Burr-free rounding device for packaging bags

A burr-free, corner-rounding technology, used in grinding/polishing safety devices, grinding machines, grinding machine parts, etc., can solve problems such as chamfering burrs, and achieve the effect of improving accuracy, convenience and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

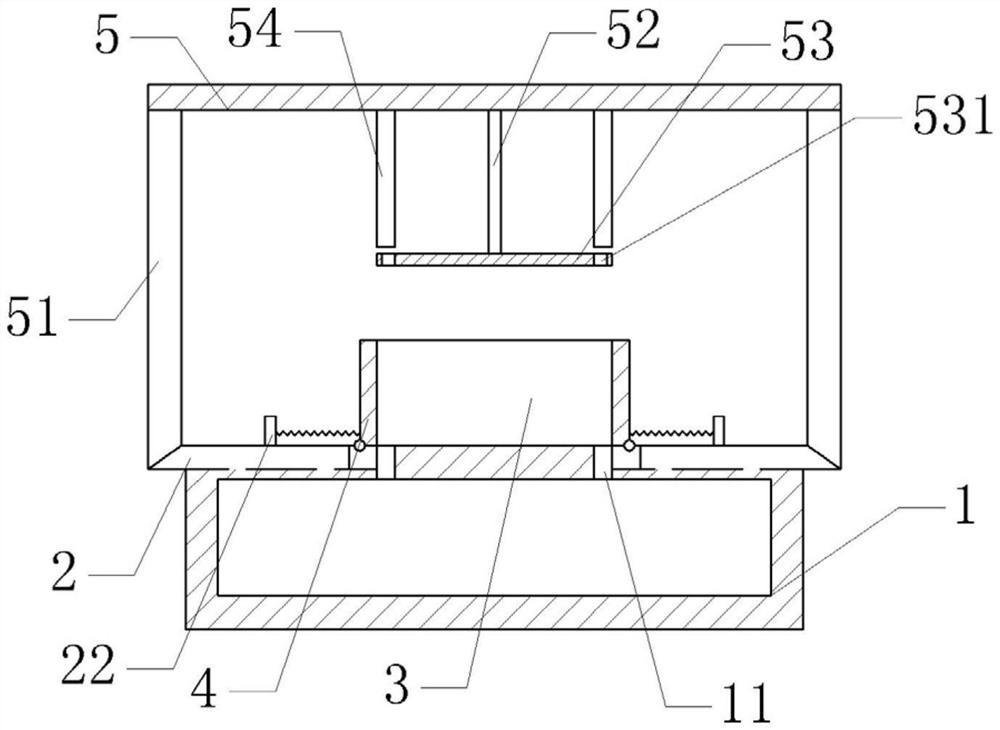

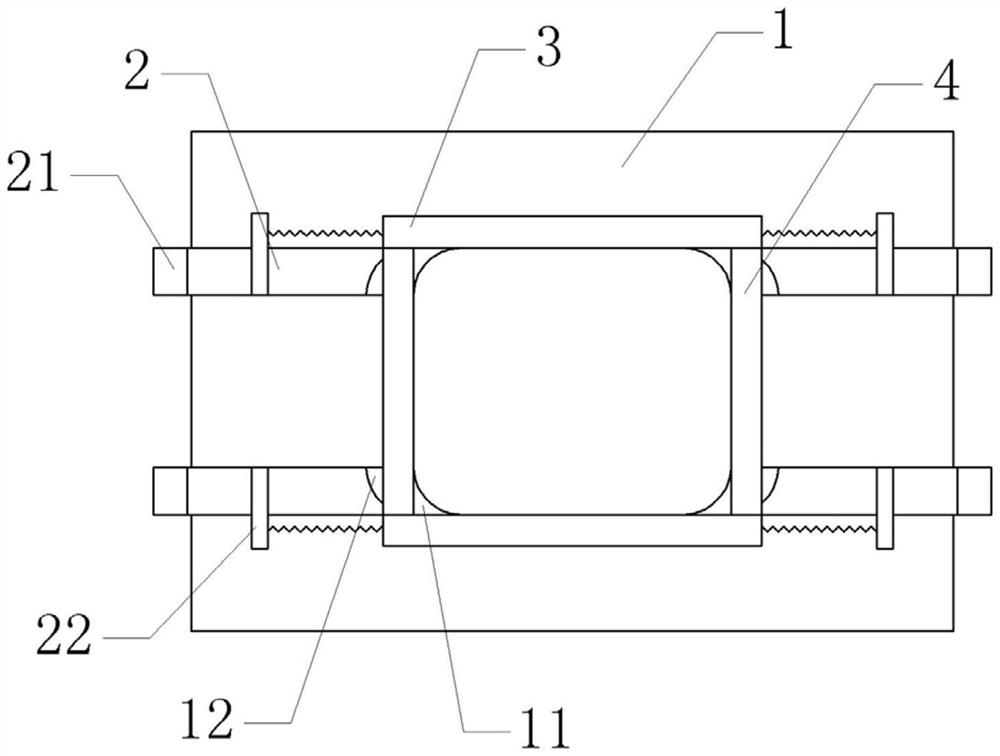

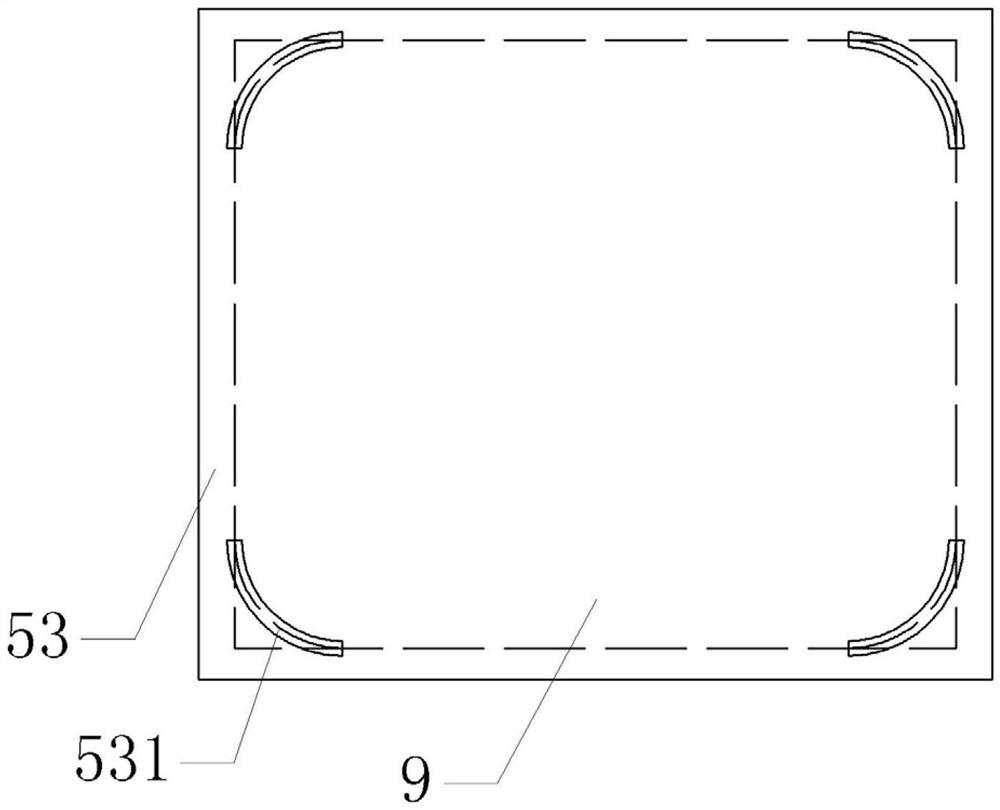

[0038] Packing bag burr-free rounding device, basically as attached figure 1 As shown, it includes a hollow workbench 1 and a support arranged above the workbench 1 . Two limit plates 3 are arranged on the upper surface of the workbench 1, and the two limit plates 3 are arranged in parallel, and the working surfaces of the limit plates 3 are arranged oppositely; The hinge is hinged with a baffle plate 4. When the baffle plate 4 is vertically arranged, magnet layers are arranged on opposite sides, and the two magnet layers attract each other. The two baffle plates 4 and the two limit plates 3 form a square Place cavity.

[0039] combine figure 2 As shown, the upper surface of the workbench 1 is located at the four corners of the placement cavity and is provided with an arc-shaped receiving port 11 and four chutes 12 respectively connected to the receiving port 11, and the chute 12 is arranged horizontally. In the groove 12, there is a material blocking plate 2 which is hori...

Embodiment 2

[0048] Embodiment 2 differs from Embodiment 1 only in that, as Figure 5 , Figure 6 As shown, the grinding part in the present embodiment includes a grinding wheel 6, the chamfering knife 54 is hollow, and the grinding wheels 6 are arranged in multiple rows from top to bottom, and the grinding surface of the grinding wheel 6 and the inner arc of the chamfering knife 54 The surfaces are coplanar, and a rotating shaft 7 is coaxially fixed on the grinding wheel 6 , and a section of the rotating shaft 7 principle grinding wheel 6 is connected to the chamfering knife 54 in rotation. Specifically, the outer arc surface of the hollow chamfering knife 54 is provided with a rotating hole matched with the rotating shaft 7, and the rotating shaft 7 is rotatably connected in the rotating hole. The adjacent grinding wheels 6 of each row of grinding wheels 6 are in close contact; the adjacent rotating shafts 7 of each row are driven by a belt. Gear 71 is fixed on the rotating shaft 7 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com