Chamfering machining equipment and chamfering machining method for curved surfaces of orifices of oil holes of connecting rods

A technology of processing equipment and processing methods, applied in metal processing equipment, milling machine equipment, details of milling machine equipment, etc., can solve the problems of difficult to meet the use requirements of connecting rods, complicated processing equipment, low processing efficiency, etc., and achieve chamfering consistency. And the effect of surface roughness improvement, large feed rate and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

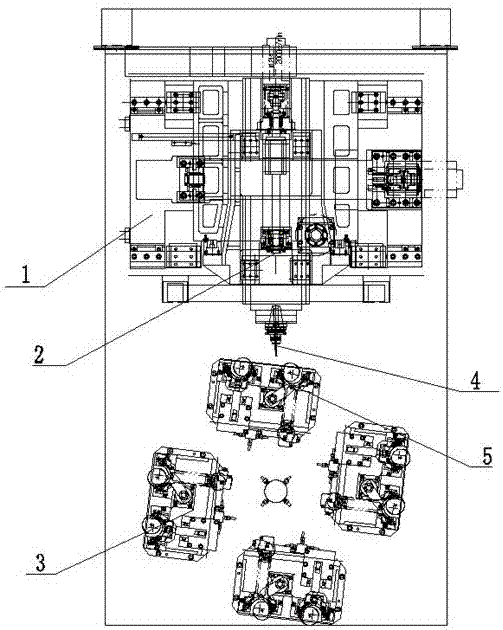

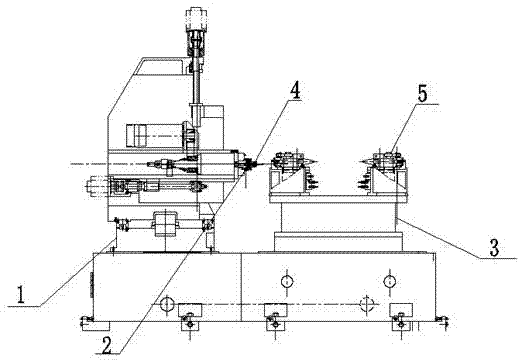

[0032] As a preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0033] Connecting rod oil hole orifice surface chamfering processing equipment, including a horizontal three-coordinate drive mechanism 1, a servo spindle drive mechanism 2 and an indexing table 3, and the servo spindle drive mechanism 2 is set on the horizontal three-coordinate drive mechanism 1 , the horizontal three-coordinate drive mechanism 1 drives the servo spindle drive mechanism 2 to move, the end of the servo spindle drive mechanism 2 is fixed with a milling cutter handle 4, and a milling cutter is fixed on the milling cutter handle 4, and the indexing table A hydraulic clamp 5 is installed on the 3, and the hydraulic clamp 5 is used to fix the connecting rod. The indexing table 3 is located at the front end of the servo spindle drive mechanism 2. By adopting the chamfering processing technology of the curved surface of the connecting...

Embodiment 2

[0035] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0036] Connecting rod oil hole orifice surface chamfering processing equipment, including a horizontal three-coordinate drive mechanism 1, a servo spindle drive mechanism 2 and an indexing table 3, and the servo spindle drive mechanism 2 is set on the horizontal three-coordinate drive mechanism 1 , the horizontal three-coordinate drive mechanism 1 drives the servo spindle drive mechanism 2 to move, the end of the servo spindle drive mechanism 2 is fixed with a milling cutter handle 4, and a milling cutter is fixed on the milling cutter handle 4, and the indexing table A hydraulic clamp 5 is installed on the 3, and the hydraulic clamp 5 is used to fix the connecting rod. The indexing table 3 is located at the front end of the servo spindle drive mechanism 2. The milling tool holder 4 is a heat-expanding tool holder; the tool holder interfa...

Embodiment 3

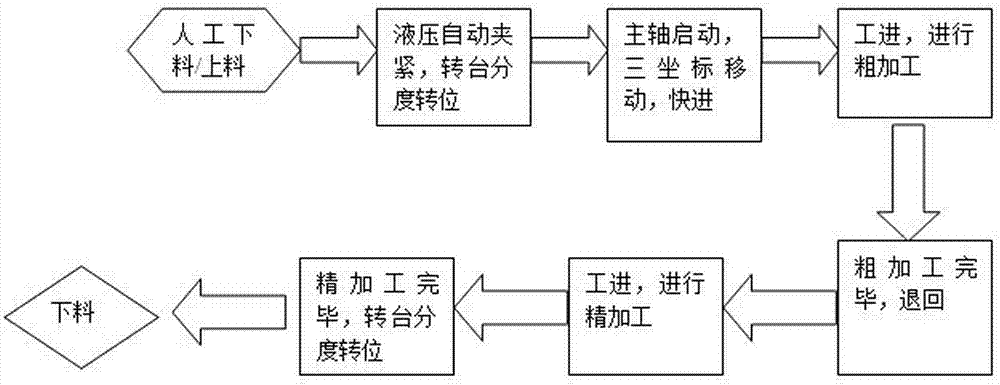

[0038] As another preferred embodiment of the present invention, with reference to the attached image 3 , this example discloses:

[0039] The method for chamfering the curved surface of the oil hole of the connecting rod comprises the following steps:

[0040] A. Establish a mathematical model according to the positioning hole coordinates of the oil hole, the processing hole coordinates and the processing hole size data, and simulate the established mathematical model through software to determine whether the established mathematical model meets the process requirements;

[0041] B. Analyze the mathematical model that meets the process requirements, convert the established mathematical model into a processing program, input the converted processing program into the horizontal three-coordinate drive mechanism 1 system, convert it into an executable program, and execute the program to make the horizontal The three-coordinate drive mechanism 1 moves according to the mathemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com