Chamfering equipment for willow handicraft processing

A technology of wood crafts and chamfering, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as unsuitable chamfering of willow boards, unfavorable working environment cleanliness, and reduction of production costs. Strong practicability, wide application range, and the effect of maintaining neatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

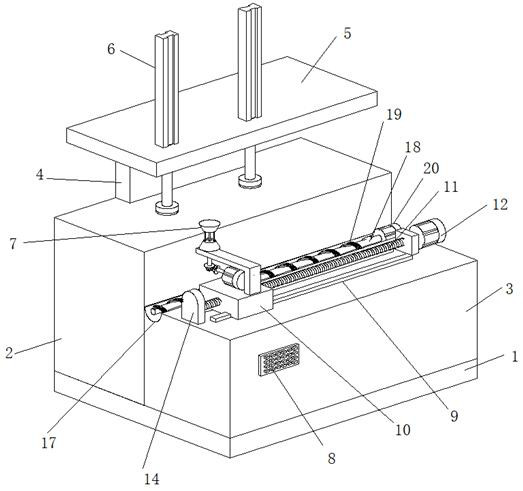

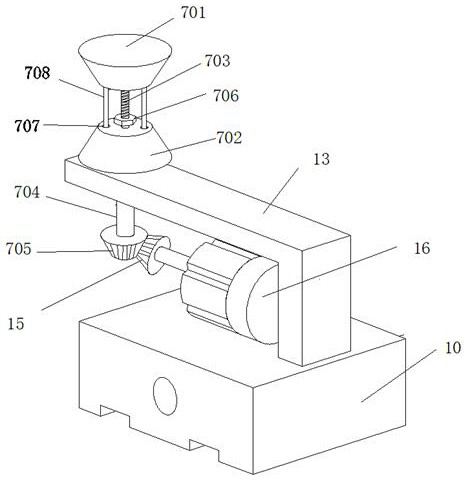

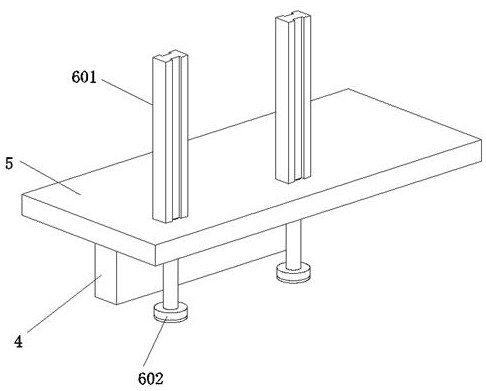

[0035] A kind of chamfering equipment for willow handicraft processing, such as figure 1 and Figure 4 As shown, including the base 1, the upper end surface of the base 1 is fixedly installed with a workbench 2 and a chamfering platform 3, and the workbench 2 is arranged on the rear side of the chamfering platform 3, and the workbench 2 is higher than the chamfering platform 3, and the workbench The upper end surface of 2 is fixed with a top frame 5 through the connecting seat 4, and several hydraulic fixing mechanisms 6 are fixed on the top frame 5. A pair of metal guide rails 9 are fixed on the upper end surface of the chamfering table 3, and the upper ends of a pair of metal guide rails 9 are slidingly installed. There is a sliding seat 10, the interior of the sliding seat 10 runs through and is threadedly connected with an advancing and retreating screw 11, one end of the advancing and retreating screw 11 is connected with the output end of the advancing and retreating mot...

Embodiment 2

[0042] Embodiment 2 is on the basis of embodiment 1, as Figure 6 As shown, the upper end of the workbench 2 is also rotatably equipped with a turntable 21, and the turntable 21 is driven by a rotating motor; the top surface of the top frame 5 also has a second hydraulic cylinder 22, and the telescopic end of the second hydraulic cylinder 22 is fixed with a bearing seat 23, The bottom end of the bearing seat 23 is rotatably mounted with a circular plate 24 , and the central axis of rotation of the circular plate 24 coincides with the central axis of rotation of the turntable 21 .

[0043] When it is necessary to chamfer the round willow plank, it can be placed on the upper end of the rotating disk 21, then the second hydraulic cylinder 22 is extended downwards and the circular plate 24 is pressed against the round willow plank, and then the chamfering grinding wheel mechanism 7 is moved to The position of the tangent point of the turntable 21 can realize chamfering the circumf...

Embodiment 3

[0045] Embodiment 3 is on the basis of embodiment 2, as Figure 6 As shown, a hanger 25 is fixed on the left side wall of the connection between the workbench 2 and the chamfering platform 3, and the ash collection box 26 is articulated on the hanger 25.

[0046] After the chamfering is completed, the cleaning motor 20 can be powered on and drive the cleaning shaft 18 to rotate clockwise, and the cleaning brush 19 also follows the rotation of the cleaning shaft 18, so that the sawdust can be continuously pushed and discharged, which is conducive to keeping the table clean and tidy property; the debris discharged will directly drop into the ash collection box 26 inside, which is convenient for dumping and cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com