Dust collection device

A technology of dust removal device and blowing device, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc. Easy to install in place, prevent disconnection, and save the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

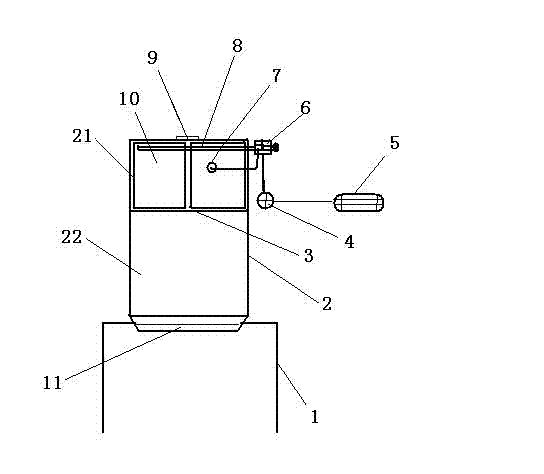

[0028] like figure 1 As shown, a dust removal device includes a support 1, the support 1 is located directly above the dust removal point, a box 2 is fixed on the support 1, the upper box 21 of the box 2 and the lower box 22 is provided with a deflector 3 in the middle, and two bag-type dust collectors 10 are arranged inside the upper box body 21, and the bottom end of the lower box body 22 is movably connected with an ash unloading plate 11; the outer side of the box body is fixed There is a blowing device, and the blowing device communicates with the upper box body 21 through the blowing pipe 8 . The blowing device includes an air bag 4, the two ends of the air bag 4 are respectively connected to a centrifugal fan 5 and an electromagnetic pulse valve 6, and the electromagnetic pulse valve 6 is connected to the blowing pipe 8 located at the upper end of the upper box body 21; The filter bag 10 is provided with a controller 7 for detecting airflow resistance in the filter bag...

Embodiment 2

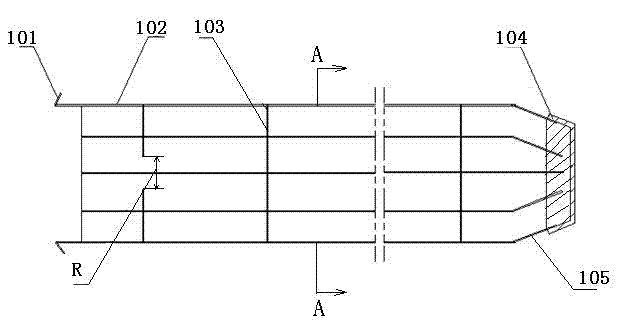

[0034] like figure 2 As shown, the bag cage of the dust collector includes a cage body composed of a top cover 104, vertical ribs 102, and ring ribs 103. The ring ribs 103 are arc-shaped and fixed to the vertical ribs 102, and the radius of the top cover 104 Smaller than the radius of the ring rib 103 , the vertical rib 102 is connected to the top cover 104 through the oblique rib 105 . The loop rib is made of elastic material PVC, the distance R between the two ends of the arc-shaped loop rib is 4CM, and the bottom end of the vertical rib 102 is provided with an upper bag hook 101 .

[0035] The gaps on the multiple ring ribs on the bag cage can be arranged on the vertical ribs in a staggered manner, so that the diameter of the bag cage can change more, which is more convenient for installation and protects the safety of the filter bag.

[0036] The bag cage of the bag type dust collector in the dust removal device of the present invention reaches the variable diameter of the...

Embodiment 3

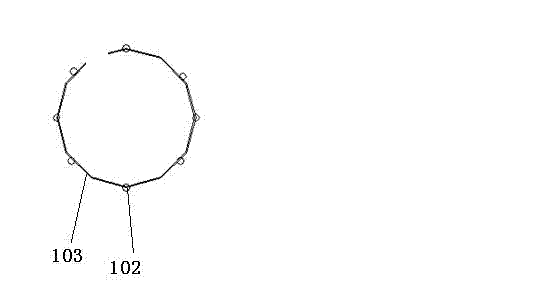

[0039] image 3 It is the A-A sectional view of the bag cage in the bag filter. The bag cage includes a cage body composed of a top cover, vertical ribs 102, and ring ribs 103. The ring ribs 103 are arc-shaped and fixed to the vertical ribs 2. The top cover The radius of the vertical rib 102 is smaller than the radius of the ring rib 103, and the vertical rib 102 is connected with the top cover through the oblique rib. Described loop rib is made of elastic material plastic, and the distance between the two ends of loop rib is 5CM, and the bottom end of vertical rib 102 is provided with upper bag hook.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com