Manufacturing method of lithium-sulfur battery positive electrode and lithium-sulfur battery

A technology for a lithium-sulfur battery and a manufacturing method, applied in the field of lithium-ion batteries, can solve problems such as poor stability, low rate, and low rate performance, and achieve the effects of ensuring uniformity and conductivity, balancing volume changes, and improving contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

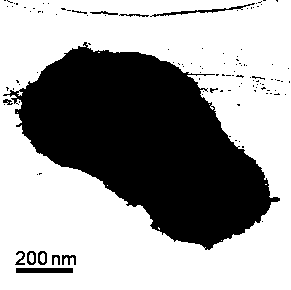

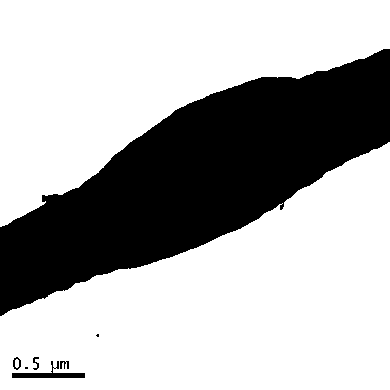

Image

Examples

Embodiment 1

[0041] A method for making a positive electrode of a lithium-sulfur battery, specifically comprising the following steps:

[0042] Step 1. Take 10g of Bacillus subtilis powder (GPBBS), add 4g of glucose and 200ml of deionized water, stir well and let it stand for 16 hours to activate.

[0043] Step 2: Take the activated bacterial suspension and centrifuge at 1500 rpm for 2 minutes, and discard the precipitate.

[0044] Step 3: Take the centrifuged turbid liquid in step 2 and centrifuge it at 4500 rpm for 5 min, discard the supernatant, and precipitate the crude GPBBS.

[0045] Step 4, the crude GPBBS was washed and centrifuged in sequence with ethanol, hydrochloric acid and water to obtain a refined GPBBS wet powder, which was freeze-dried for 72 hours to obtain a refined GPBBS dry powder.

[0046] Step 5. After heating the refined GPBBS dry powder at 500°C for 4 hours without oxygen, mix it with sulfur powder at a mass ratio of 1:2, and mill it with a high-energy ball mill a...

Embodiment 2

[0057] A method for making a positive electrode of a lithium-sulfur battery, specifically comprising the following steps:

[0058] Step 1: Take 10 g of camellia oleifera shells and soak them in sulfuric acid for 12 hours, then wash them with ethanol and clear water.

[0059] Step 2: Mechanically grind the camellia oleifera husk to a particle size of about 900nm, remove impurities, and freeze-dry.

[0060] Step 3: Heat the freeze-dried camellia oleifera shell to 410°C for 2 hours without oxygen to obtain charcoal powder of camellia oleifera shell, then mix it with sulfur powder at a mass ratio of 1:2, and ball mill at 3500 RPM.

[0061] Step 4, Step 3: Take 0.4g of the sulfur composite bacterial carbon powder obtained from the sulfur composite camellia shell charcoal obtained in step 3 and disperse it in 4.5g N,N-dimethylformamide (DMF), add 0.6g polyacrylonitrile (PAN), and carry out Electrospinning, controlling the thickness of the electrospinning thread to be about 1000nm, ...

Embodiment 3

[0067] A method for making a positive electrode of a lithium-sulfur battery, specifically comprising the following steps:

[0068] Step 1: Take 10 g of dried osmanthus leaves and soak them in sulfuric acid for 12 hours, then wash them with ethanol and clear water.

[0069] Step 2: mechanically grind the leaves of osmanthus fragrans to a particle size of about 900nm, remove impurities and freeze-dry.

[0070] Step 3: Heat the obtained Osmanthus fragrans leaves to 600°C for carbonization in isolation from oxygen, then mix with sulfur powder at a mass ratio of 1:2, and ball mill at 3500 RPM.

[0071] Step 4. Take 0.8g of the obtained sulfur composite leaf charcoal powder and disperse it in 4.5g of N, N-dimethylformamide (DMF), add 0.6g of polyacrylonitrile (PAN), and carry out electrospinning to control the The thread thickness is about 1000nm. Obtain multi-level micro-tandem osmanthus leaf charcoal.

[0072] Step five, the multi-stage micro-tandem sweet-scented osmanthus tree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com