Automatic workpiece chamfering equipment and control method

A workpiece and chamfering technology, which is applied to the special processing equipment for workpiece chamfering and its control field, can solve the problems of high labor intensity, low production efficiency, long chamfering cycle, etc., and achieves a high degree of intelligence, convenient operation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

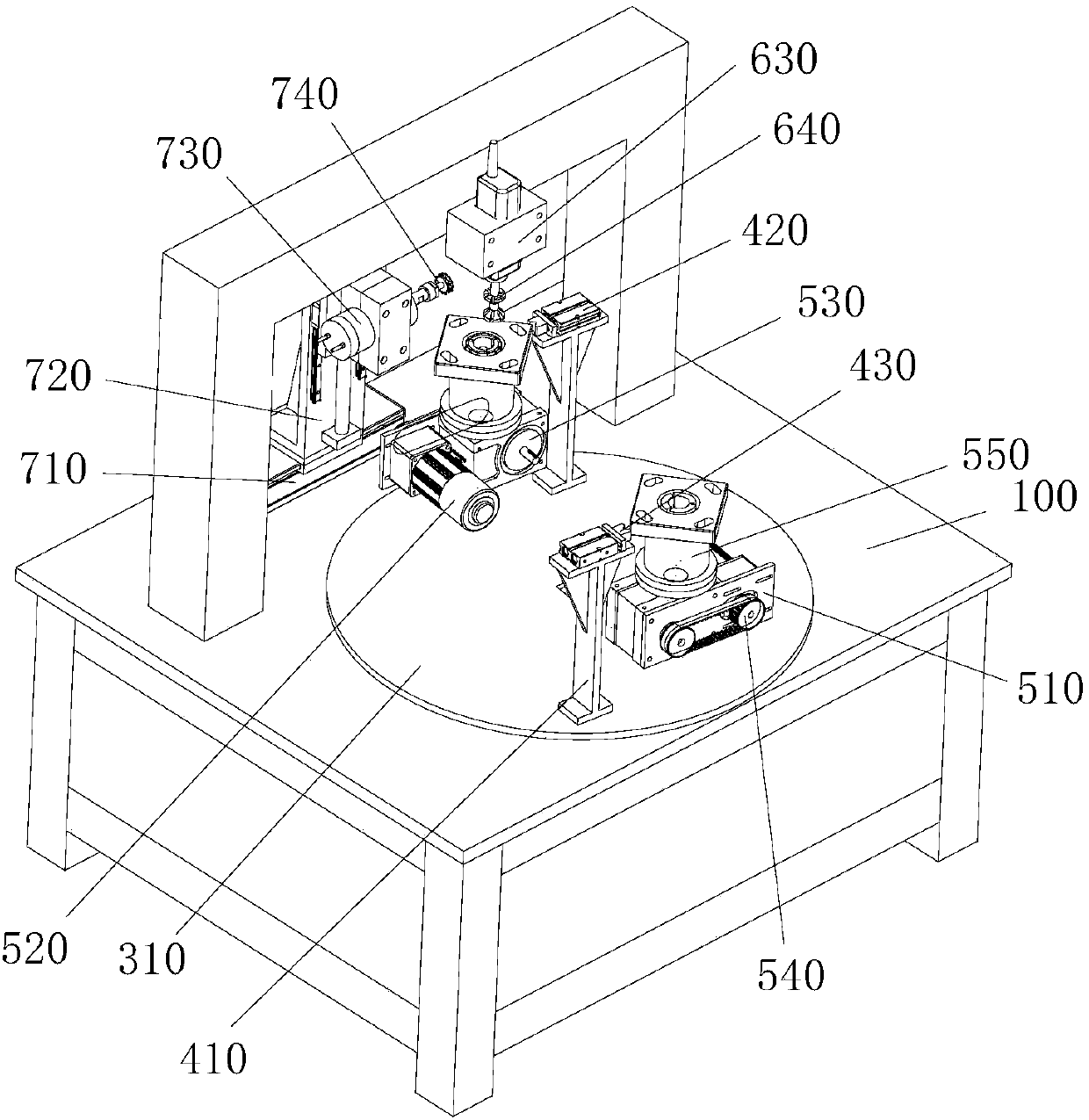

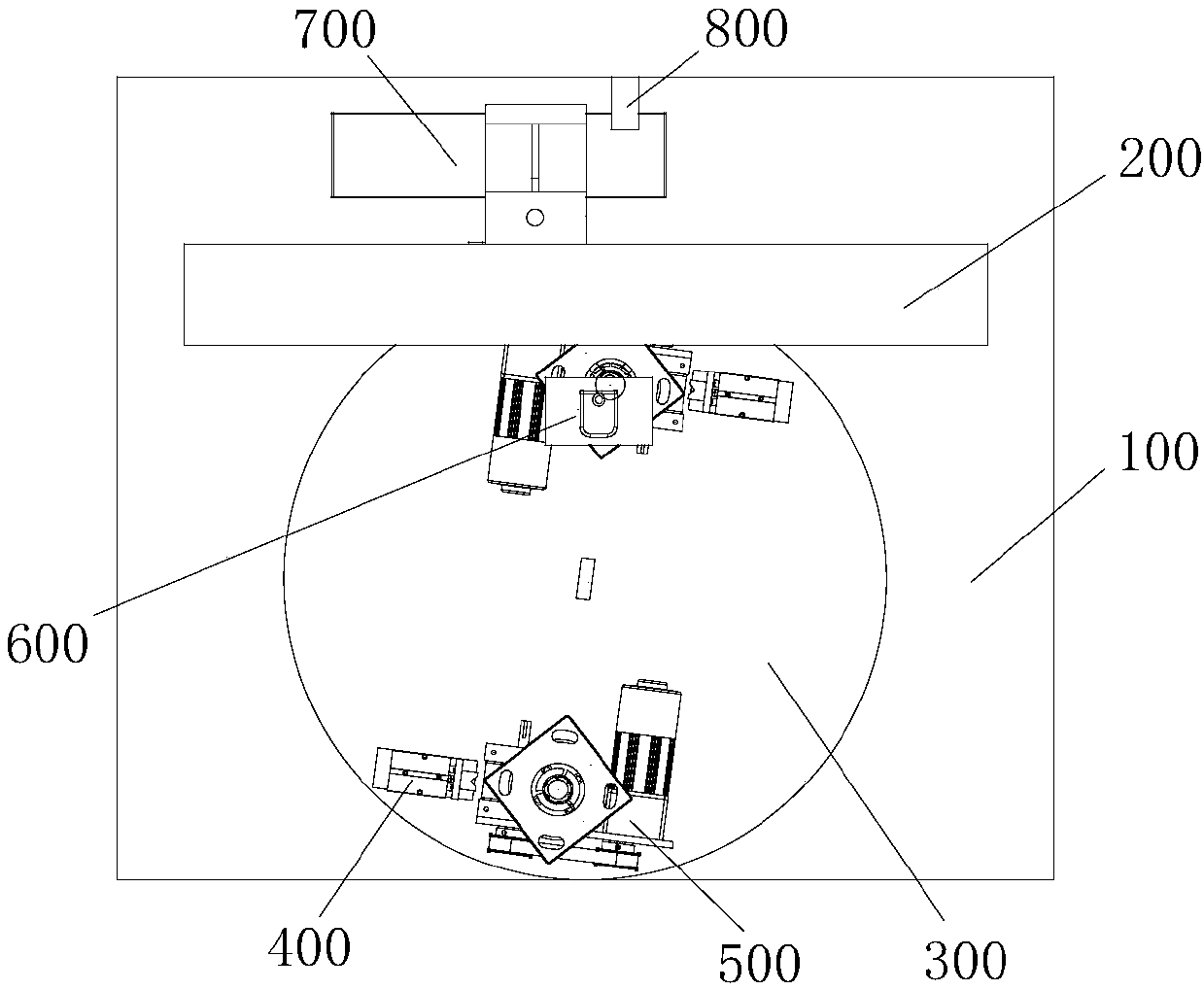

[0039] Such as figure 1 and figure 2 As shown, the present invention discloses a workpiece automatic chamfering equipment, which mainly includes a workbench 100, a gantry 200 arranged on the workbench 100, a conversion table 300 for loading and unloading, and a positioning device for correcting the position of the workpiece. The mechanism 400, the locking mechanism 500 for fixing the position of the workpiece, the first chamfering mechanism 600 for chamfering the R corner of the workpiece, and the second chamfering mechanism 700 for chamfering the edge of the workpiece. Both the locking mechanism 500 and the positioning mechanism 400 are fixed on the conversion table 300, and the conversion table 300 is installed on the workbench 100, and rotated to the chamfering station with the locking mechanism 500 and the positioning mechanism 400 for processing. The gantry 200 is installed on the workbench 100 and is located on one side of the conversion platform 300 . The first chamf...

Embodiment 2

[0060] This embodiment discloses a special machine for workpiece chamfering, including: a workbench 100; a double-station transfer table 300 installed directly above the workbench 100; a gantry 200 installed above the workbench 100 and One side of the double station transfer table 300; two workpiece positioning mechanisms 400 symmetrically installed on the double workpiece transfer table 300; a laser detection mechanism installed on the right side of the workpiece positioning mechanism 400, and the laser detection mechanism is installed on the working On the platform 100; the edge chamfering mechanism installed directly in front of the gantry 200; the chamfering R angle mechanism installed directly behind the gantry 200;

[0061] In the above technical solution, the workpiece to be chamfered is placed in the workpiece positioning mechanism 400 manually or by a robot, and the double-station transfer table 300 installed on the workbench 100 rotates 180 degrees to transfer the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com