Cut tobacco recycling device in dedusting system of machine for cutting tobacco leaves

A technology of a shredded tobacco recovery device and a dust removal system, which is applied in the fields of tobacco, tobacco processing, and application, can solve the problems of affecting the dust removal of the shredder machine, high labor intensity, and blockage of the air duct, so as to ensure normal dust removal, reduce labor intensity, The effect of avoiding mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

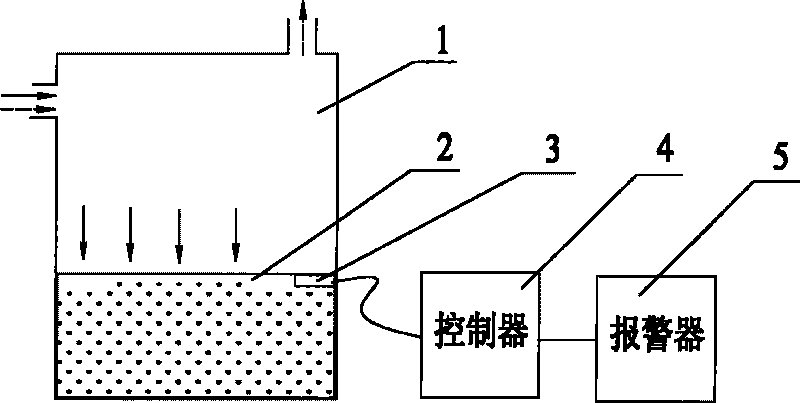

[0021] The basic idea of the present invention is to detect the amount of shredded tobacco in the recovery box in real time, and give an alarm at an appropriate time to prompt the shredded tobacco to be recovered.

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

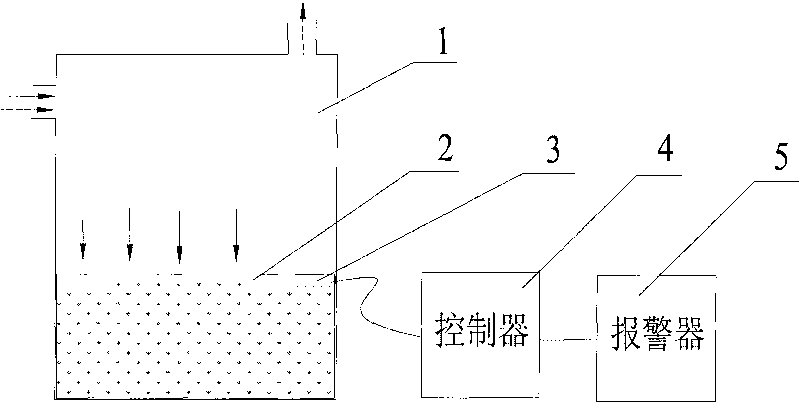

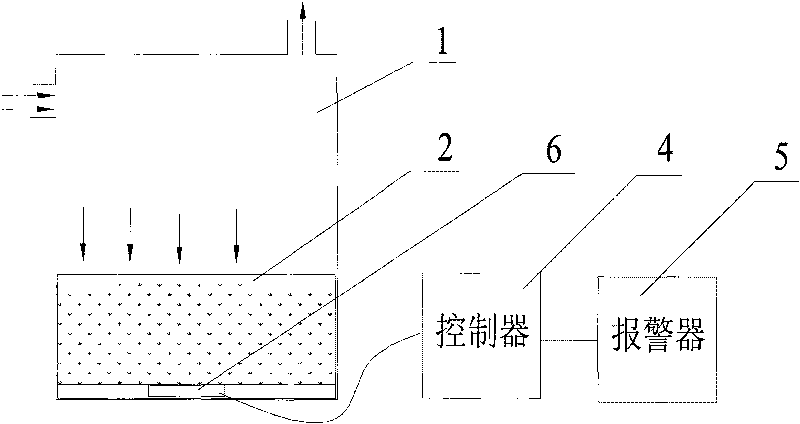

[0023] see figure 1 , which is a schematic diagram of the first embodiment of the shredded tobacco recovery device in the dust removal system of the tobacco leaf cutter of the present invention. The shredded tobacco recovery device includes:

[0024] Shredded tobacco and dust separation chamber 1 is a chamber with variable volume. Specifically, an air bag can be provided, and the volume of the separation chamber 1 can be changed by inflating and deflating the air bag.

[0025] The shredded tobacco recovery box 2 is located at the bottom of the separation chamber 1 . Pulleys are set at the bottom of the recovery box 2, and guide rails a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com