Explosion-proof power distribution cabinet for dust workshop

A technology for power distribution cabinets and workshops, which is used in substation/distribution device housing, substation/switchgear cooling/ventilation, climate change adaptation, etc. It can solve problems such as explosion and distribution cabinet accumulation, and reduce the amount of dust , to ensure normal work, to avoid the effect of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

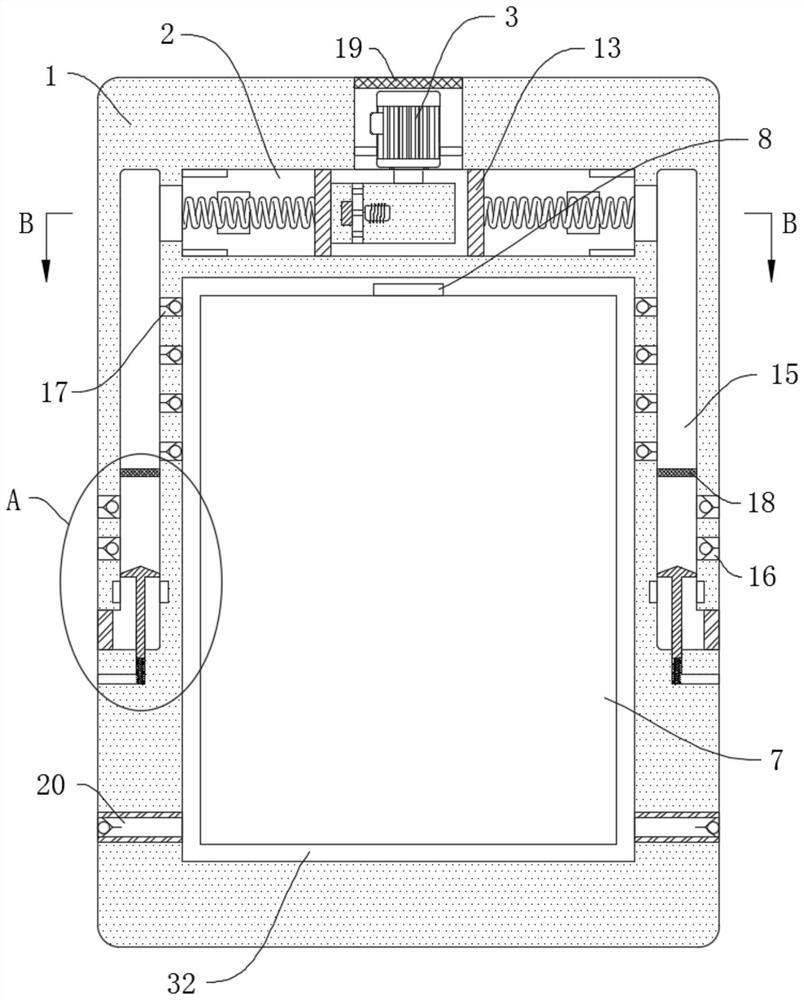

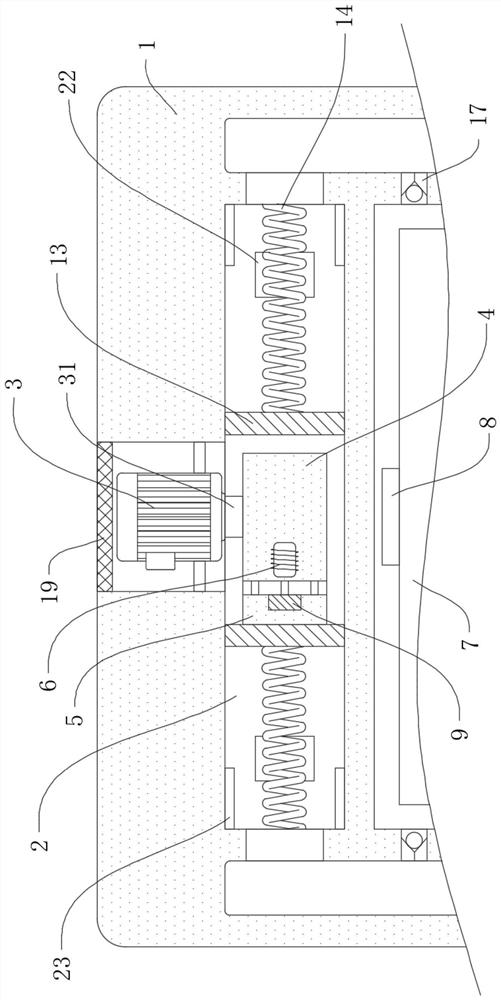

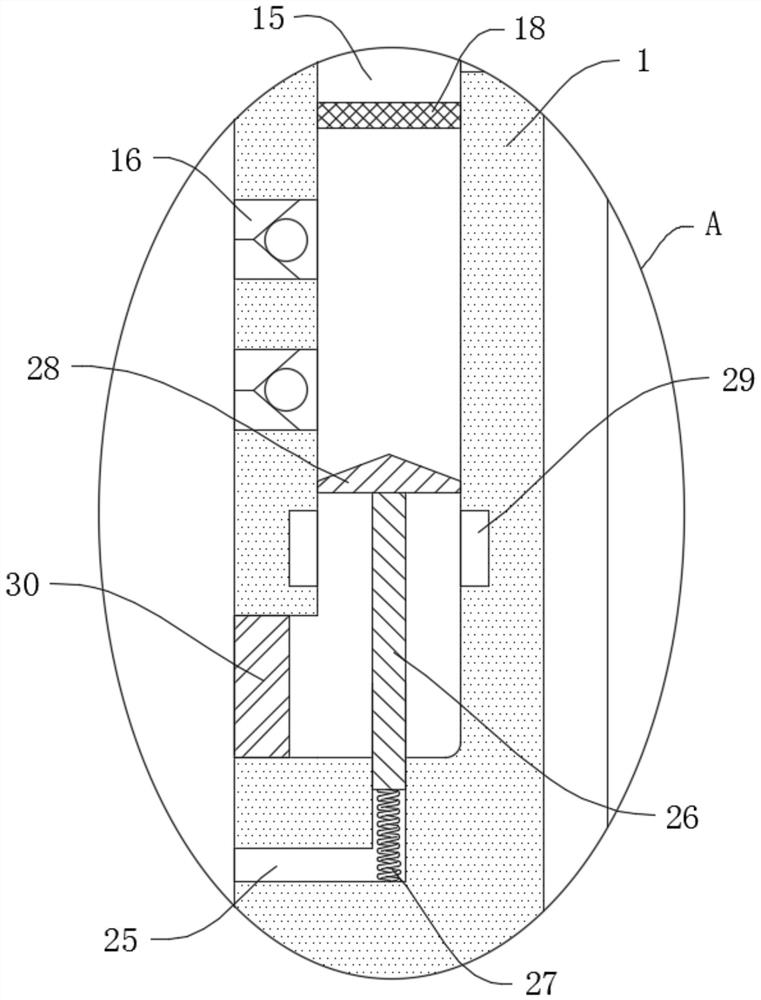

[0027] Reference Figure 1-7 , An explosion -proof power power distribution cabinet with a dust workshop, including cabinet 1, cabinet 1 with installation cavity 32 and function tank 2, installation cavity 32 inner wall fixed connection with heat conduction plate 7, electrical component installation of the power distribution cabinet installation On the thermal conductivity 7, the heat transmission can be better passed through the thermal conductivity 7, and the temperature of the electronic component can be perceived. There is a self -regulating pump heat dissipation mechanism in the function slot 2;

[0028] Self -regulating pump gas dissipation mechanism includes a deceleration motor 3, a fixed connection of the inner wall of the function slot 2, and the output shaft fixed connection of the deceleration motor 3 has a rotor shaft 31, the rotating shaft 31 convergence of the switch block 4, the rotary block 4 There are electromagas 6 in the inside, and there are several first slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com