Atomization dust removal device for refuse treatment station

A dust removal device and garbage disposal technology, applied in the field of environmental purification, can solve the problems of poor use effect, low efficiency of atomization nozzle, inability to completely cover dust removal and deodorization in the discharge room, etc., to achieve good atomization effect and good fog Optimize the effect of dust removal and realize the effect of intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

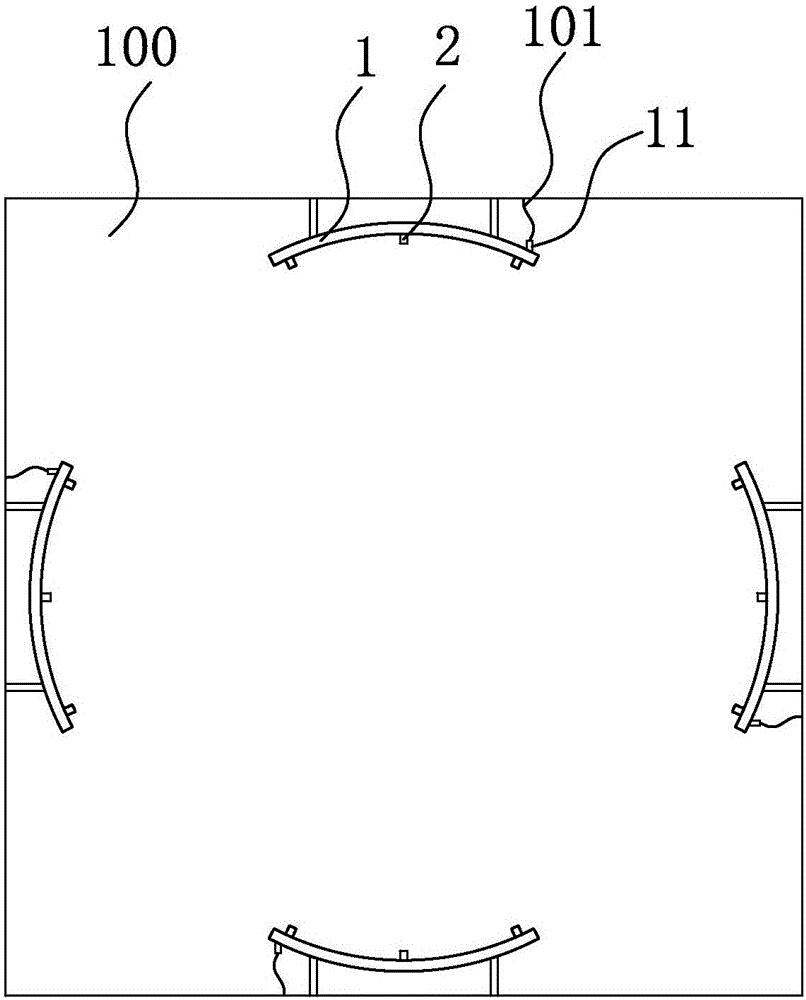

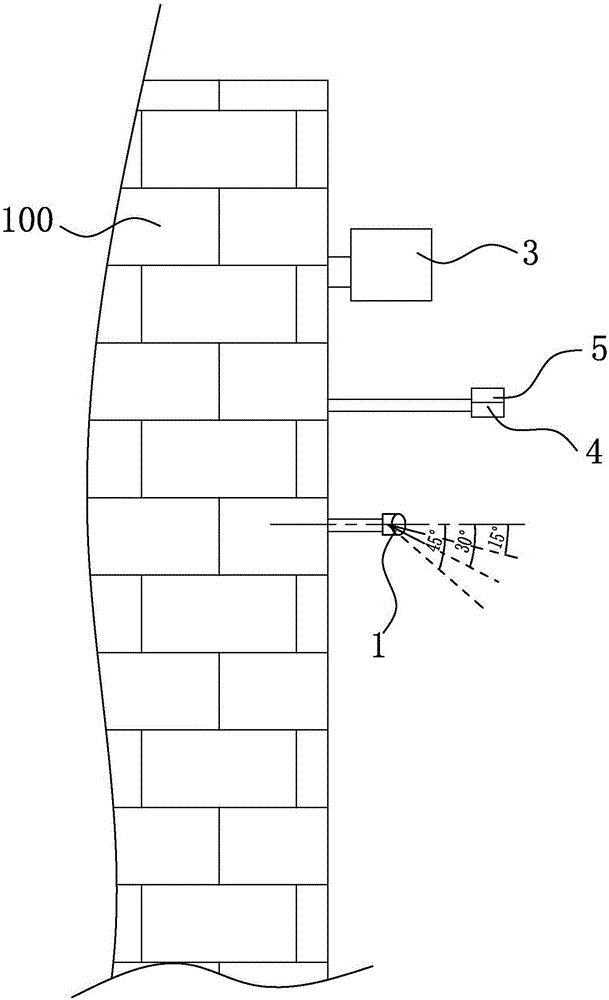

[0025] refer to figure 1 and figure 2 , an atomizing and dedusting device for a garbage disposal station, installed in the unloading room 100, which includes a water pump, atomizing equipment, and four atomizing nozzle mechanisms connected to the atomizing equipment and the water pump through pipelines 101, the atomizing The nozzle mechanisms are respectively installed on the four walls in the unloading room 100. The atomizing nozzle mechanism includes a nozzle 1 and three nozzles 2 arranged in the radial direction of the nozzle 1. The nozzle 1 is an arc-shaped tubular structure. One end of the spray pipe 1 is provided with a water inlet 11 connected to the water pump, and the inclination angles between the output direction of the nozzle 2 and the horizontal direction are respectively 15 degrees, 30 degrees, and 45 degrees horizontally downward, and each nozzle 2 is connected to the horizontal direction. The inclination angle increases evenly from the water inlet to the othe...

Embodiment 2

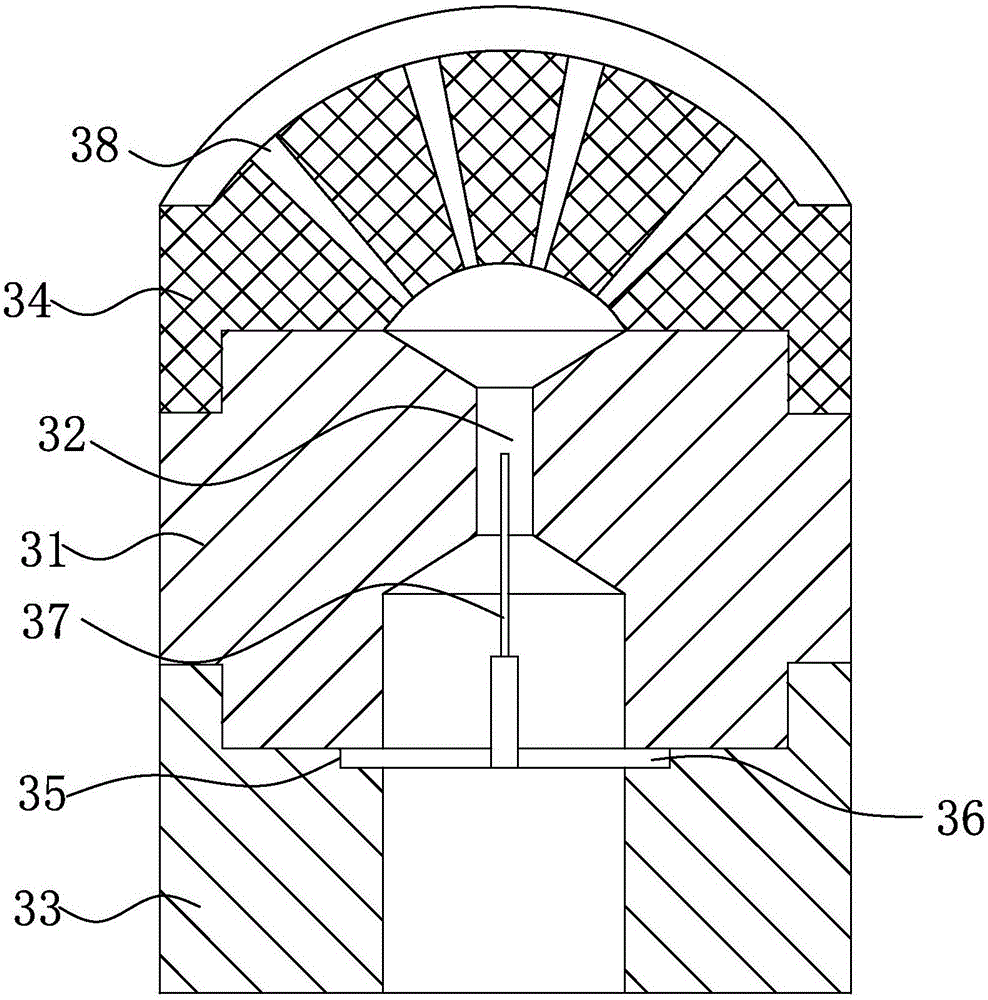

[0032] Such as Figure 4 , Figure 5 As shown, compared with the first embodiment, the parallel spray head 3 removes the step 35, the cross support frame 36 and the copper sheet 37, and a metal ring 39 is detachably clamped in the water flow channel 32. The metal ring The inner surface of 39 extends toward the center with eight baffles 391, the width direction of each baffle 391 is the same as the axis of the cluster block 31, and the thickness of each baffle 391 gradually increases from the water flow direction along the water flow channel 32, the The structure simplifies the structure of the original parallel nozzle 3 and improves the stability of the equipment.

[0033] In the present invention, the spray pipe 1 can also be connected to the atomization equipment, and the deodorant agent can be used for atomization and spraying.

[0034]This technical solution adopts the form of nozzles and multiple nozzles, which can ensure sufficient coverage area when the water is disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com