Glass chamfering device

A technology of chamfering device and glass, which is applied to grinding drive device, automatic grinding control device, grinding machine, etc., can solve the problem of low production efficiency, achieve the effect of convenient operation, improve processing efficiency and improve chamfering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

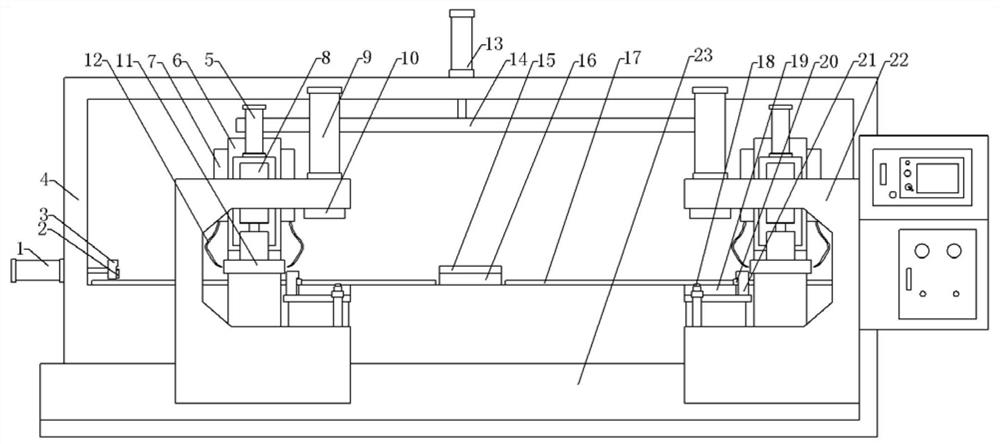

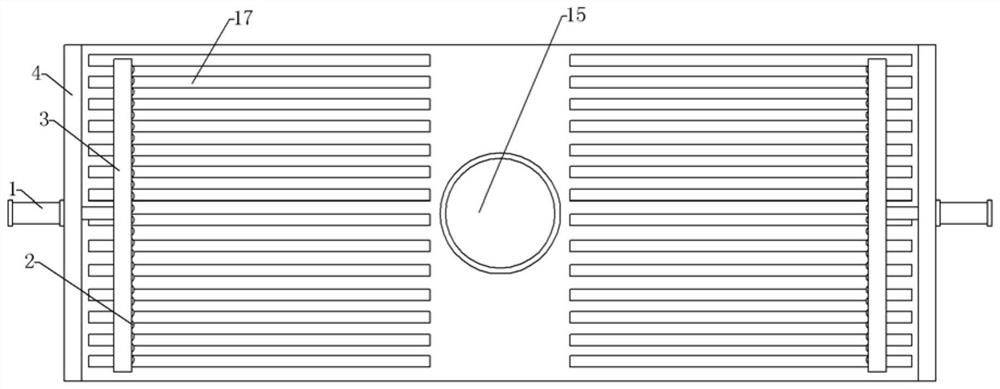

[0033] Such as figure 1 As shown, the glass chamfering device includes a base 23, on which a water collection tank (not shown in the figure) is opened, and the water collection tank is connected with a sewage pipe. Two bodies 22 are installed on the base 23 , the right side body 22 is fixed on the base 23 , the left side body 22 is slidably connected with the base 23 , and the two bodies 22 have the same structure.

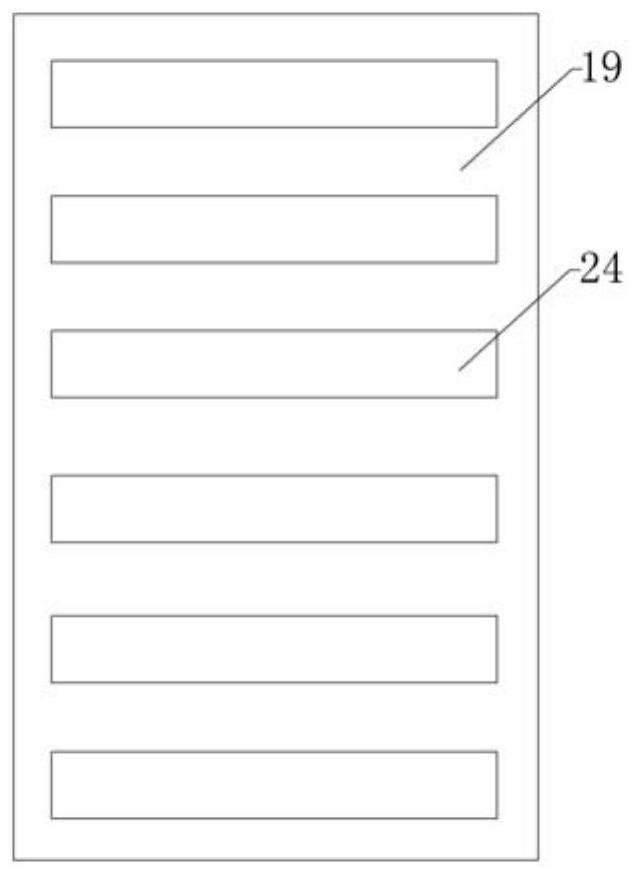

[0034] The machine body 22 includes a support platform 19 with scales engraved on the support platform 19 (not shown in the figure). A pressing plate 10 is vertically slidably arranged above the support table 19 , and a pressing cylinder 9 for driving the pressing plate 10 to move vertically is installed on the body 22 . A side of the two support platforms 19 away from each other is fixed with a limit frame 21 , and the limit frame 21 is welded on the body 22 , and a plurality of limit wheels 20 are rotatably installed on the opposite side of the two limit frames...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com