Powdery active carbon regeneration system and powdery active carbon preparation method

A technology of powder activated carbon and regeneration system, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of powder carbon pore distribution change, large energy loss and other problems, achieve small gas dust volume and high heat utilization efficiency , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Taking the waste activated carbon produced in a sewage treatment plant in Beijing as an example, the water content of the powdered carbon after passing through the plate and frame filter press ranges from 35% to 40%.

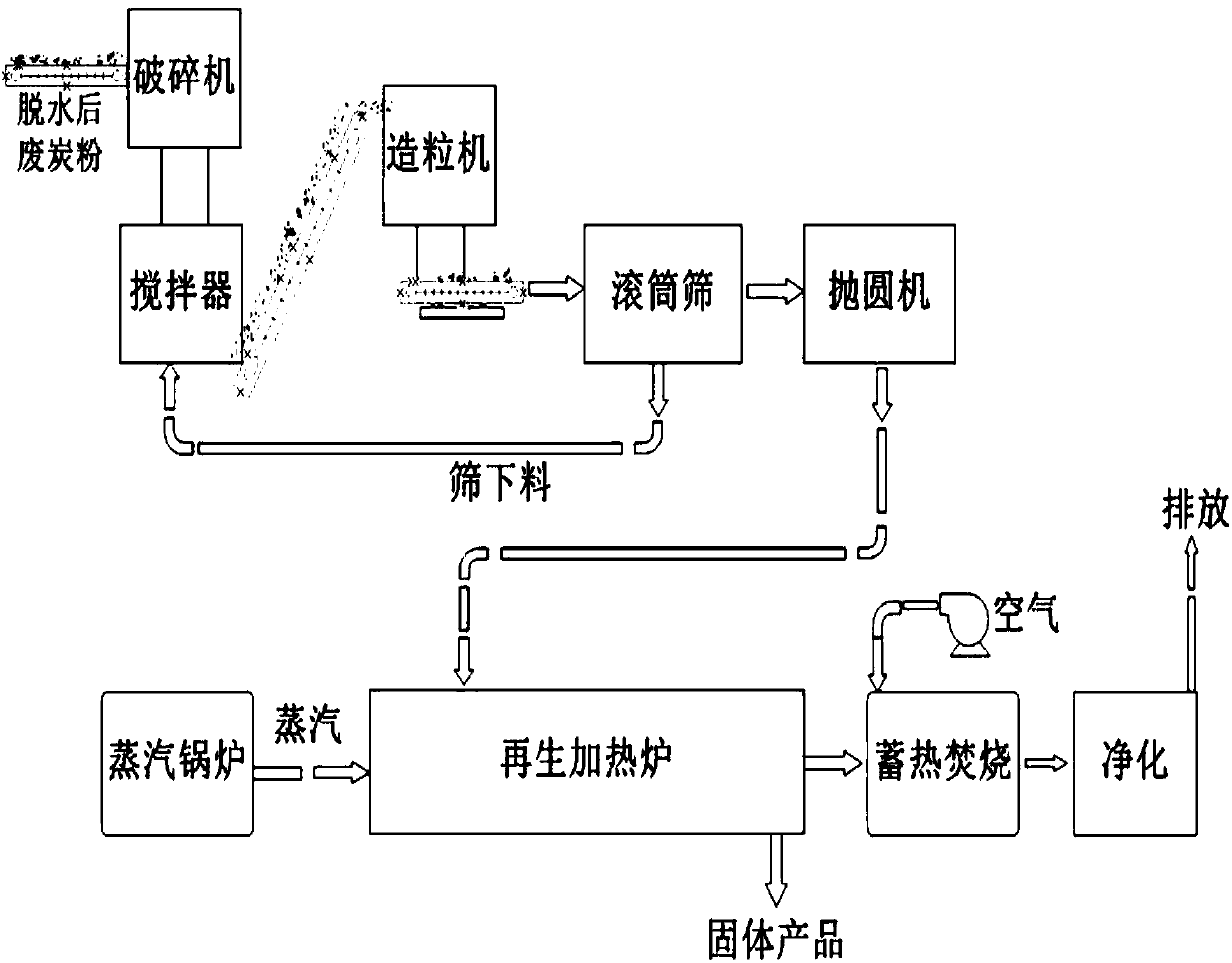

[0034] like figure 1 As mentioned above, the working process of the powdered activated carbon regeneration system is: after the materials are processed by the crusher and the agitator, the powdered carbon is added to the granulator through the conveyor belt for granulation; the prepared powder particles are passed through the drum sieve, and the undersize is Put it into the agitator and re-granulate; the sieved powder is put into the regenerative heating furnace connected with the steam boiler, and after drying, regeneration and activation treatment, the regenerated powdered activated carbon can be obtained; the gas generated by the activation is burned after heat storage , directly discharged after purification.

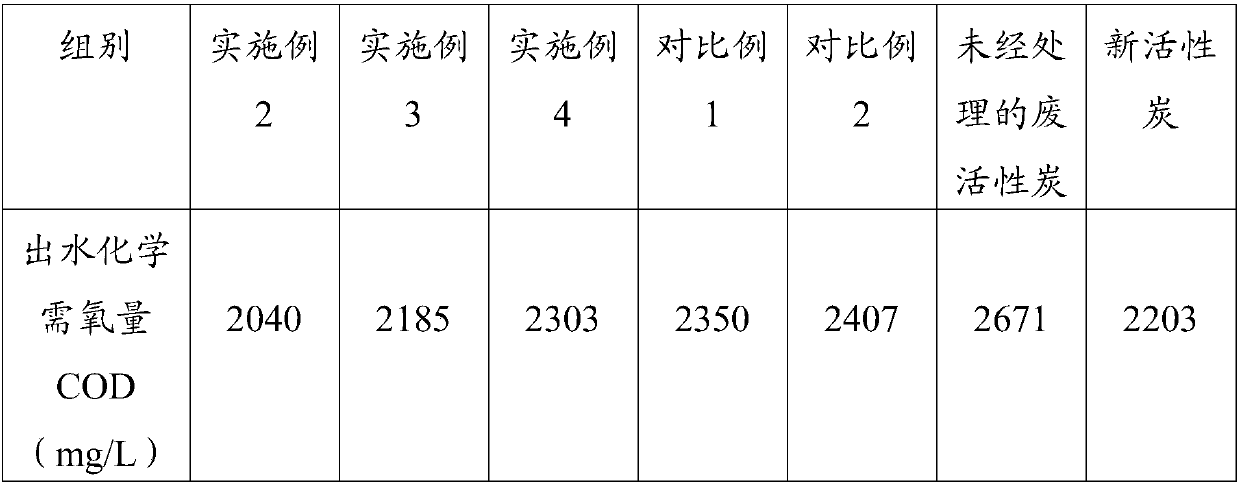

Embodiment 2

[0036] The method for preparing powdered activated carbon using the above-mentioned powdered activated carbon regeneration system includes:

[0037] Step 1: After crushing and stirring the powdered charcoal with a moisture content of 40%, adjust the drum granulator to rotate at 150r / min and incline at 3°C;

[0038] Step 2: Put the powder prepared in step 1 through the drum sieve and enter the rounding machine; and add the charcoal powder under the sieve to the crusher again, and re-granulate;

[0039] Step 3: Put the powder prepared in step 2 into the regenerative heating furnace, and undergo drying, carbonization and activation treatment. The drying temperature is 100°C, the drying time is 2h, the carbonization temperature is 700°C, and the carbonization time is 1h , the activation temperature is 850°C, and the activation time is 2h, and the regenerated activated carbon is obtained.

[0040] Step 4: The gas components generated after activation are treated by a regenerative ...

Embodiment 3

[0043] The method for preparing powdered activated carbon using the above-mentioned powdered activated carbon regeneration system includes:

[0044] Step 1: After crushing and stirring the powdered charcoal with a water content of 40%, adjust the drum granulator to rotate at 120r / min and incline at 5°C;

[0045] Step 2: Put the powder prepared in step 1 through the drum sieve and enter the rounding machine; and add the charcoal powder under the sieve to the crusher again, and re-granulate;

[0046] Step 3: Put the powder prepared in step 2 into the regenerative heating furnace, and undergo drying, carbonization and activation treatment, wherein the drying temperature is 150°C, the drying time is 1h, the carbonization temperature is 700°C, and the carbonization time is 1h , the activation temperature is 850°C, the activation time is 1h, and the regenerated activated carbon is obtained.

[0047] Step 4: The gas components generated after activation are treated by a regenerative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com