Outdoor power distribution cabinet with dust removal mechanism

A power distribution cabinet and outdoor technology, which is applied in the field of outdoor power distribution cabinets with a dust removal mechanism, can solve the problems that the heat dissipation network is difficult to remove dust, and the heat dissipation network is blocked by the normal heat dissipation of the power distribution cabinet, so as to prevent electrical components from being damaged due to short circuit, Reasonable structure, the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

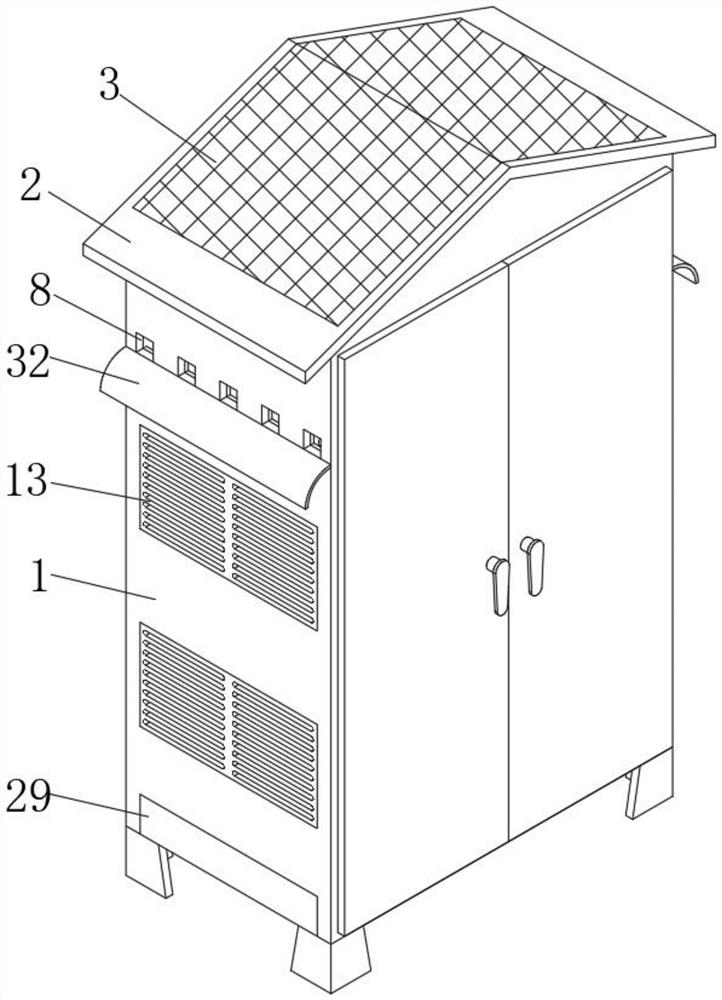

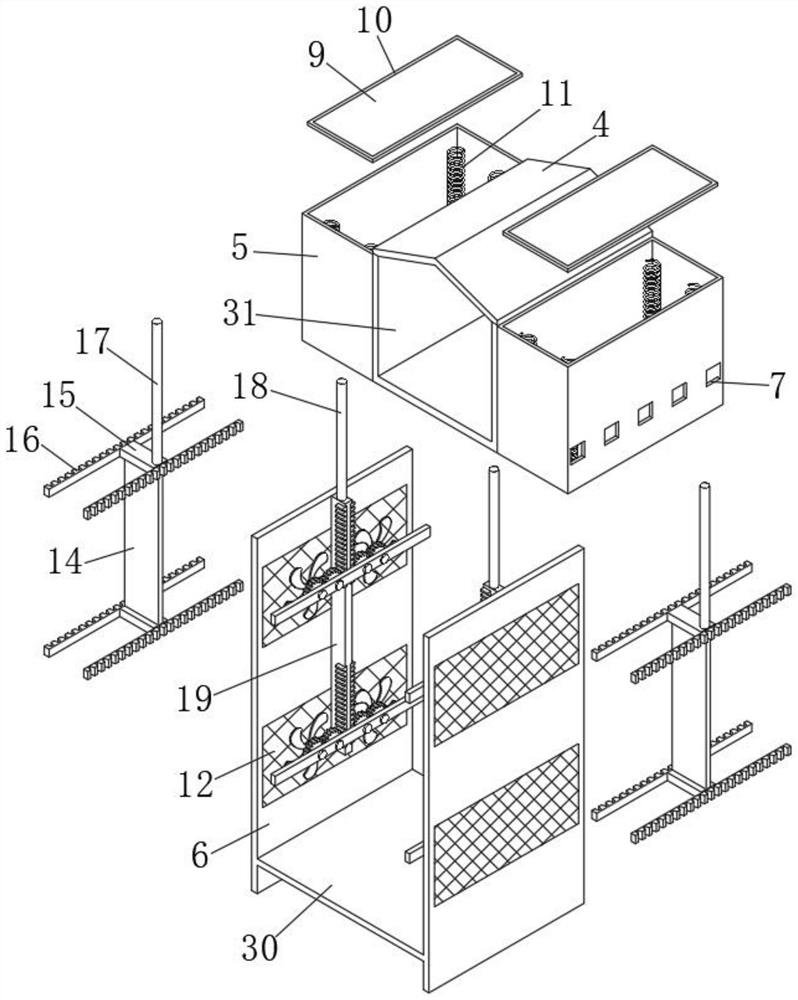

[0031] refer to Figure 1-6 , an outdoor power distribution cabinet with a dust removal mechanism, comprising a cabinet body 1, a rain shield 2 is fixedly installed on the top of the cabinet body 1, a separation net 3 is fixedly embedded on the top surface of the rain shield 2, and the separation net 3 is conducive to blocking The sundries such as leaves, sand and gravel from the outside fall into the water storage tank 5. The bottom of the separation net 3 is provided with a splitter plate 4 fixed to the top of the inner side of the cabinet 1. The inner side of the cabinet 1 is provided with a movable dust removal mechanism, which is used for matching. The dust-proof net 12 in the electric cabinet 1 and the wet dust adhering to the heat-dissipating net 13 are scraped off;

[0032] The movable dust removal mechanism includes two water storage tanks 5 and two divided vertical plates 6. The two water storage tanks 5 are respectively located at the inner ends of the top inner sid...

Embodiment 2

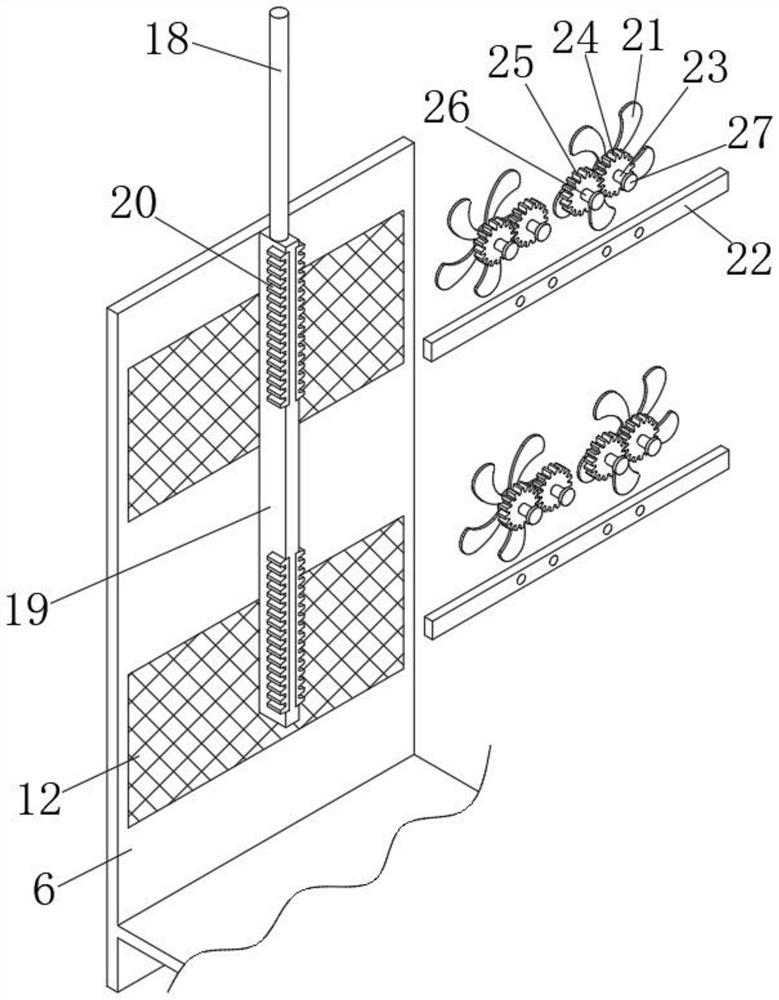

[0037] like Figure 1-5 As shown, this embodiment is basically the same as Embodiment 1. The two dust blowing assemblies both include a second push rod 18 and a movable vertical rod 19. The two second push rods 18 are located on one side of the bottom of the two water storage tanks 5 respectively. The two push rods 18 penetrate through the bottom of the water storage tank 5 and are fixedly connected to the movable plate 9. The movable vertical rod 19 is located at the bottom of the second push rod 18 and is fixedly connected to the second push rod 18. The four corners of the movable vertical rod 19 are fixedly embedded with limit teeth. Strip 20. Fan blades 21 are provided on both ends of one side of the dust-proof net 12, a fixed cross bar 22 fixed to the cabinet 1 is provided on one side of the dust-proof net 12, and a first horizontal shaft 23 is fixedly connected on one side of the fan blade 21. , the outer side of the first horizontal shaft 23 is fixedly sleeved with a fi...

Embodiment 3

[0040] like figure 2 and Figure 4 As shown, this embodiment is basically the same as Embodiment 1. A U-shaped sealing plate 31 fixed to the cabinet 1 is sealed and welded at the bottom of the manifold 4 , and the two ends of the U-shaped sealing plate 31 are sealed and welded to one end of the two water storage tanks 5 respectively.

[0041] In this embodiment, when it rains, the diverter plate 4 discharges the rainwater entering through the separation net 3 into the two water storage tanks 5 respectively. Limiting and sealing improve the sealing performance of the top of the entire power distribution cabinet, preventing rainwater from falling into the interior of the power distribution cabinet from the top of the power distribution cabinet and causing damage to electrical components due to short circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com