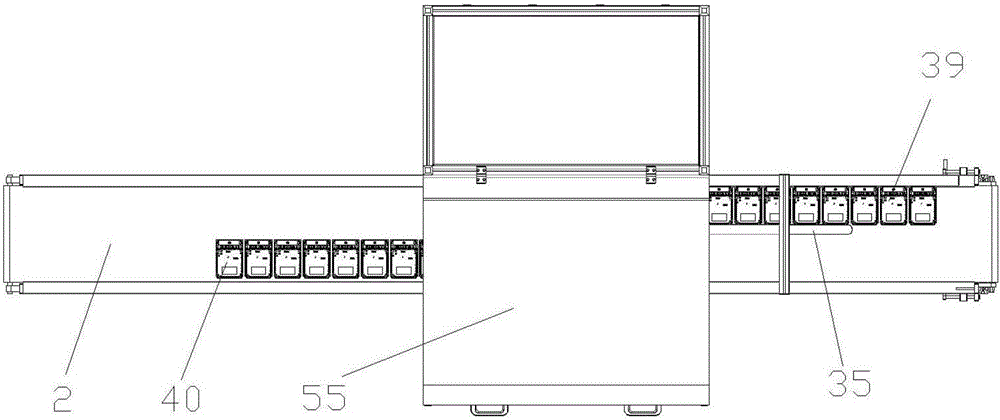

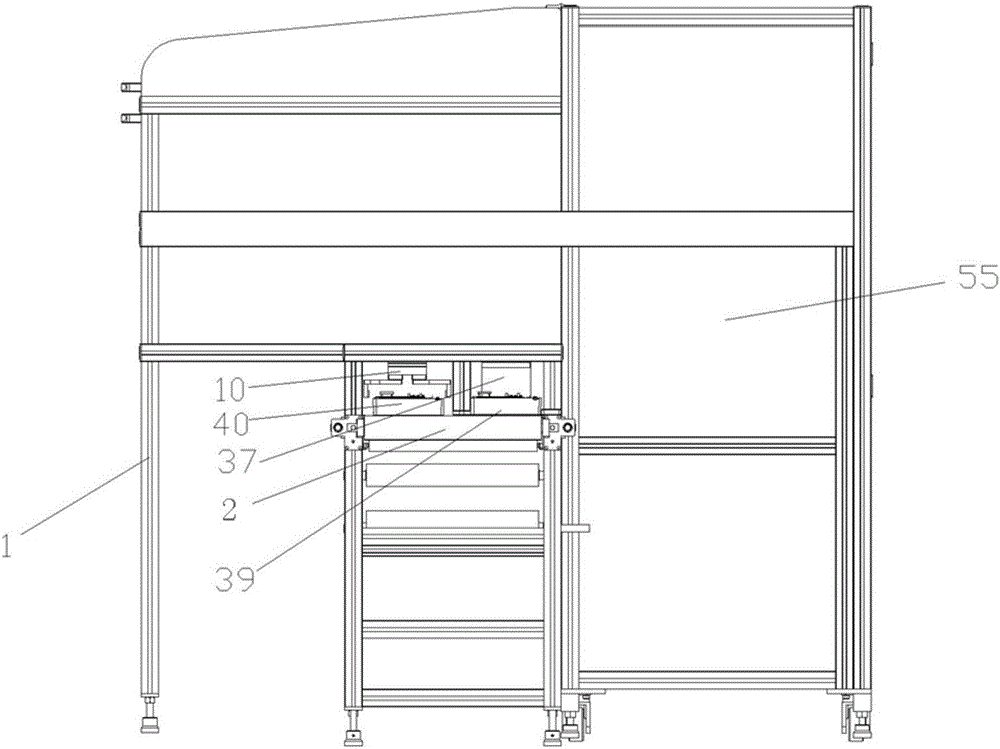

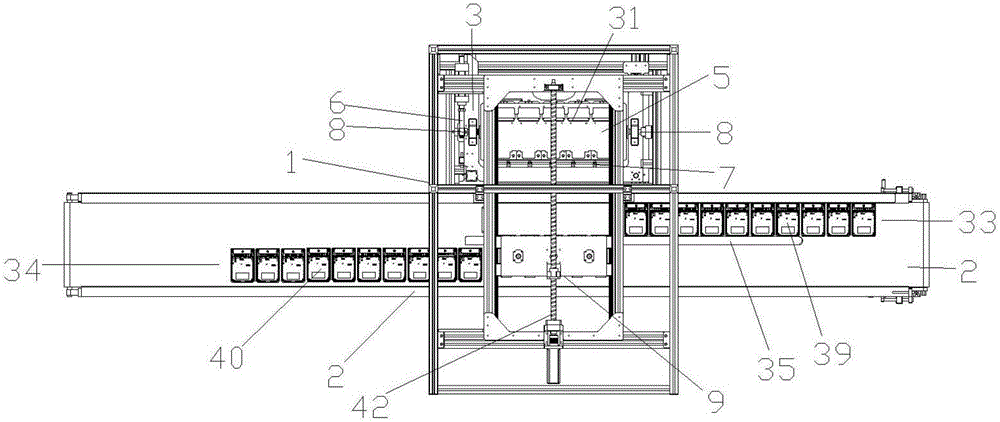

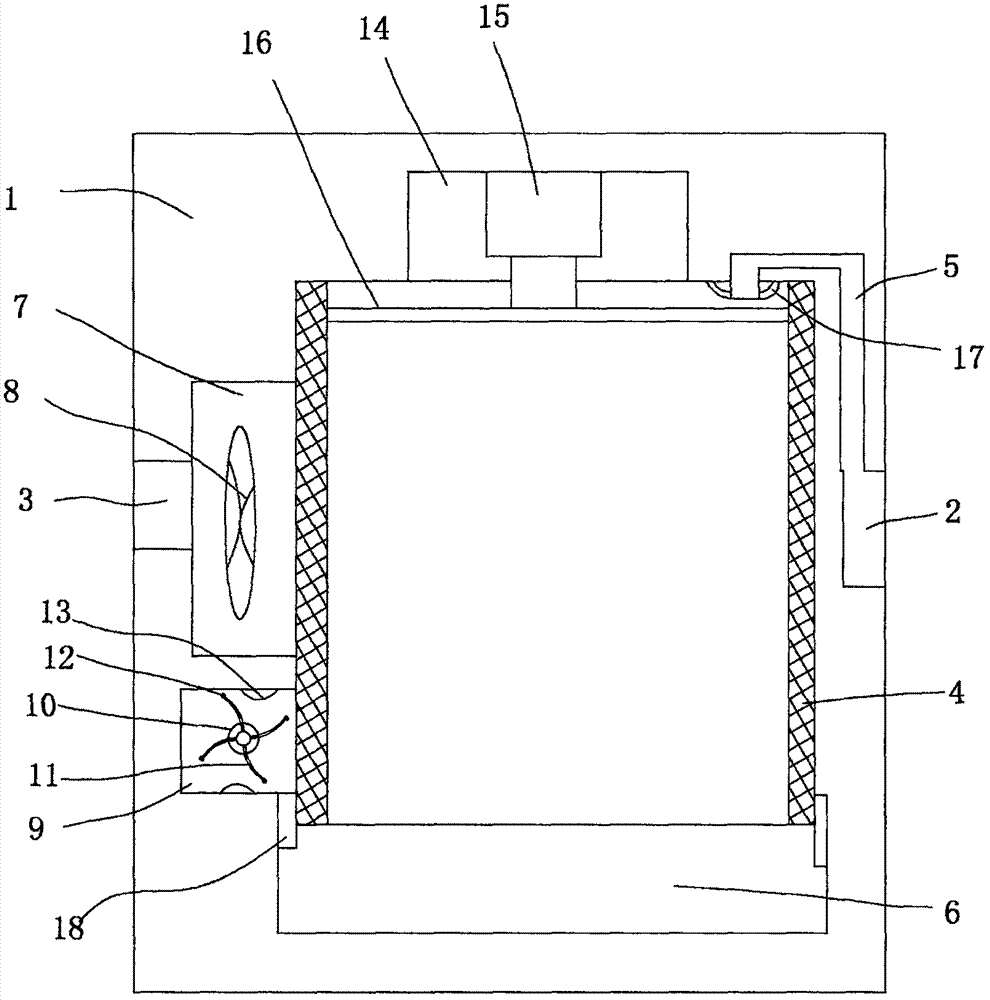

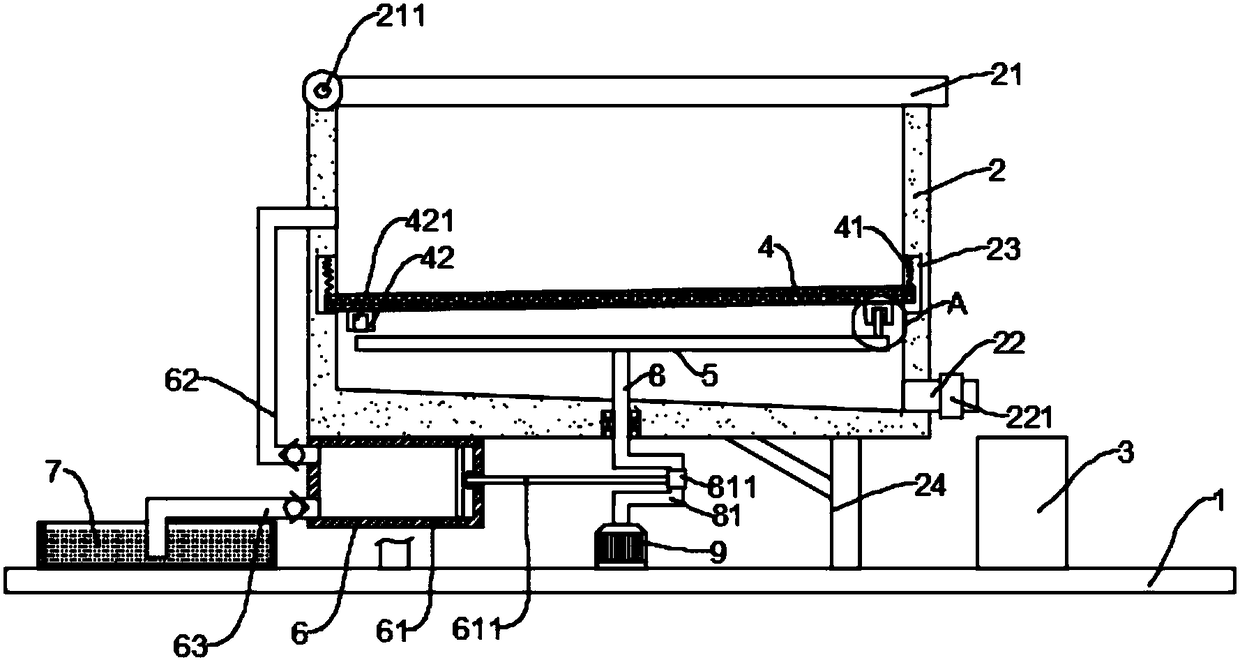

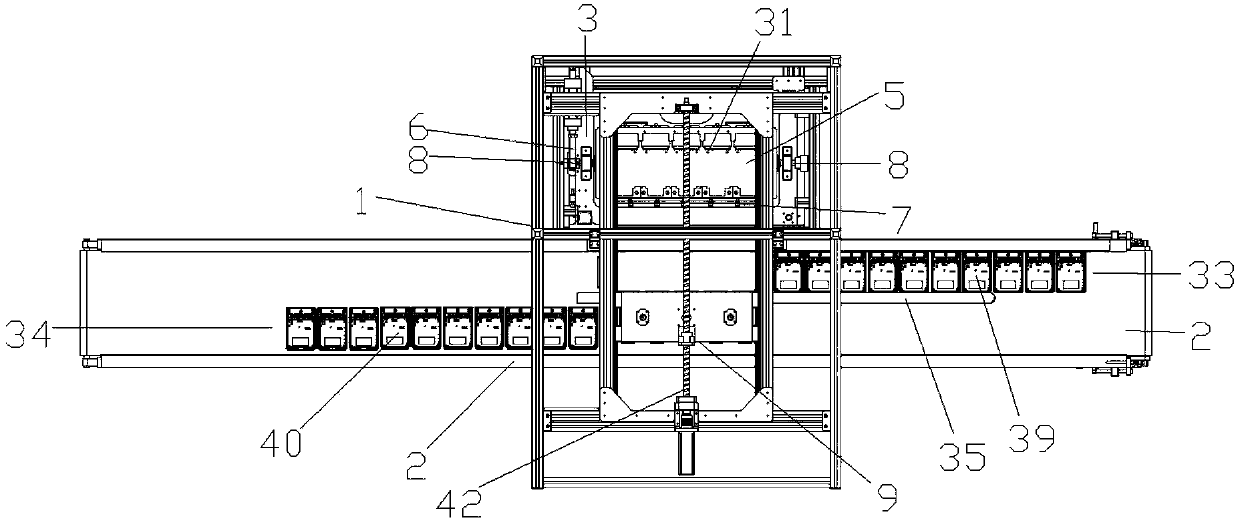

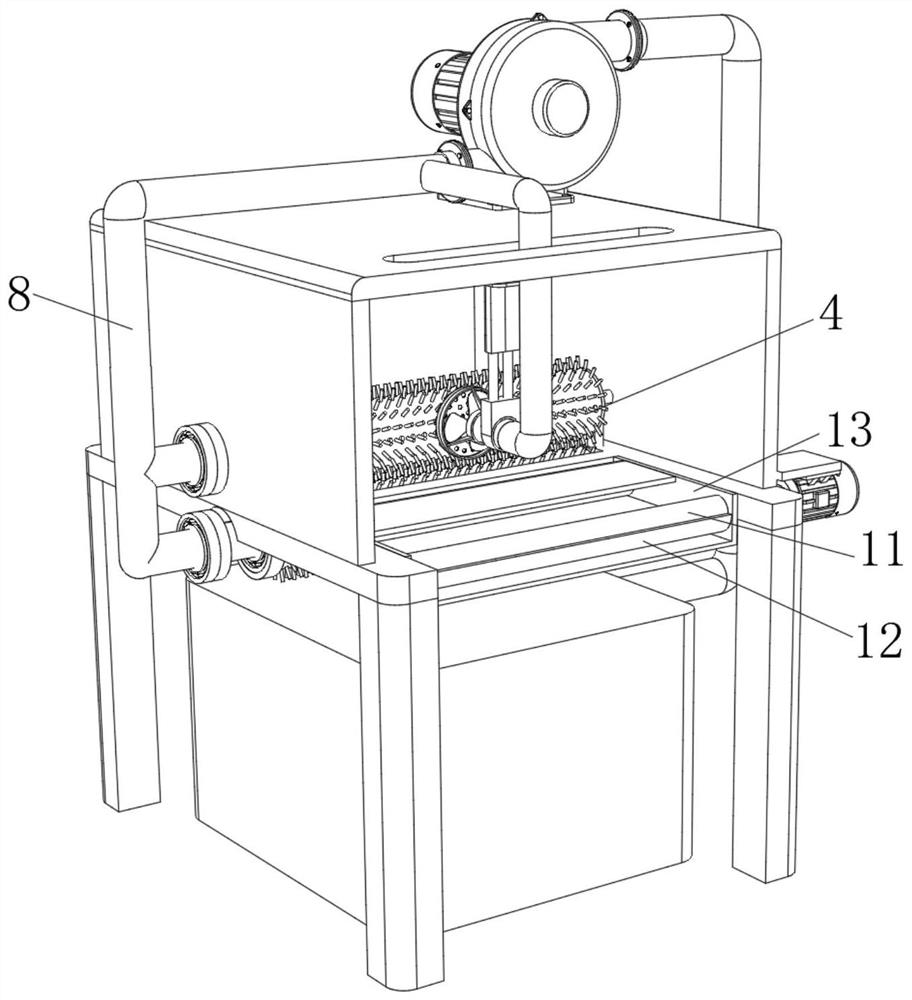

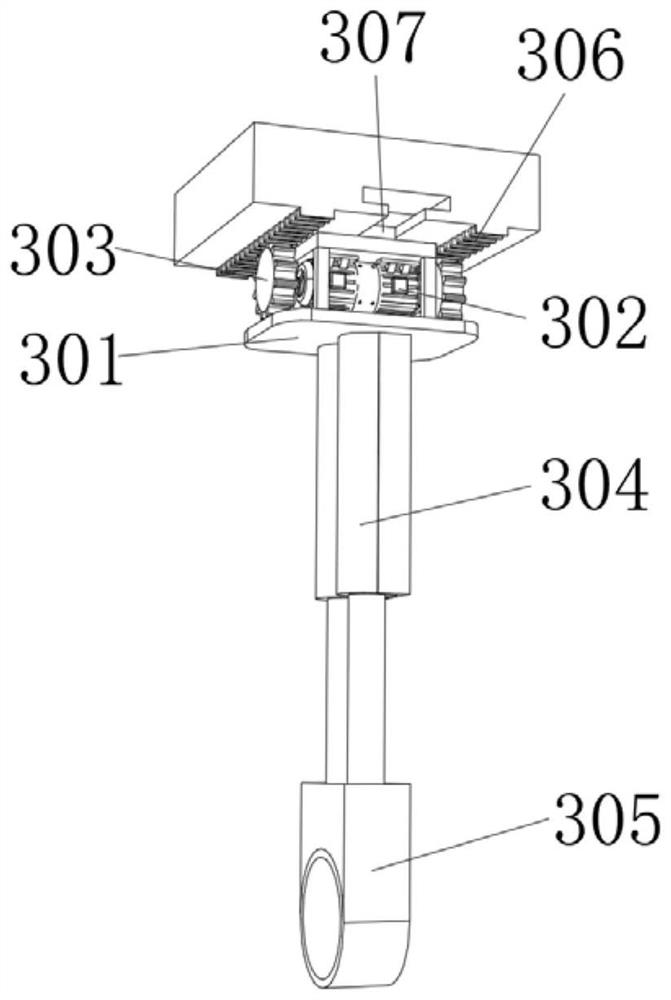

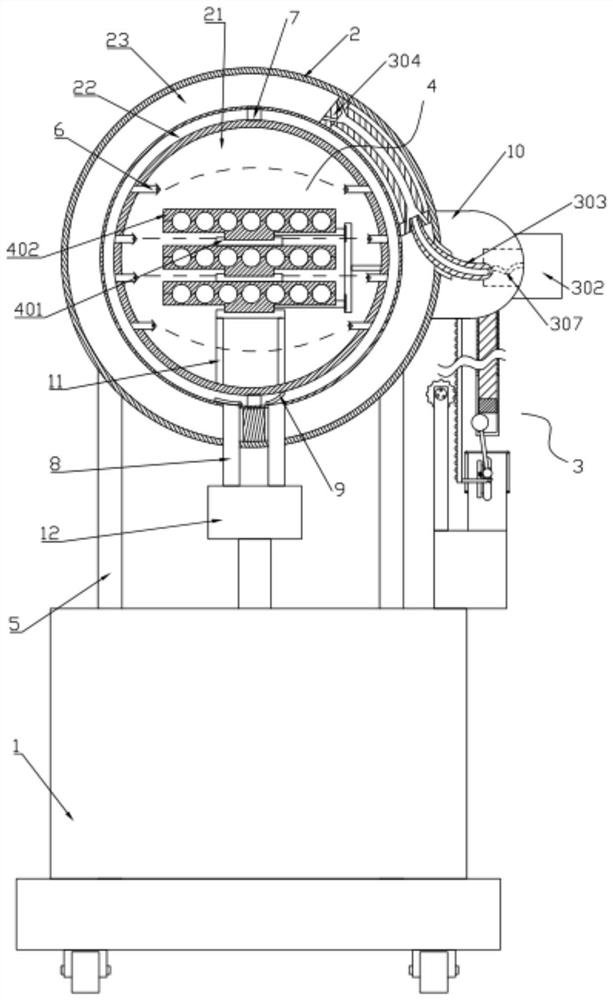

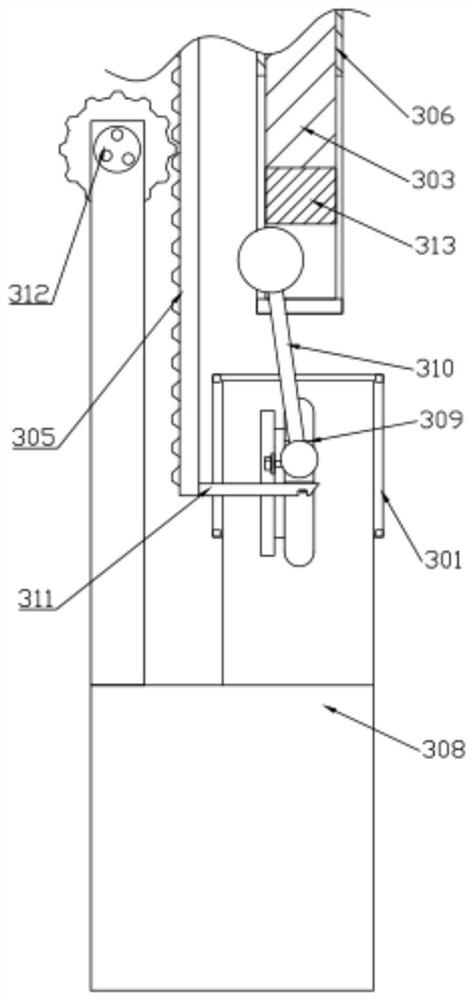

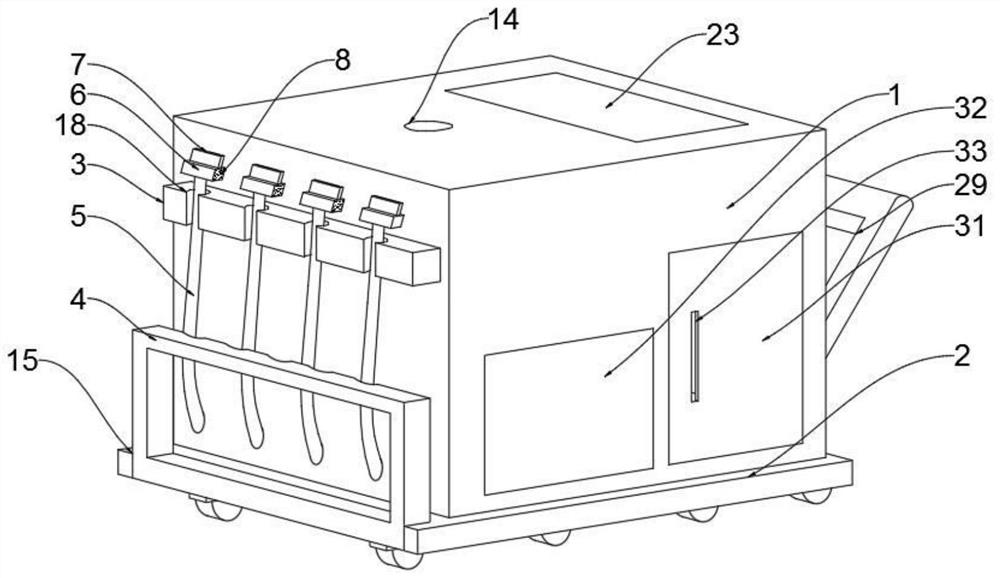

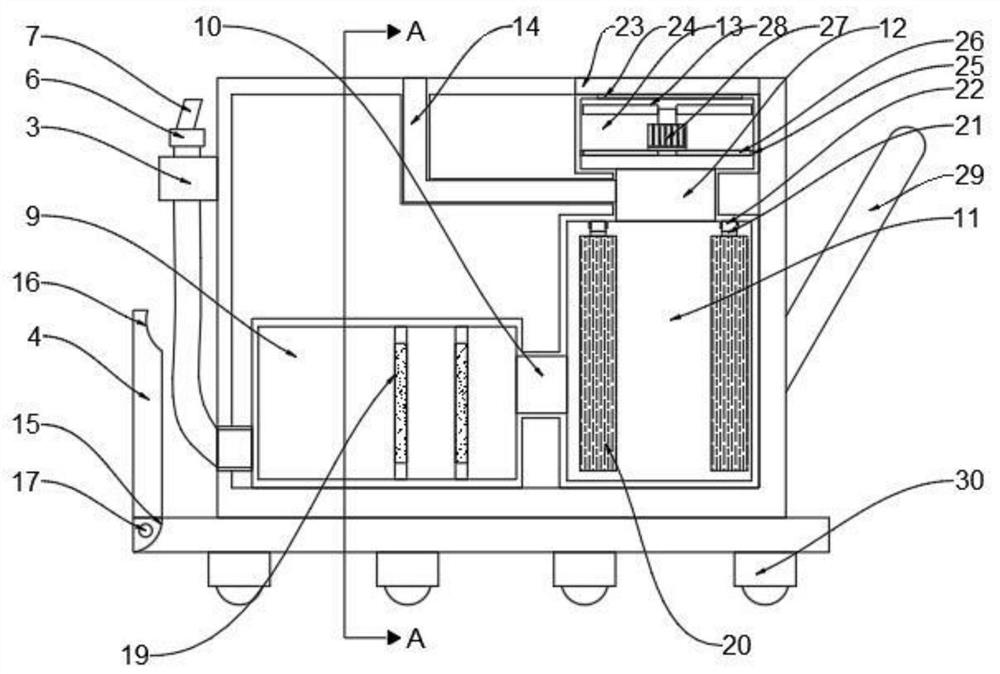

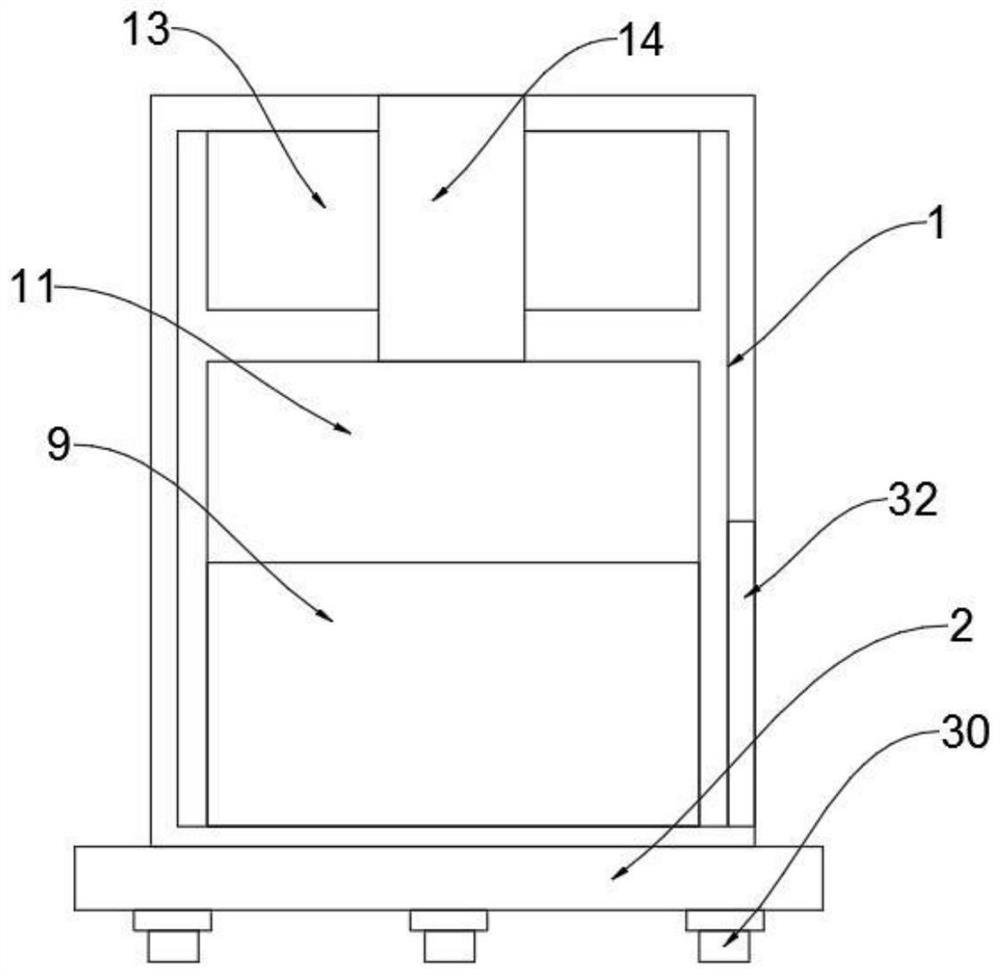

Automatic dust removal equipment for electric energy meters

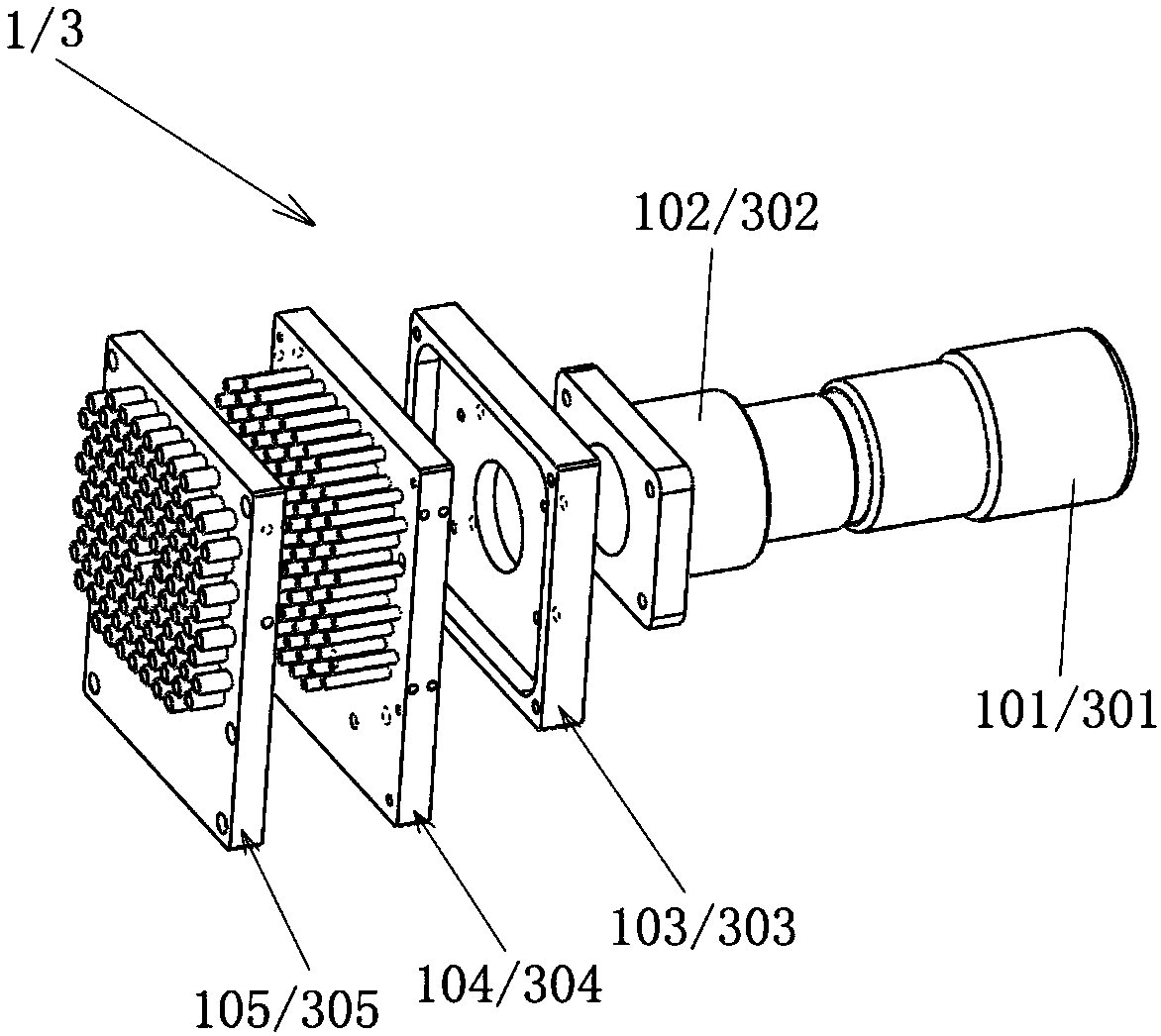

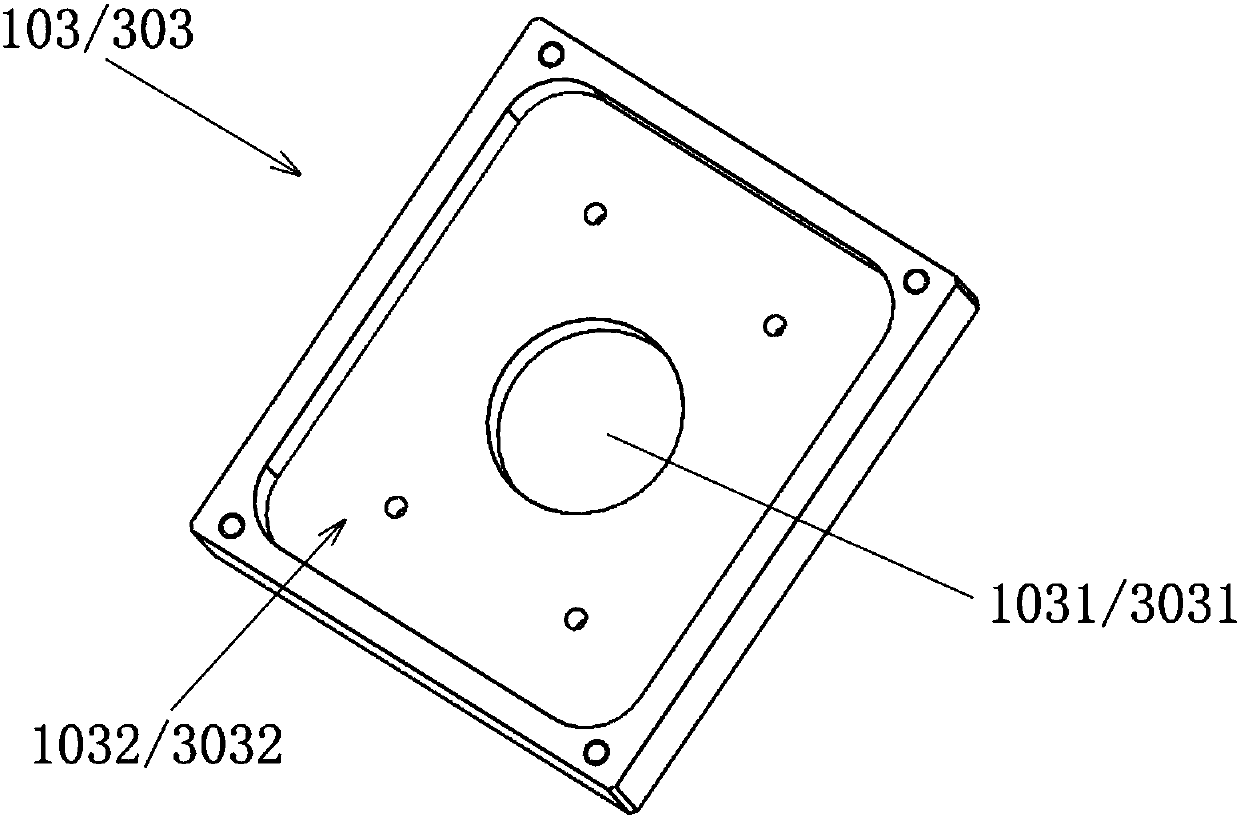

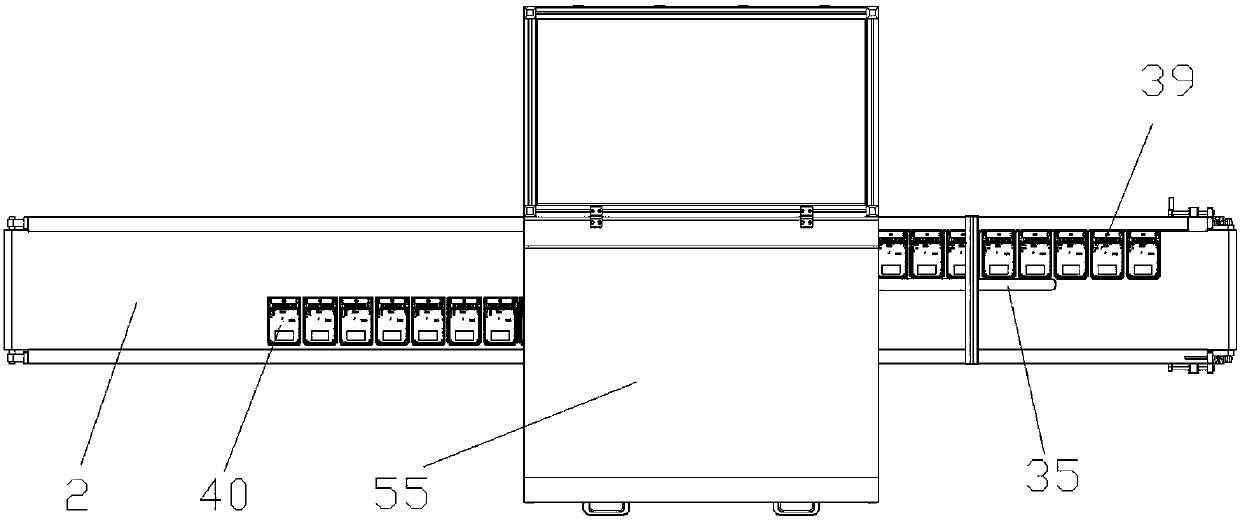

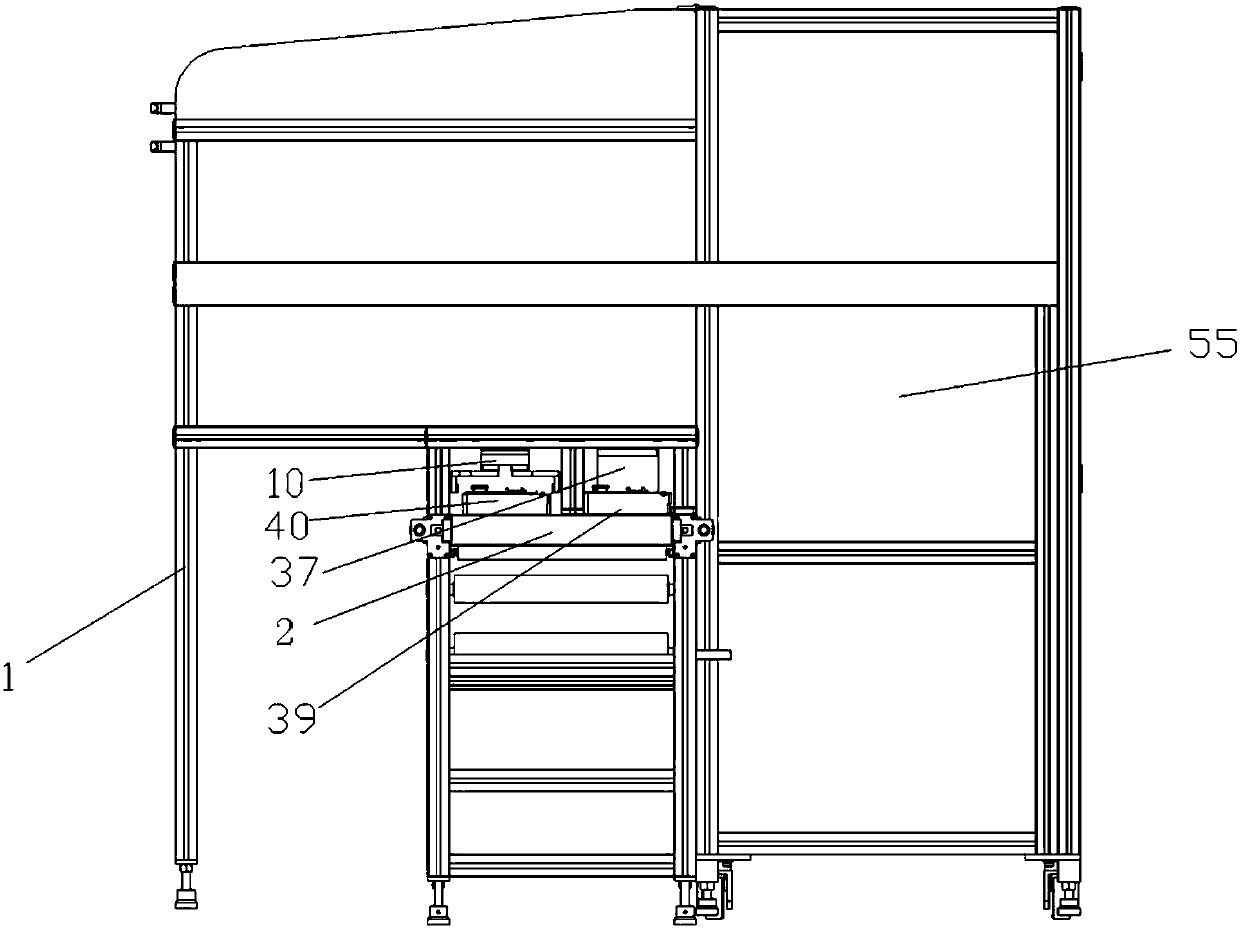

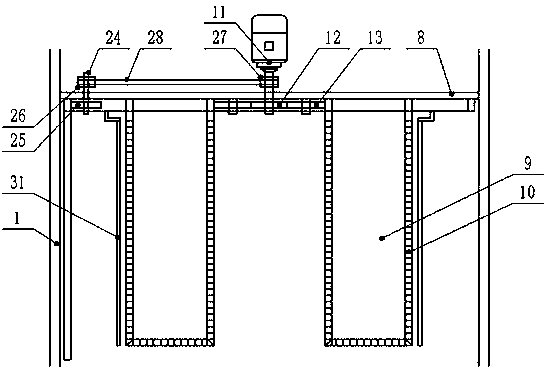

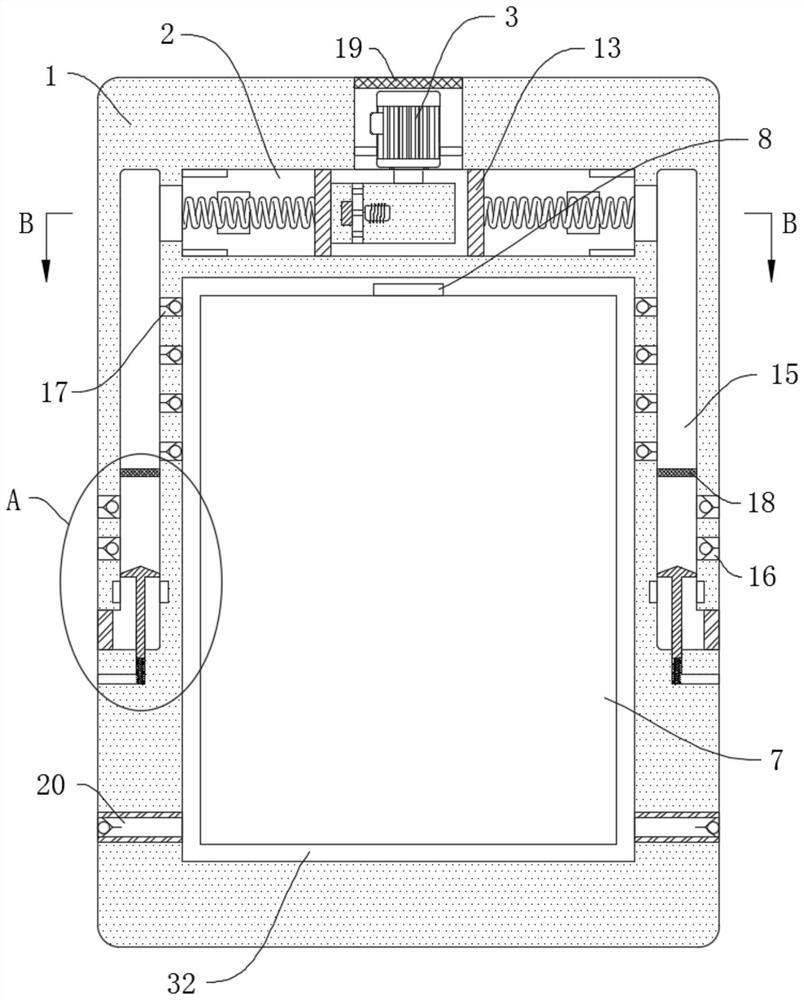

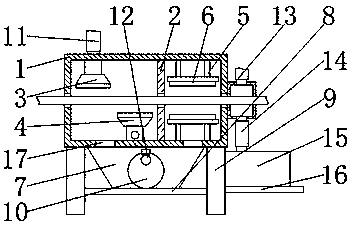

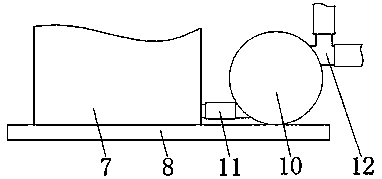

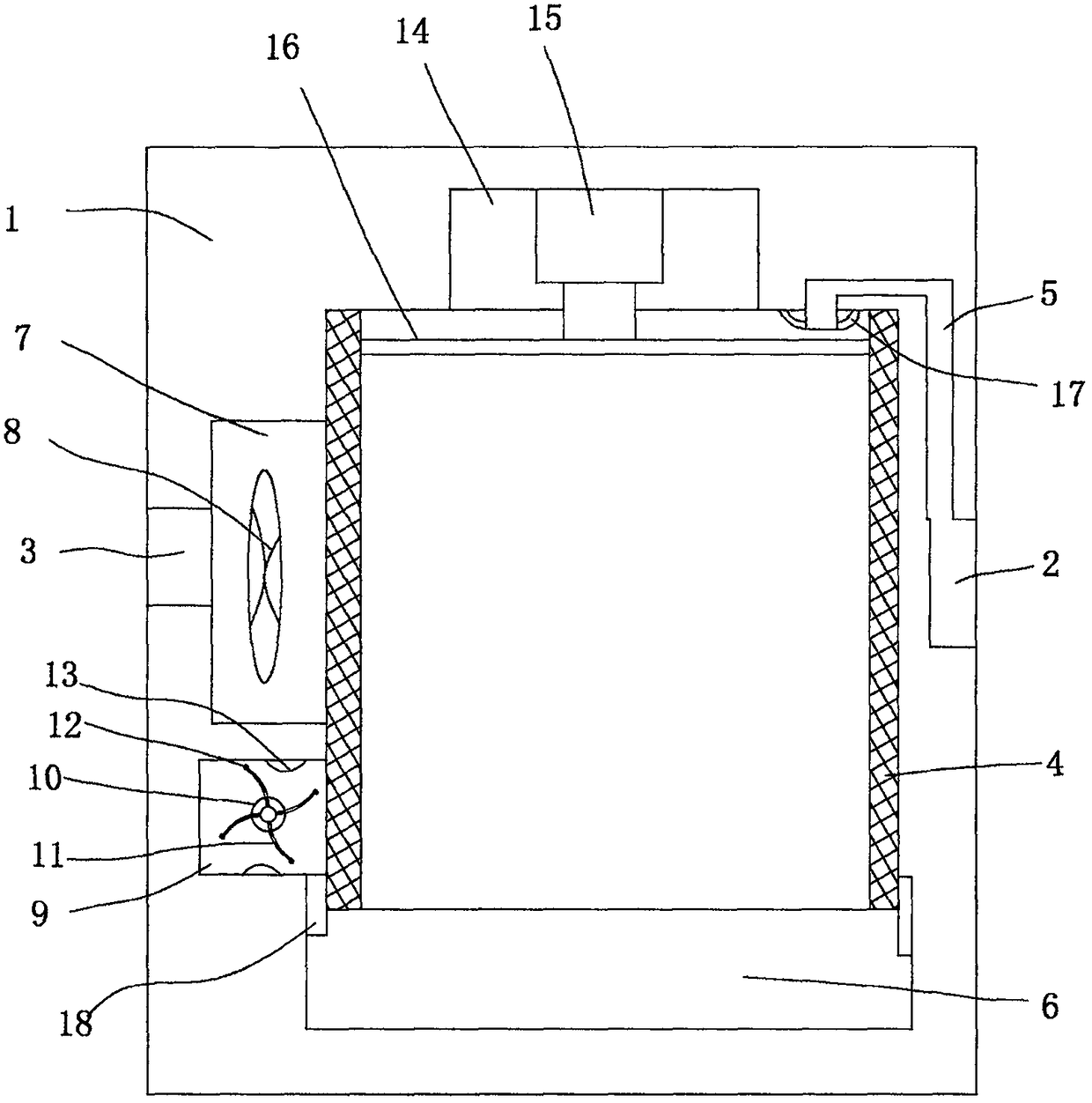

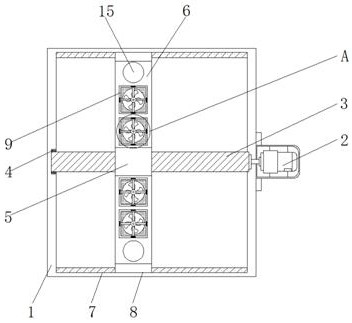

The invention discloses automatic dust removal equipment for electric energy meters. The automatic dust removal equipment for the electric energy meters comprises a rack, a conveying device and a dust removal device. The automatic dust removal equipment is characterized in that the conveying device and the dust removal device are arranged on the front part and the rear part of the rack in parallel; the dust removal device comprises a location fixture used for fixing the plurality of electric energy meters, an air-blowing device and a turnover mechanism used for driving the location fixture to turn over up and down; and a transferring-loading mechanism is further arranged above the rack, and between the conveying device and the location fixture, and used for grabbing the electric energy meters to be subjected to dust removal on the conveying device and moving the electric energy meters onto the location fixture or grabbing the electric energy meters subjected to dust removal on the location fixture and moving the electric energy meters onto the conveying device. According to the automatic dust removal equipment for the electric energy meters, the conveying device and the dust removal device are mutually separated, so that dust in the electric energy meters can be adequately eliminated.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

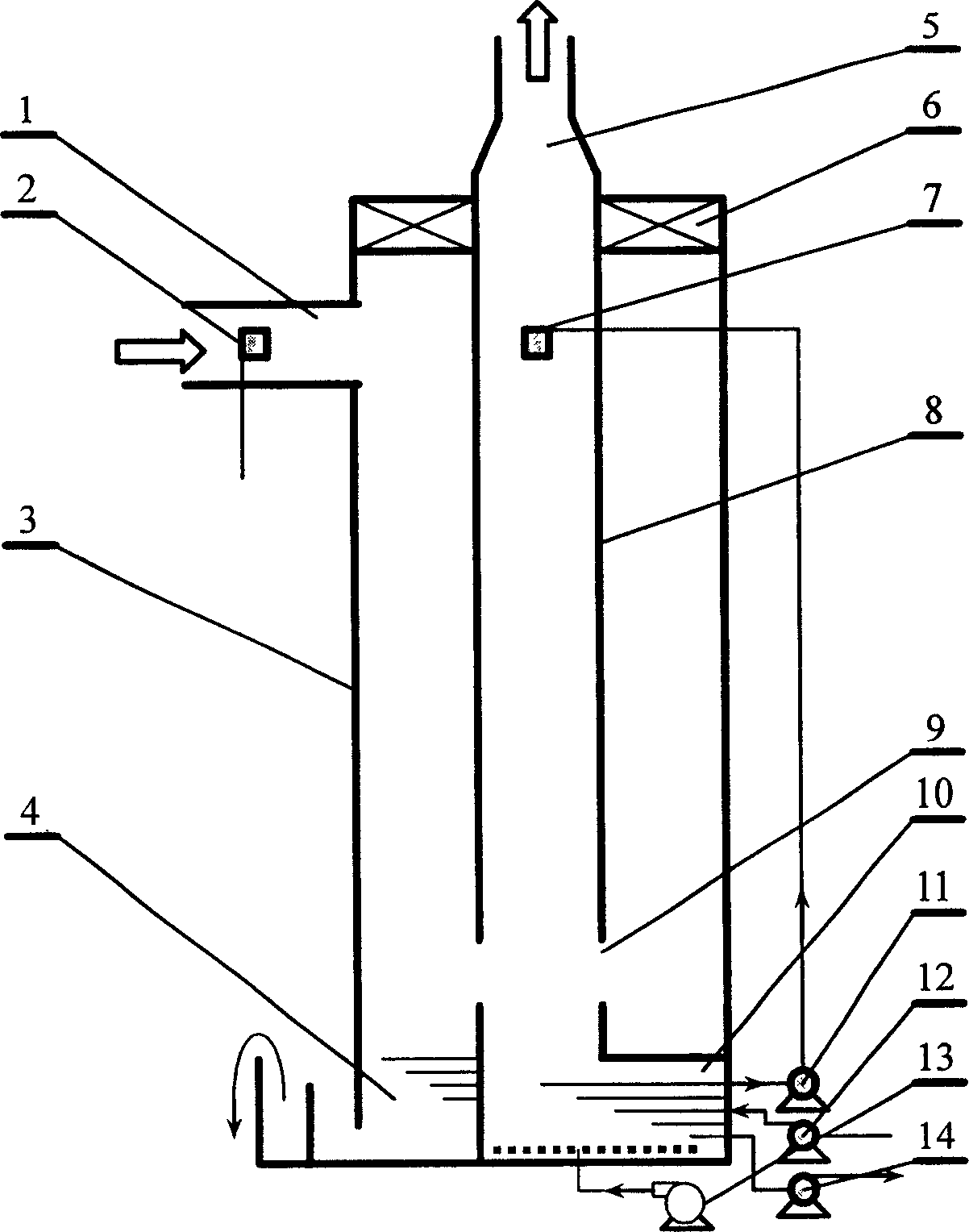

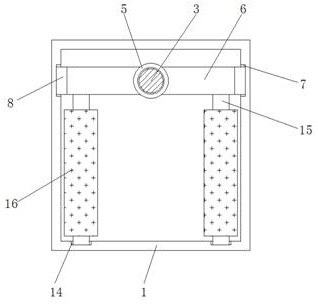

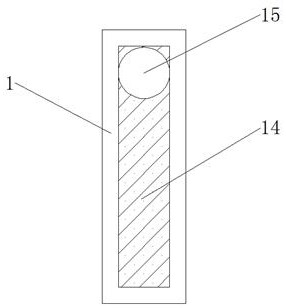

Radial grading desulfurization dust-removing device

InactiveCN101007238AGuaranteed dust removalImprove reliabilityDispersed particle separationNuclear engineeringProduct gas

The invention involves a radial grading desulfurizing dust cleaning apparatus which used for removing the dust and the sulfur dioxide gas in coal-fired boiler gas at the same time. The gas containing smoke and dust and sulfur dioxide are dedusted and desulfurized in two areas of circular reactor respectively which are divided radially, it is dedusted by cyclone water film in central area and is desulfurized in radial outer area. The invention divides the reactor into two regions along radially, reaches the effective separation of desulfurization and dedusting function, ensures the stability of desulfurization and dedusting property, improves system reliability and reduces the initial investment and operating costs.

Owner:SHANDONG UNIV

Filtering apparatus capable of realizing falling of dust from filter screen

ActiveCN106902579AGuaranteed filtering effectGuaranteed dust removalGas treatmentDispersed particle filtrationEngineeringFilter effect

Owner:北京新世翼节能环保科技股份有限公司

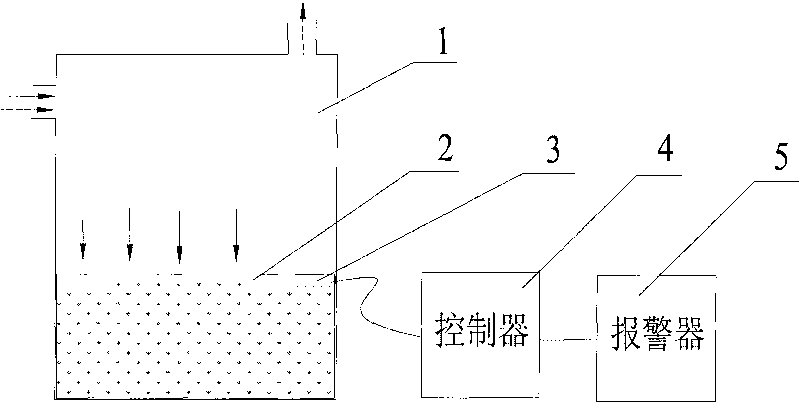

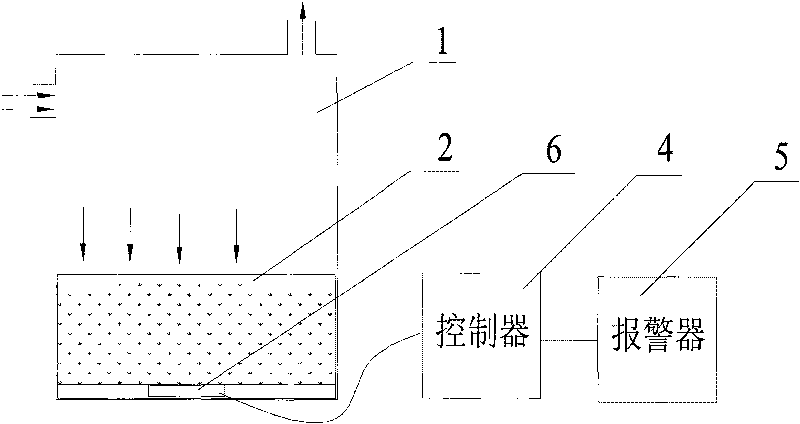

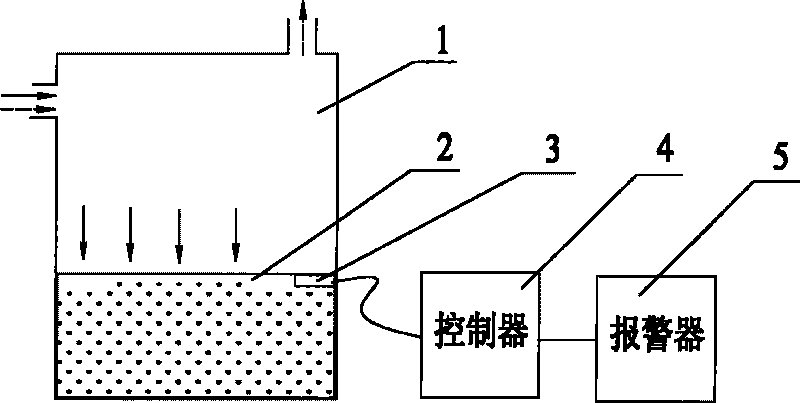

Cut tobacco recycling device in dedusting system of machine for cutting tobacco leaves

The invention discloses a cut tobacco recycling device in a dedusting system of a machine for cutting tobacco leaves, comprising a cut tobacco and fume dust separating cavity, a cut tobacco recycling box, a metering device, a controller and an alarming device. The cut tobacco recycling box is arranged at the bottom of the cut tobacco and fume dust separating cavity; the metering device is arranged on the cut tobacco recycling box and is used for detecting and outputting a cut tobacco metering signal in the cut tobacco recycling box; the controller is used for calculating the amount of the cut tobacco in the cut tobacco recycling box according to the cut tobacco metering signal and outputting an alarm prompting signal when the amount of the cut tobacco reaches the preset amount; and the alarming device is used for sending an alarming signal according to the alarm prompting signal. Because the amount of the cut tobacco in the cut tobacco recycling box is detected, the cut tobacco can be recycled at right time, the blockage of the air channel can be avoided, and the machine for cutting the tobacco leaves can be kept dedusting normally.

Owner:CHINA TOBACCO GUANGDONG IND

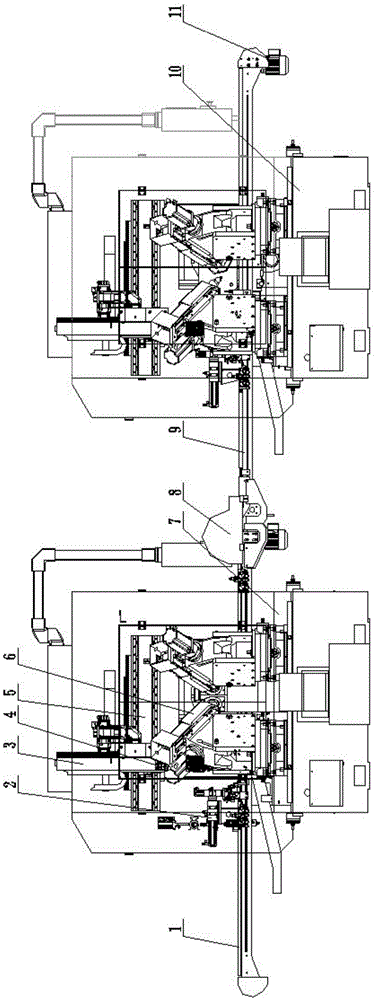

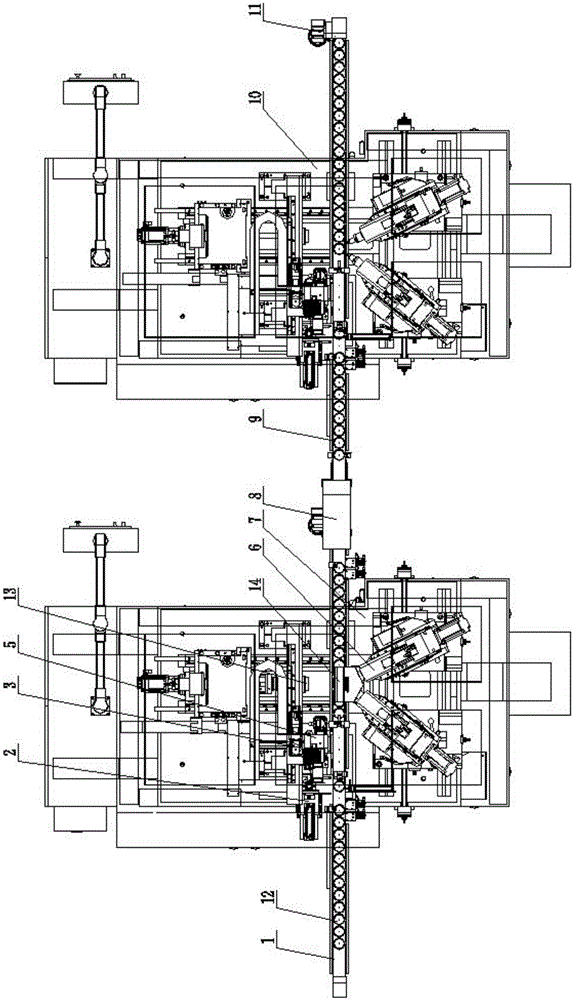

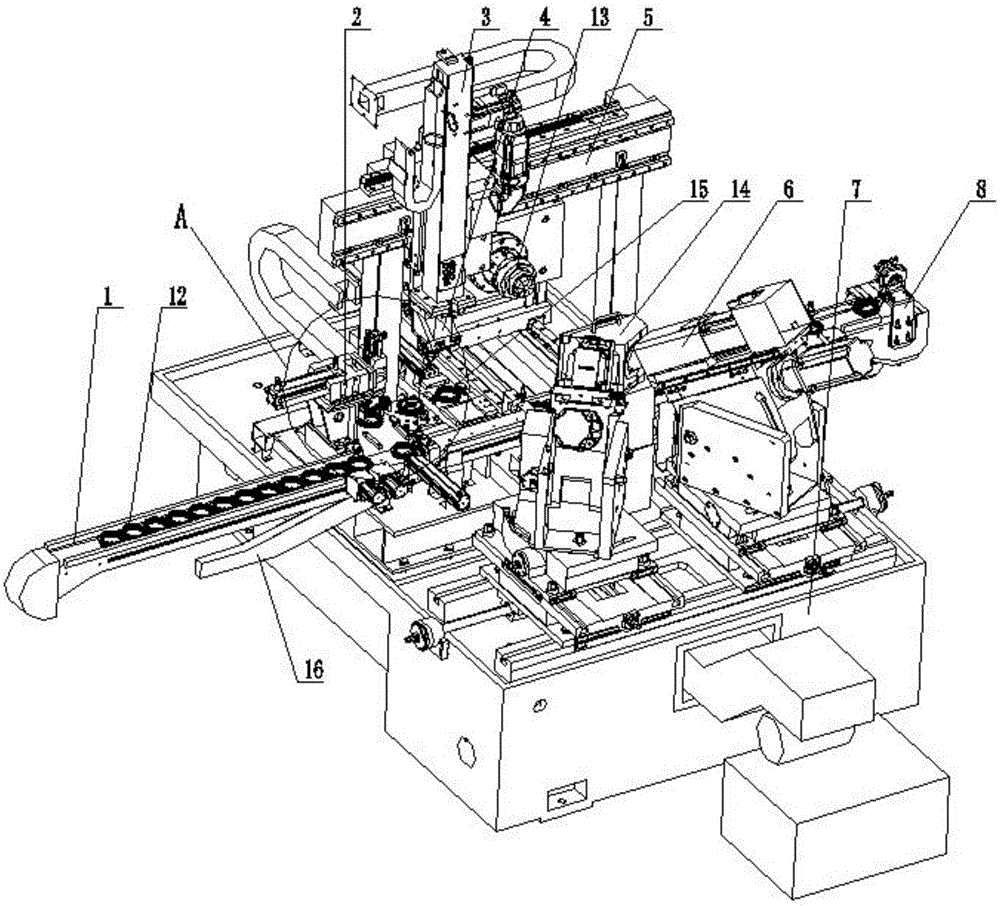

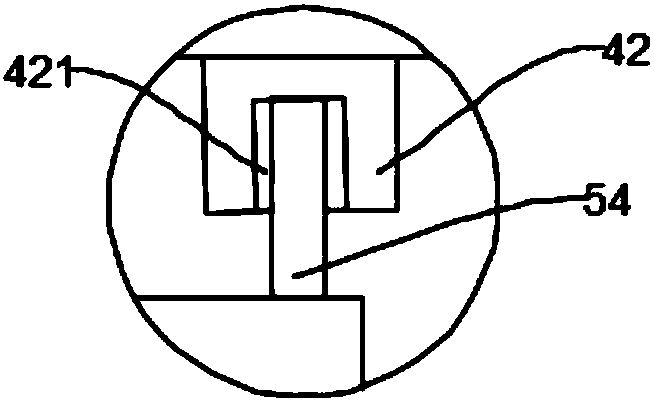

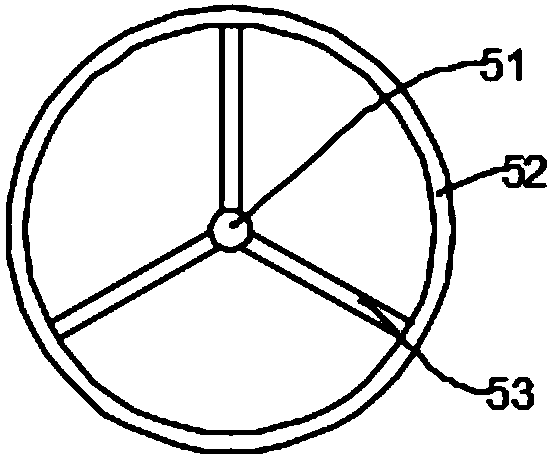

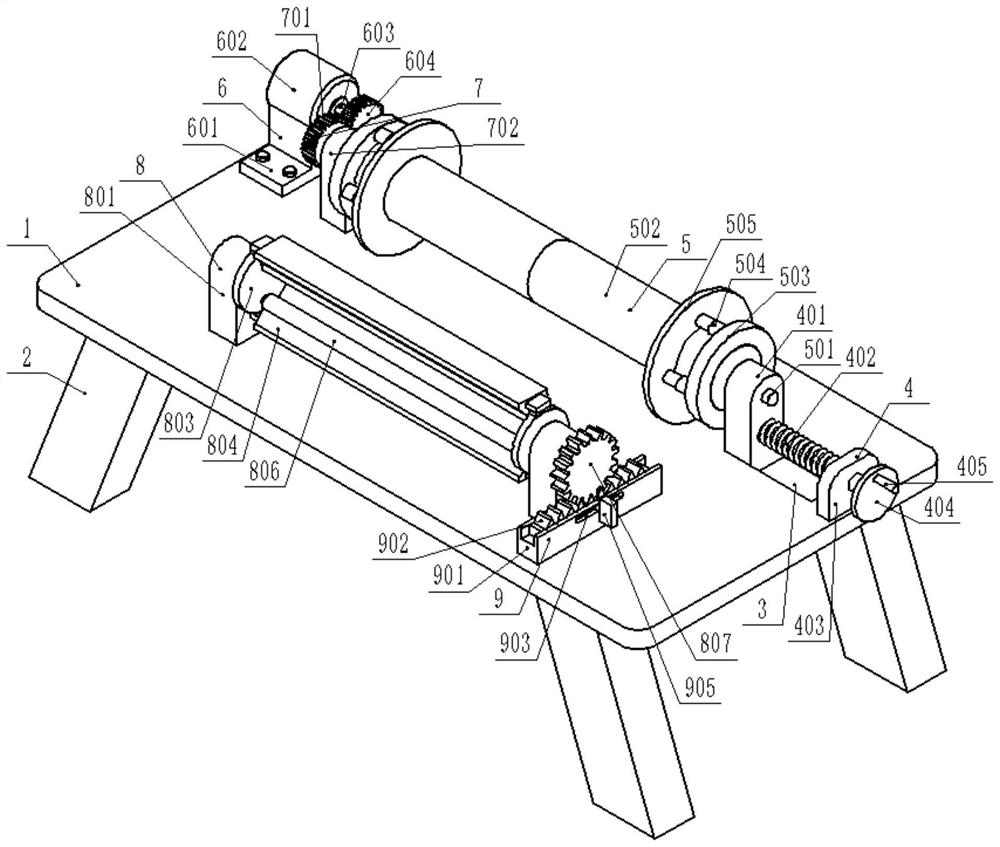

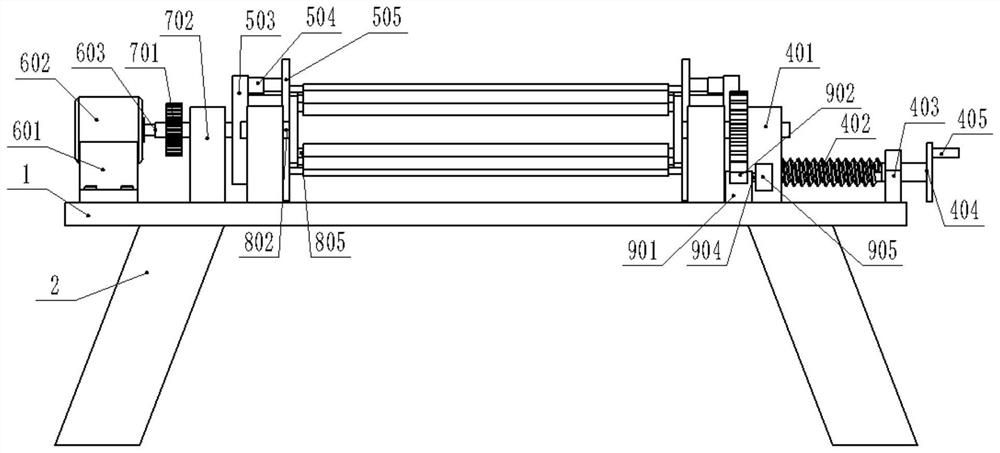

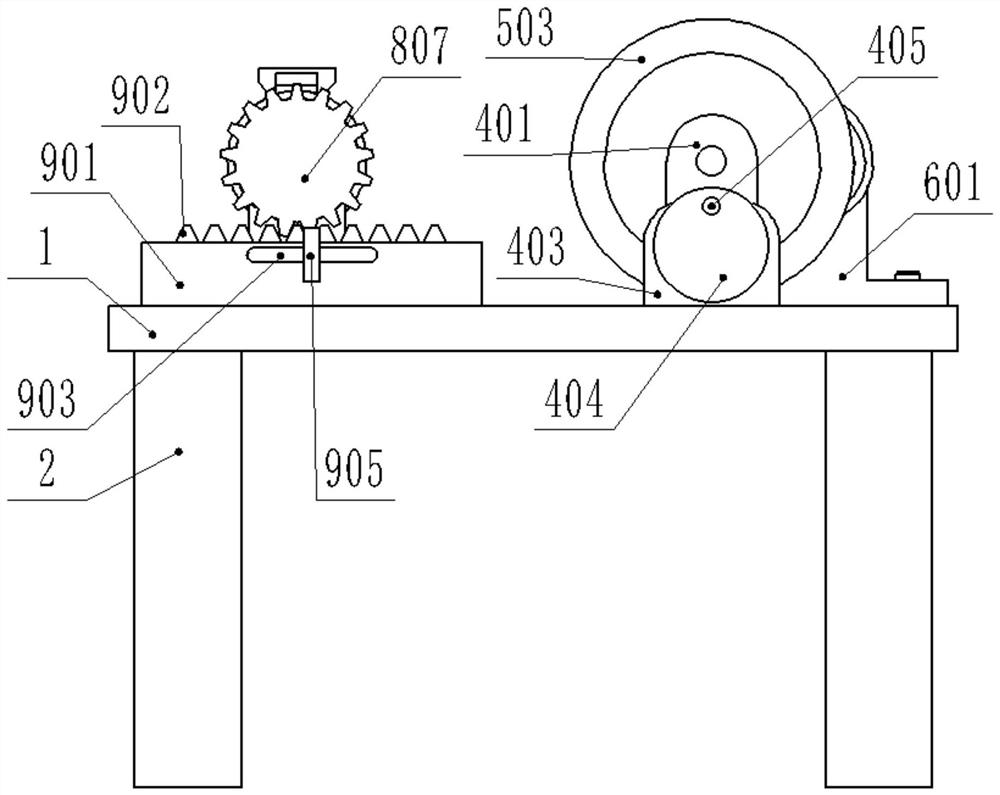

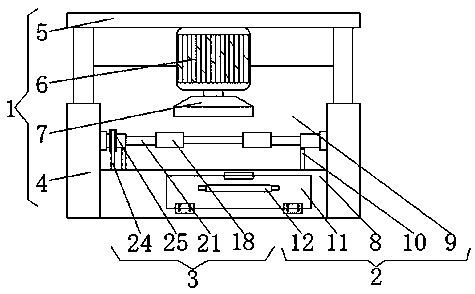

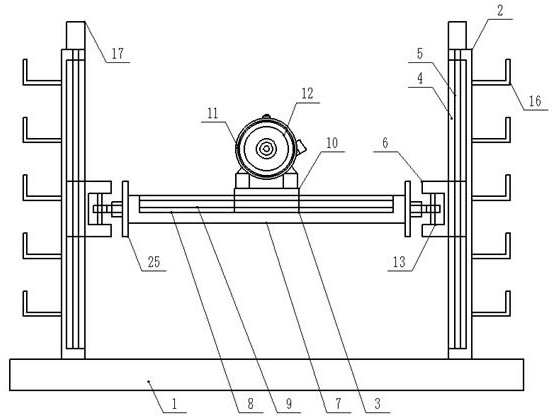

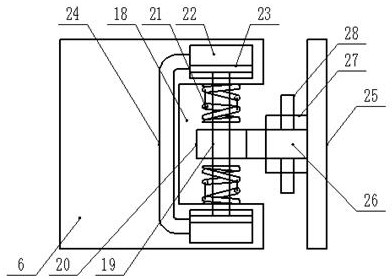

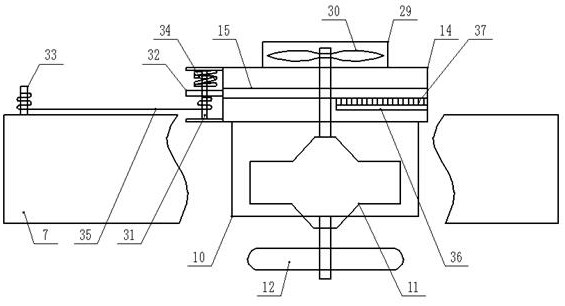

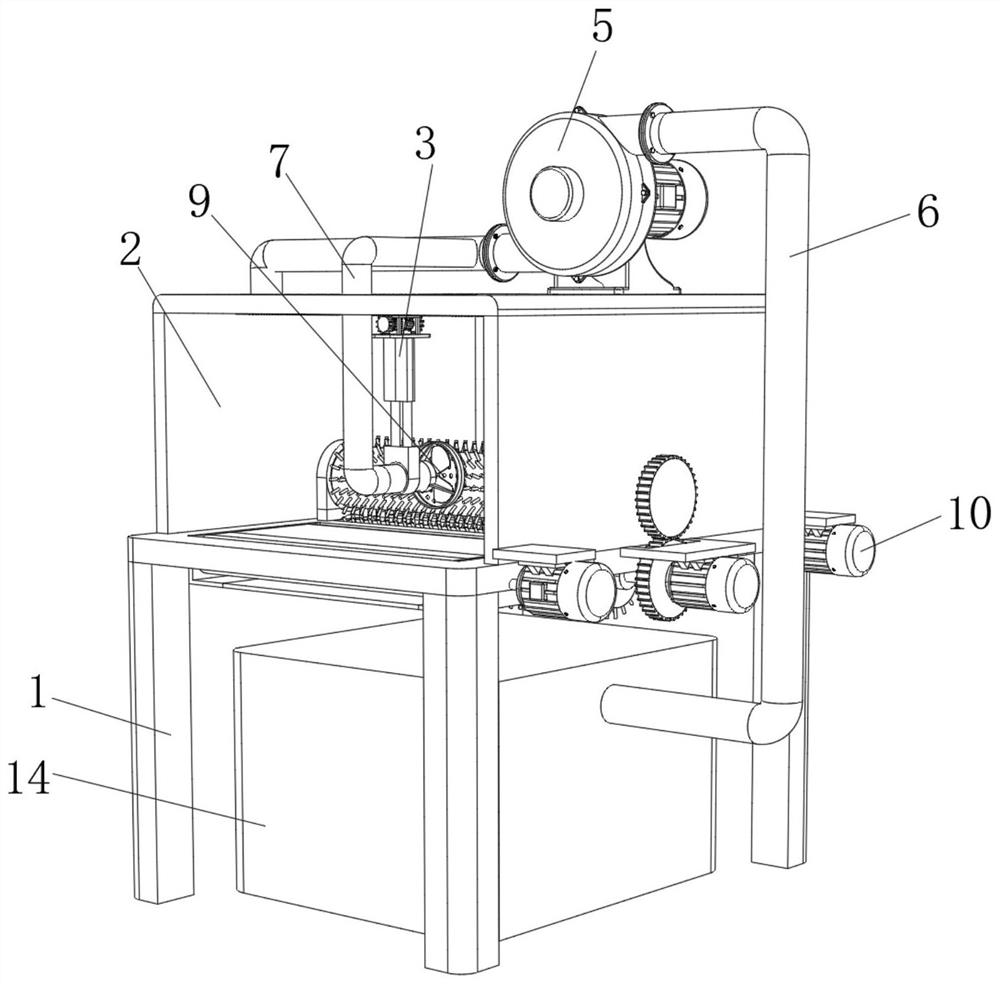

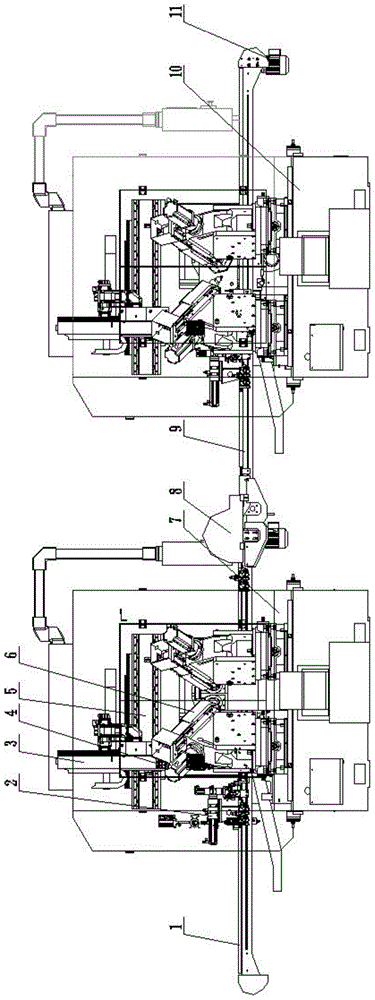

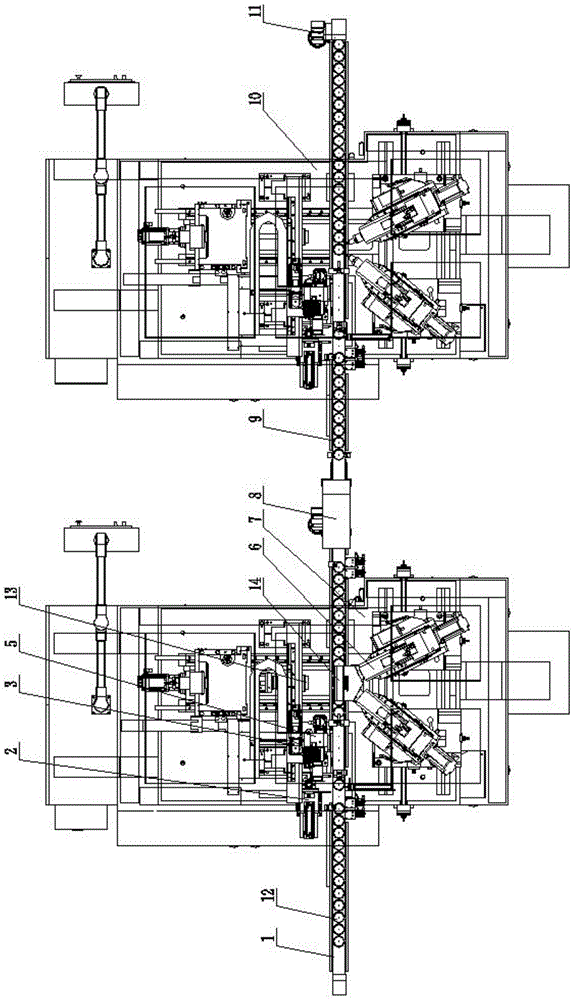

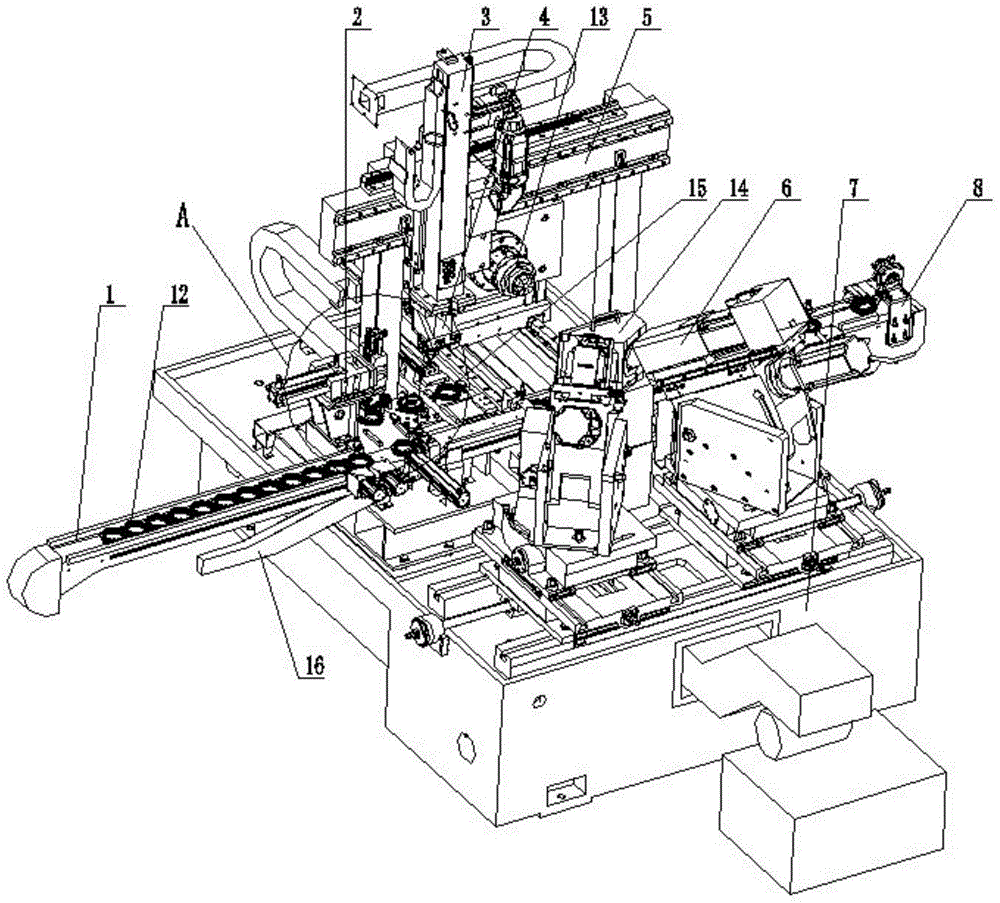

Double-face chamfering continuous machining system for gear sleeve of vehicle synchronizer

ActiveCN105149698AReduce configurationGuaranteed accuracyMetal working apparatusMaintainance and safety accessoriesDrive motorMachining system

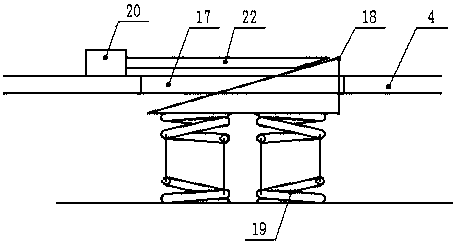

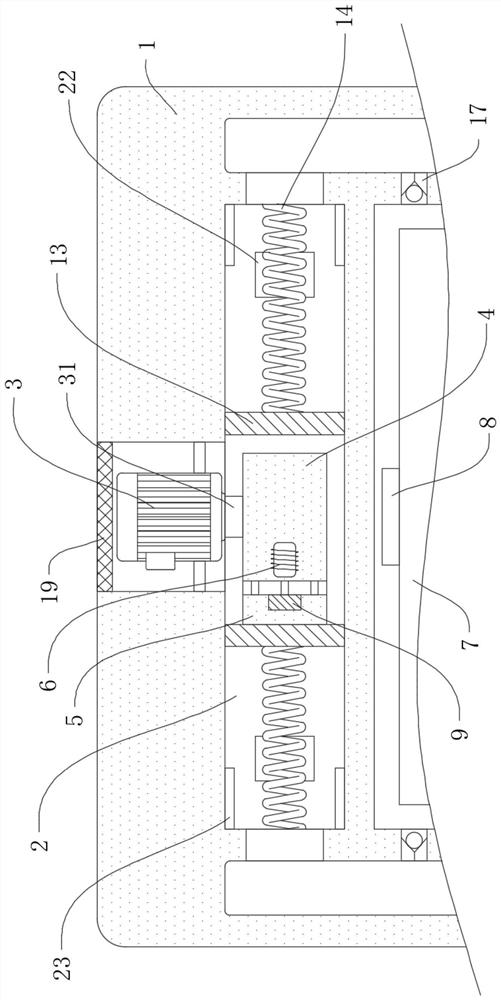

The invention relates to a double-face chamfering continuous machining system for a gear sleeve of a vehicle synchronizer. The double-face chamfering continuous machining system is formed by two same double-cutter machining chamfering machines and a linear feeding mechanism penetrating two chamfering machine machining stations transversely; the two same double-cutter machining chamfering machines are arranged into a row in parallel, each chamfering machine comprises a cutter for conducting chamfering machining, a workpiece driving machine head and a tooth alignment mechanism, a center line where the two cutters are located is arranged to right face the workpiece driving machine heads, tooth alignment mechanisms are arranged at front end working procedure components of the workpiece driving machine heads, and the workpiece driving machine heads are installed on a machine head base; each chamfering machine is horizontally and fixedly provided with a linear type feeding mechanism at the position, in front of the workpiece driving machine heads and behind the two cutters, of the corresponding machine body, and each linear type feeding mechanism is driven by a driving motor to drive a transmission belt in a material way to rotate; and a tooth sleeve turnover mechanism is installed between the two linear type feeding mechanisms, and pushing air cylinders are fixedly installed on the outer sides, corresponding to the tooth alignment mechanisms, of the material way. By means of the machining system, double-face chamfering machining of an overall tooth sleeve can be completed at a time, the production efficiency is greatly improved, meanwhile, allocation of a feeding mechanical arm and a feeding mechanism is omitted, and the overall machining area is decreased.

Owner:TIANJIN DAXIN PRECISION MECHANICAL EQUIP

Construction site sand screening device capable of preventing raise dust

InactiveCN108160458AAvoid pollutionProtect your healthSievingScreeningScreening effectPhysical well being

Owner:安徽嘉诚建设工程有限公司

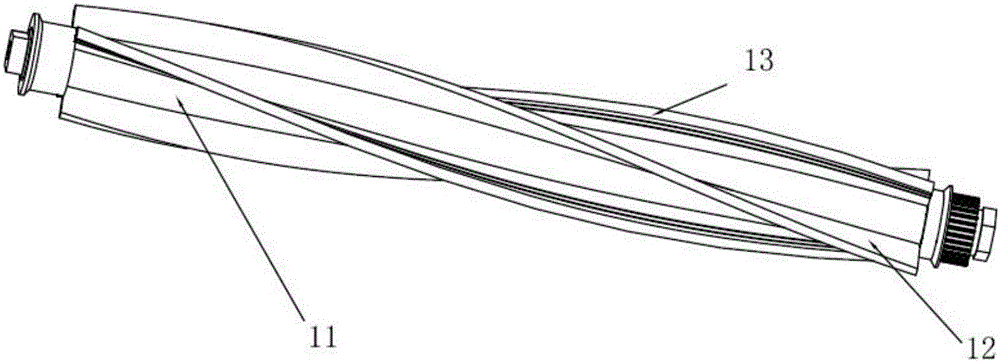

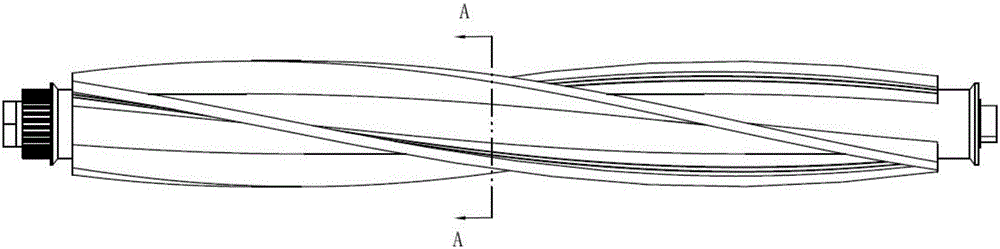

Rolling brush and cleaning appliance with same

InactiveCN105919513AEliminate static electricityMinimize or avoid damageSuction nozzlesElectric equipment installationBristleBand shape

The invention discloses a rolling brush which comprises flexible bristle strips and strap-shaped flexible rubber structures. The flexible bristle strips and the strap-shaped flexible rubber structures are alternately mounted. The rolling brush has the advantages that static electricity on bed surfaces can be eliminated during cleaning, adhesive fine dust generated by the static electricity can be sucked, and accordingly the dust removal capacity of the rolling brush can be improved; damage to super-soft materials such as wool and silk can be reduced or prevented when the rolling brush is used for cleaning, and accordingly unnecessary loss can be reduced; dust in the deep layers can be removed by the strap-shaped flexible rubber structures by means of patting, the deep layers can be simultaneously patted and cleaned, and accordingly the cleaning efficiency can be improved.

Owner:KINGCLEAN ELECTRIC

Dust collection device

InactiveCN102728153AExtend the lifespanReduced lifespanDispersed particle filtrationBaghouseStructural engineering

The invention provides a dust collection device, which comprises a bracket. The bracket is arranged right above a dust collection point, a box body is fixedly arranged on the bracket, and a deflector is arranged between the upper box body and the lower box body of the box body. A bag-type dust collector is arranged in the upper box body. The bottom end of the lower box body is movably connected with a dust discharging slide. A blowing device is fixedly arranged outside the box body. The blowing device is communicated with the upper box body through a blow tube. With the adoption of the dust collection device, the generated dust is absorbed to achieve the purpose of purifying the environment and realizing the standard of the environment protection. The detained dust on a filtering bag is timely cleared through pulse airflow, and therefore, the dust collection effect of the bag-type dust collector can be guaranteed.

Owner:解波

Atomization dust removal device for refuse treatment station

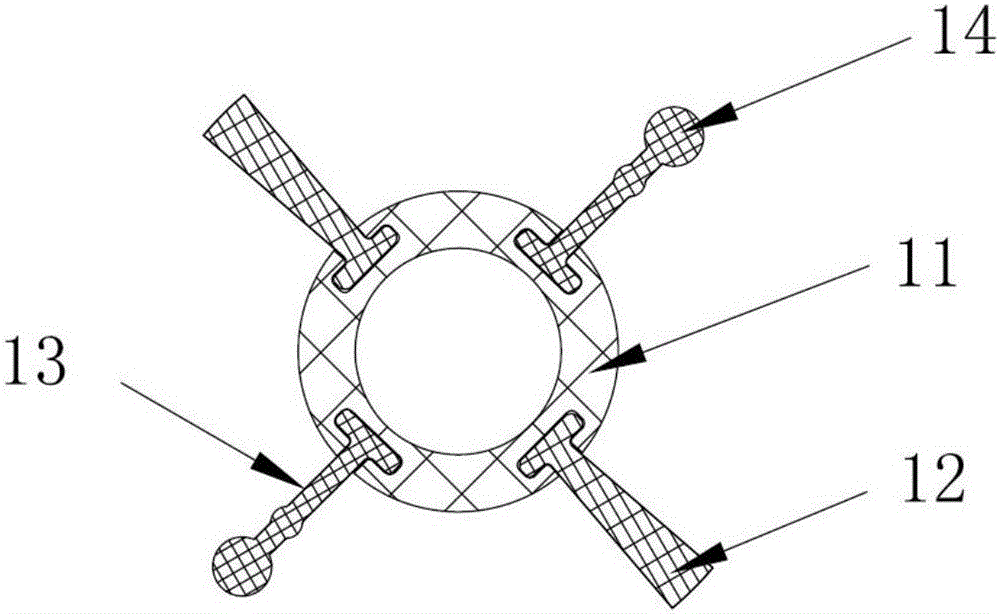

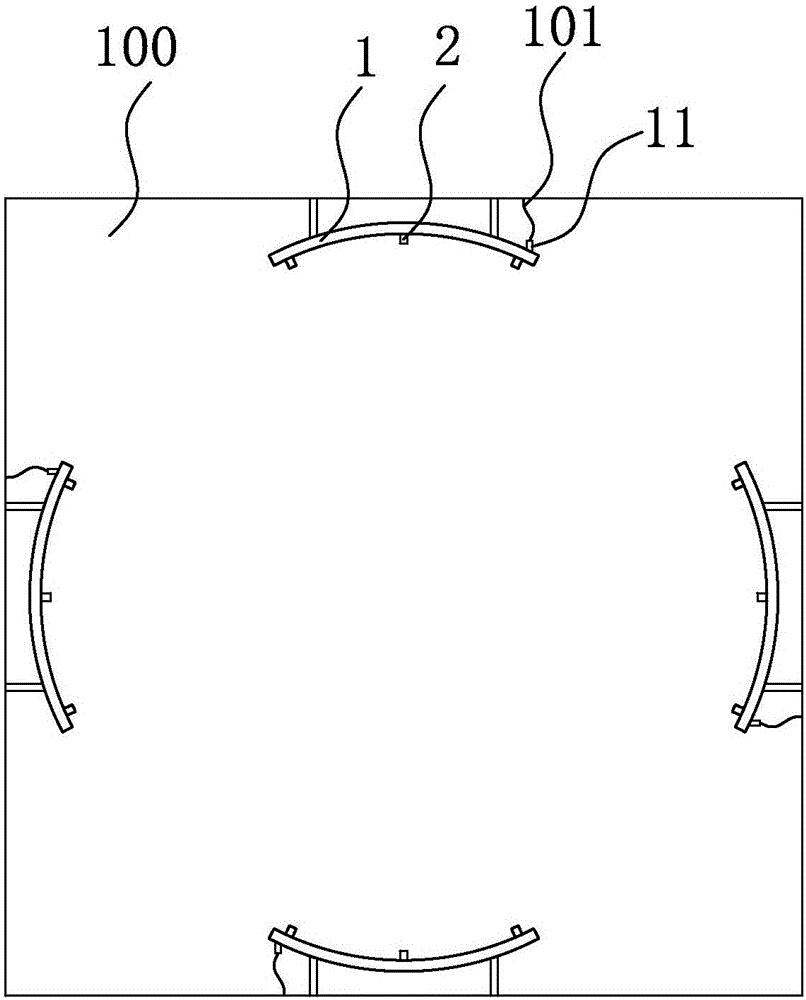

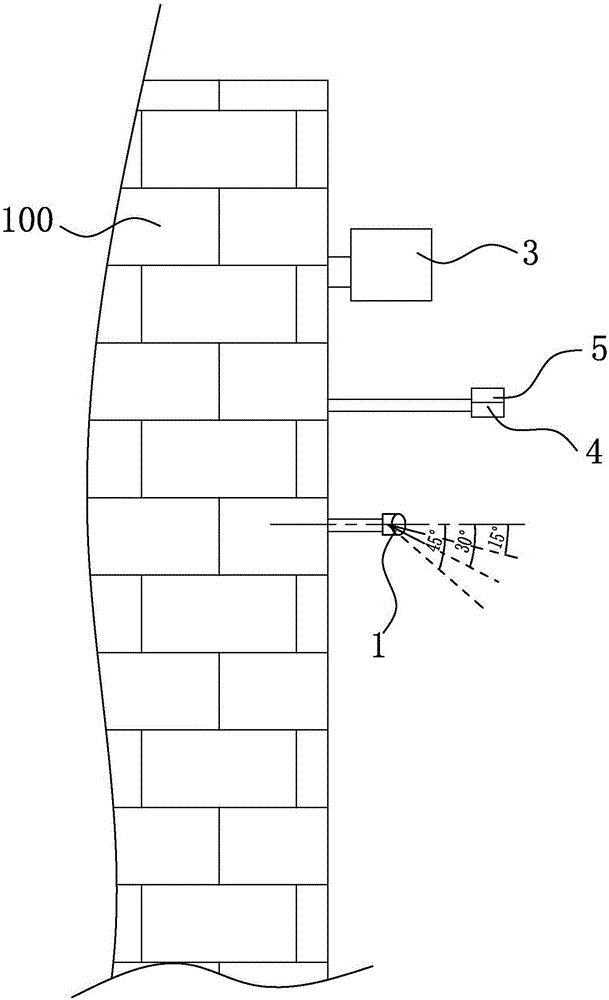

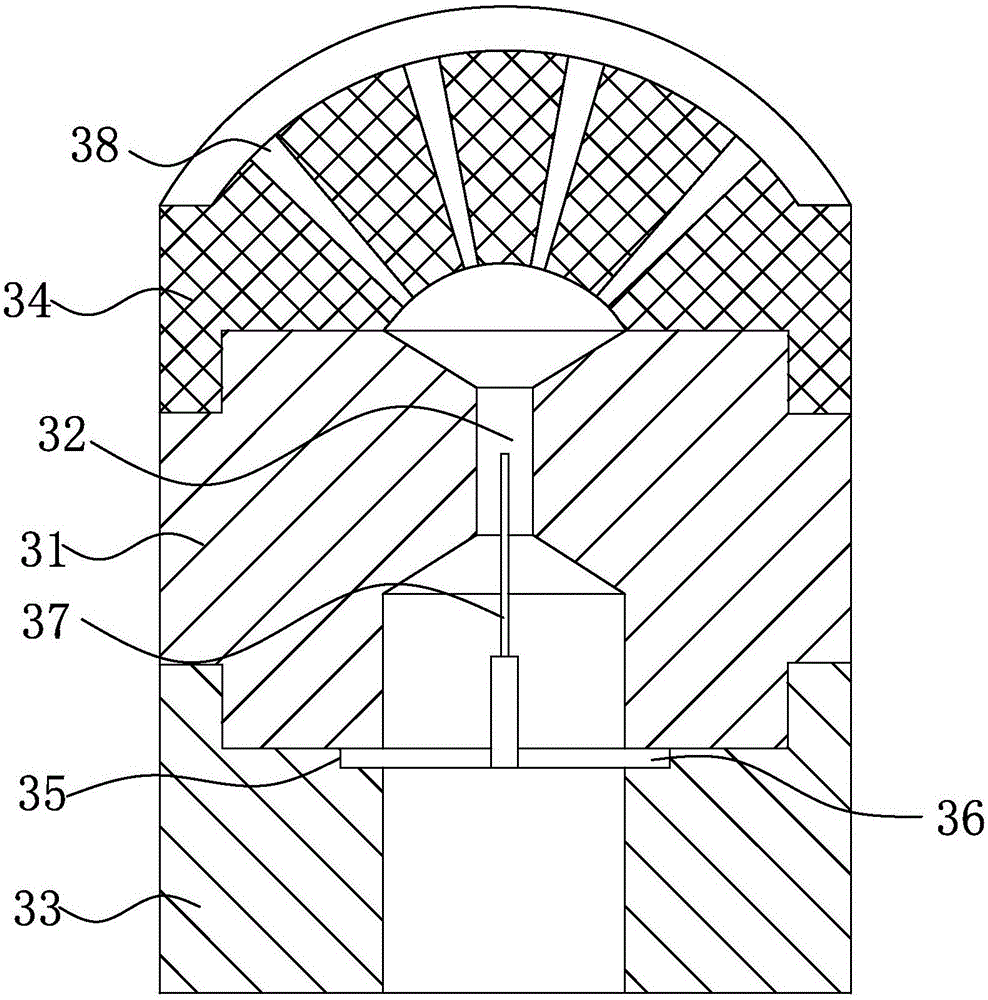

ActiveCN106823623AGuaranteed water mist concentrationWill not touch each otherUsing liquid separation agentDirt cleaningSlant angleSpray nozzle

The invention relates to the environmental purification field and particularly relates to an atomization dust removal device for a refuse treatment station. The atomization dust removal device comprises a water pump, atomization equipment and four atomizing nozzle mechanisms, wherein the four atomizing nozzle mechanisms are connected to the atomization equipment and the water pump through pipelines and are respectively mounted on four walls in a discharging room. The atomization dust removal device is characterized in that each atomizing nozzle mechanism comprises a spray pipe and a plurality of nozzles arranged on the radial direction of the spray pipe, wherein a water inlet connected with the atomization equipment or the water pump is formed in one end of the spray pipe, horizontal downward slant angles formed by the output directions of the spray nozzles and the horizontal direction are 15-45 degrees, and the slant angles formed by the output directions of the spray nozzles and the horizontal direction are different and uniformly increase from the water inlet to the other end of the spray pipe; and each atomizing nozzle mechanism comprises a parallel nozzle, and the parallel nozzle is arranged above the spray pipe and is connected with the atomization equipment.

Owner:福建鑫骉科技有限公司

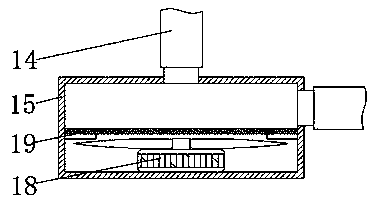

Lens dedusting device

PendingCN107931248AImprove dust removal efficiencyDust removal speed is fastDirt cleaningCleaning using gasesEngineeringElectrical and Electronics engineering

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

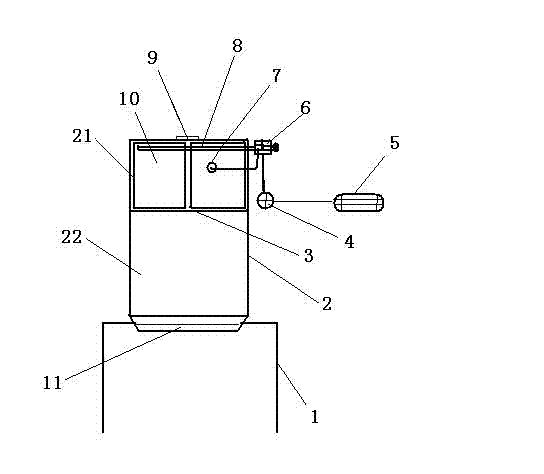

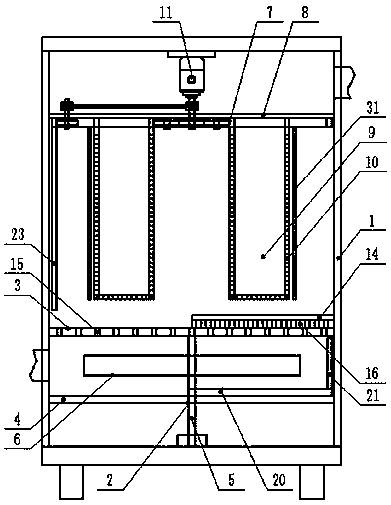

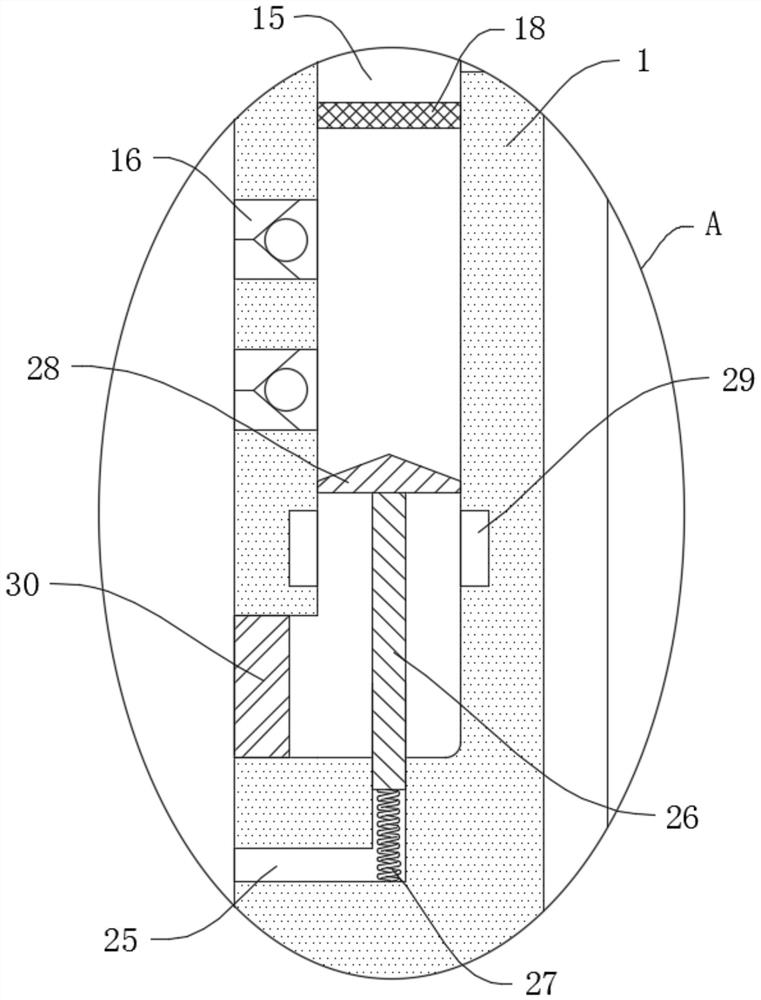

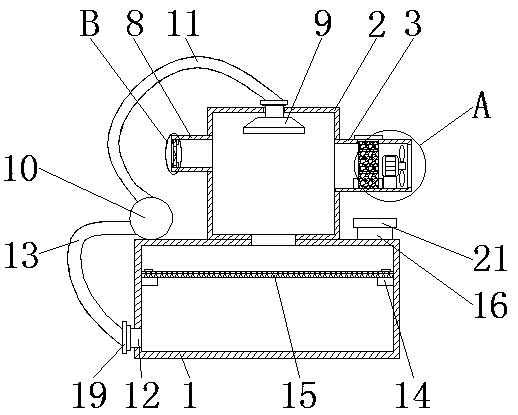

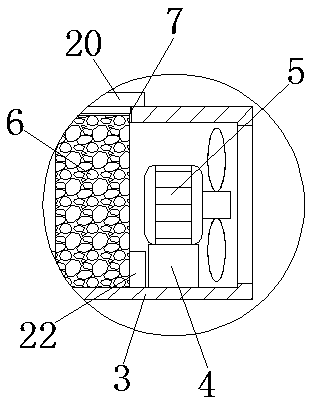

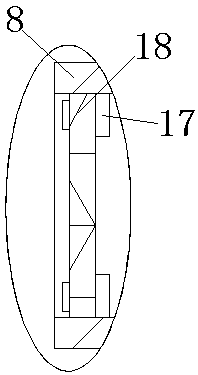

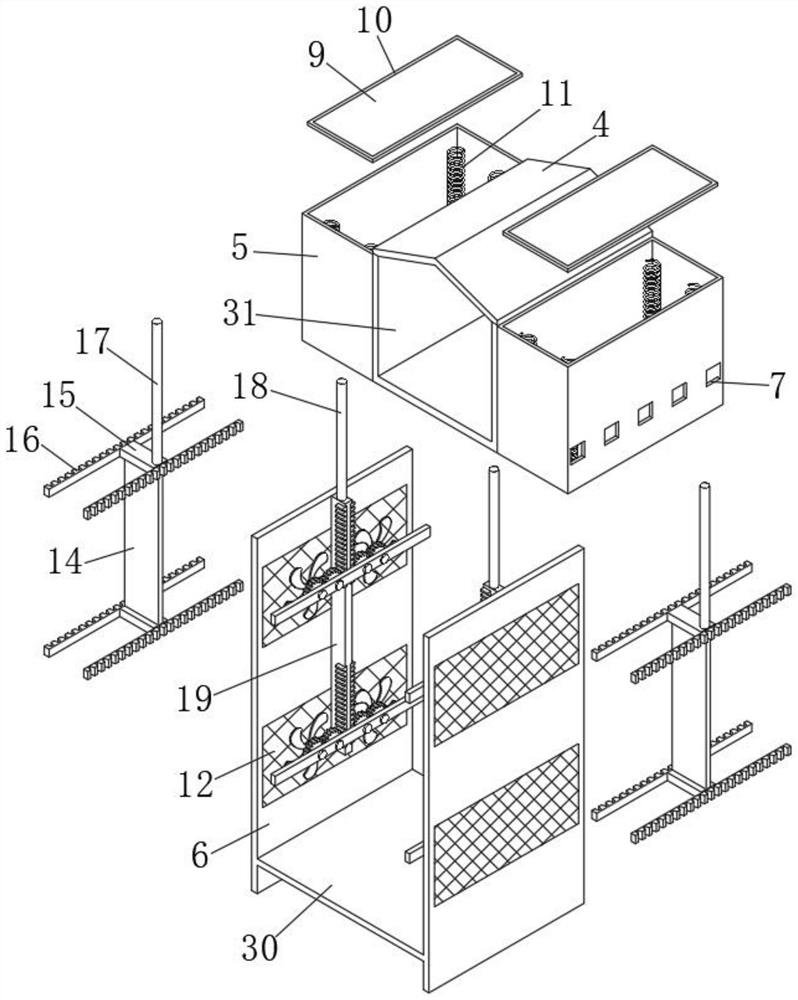

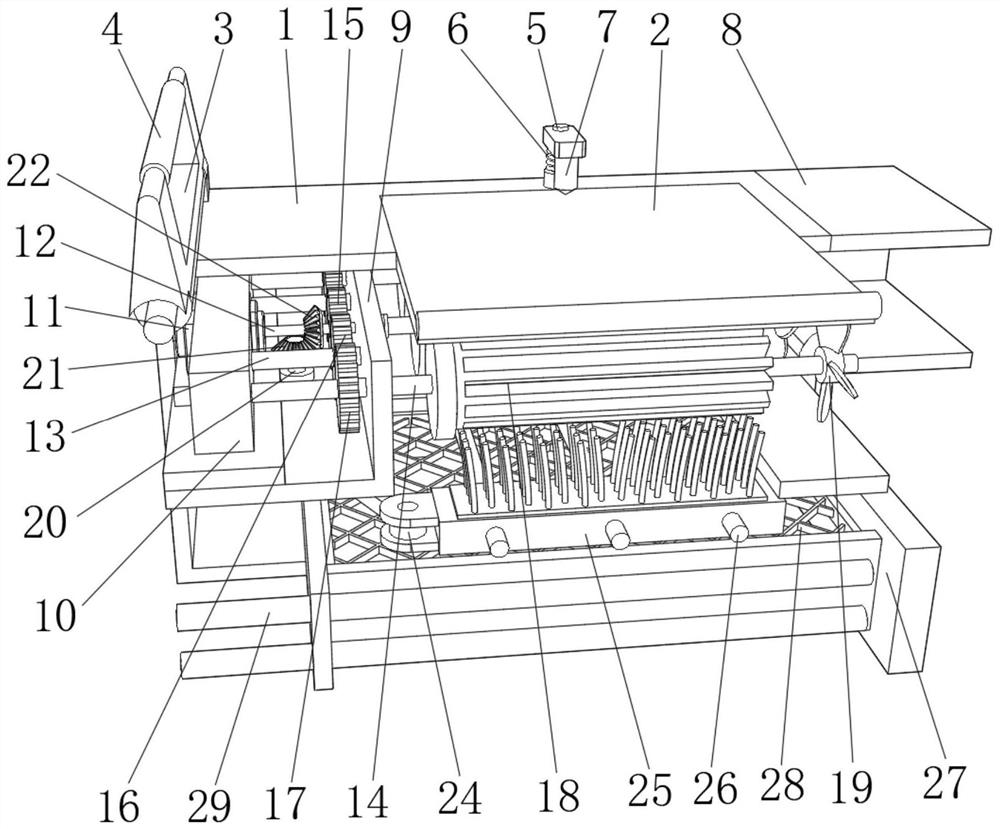

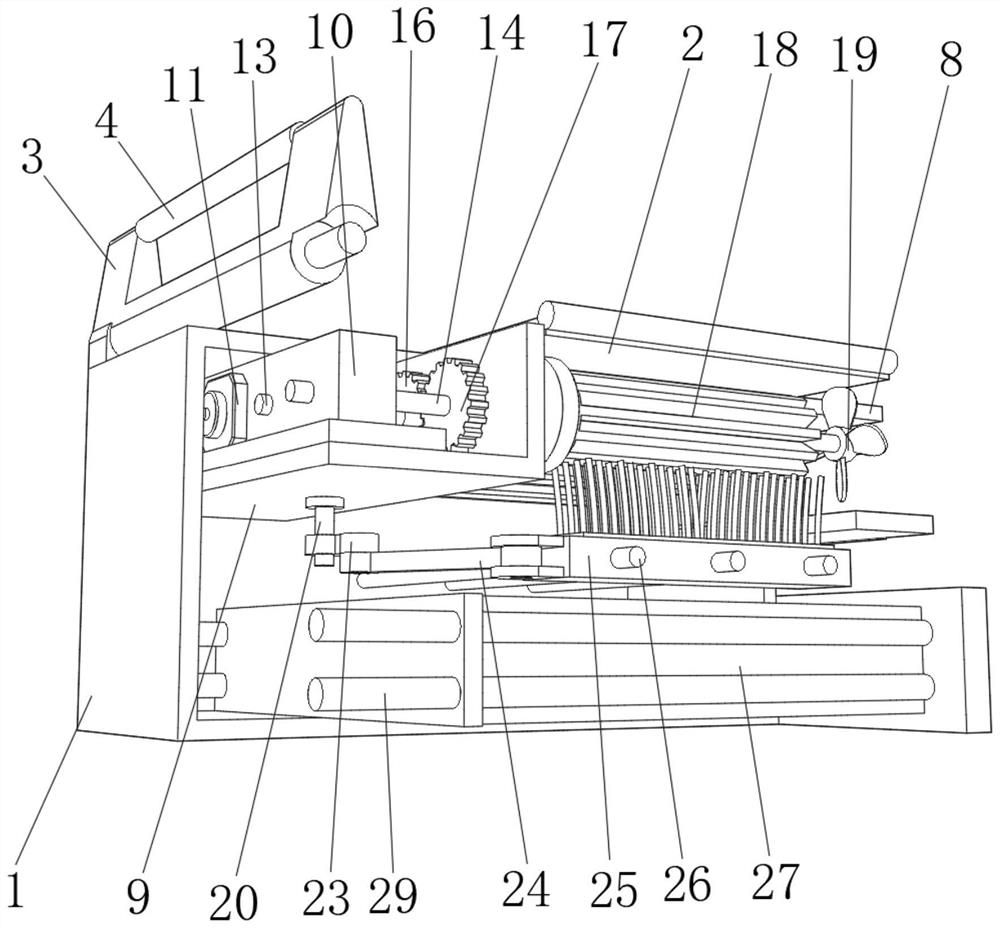

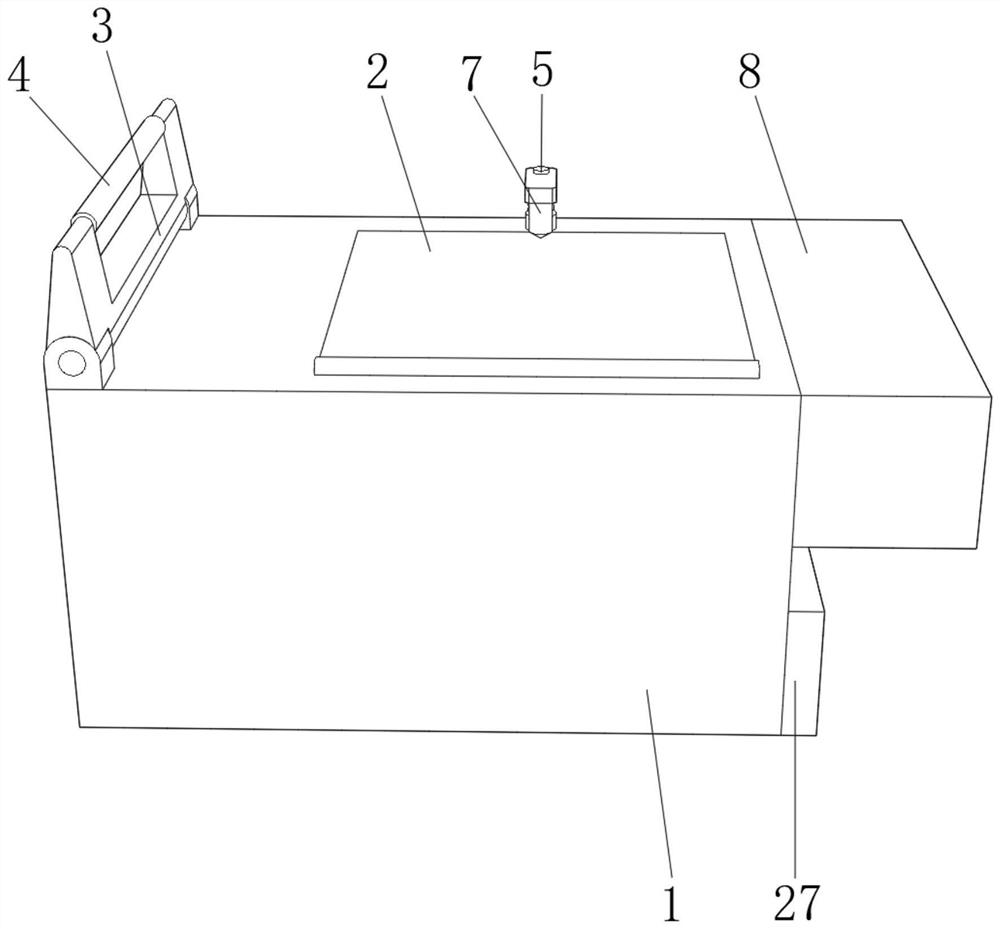

Automatic dust removal equipment for electric energy meters

The invention discloses automatic dust removal equipment for electric energy meters. The automatic dust removal equipment for the electric energy meters comprises a rack, a conveying device and a dust removal device. The automatic dust removal equipment is characterized in that the conveying device and the dust removal device are arranged on the front part and the rear part of the rack in parallel; the dust removal device comprises a location fixture used for fixing the plurality of electric energy meters, an air-blowing device and a turnover mechanism used for driving the location fixture to turn over up and down; and a transferring-loading mechanism is further arranged above the rack, and between the conveying device and the location fixture, and used for grabbing the electric energy meters to be subjected to dust removal on the conveying device and moving the electric energy meters onto the location fixture or grabbing the electric energy meters subjected to dust removal on the location fixture and moving the electric energy meters onto the conveying device. According to the automatic dust removal equipment for the electric energy meters, the conveying device and the dust removal device are mutually separated, so that dust in the electric energy meters can be adequately eliminated.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

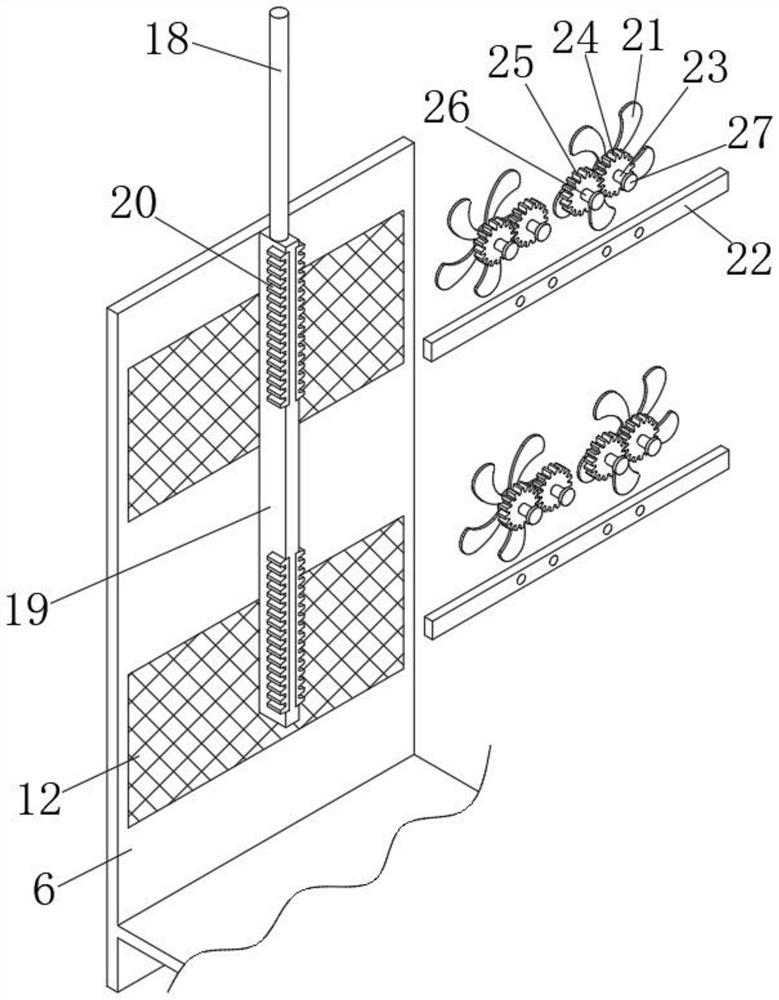

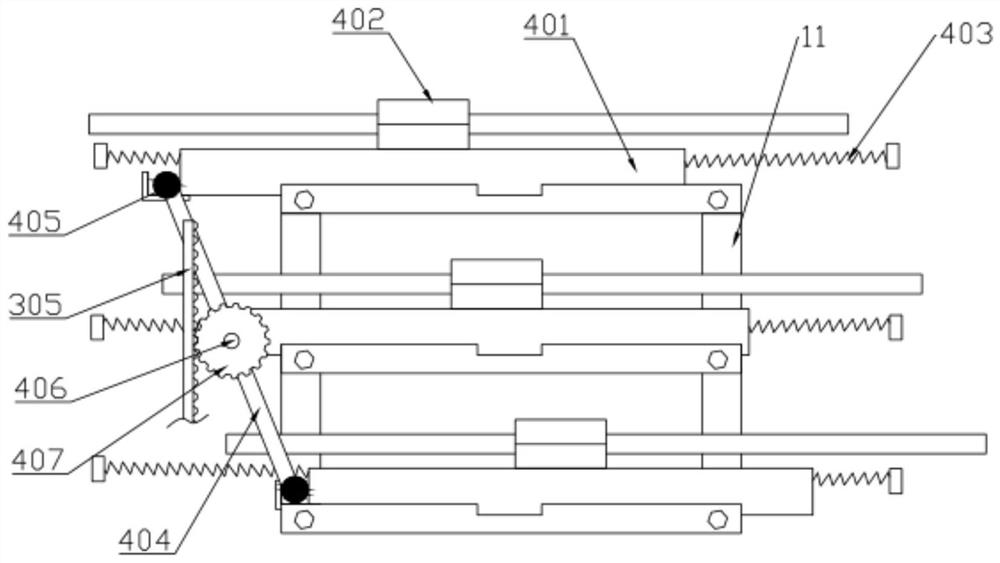

Textile cloth winding device with dust removal function

InactiveCN112408032ASmooth transmissionGuaranteed dust removalMechanical cleaningPressure cleaningDust controlStructural engineering

The invention discloses a textile cloth winding device with a dust removal function, and relates to the textile field. The textile cloth winding device with the dust removal function comprises a workbench, wherein supporting legs are fixedly connected to the lower side of the workbench in a front-back and left-right symmetry mode. A sliding groove is formed in the right side of the portion, on therear side of the middle, of the upper side of the workbench. The sliding groove is connected with a mounting mechanism in a sliding manner, and the mounting mechanism is rotationally connected with awinding mechanism. The left end of the portion on the rear side of the middle of the upper side of the workbench is fixedly connected with a driving mechanism, the driving mechanism is engaged with atransmission mechanism, and the transmission mechanism is fixedly connected with the winding mechanism. A dust removal mechanism is fixedly connected with the front end of the middle of the upper side of the workbench and is engaged with an adjusting mechanism. The textile cloth winding device with the dust removal function is simple in structure, convenient to use, and good in use experience.

Owner:安徽美诗兰科技有限公司

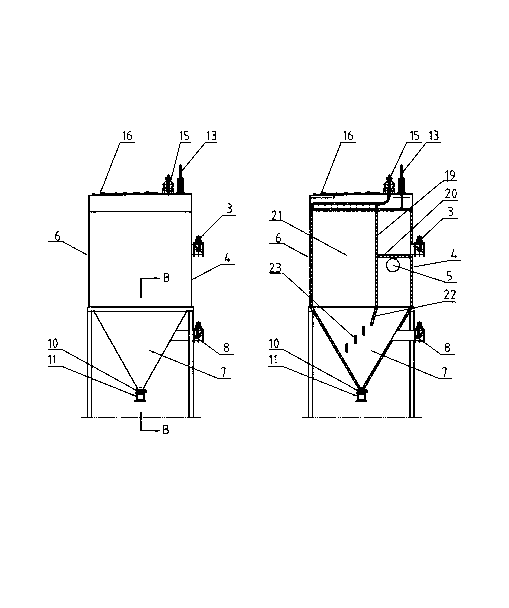

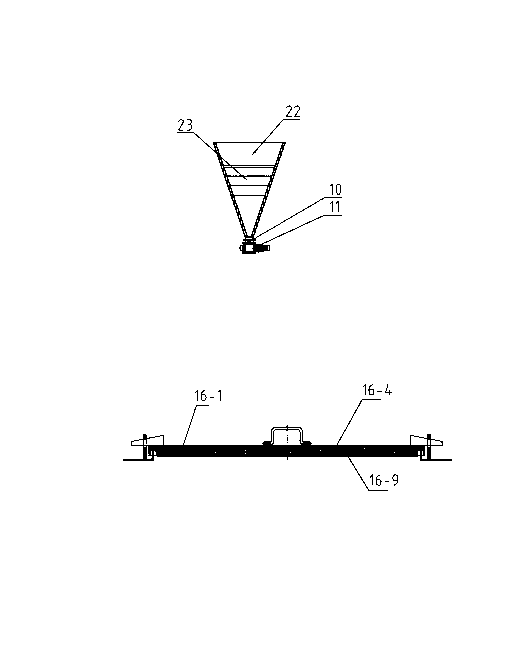

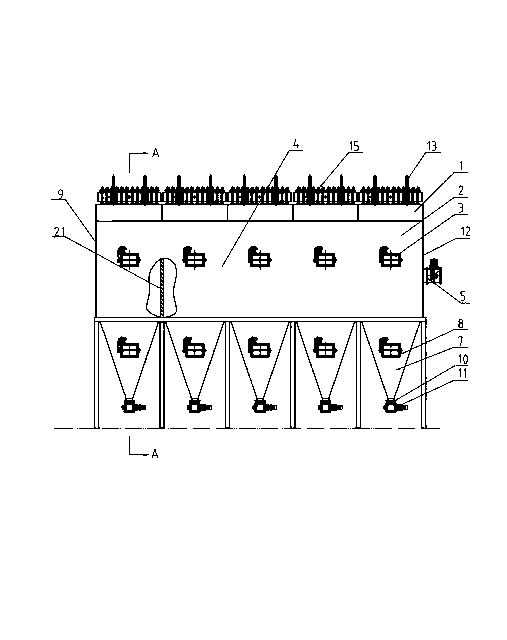

High-temperature bag type pulsed dust collector

InactiveCN102872661AEvenly distributedConducive to efficient dust removalDispersed particle filtrationCold airFlue gas

The invention relates to a bag type pulsed dust collector capable of treating high-temperature flue gas and other high-temperature dust. The bag type dust pulsed dust collector comprises an upper blowing system, an upper box body, a middle box body which is formed by circling four side plates and a top pattern plate, and a plurality of lower dust hoppers, wherein a door cover is arranged on the top of the upper box body; the upper blowing system and a pneumatic lift valve are arranged on the upper box body; an air channel is arranged on one side in the middle box body; a spacer plate which divides the air channel into an upper air chamber and a lower air chamber is arranged in the air channel; the upper air chamber of the air channel is communicated with the upper box body, and the lower air chamber of the air channel is communicated with the lower dust hoppers; a dust-contained gas air inlet is formed on each lower dust hopper on one side of the air channel; a purified gas air outlet corresponding to the air inlet is formed on a middle box body side plate of the upper air chamber; and a cold air inlet is formed at one end of the lower air chamber. Because the cold air inlet is formed at one end of the lower air chamber, once the dust collector encounters an ultra-temperature alarm, the valve can be automatically opened quickly, and then cold air is directly supplemented to effectively protect a filter bag of the dust collector.

Owner:江苏南方机械有限公司

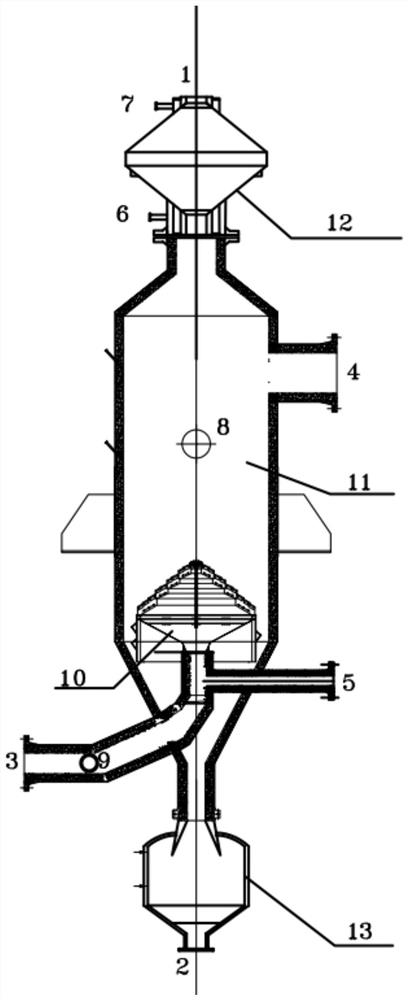

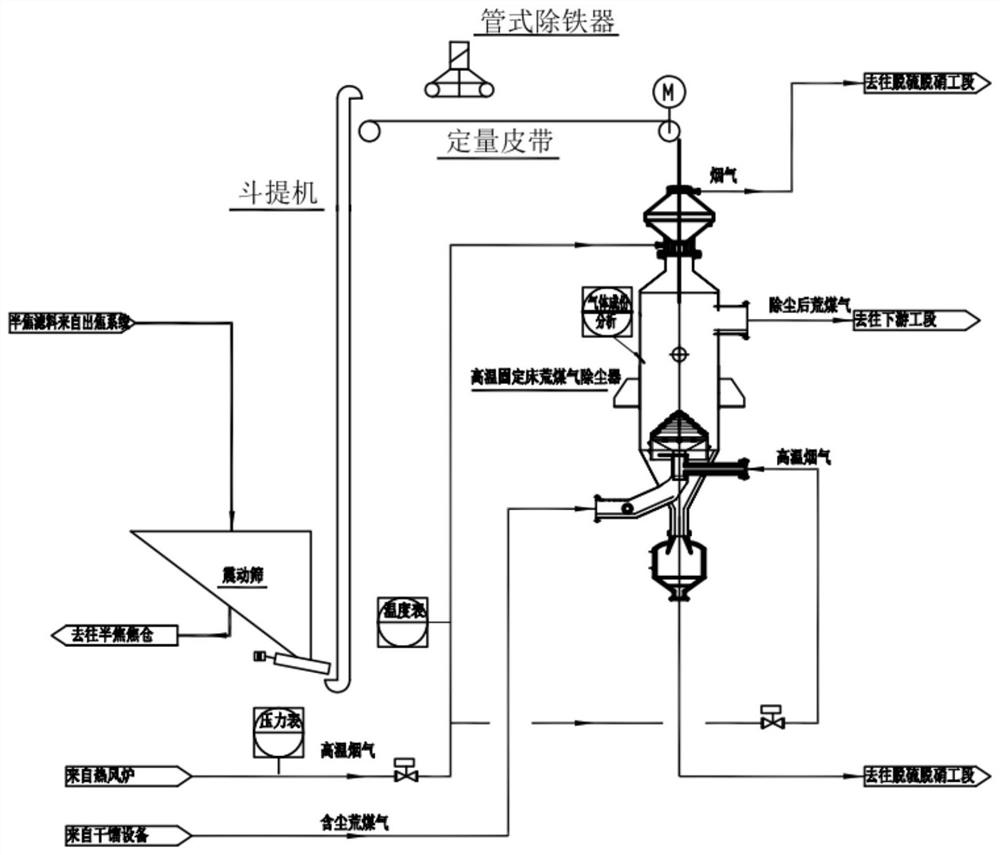

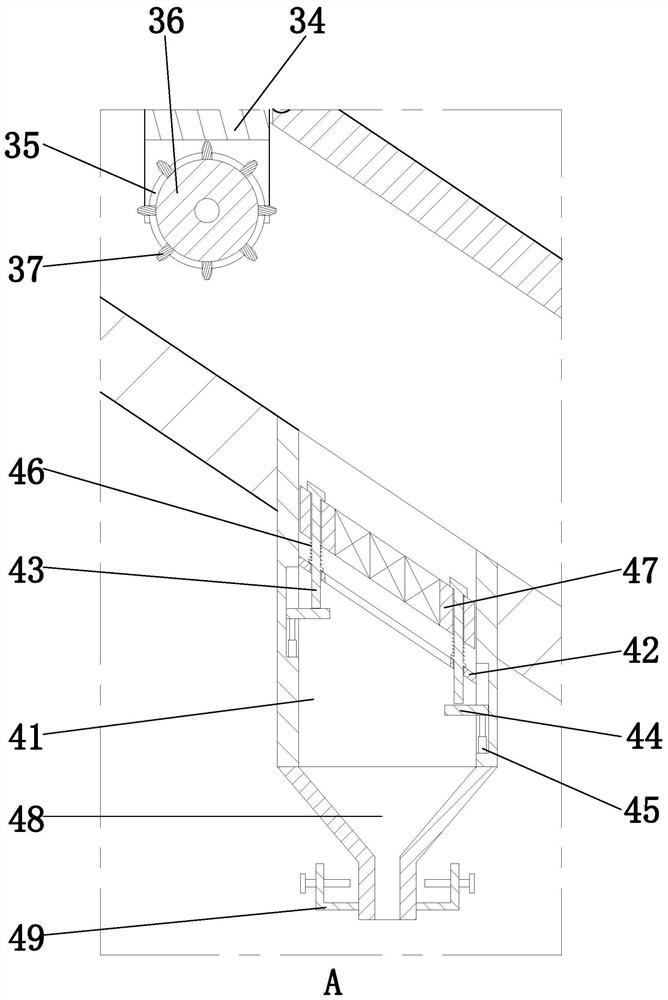

Raw coke oven gas high-temperature dust removal process and device

PendingCN111826210ASolve the regeneration problemPrevent leakageEnergy inputGas dust removalFixed bedCoke

The invention discloses a raw coke oven gas high-temperature dust removal process and device. Semi-coke is used as a filter medium for a dust remover. Pyrolysis dust-containing raw coke oven gas is discharged from pyrolysis equipment and then directly connected to the bottom of a fixed bed / granular bed raw coke oven gas high-temperature dust remover through a raw coke oven gas pipeline, and purified raw coke oven gas is discharged from an outlet in the upper portion of the dust remover to enter a downstream procedure after passing through the filter material and filtering dust in the raw cokeoven gas from bottom to top. In the whole filtering and dedusting process, the pipeline and the dust removal device are kept in a high-temperature state to prevent tar precipitation. And the filteredand saturated semicoke filter material is discharged from the bottom of the dust removal device through the discharging device and falls into a coke quenching waste heat recovery device to be cooled.The dust removal device is composed of a dust remover body, a semi-coke preheater and a discharging lock hopper. The invention has the characteristics of accessible filter medium, simple structure, convenient operation, stable operation, low operation cost, environment friendliness, energy saving and the like.

Owner:上海电气集团国控环球工程有限公司

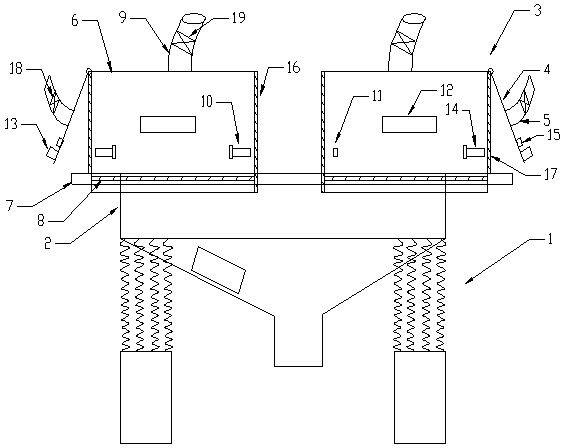

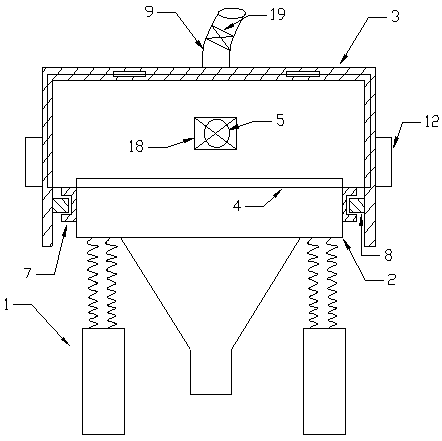

Novel shakeout machine provided with dust collecting and noise reducing structure

The invention discloses a novel shakeout machine provided with a dust collecting and noise reducing structure. The shakeout machine comprises a noise reducing and dust collecting cover which is arranged on a shakeout grid bed of a shakeout machine body; the noise reducing and dust collecting cover is a rectangular groove type and is formed by a muffling plate; the openings of the two ends of the noise reducing and dust collecting cover are separately articulated with baffles; each baffle is provided with an air charging pipe; the noise reducing and dust collecting cover is composed of two noise reducing and dust collecting cover combination blocks which are the same in structure; the two sides of the shakeout grid bed are each provided with a sliding chute; the inner sides of two side plates of each noise reducing and dust collecting cover combination block are separately provided with sliding bars matched with the sliding chutes; and a top plate of each noise reducing and dust collecting cover combination block is provided with an exhaust pipe. The novel shakeout machine disclosed by the invention can prevent overflowing of dust generated in a shakeout process of a casting and effectively and intensively discharge the dust, can also reduce the noise generated in the shakeout process of the casting and can prevent the dust and the noise from polluting the environment of a workshop, so the body health of a worker can be protected from harms of dust and the noise.

Owner:绵阳易简环保科技有限公司

Anti-corrosion high-temperature-resistant bag-type dust removal device

ActiveCN110639294APlay a protective effectClean up and orderlyDispersed particle filtrationTransportation and packagingDust controlElectric machinery

The invention discloses an anti-corrosion high-temperature-resistant bag-type dust removal device, and belongs to the field of bag-type dust removal devices. The anti-corrosion high-temperature-resistant bag-type dust removal device comprises a dust removal device body, wherein a gas guide filtering mechanism is arranged at the lower end in the dust removal device body, and comprises an upper moving plate, a lower fixing plate, a rotating shaft and flow guide blades, a cloth bag dust removal mechanism is arranged in the inner cavity of the dust removal device body and is positioned above the upper moving plate, and the cloth bag dust removal mechanism comprises an installing frame, a ventilation pipe, a cloth bag, a motor, a transmission gear and a transition gear. The anti-corrosion high-temperature-resistant bag-type dust removal device of the invention has characteristics of corrosion resistance and high-temperature resistance, achieves the mechanical cleaning of internal filteringholes, achieves the convenient cleaning of impurity filtering, reduces labor burden, and reduces waste gas treatment cost.

Owner:盐城市吉盛达环保工程有限公司

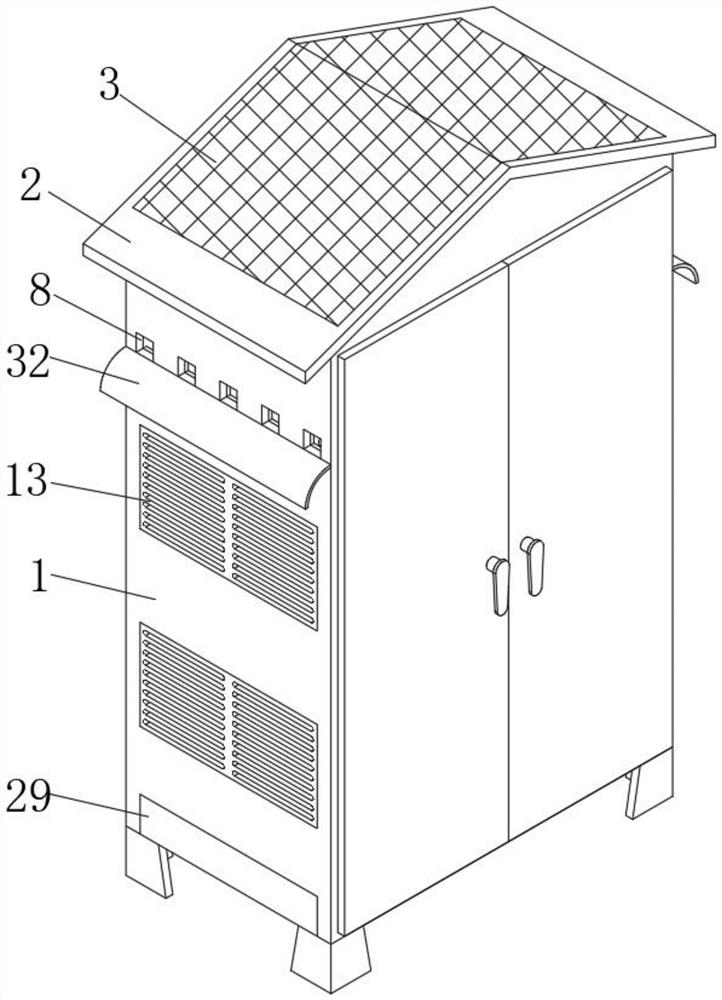

Explosion-proof power distribution cabinet for dust workshop

PendingCN114883922AReduce the possibility of entering the distribution cabinetReduce the amount of dustClimate change adaptationSubstation/switching arrangement cooling/ventilationPhysicsEngineering

The invention discloses an explosion-proof power distribution cabinet for a dust workshop, and the cabinet comprises a cabinet body, the cabinet body is internally provided with a mounting cavity and a functional groove, the inner side wall of the mounting cavity is fixedly connected with a heat conduction plate, and the functional groove is internally provided with a self-adjusting pumping heat dissipation mechanism; and the self-adjusting air pumping heat dissipation mechanism comprises a gear motor, the gear motor is fixedly connected with the inner side wall of the functional groove, an output shaft of the gear motor is fixedly connected with a rotating shaft, the rotating shaft is in interference fit with a rotating block, and an electromagnet is arranged in the rotating block. The power distribution cabinet has the advantages that the pumping amount can be adjusted according to the temperature, the probability that dust enters the power distribution cabinet is reduced, the probability that the dust enters the power distribution cabinet is greatly reduced by matching with filtering of the first filter screen, the dust amount in the power distribution cabinet is reduced, the explosion risk is avoided, meanwhile, the temperature in the power distribution cabinet can be better controlled, and the power distribution cabinet is more convenient to use. And dust in the workshop is removed to a certain extent, and workshop safety is guaranteed.

Owner:南通金茂防爆电气有限公司

Dust removal equipment with energy saving and environment protection effects

The invention discloses dust removal equipment with energy saving and environment protection effects. The dust removal equipment comprises a water box, wherein the top of the water box is communicatedwith a purification box; the right side of the purification box is communicated with a gas inlet pipe; the right side of the bottom of an inner cavity of the gas inlet pipe is fixedly connected witha connecting block; the top of the connecting block is fixedly connected with a negative pressure suction ventilator; a filtering core is arranged at the inner cavity of the gas inlet pipe and is positioned at the left side of the suction ventilator; an opening is formed in the top of the gas inlet pipe and is positioned above the filtering core. Through the matched use of the water box, the purification box, the gas inlet pipe, the connecting block, the negative pressure suction ventilator, the filtering core, the opening, a gas outlet pipe, an atomization spray head, a water pump, a first hose, a water outlet pipe, a second hose, a first fixing block, a filtering net and a water inlet pipe, dust generated in the production and manufacturing work procedures can be filtered and removed; the environment pollution is reduced; the possible injure to the body of operation personnel is also reduced; high energy saving and environment protection effects are achieved.

Owner:ZHENGZHOU KANGXIAO TECH CO LTD

Dyeing machine with uniform dyeing function for textile

InactiveCN109252305AImprove efficiencyReduce manufacturing costMechanical cleaningPressure cleaningSprayerEngineering

The invention discloses a dyeing machine with a uniform dyeing function for textile. The dyeing machine with the uniform dyeing function for textile comprises a working box, wherein the right side ofthe cavity of the working box is fixedly connected with a partition; the left side of the top of the cavity of the working box is fixedly connected with a first sprayer; a second sprayer is fixedly connected to the bottom of the cavity of the working box and is positioned on the left side of the partition; the right sides of the top and the bottom of the cavity of the working box are separately fixedly connected with connecting rods; the end, which is away from the cavity of the working box, of each connecting rod is fixedly connected with a drying lamp; the bottom of the working box communicates with a material box; and the bottom of the material box is fixedly connected with a supporting plate. By cooperation of the working box, the partition, the first sprayer, the second sprayer, the drying lamp, the material box, the water pump, a hose, a three-way tube, a dust suction cover and a dust suction tube, cloth can be dyed, drying and dust removal on cloth can further be carried out ata time, the dyeing efficiency is improved, and the production cost is reduced.

Owner:赵斌

Automobile data recorder lens polishing device

InactiveCN109877673AProtect healthImprove polishing efficiencyOptical surface grinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention discloses an automobile data recorder lens polishing device. The device comprises a supporting mechanism, wherein a dust sucking mechanism is fixedly connected to the bottom of the supporting mechanism, and a clamping mechanism is fixedly connected to the bottom of the supporting mechanism and located above the dust sucking mechanism. According to the device, through the cooperationamong first electric telescopic rods, a top plate, a first motor and a polished plate, a lens can be polished; through the cooperation among a dust suction box, a back plate, shielding plates, a box door, a handle, a separation plate, a fixing block, a dust suction fan, an isolation net and dust suction holes, chippings generated during polishing can be adsorbed, so that the chippings do not driftaround, so that the health of workers can be better guaranteed; and through the cooperation of clamping plates, a second motor, rubber pads, a second electric telescopic rod, a mounting block, a driving belt disc, a belt and a driven belt disc, not only the lenses with different sizes can be clamped, but also the to-be-polished surfaces can be automatically replaced.

Owner:杨雪

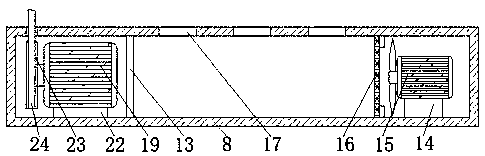

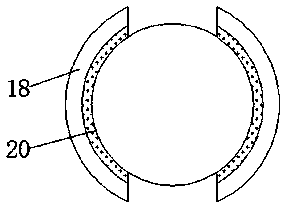

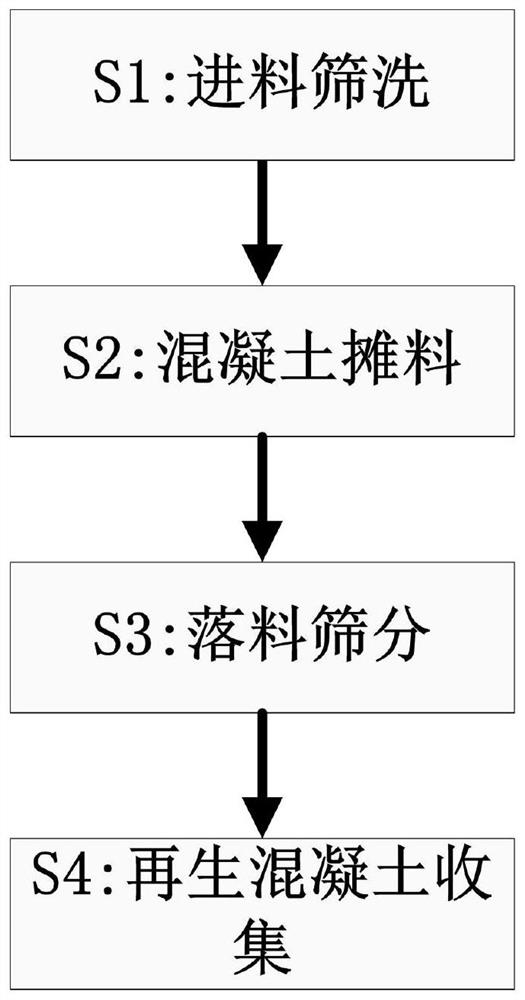

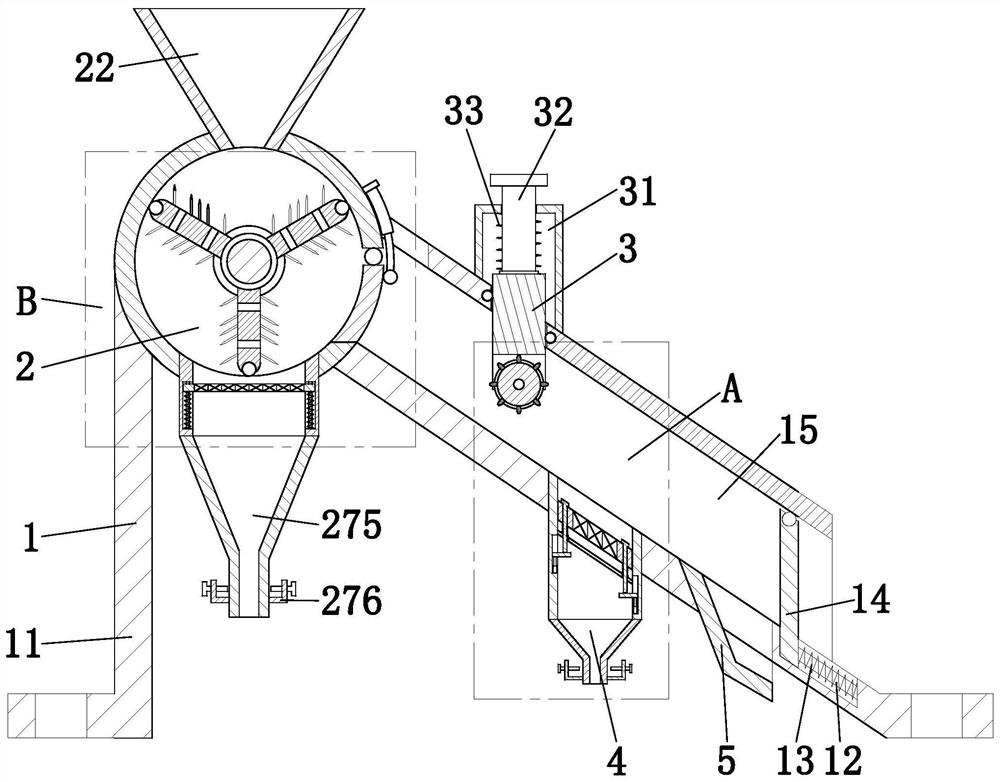

A kind of recycled concrete preparation method

ActiveCN112028520BSpeed up sievingGuaranteed ScreeningSolid waste managementArchitectural engineeringDust control

The invention provides a method for preparing recycled concrete. The preparation and regeneration of concrete is completed by the cooperation of the installation frame group, the dust removal device, the spreading device, the sieving device and the material guide cover; The dust mixed in the concrete blocks is difficult to clean, which seriously affects the cohesiveness of the concrete blocks; and the size of the concrete blocks is different, and the current screening method is difficult to process the concrete blocks of different sizes, which makes it difficult to screen a large number of concrete blocks at the same time. Guarantee its screening effect and other problems.

Owner:金华浙通混凝土有限公司

Outdoor power distribution cabinet with dust removal mechanism

PendingCN114725784AReduce electricity costsEasy to operateGeneral water supply conservationSubstation/switching arrangement cooling/ventilationProcess engineeringWater storage tank

The outdoor power distribution cabinet comprises a cabinet body, a rain baffle is fixedly installed at the top of the cabinet body, a separation net is fixedly embedded in the surface of the top of the rain baffle, a splitter plate fixed to the top of the inner side of the cabinet body is arranged at the bottom of the separation net, and the movable dust removal mechanism is arranged on the inner side of the cabinet body. The movable dust removal mechanism comprises two water storage tanks and two partition vertical plates, and the two water storage tanks are located at the two ends of the inner side of the top of the cabinet body respectively and welded to the cabinet body in a sealed mode. According to the outdoor power distribution cabinet, the problems that dust adhered to a heat dissipation net in an existing outdoor power distribution cabinet is difficult to clean, so that the heat dissipation net is blocked, normal heat dissipation of the power distribution cabinet is affected, and electric appliance elements in the power distribution cabinet are damaged due to too high temperature during working are effectively solved, so that the power distribution cabinet is more convenient to clean and collect dust, and the working efficiency is improved. The sealing performance of the whole power distribution cabinet is improved, damage to electrical components due to short circuit caused by water entering the power distribution cabinet is prevented, and the service life of the power distribution cabinet is prolonged.

Owner:安徽蓝润正华电子有限公司

An easily adjustable grinder

ActiveCN112059819BHas to clean upRealize regulationGrinding carriagesDispersed particle filtrationCushioningDust control

The invention discloses an easily adjustable grinder, which relates to the field of grinders, and comprises a base, the upper ends of both sides in the length direction of the base are vertically fixed with brackets, a grinding wheel assembly is arranged between the brackets, and the grinding wheel assembly It includes a vertical groove, a first screw rod, a vertical slide seat, a bar frame, a bar groove, a second screw rod, a bar slide seat, a grinding wheel motor and a grinding wheel sheet, and the lengthwise end of the bar frame There are cushioning components between the vertical sliding seat and the upper end of the strip-shaped sliding seat. Equipped with grinding wheel rack. The grinder has a shock-absorbing function. While reducing the working noise of the equipment, it can also reduce the impact of the vibration of the grinder on its working use. It can realize the flexible control of the position of the grinder and greatly expand the working range of the equipment. With the function of dust removal, while ensuring the working environment of the equipment, it also ensures the health of the operators.

Owner:YANCHENG JIANFENG ELECTRIC MOTOR INSTR

A new energy dust removal device

ActiveCN112077036BEasy to removeRealize the collectionDirt cleaningCleaning using toolsNew energyDust control

The invention relates to the technical field of dust removal devices, and discloses a new energy dust removal device, which includes a support frame, the upper surface of the support frame is fixedly connected with a stabilizer, and the rear side of the inner top side wall of the stabilizer is provided with a rotating suction Dust device, the top of the support frame is provided with a sliding dust suction device, the left side of the upper surface of the stable frame is fixedly connected with a vacuum cleaner, and the output end of the vacuum cleaner is connected with an output pipe. The new energy dust removal device, through the rotation of the dust collection device and the vacuum cleaner and the dust collection hood, performs multi-level treatment on the dust generated during cleaning, which has better dust removal effect, can better remove the dust on the photovoltaic panel, and is more efficient The dust can be fully collected to achieve a more ideal dust collection effect, which greatly improves the dust suction efficiency, avoids the dust from flying around and affects the surrounding environment, and further improves the convenience of use.

Owner:无锡谐圣环保设备有限公司

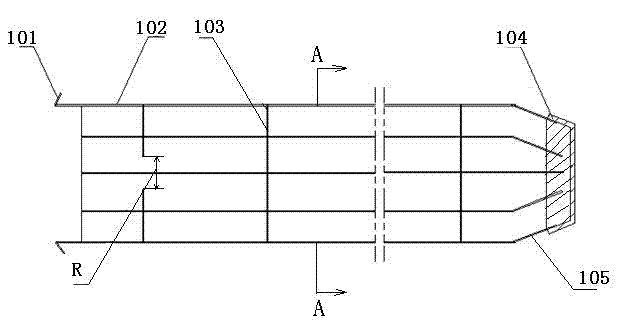

A device for automatically arranging network optical cables based on big data

ActiveCN113296212BGuaranteed dust removalReduce moisture contentOptical fibre/cable installationThermodynamicsDust control

The invention discloses a network optical cable automatic arrangement device based on big data, relates to the technical field of cable arrangement, and includes a trolley, an atomizing cylinder, a circulation mist removal mechanism and a swing adjustment mechanism. The present invention forms a local low-temperature steam and water mist circulation environment in the mist discharge chamber by setting a circulation mist discharge mechanism on the atomization cylinder, and quickly eliminates static electricity on both sides of the cable with a circular longitudinal section respectively, so as to realize the guarantee Reduce the water content in the network computer room under the premise of static electricity elimination and dust removal; by setting a swing adjustment mechanism in the mist removal chamber, during the process of cable pre-wiring, static electricity elimination and automatic wiring are carried out simultaneously. The lifting degree of the end is increased to increase the lifting stroke of the counterweight, thereby achieving the purpose of increasing the amount of water mist sprayed when the cable group is bent and routed, and simultaneously balancing the compressive and tensile stress on both sides of the inner and outer edges of the bend of the cable row. Avoid warping or even core breakage after the cable is fixed.

Owner:ANQING NORMAL UNIV

Integral machine room dust removal device with ventilation and deodorization functions and dust removal method

ActiveCN112222136AAvoid overpoweringGuaranteed dust removalCombination devicesDirt cleaningImpellerSuction force

The invention relates to the technical field of machine room cleaning, and discloses an integral machine room dust removal device with ventilation and deodorization functions and a dust removal method. The dust removal method is characterized by comprising the following steps that S1, a position is moved, an operator lifts an anti-skid cylinder on a lifting handle rod, and an air cylinder on a shell is towards to the position, needing dust removal, in a machine room; and S2, the device is started, a motor is started, the motor drives a connecting shaft to rotate, a driving gear on the connecting shaft drives two driven gears to rotate, the driven gears drive rotating gears and linkage shafts to rotate, the connecting shaft and the two linkage shafts drive impellers and rotating vanes to rotate, suction force is generated, and dust collection operation is conducted on the machine room. Excessive power operation of the integral machine room dust removal device can be avoided, it is guaranteed that the dust removal device can conduct machine room dust removal operation multiple times and multiple aspects, dust in the device can be subjected to dust falling operation, the dust is sweptdown from a rotating frame through a row brush, and the performing of the dust removal operation of the device can be guaranteed.

Owner:衡阳佳鑫信息技术有限公司

Filter unit with filter dust fallout

ActiveCN106902579BGuaranteed filtering effectGuaranteed dust removalGas treatmentDispersed particle filtrationEngineeringFilter effect

The invention discloses a filter device with dust falling from the filter screen, which comprises a device housing, an air inlet and an air outlet are arranged on the device housing, a filter screen is arranged in the device housing, and a connecting air inlet is provided on the top of the filter screen There is a dust collection box on the bottom wall of the device housing, a dust discharge chamber in the side wall of the device housing, an exhaust fan is fixed in the dust discharge chamber, and a dust collector in the side wall of the device housing Control chamber, the side of the filter is at the opening of the control chamber, there is a rotating motor in the control chamber, the shrapnel is evenly fixed on the main shaft of the rotating motor, there is a hitting ball at the end of the shrapnel, and the top wall of the control chamber Arc-shaped pressure blocks are fixed on the bottom wall and the bottom wall. The structure of the invention is reasonably arranged, can guarantee the filtering effect of the filter net, solves the technical deficiency in the traditional technology that the filter net is easy to absorb dust and affects the filtering effect, and has good stability and strong applicability.

Owner:北京新世翼节能环保科技股份有限公司

Multifunctional electric engineering dust removal device

InactiveCN112827942AShorten the timeImprove work efficiencyCleaning using toolsCleaning using gasesElectric machineryDust control

The invention discloses a multifunctional electrical engineering dust removal device which comprises an electrical engineering device body, a first motor, a cutting board, an exhaust fan and a first roller. The first motor is arranged on the right side of the electrical engineering device body, a bearing is fixed to the outer wall of a first threaded rod, a sliding groove is formed in the inner wall of the electrical engineering device body, and a protective shell is fixed to the inner wall of a fixing plate. The multifunctional electrical engineering dust removal device is provided with a clamping sleeve, the cutting board and the exhaust fan, dust in the electrical engineering device body is discharged through the exhaust fan by starting the exhaust fan, and meanwhile, the dust in the electrical engineering device body is comprehensively discharged through movement of the exhaust fan along with the fixing plate. The discharged dust is adsorbed through the cutting board connected with the inner wall of the protection shell, so that the efficiency of removing the dust in the electrical engineering device body is improved, the time spent by a user for discharging the dust is shortened, and the working efficiency of the user is improved.

Owner:GUANGDONG OCEAN UNIVERSITY

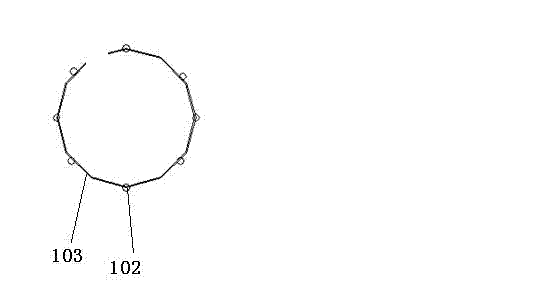

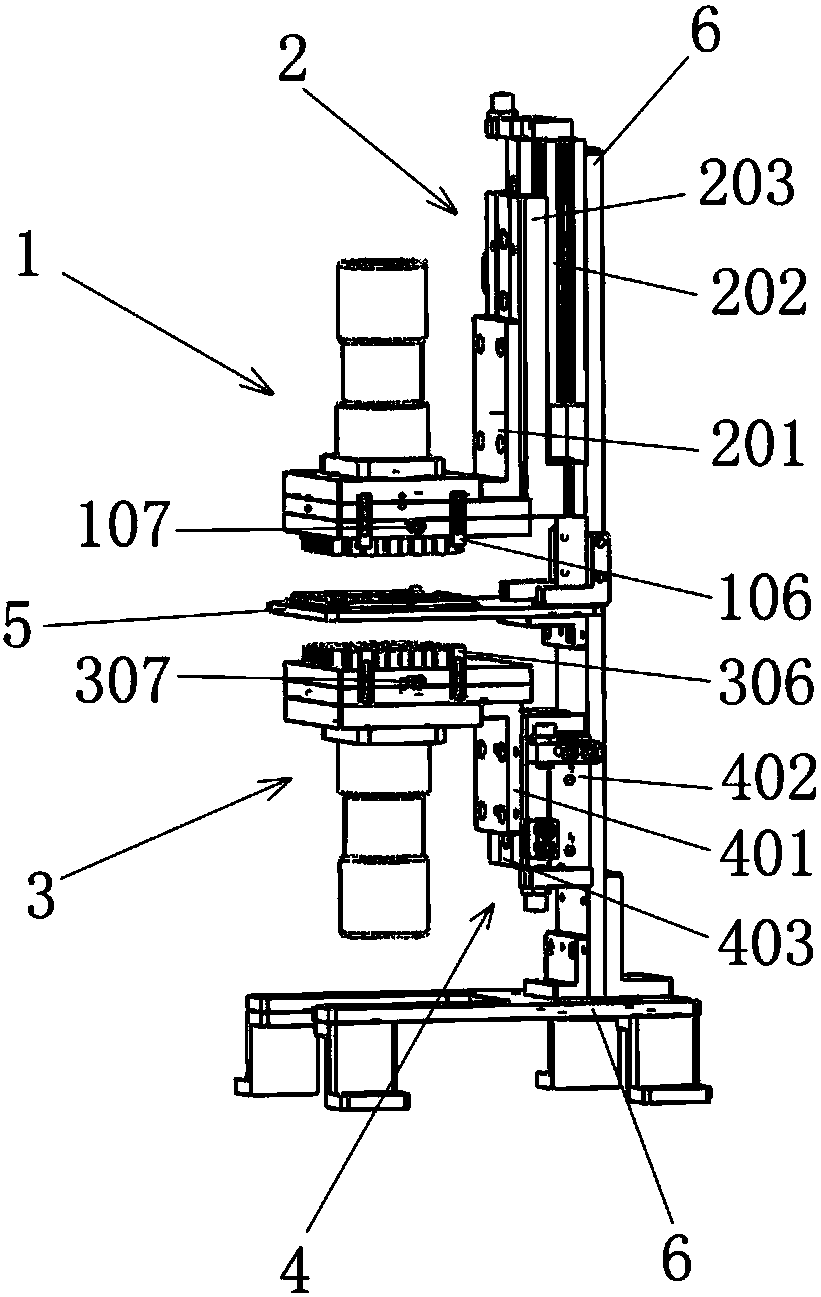

A continuous processing system for double-sided chamfering of automobile synchronizer gear sleeves

ActiveCN105149698BReduce configurationGuaranteed accuracyMetal working apparatusMaintainance and safety accessoriesTransmission beltEngineering

The invention relates to a double-face chamfering continuous machining system for a gear sleeve of a vehicle synchronizer. The double-face chamfering continuous machining system is formed by two same double-cutter machining chamfering machines and a linear feeding mechanism penetrating two chamfering machine machining stations transversely; the two same double-cutter machining chamfering machines are arranged into a row in parallel, each chamfering machine comprises a cutter for conducting chamfering machining, a workpiece driving machine head and a tooth alignment mechanism, a center line where the two cutters are located is arranged to right face the workpiece driving machine heads, tooth alignment mechanisms are arranged at front end working procedure components of the workpiece driving machine heads, and the workpiece driving machine heads are installed on a machine head base; each chamfering machine is horizontally and fixedly provided with a linear type feeding mechanism at the position, in front of the workpiece driving machine heads and behind the two cutters, of the corresponding machine body, and each linear type feeding mechanism is driven by a driving motor to drive a transmission belt in a material way to rotate; and a tooth sleeve turnover mechanism is installed between the two linear type feeding mechanisms, and pushing air cylinders are fixedly installed on the outer sides, corresponding to the tooth alignment mechanisms, of the material way. By means of the machining system, double-face chamfering machining of an overall tooth sleeve can be completed at a time, the production efficiency is greatly improved, meanwhile, allocation of a feeding mechanical arm and a feeding mechanism is omitted, and the overall machining area is decreased.

Owner:TIANJIN DAXIN PRECISION MECHANICAL EQUIP

Construction dust removal device for house building and use method of construction dust removal device

PendingCN113318561APlay the role of supporting the suction headIncrease flexibilityDispersed particle filtrationTransportation and packagingArchitectural engineeringDust control

The invention discloses a construction dust removal device for house building and a use method thereof, relates to the technical field of dust removal devices, and aims to solve the problems that an existing dust removal device is poor in flexibility during use, operation is inconvenient when some corner dust needs to be treated, the dust removal effect is poor, the inside is not easy to clean and replace, and thus the service life of the dust removal equipment is influenced. A base is arranged at the lower end of a box body, a first fixing plate is arranged at the front end of the box body, a towing bracket is arranged at the front end of the base, a plurality of suction pipes distributed at equal intervals are arranged at the front end of the box body, dust suction heads are arranged at the upper ends of the suction pipes through the first fixing plate, and suction openings are formed in the upper ends of the dust suction heads. Iron attraction layers are arranged on one sides of the suction pipes, a treatment box is arranged in the box body, a first conveying pipe is arranged on one side of the treatment box, a filtering box is arranged at the rear end of the first conveying pipe, and a second conveying pipe is arranged at the upper end of the filtering box.

Owner:安徽双凤钢结构工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com