A low-floor rail vehicle underframe structure

A rail vehicle, low floor technology, applied in the direction of the chassis, railway car body parts, transportation and packaging, etc., can solve the problems of reducing internal space, physical contact, riding comfort and unsatisfactory vision, and achieve rational use of space. , Increase the vertical spacing, the effect of good running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

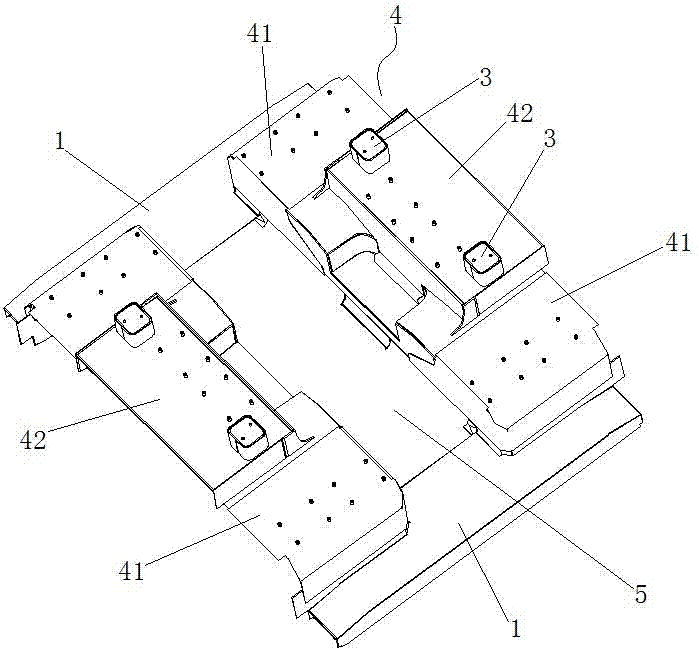

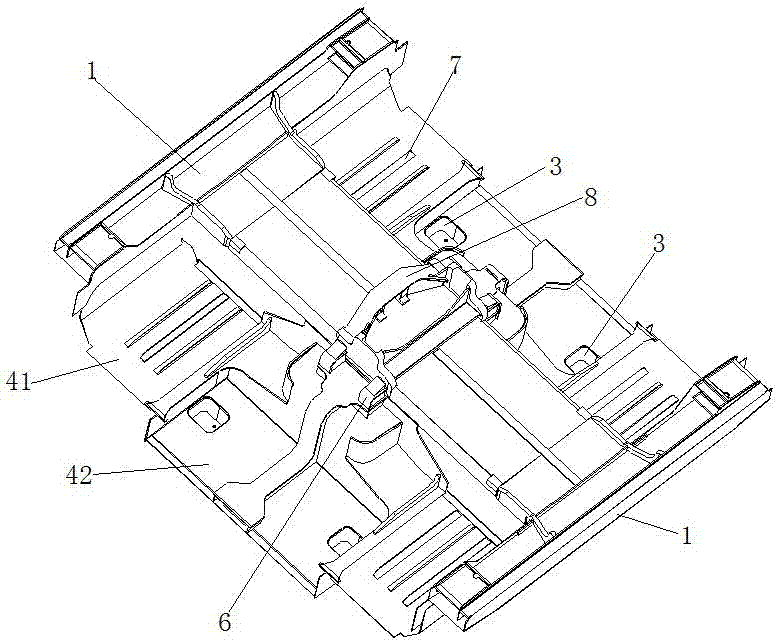

[0035] Such as Figure 1-8 As shown, a low-floor rail vehicle underframe structure includes end beams 1 respectively arranged at both ends, an aisle floor 5 is fixed in the middle of the end beams 1 at both ends, and side assemblies 4 are arranged on both sides of the aisle floor 5. The assembly is fixedly connected with the end beam 1. The side assembly 4 includes a transverse seat mounting plate 41 and a longitudinal seat mounting plate 42 higher than the transverse seat mounting plate 41 , the transverse seat mounting plate 41 and the longitudinal seat mounting plate 42 form a convex structure.

[0036] The aisle floor 5 is flush with other floors of the vehicle body.

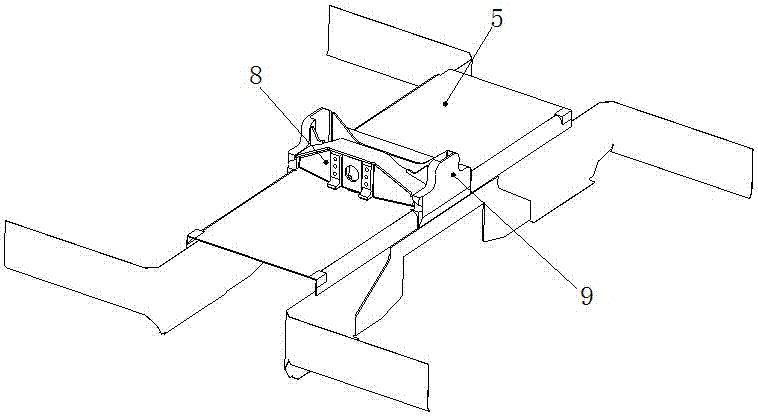

[0037] A traction seat 8 is provided on the back of the aisle floor 5 located at the longitudinal seat mounting plate 42, and a transverse stop 9 is provided on both sides of the traction seat 8, and a vertical stop 10 is vertically provided with the transverse stop 9. Both sides of the fifth wheel 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com