Cylinder body inner hole numerical control cylindrical coordinate chamfering machine

A technology of cylindrical coordinates and chamfering machines, which is applied to the parts of grinding machine tools, machine tools and grinding machines suitable for grinding the edge of workpieces, etc. It can solve the problems of manual chamfering without guarantee of quality, large and small chamfering, and high technical requirements. problem, to achieve the effect that the size of the chamfer will not be missed, the size of the chamfer is consistent, and the training cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

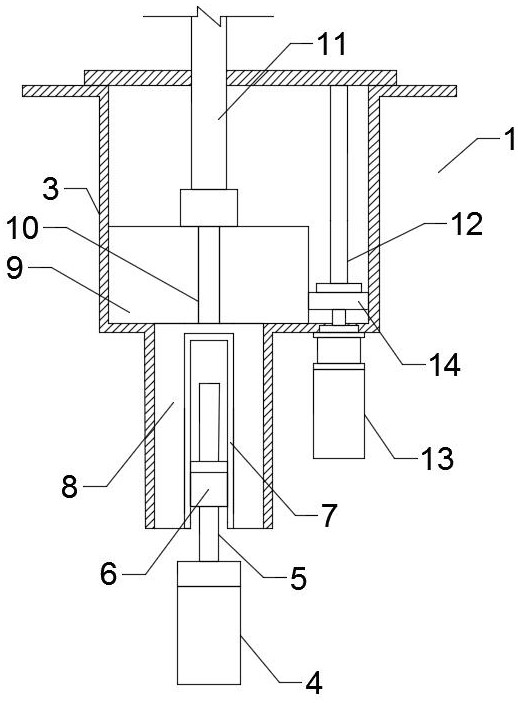

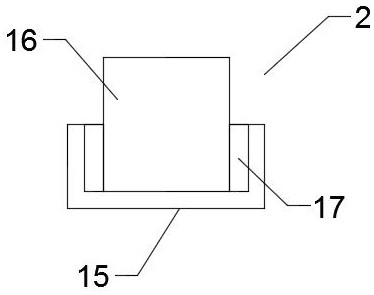

[0013] Such as Figure 1 to Figure 2 As shown, the present invention discloses a numerically controlled column coordinate chamfering machine for inner holes of cylinders. The technical solution adopted is to include a main machine 1, a grinding mechanism 2, and a numerically controlled operating system. The grinding mechanism 2 is connected to the main machine 1 and All are electrically connected with the numerical control operating system, the host 1 also includes a lower body 3, a Z-axis travel mechanism and an X-axis rotation mechanism, and the Z-axis travel mechanism also includes a Z-axis servo motor 4, a lead screw 5, a cylinder Pin 7, spline shaft 8, large gear 9 and main shaft 11, the output end of the Z-axis servo motor 4 is connected to the Z-axis reducer and then connected to the lead screw 5, and the screw nut 6 installed on the lead screw 5 is connected to the The cylindrical pin 7 is connected, the cylindrical pin 7 is connected to the spline shaft 8, and the spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com