Patents

Literature

72 results about "Right side body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

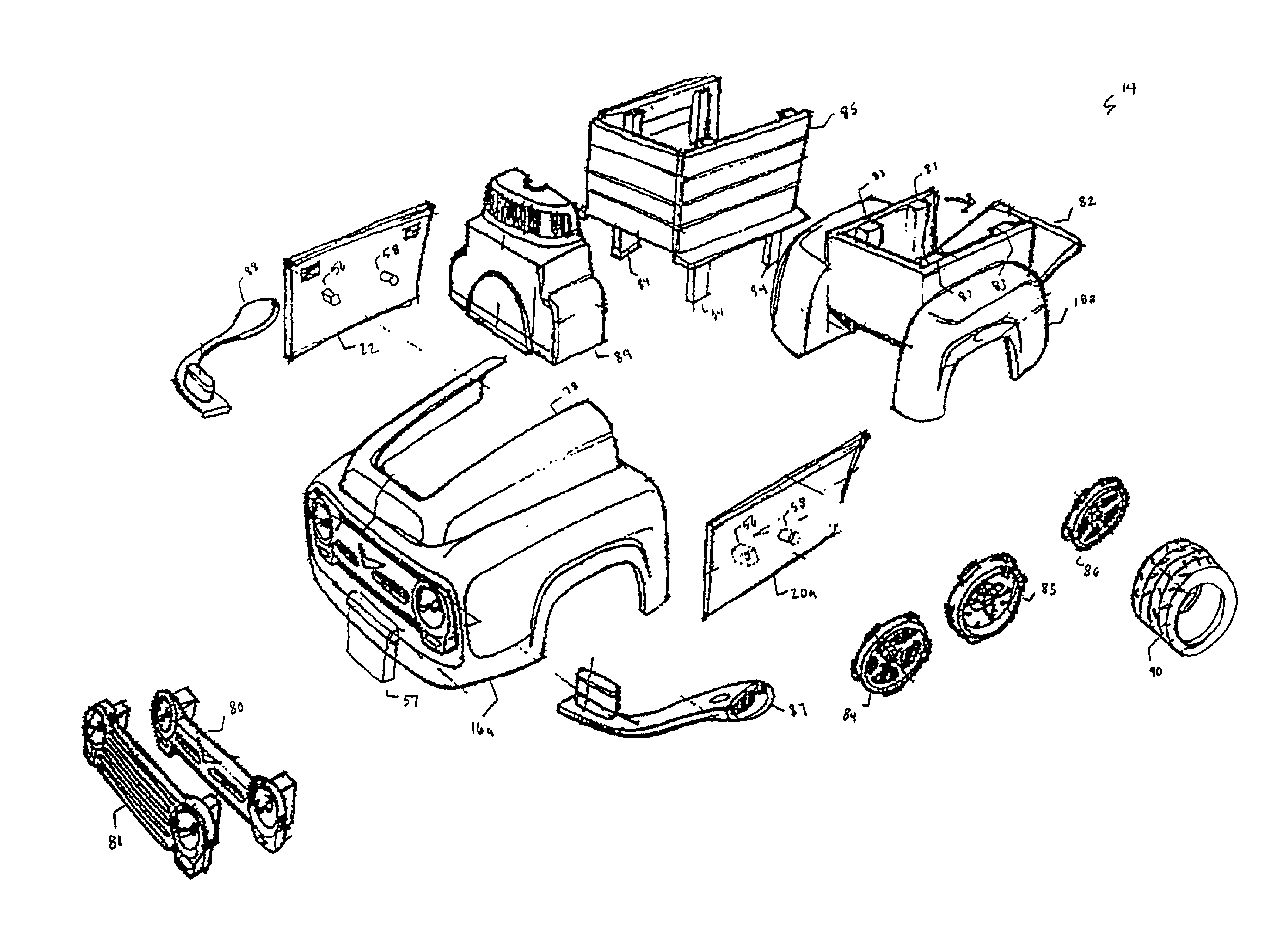

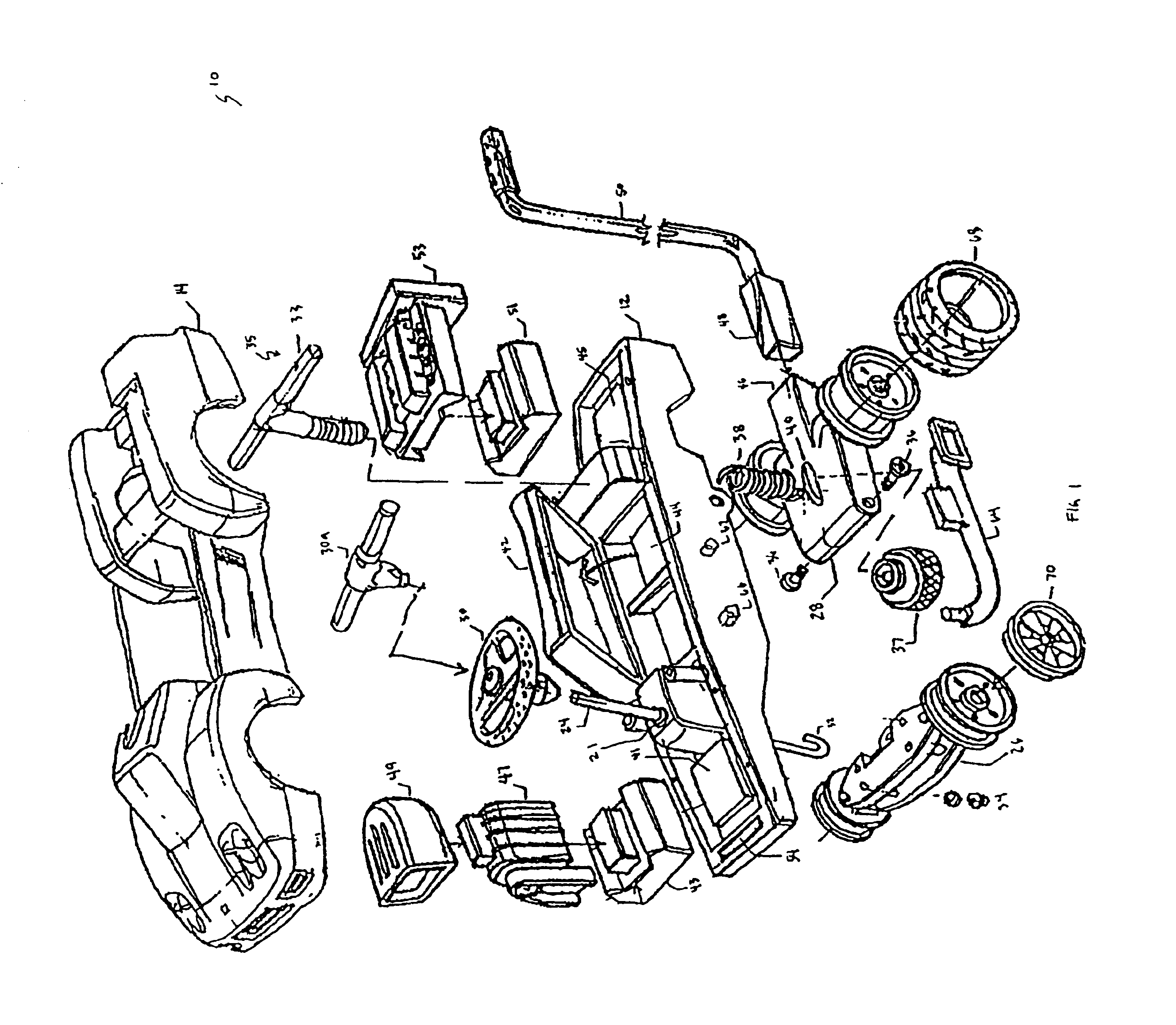

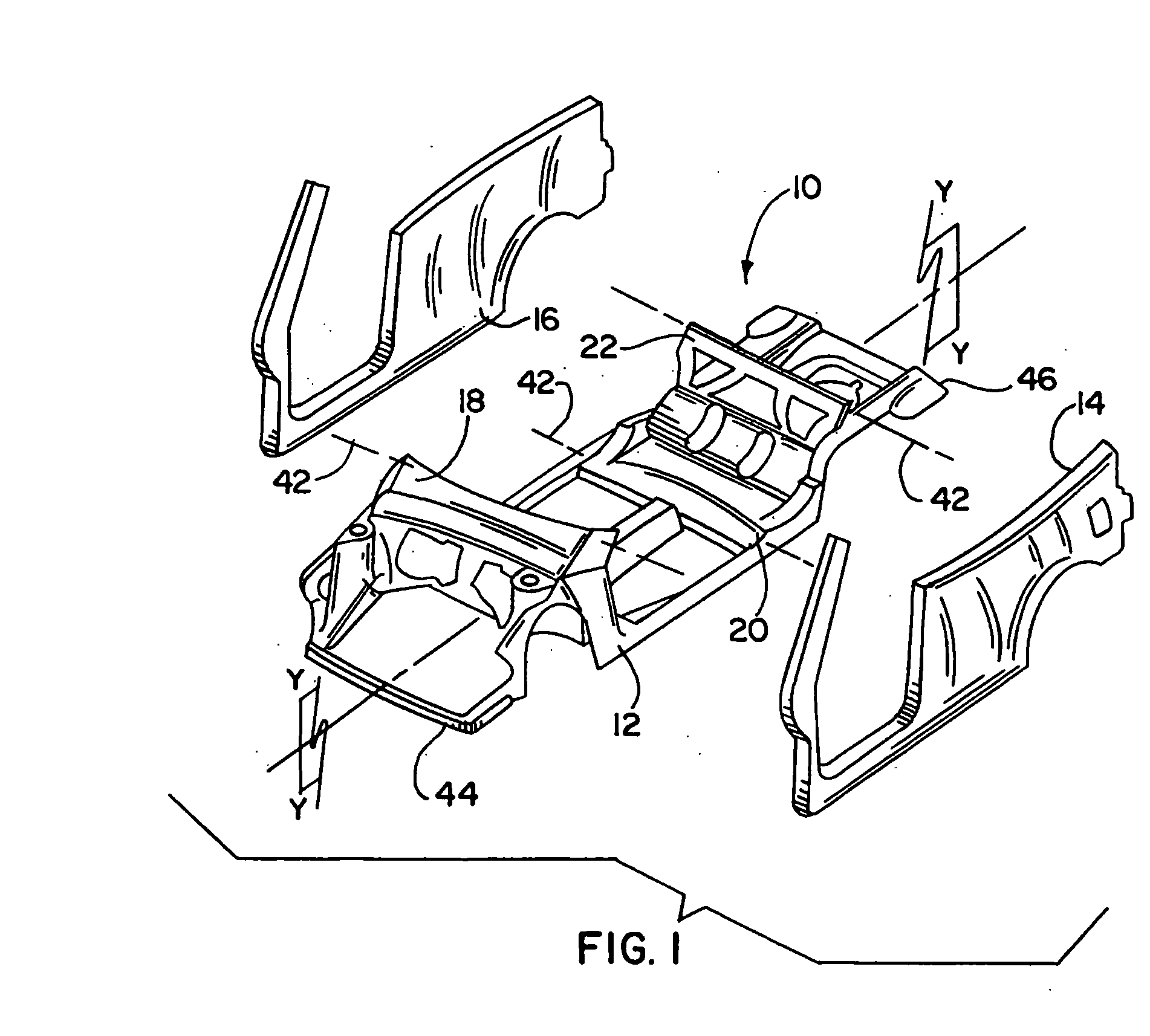

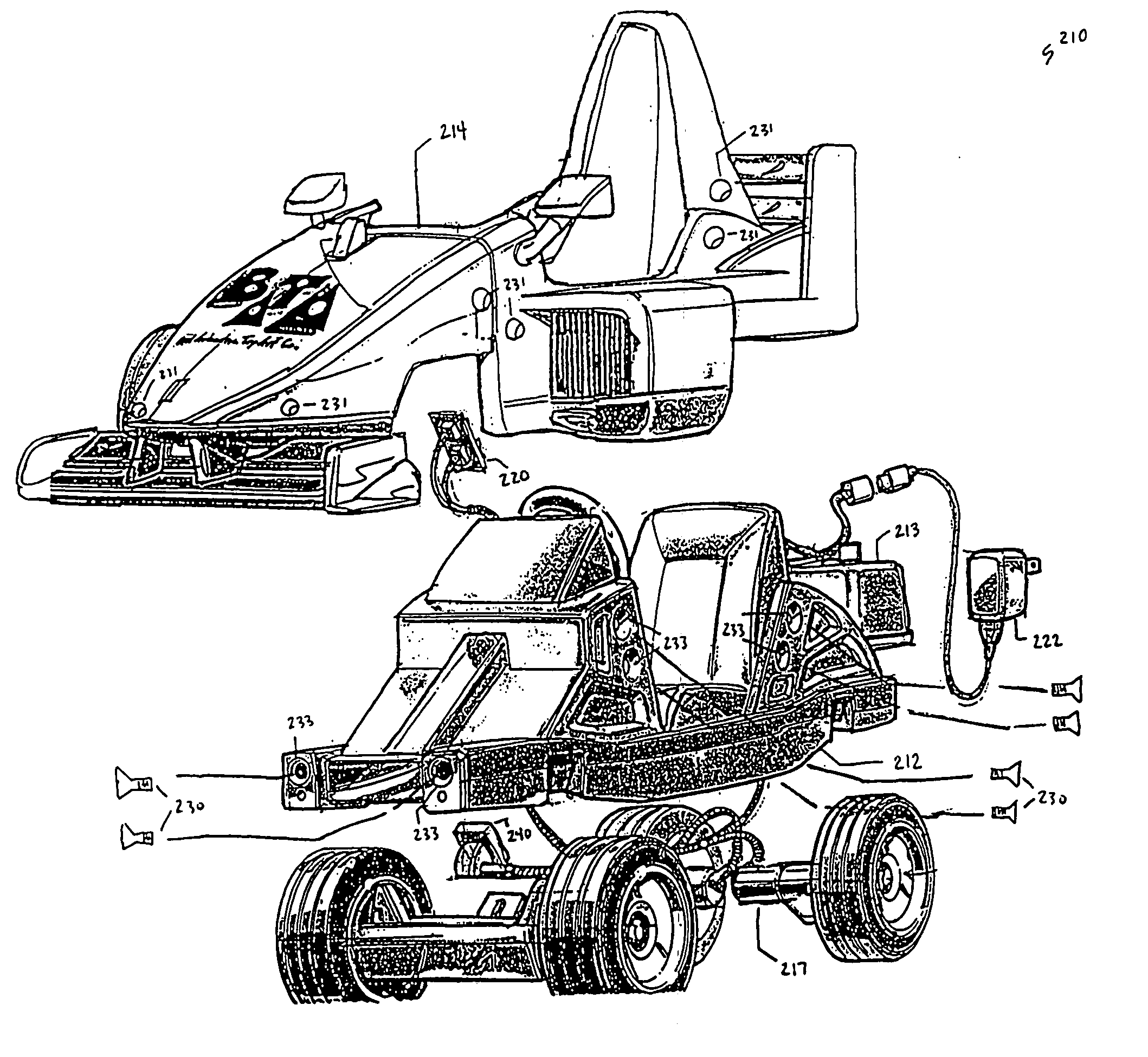

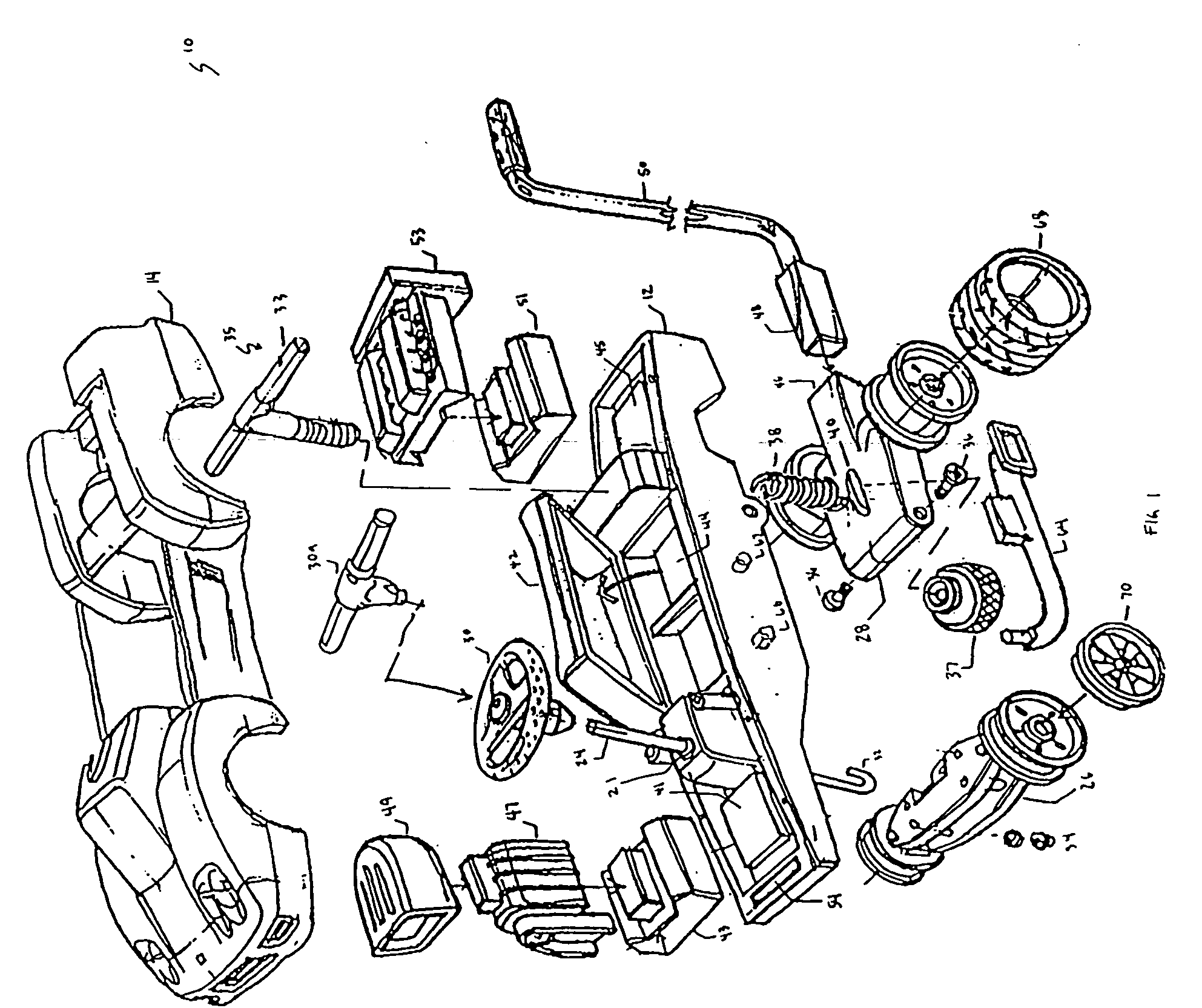

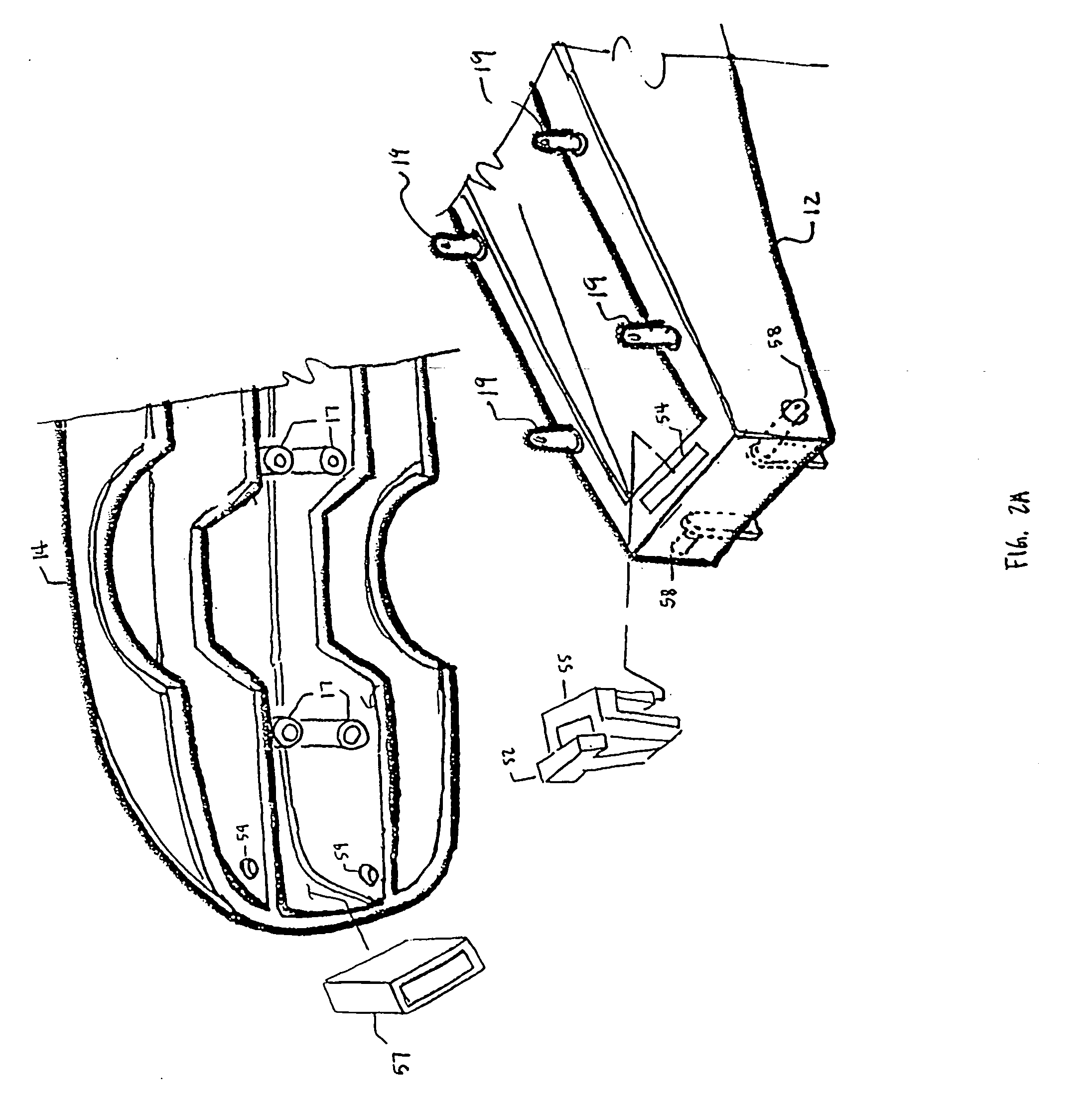

Toy vehicles having interchangeable body styles

A child-sized toy vehicle comprising a vehicle chassis upon which any number of a plurality of stylistically different interchangeable vehicle body modules may be removably secured. The various vehicle body module styles may be comprised of separate body module sections such as a front body module, a rear body module, a left side body module, and a right side body module. In addition, body modules from different body styles may be attached to the same vehicle chassis such that a hybrid vehicle is produced.

Owner:THE BEST AUTOMOTIVE TOY ART THE B A T A

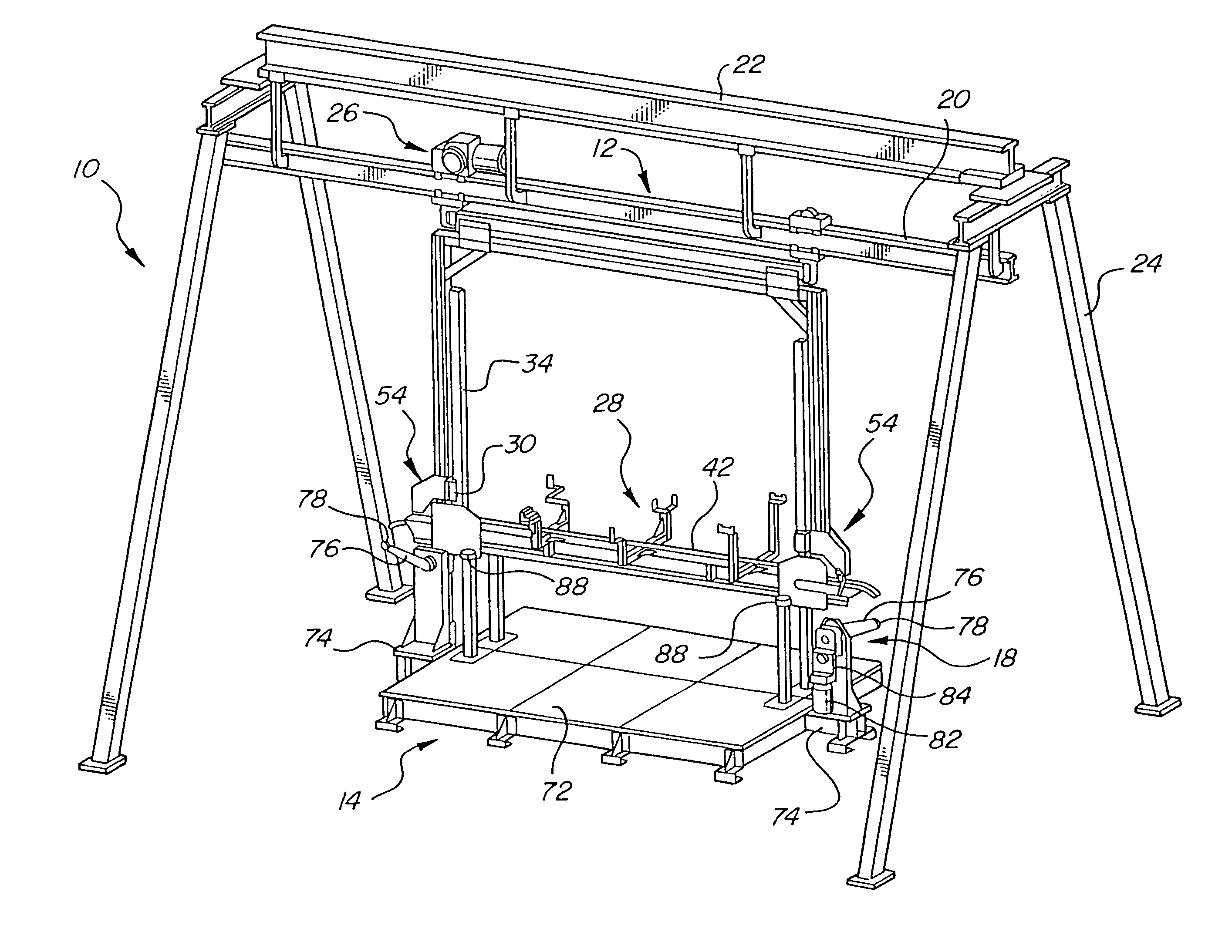

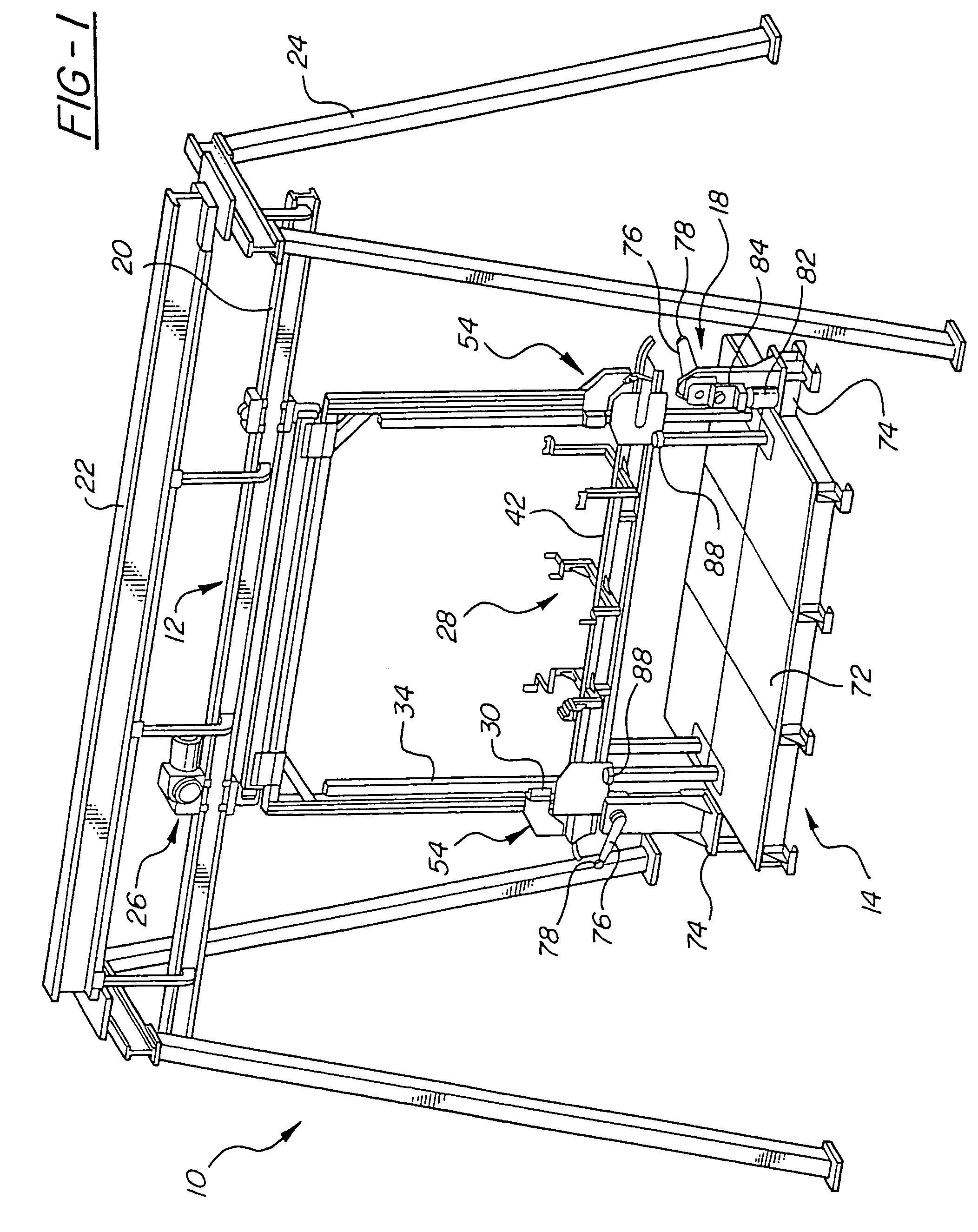

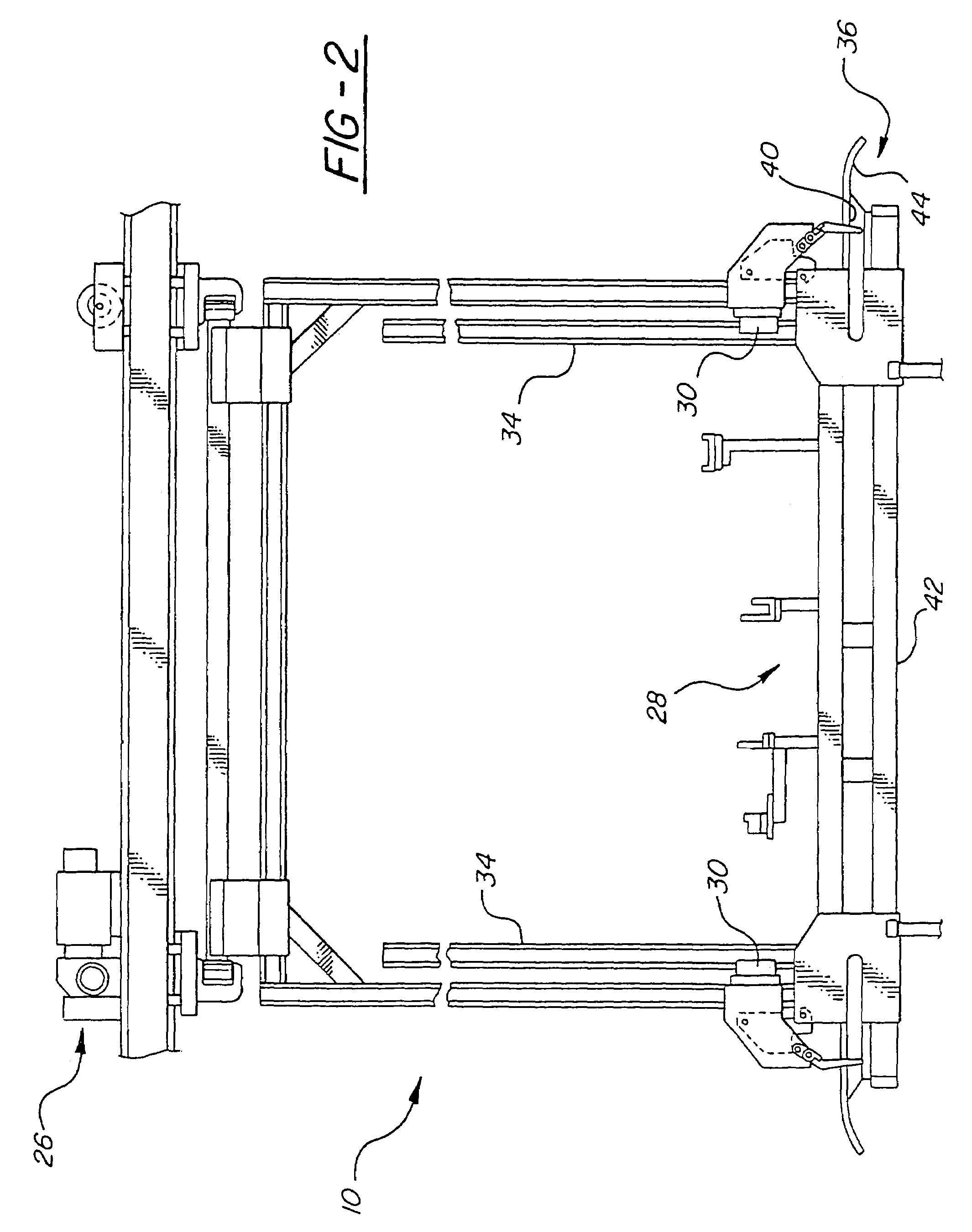

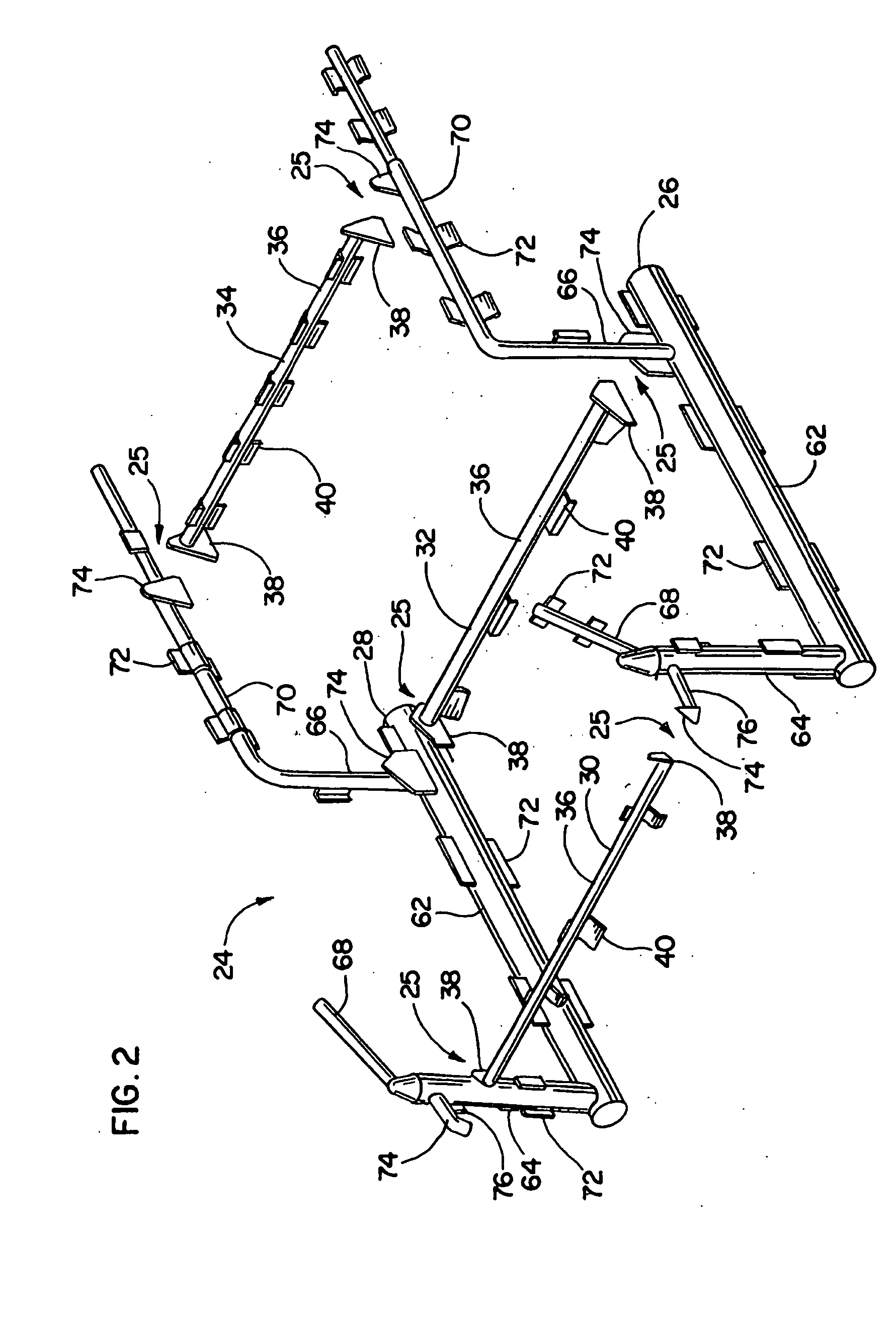

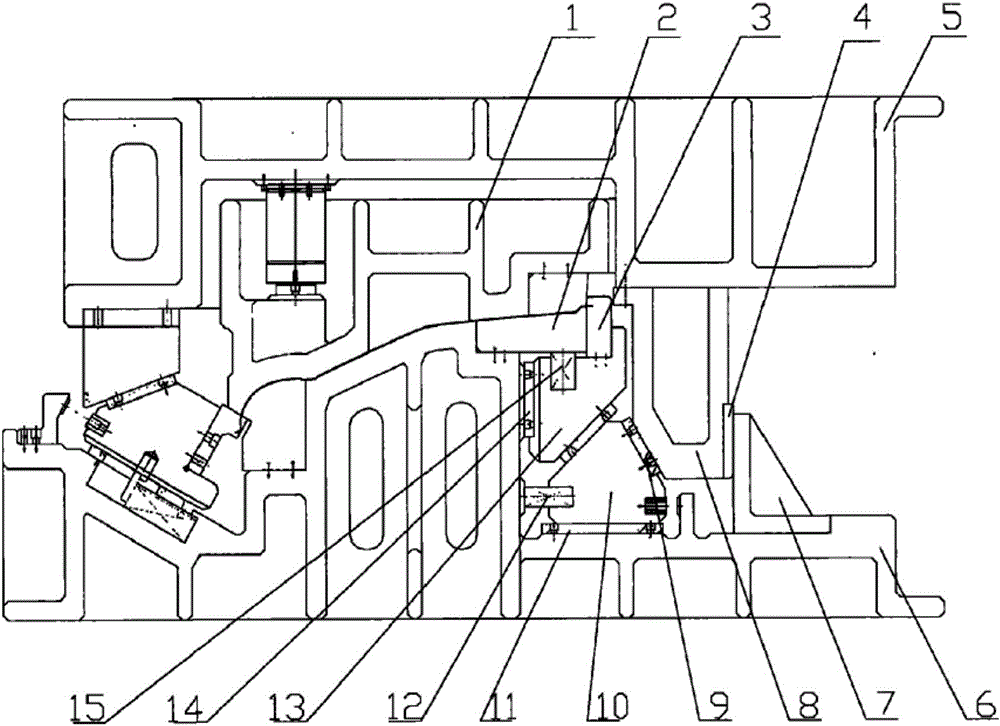

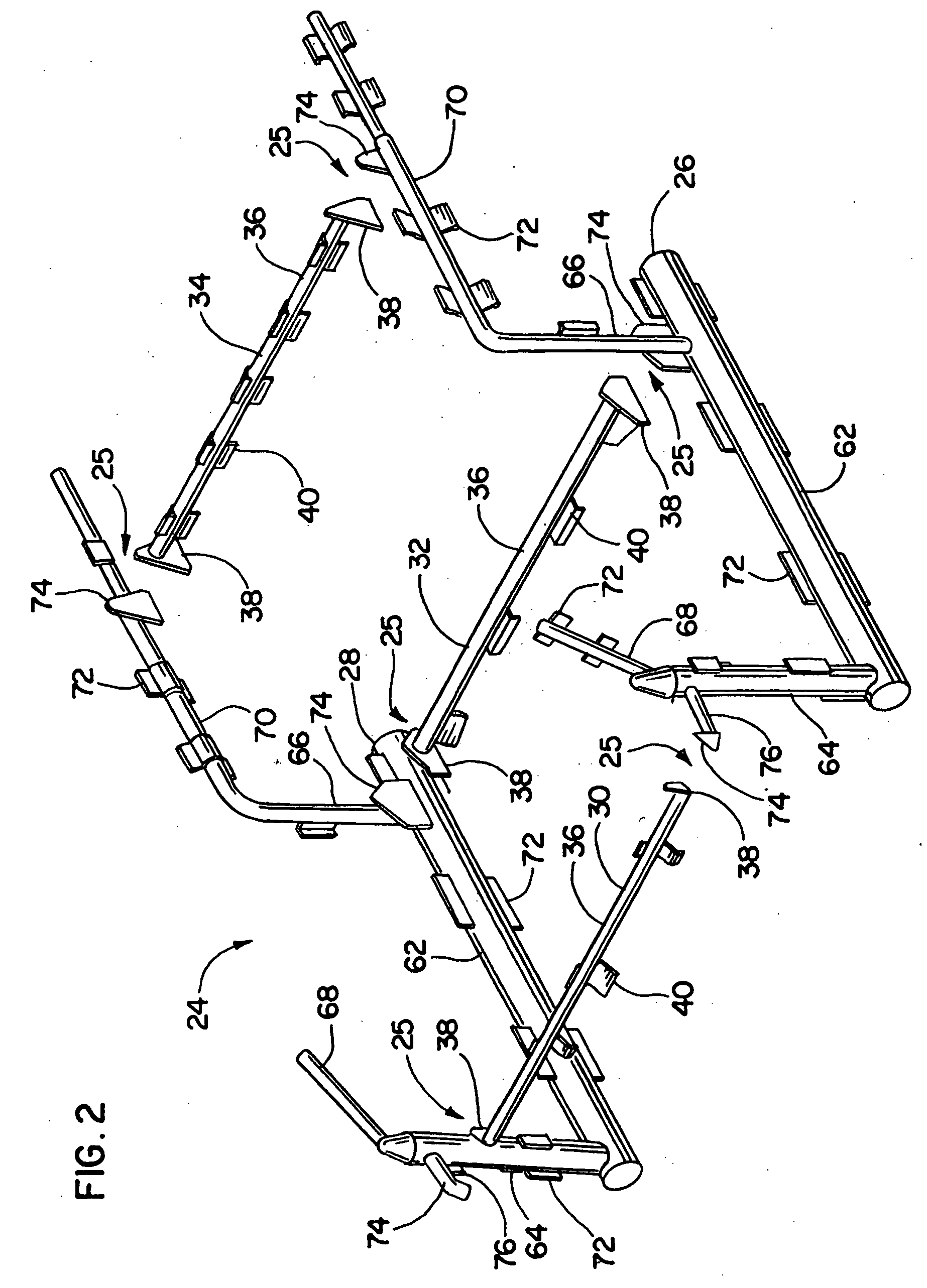

Flexible automotive assembly line method

InactiveUS7128196B2Reduce in quantityQuick and efficient changeoverControl devices for conveyorsCharge manipulationTransport systemTransit system

An apparatus for assembling an automotive body on an assembly line having a right-hand body subassembly line, a left-hand body subassembly line and an underbody subassembly line, for delivery to a pallet transport system for movement through a body framing subassembly line. The apparatus includes an overhead transport system for transporting automotive components along at least one of the subassembly lines and for conveying the automotive components along a pallet transport system on the body framing subassembly line. The overhead transport system includes a trolley movable along a single overhead rail, a carriage slidably movable relative to the trolley, and a plurality of antler nests. Each antler nest is individually engageable with the carriage. The apparatus also includes a lowerator for transferring components from the overhead transport system to a geometry fixture at a workstation along the subassembly line. The workstation along the subassembly line can include a plurality of geometry fixtures that are exchangeable at a ready position of the workstation.

Owner:COMAU LLC

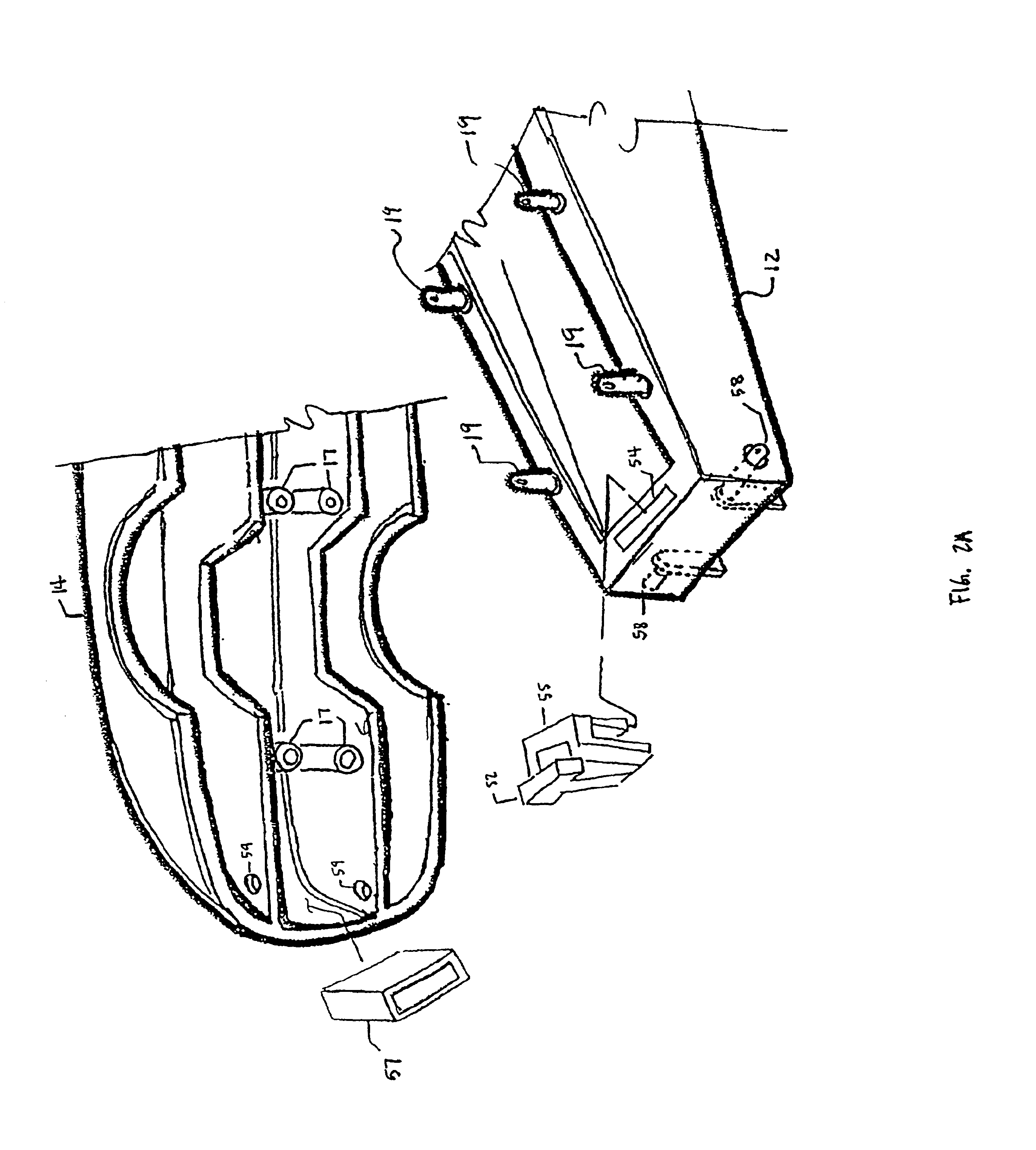

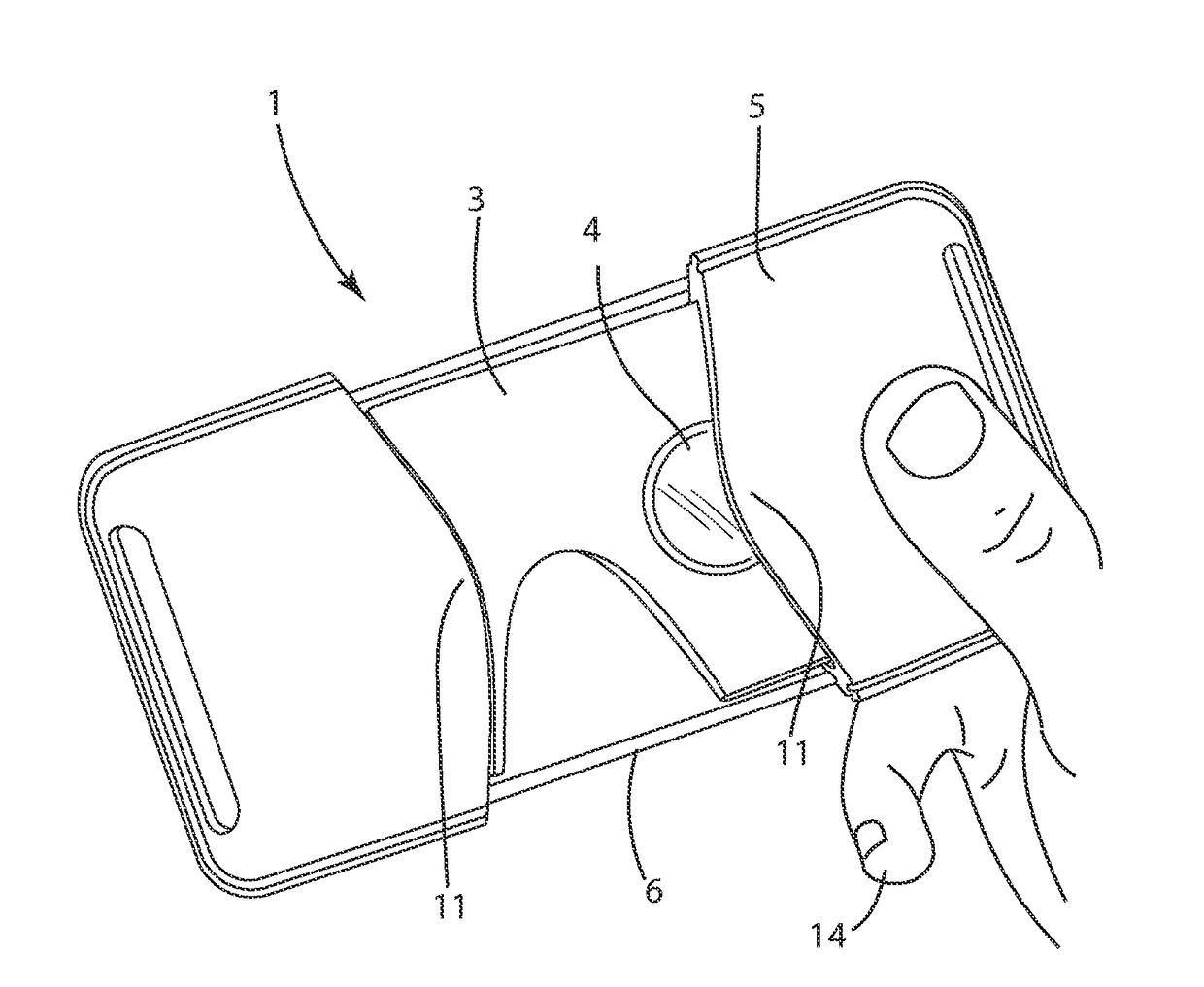

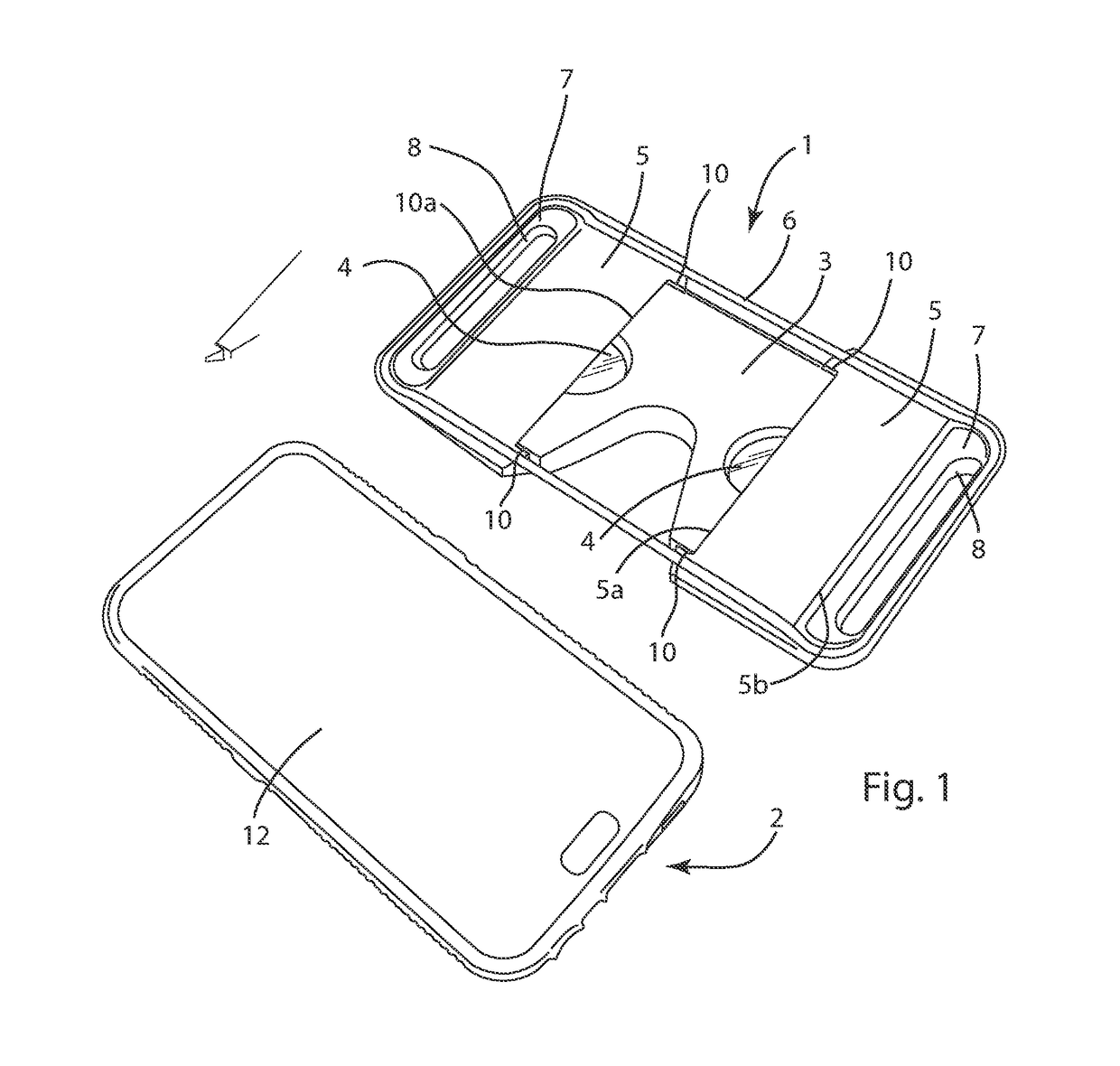

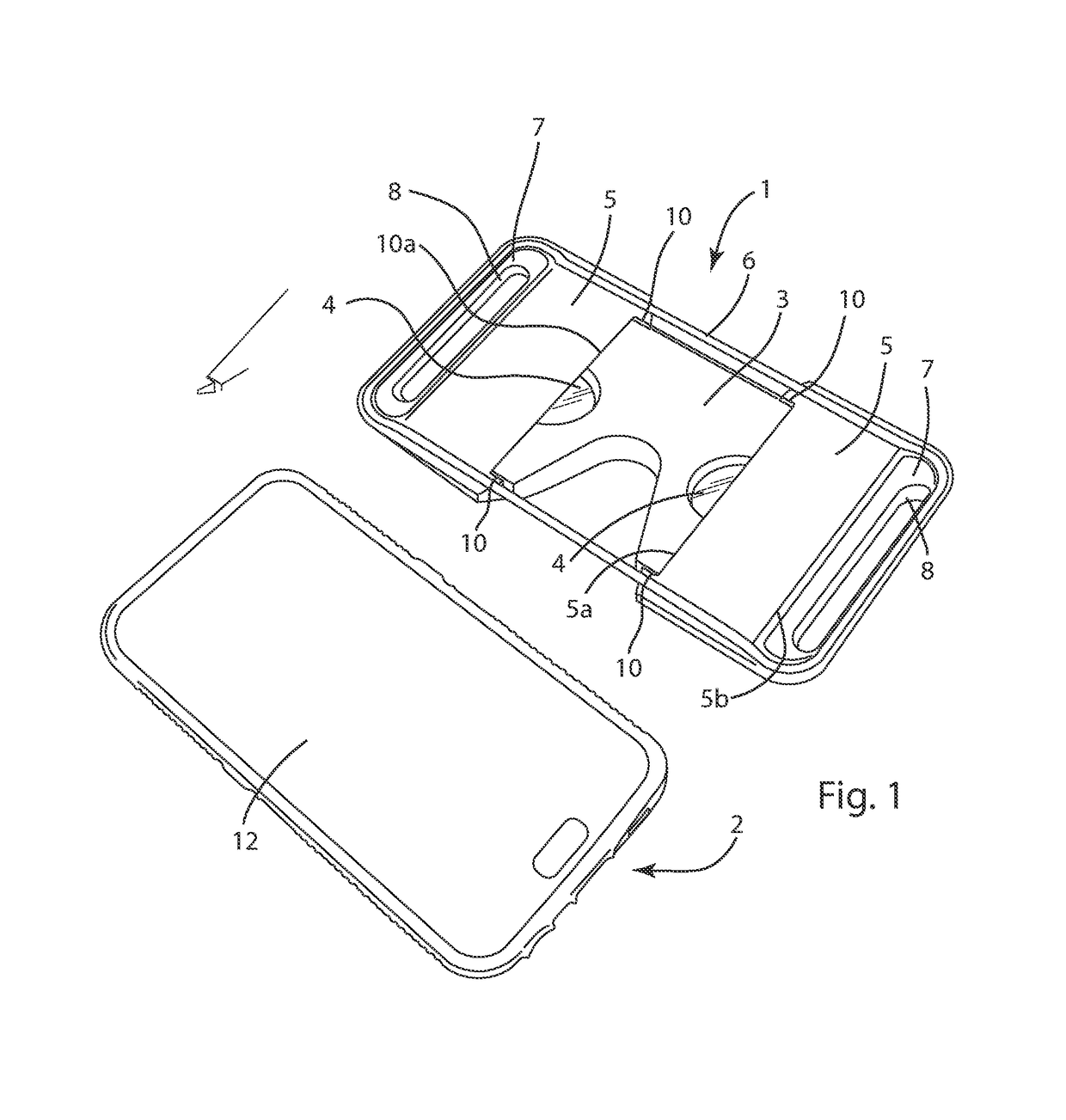

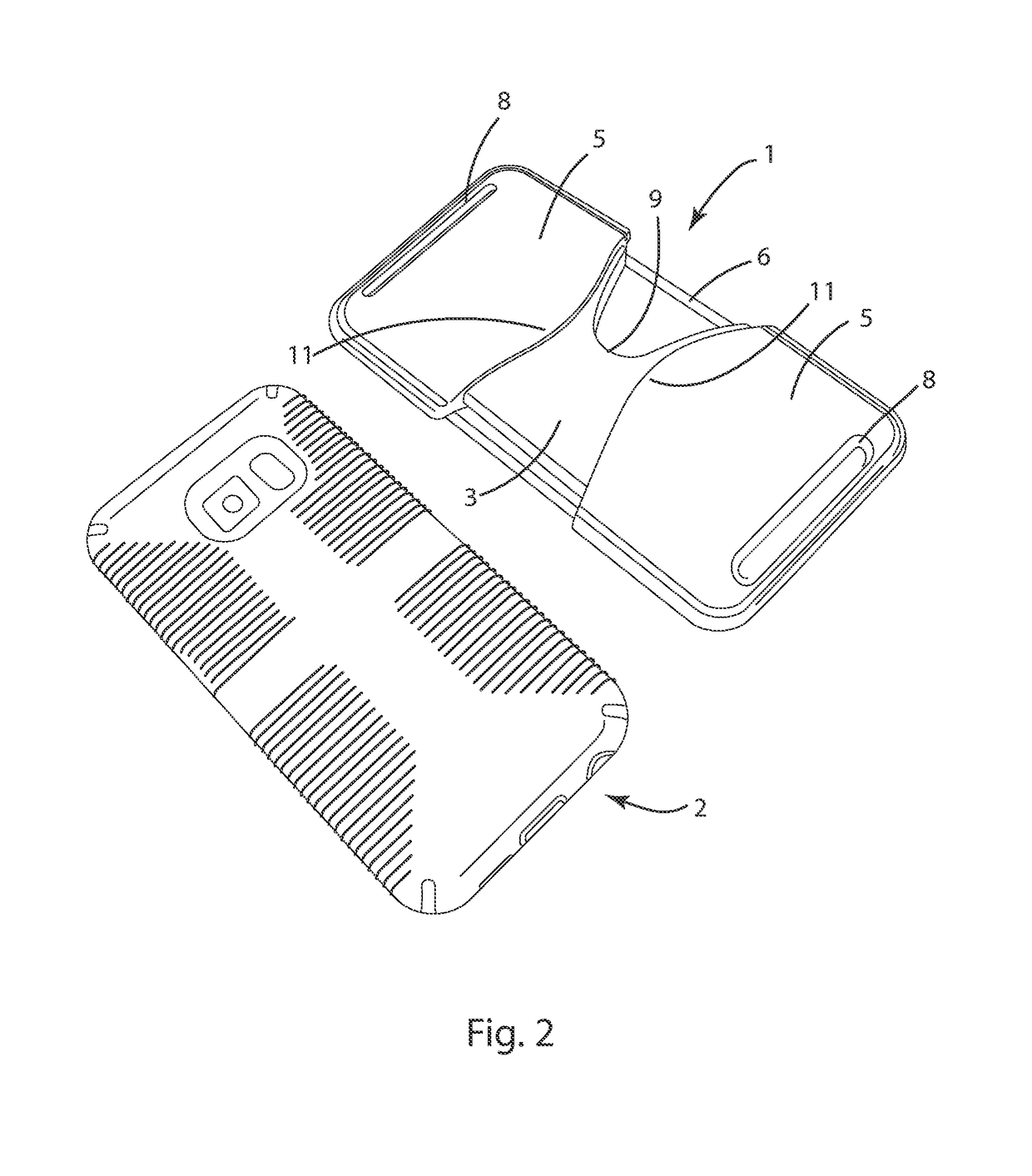

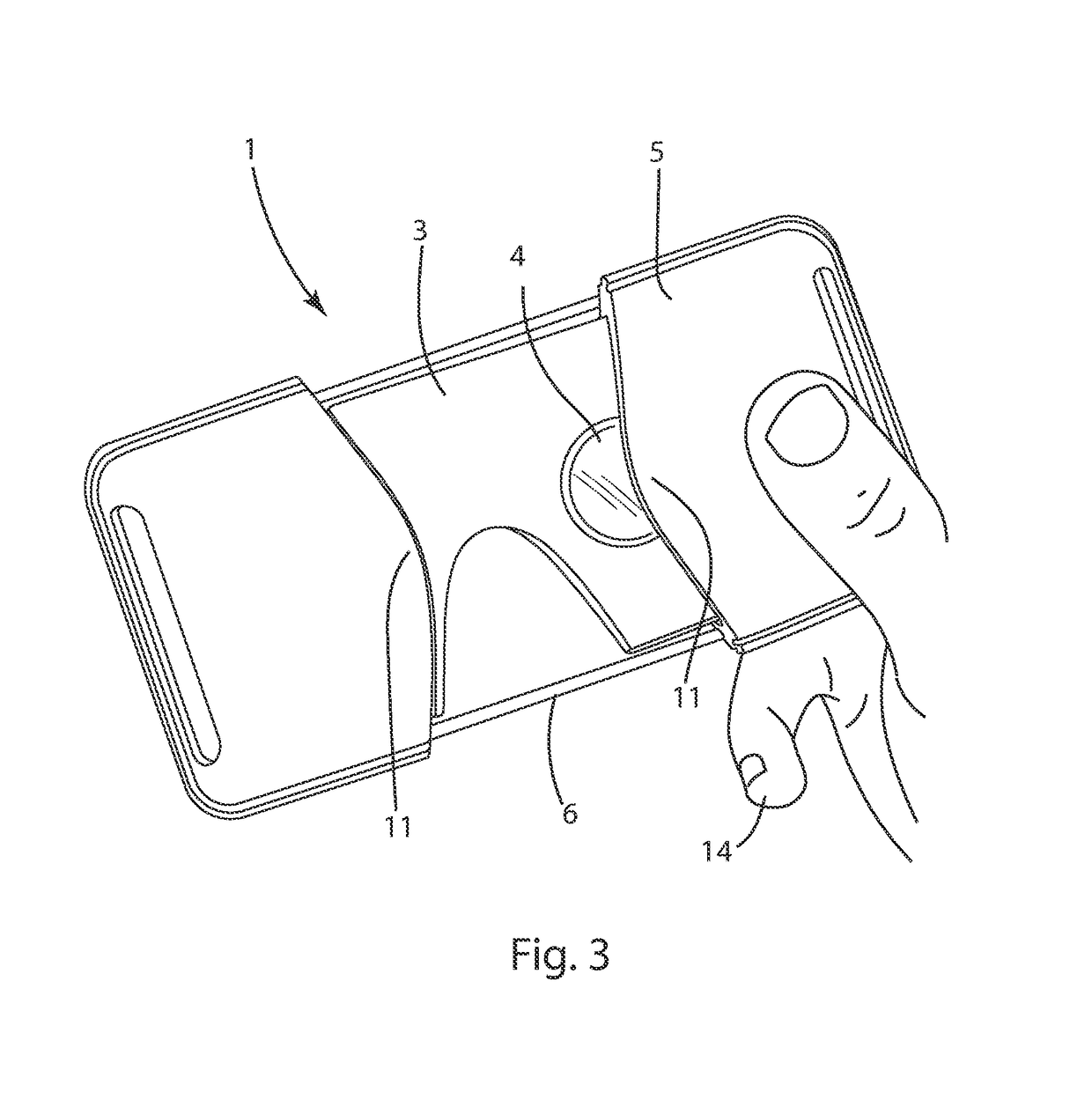

Virtual-Reality or Augmented-Reality Viewer for a Mobile Electronic Device

ActiveUS20170123217A1Expand accessImprove portabilityTransmissionOptical elementsEngineeringRight lens

A virtual-reality or augmented-reality viewer (1) for a mobile electronic device (2), the viewer (1) including a central body (3), a left lens (4) and a right lens (4) arranged in the central body (3), a left side body (5) connected to the central body (3), a right side body (5) connected to the central body (3), and a tension mechanism (6) which biases the left and right side bodies (5) towards each other. In a first viewer state, a left portion of the central body (3) is accommodated in the left side body (5) and a right portion of the central body (3) is accommodated in the right side body (5). In a second viewer state, the left portion of the central body (3) is not accommodated in the left side body (5) and the right portion of the central body (3) is not accommodated in the right side body (5), so that the left and right lenses (4) are not covered by the left or right side body (5).

Owner:SPECULATIVE PROD DESIGN

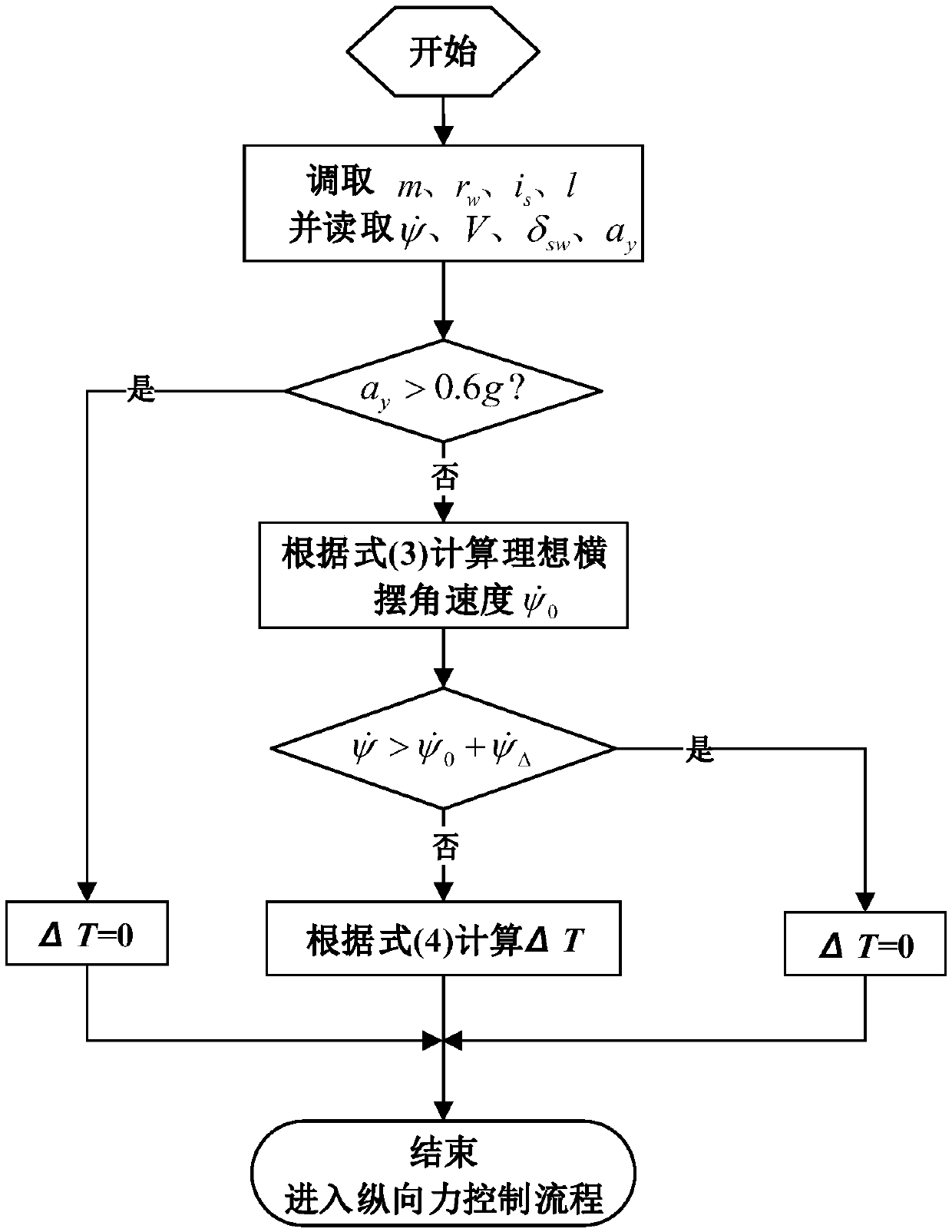

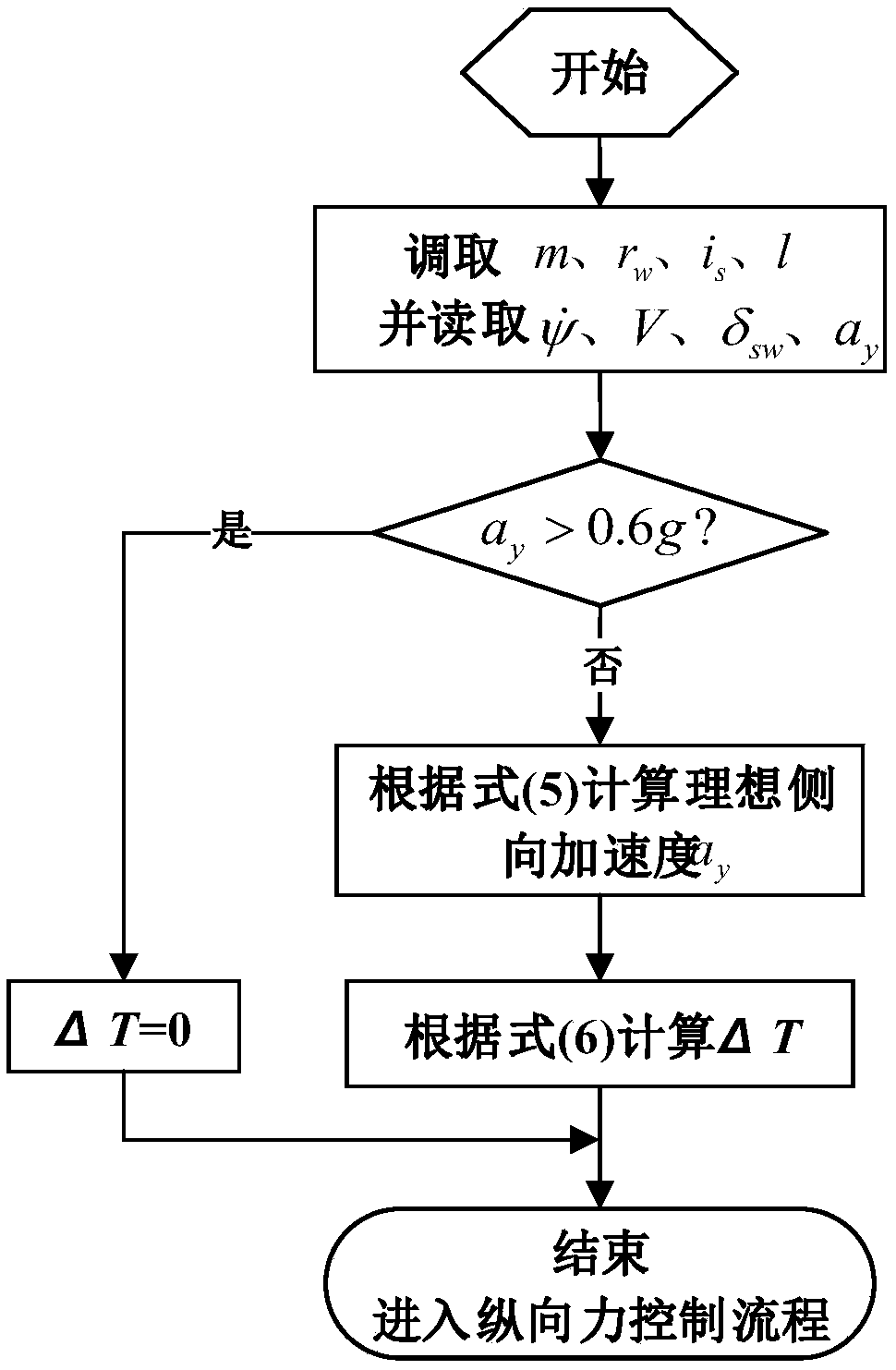

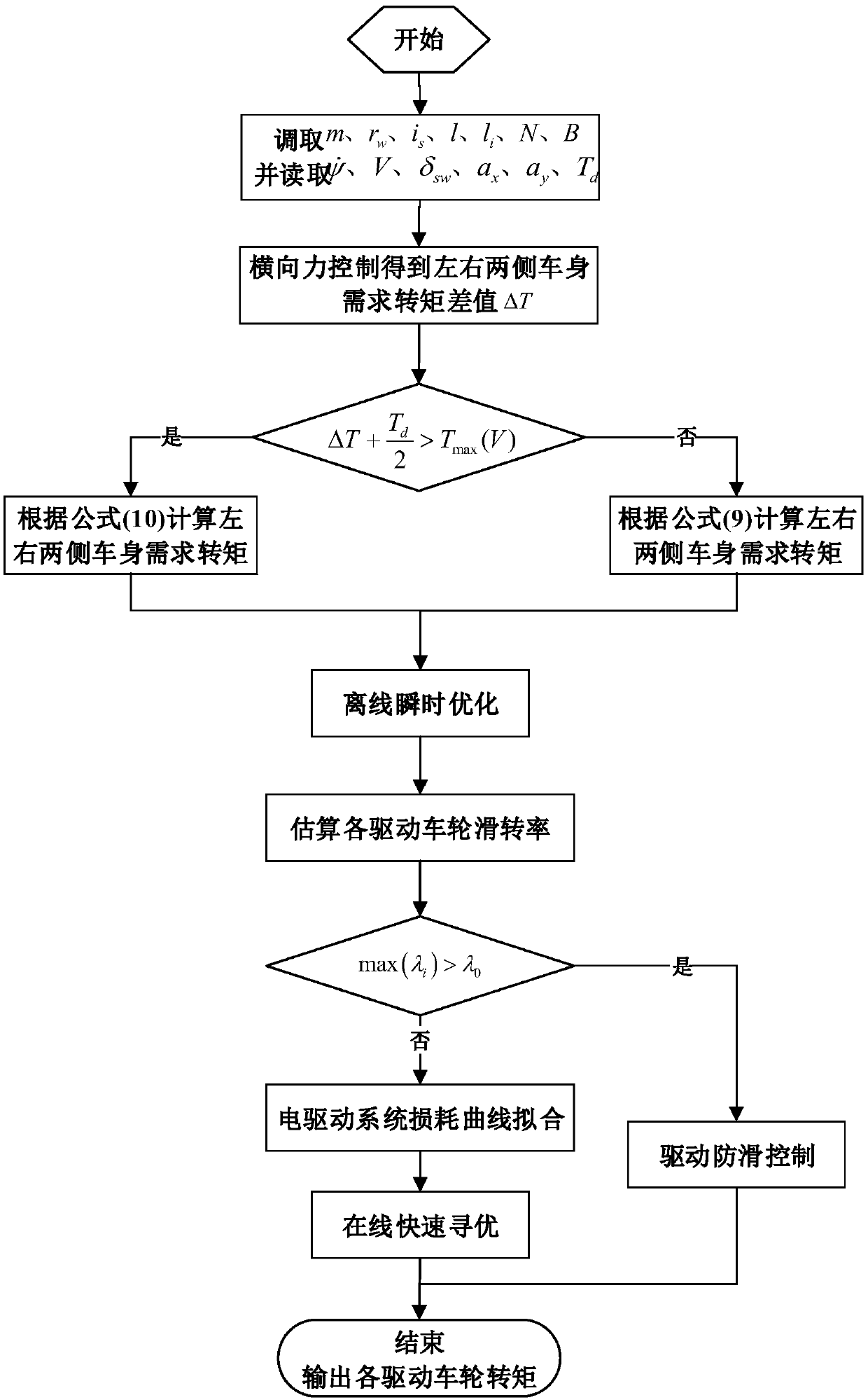

Method of wheel torque distribution for multi-axle drive electric vehicle based on online optimization of driving energy

ActiveCN108674254AEnsure driving stabilityIncreased lateral stability marginSpeed controllerOperating modesMaximum torqueDrive wheel

The invention discloses a method of wheel torque distribution for a multi-axle drive electric vehicle based on online optimization of driving energy. The method comprises the following steps that thevehicle parameters are obtained and required torque difference values between a left side vehicle body and a right side vehicle body are obtained, after a total torque difference value is applied to the left side vehicle body or the right side vehicle body separately, whether the required torque of the one-side vehicle body is larger than the maximum torque which all drive motors of the one-side vehicle body can output is judged, according to an objective function and a constraint condition, the initial optimization of data is carried out, and first distribution of drive torque of each wheel is carried out; the slip ratio of each drive wheel is calculated, and a fitting coefficient is obtained by fitting a characteristic curve of an electric drive system; and combined with the fitting coefficient, according to the following optimal objection function, the data optimization is carried out once again, and drive torque of each wheel at the optimal performance of a whole vehicle is obtained.

Owner:JILIN UNIV

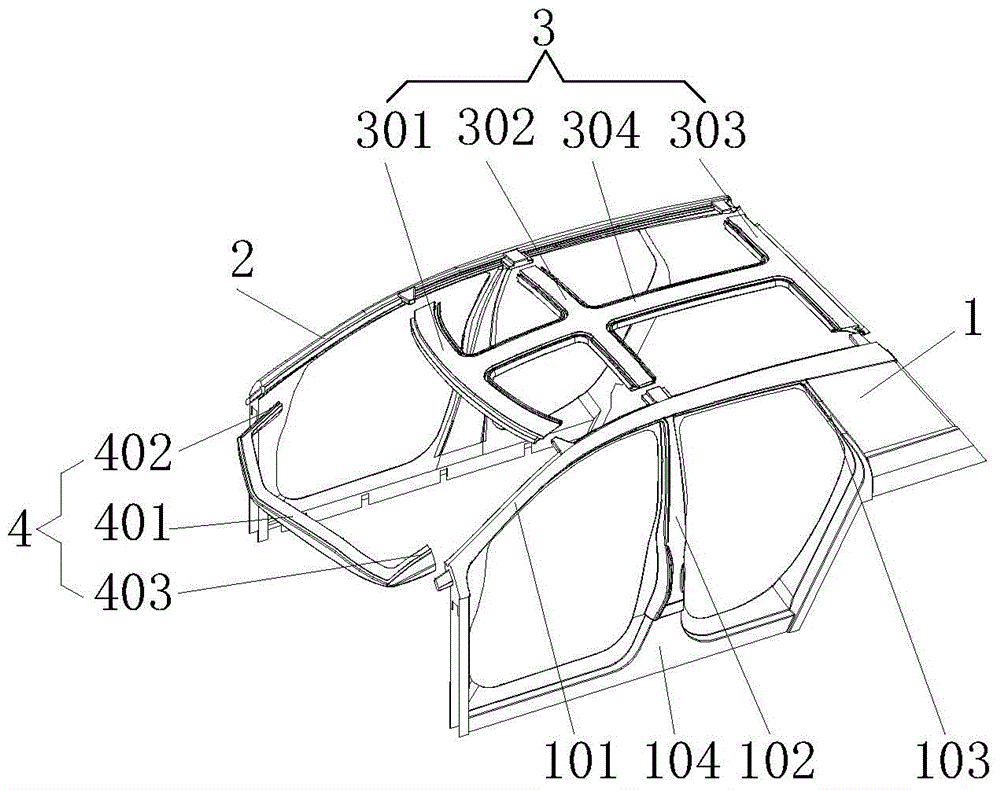

Lightweight electric vehicle body skeleton

InactiveCN103979016AHigh strengthEasy to processSuperstructure subunitsSpatial structureElectric vehicle

The invention relates to the technical field of electric vehicles, in particular to a lightweight electric vehicle body skeleton, which comprises a left side body frame, a right side body frame, a roof and a front glass bracket which are all made of carbon fiber reinforced composite materials, wherein the left side body frame and the right side body frame are respectively assembled with the roof and the front glass bracket in a cementing manner and a bolt fastening manner to form a space cage-shaped tubular body skeleton, each of the four large blocks takes an edge combining area as a piece dividing line and is further divided into an inner piece and an outer piece, and the inner pieces and the outer pieces are connected at the edge combining areas in a cementing manner. The application form of composite materials to the vehicle body is improved from the past single sided board into a double sided tubular space structure, a passenger protecting area is designed into a space cage-shaped skeleton structure, the overall strength of the body skeleton is improved through utilizing the structure characteristics of tubular columns and topological spaces, in addition, the forming efficiency is also considered by adopting the four-large-block and eight-small-piece designing method, and the forming quality is also effectively ensured.

Owner:INST OF DONGGUAN SUN YAT SEN UNIV +1

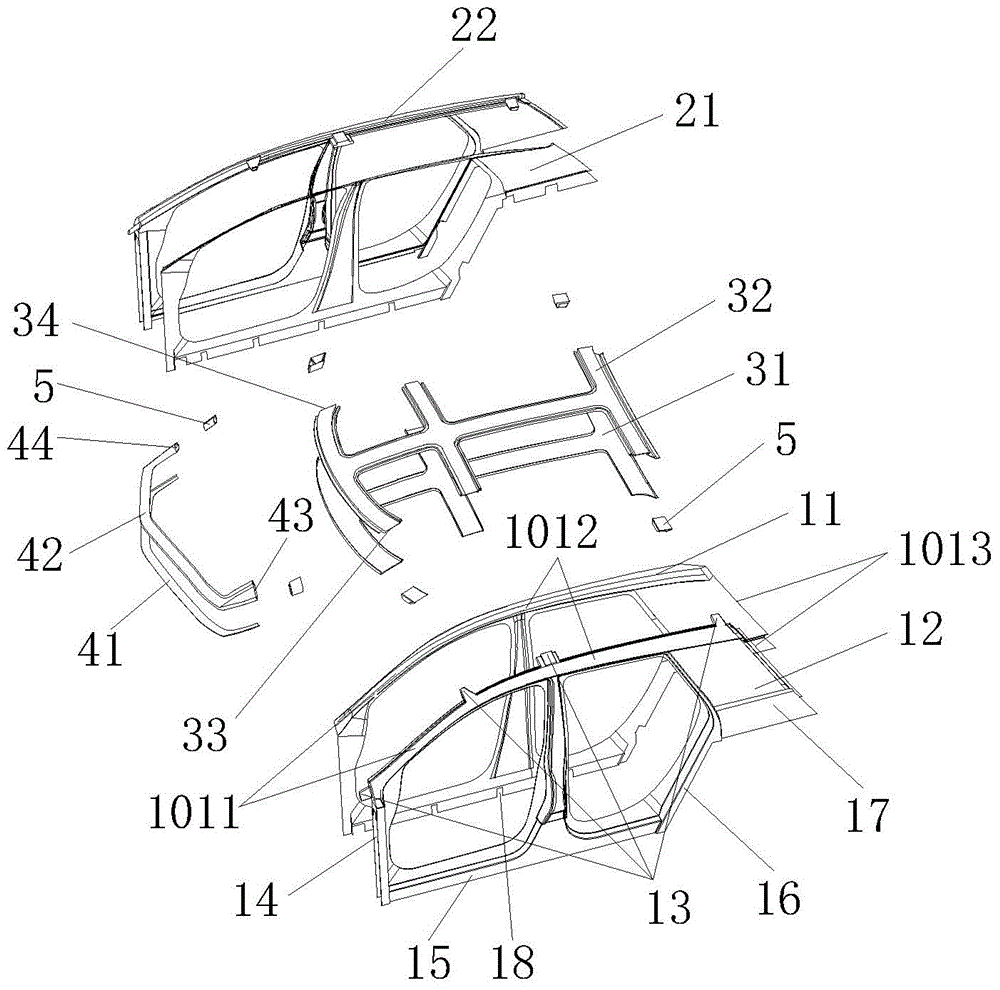

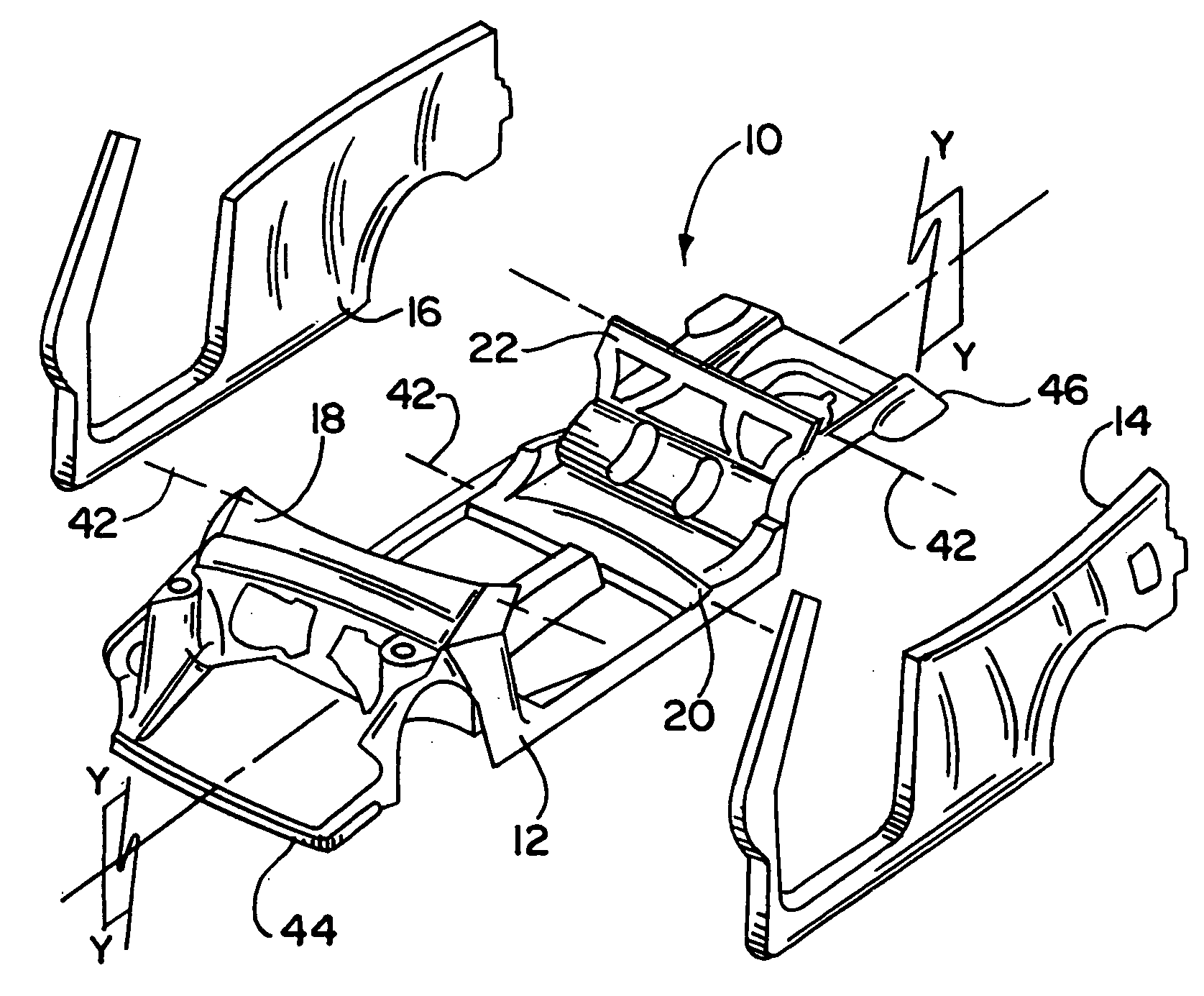

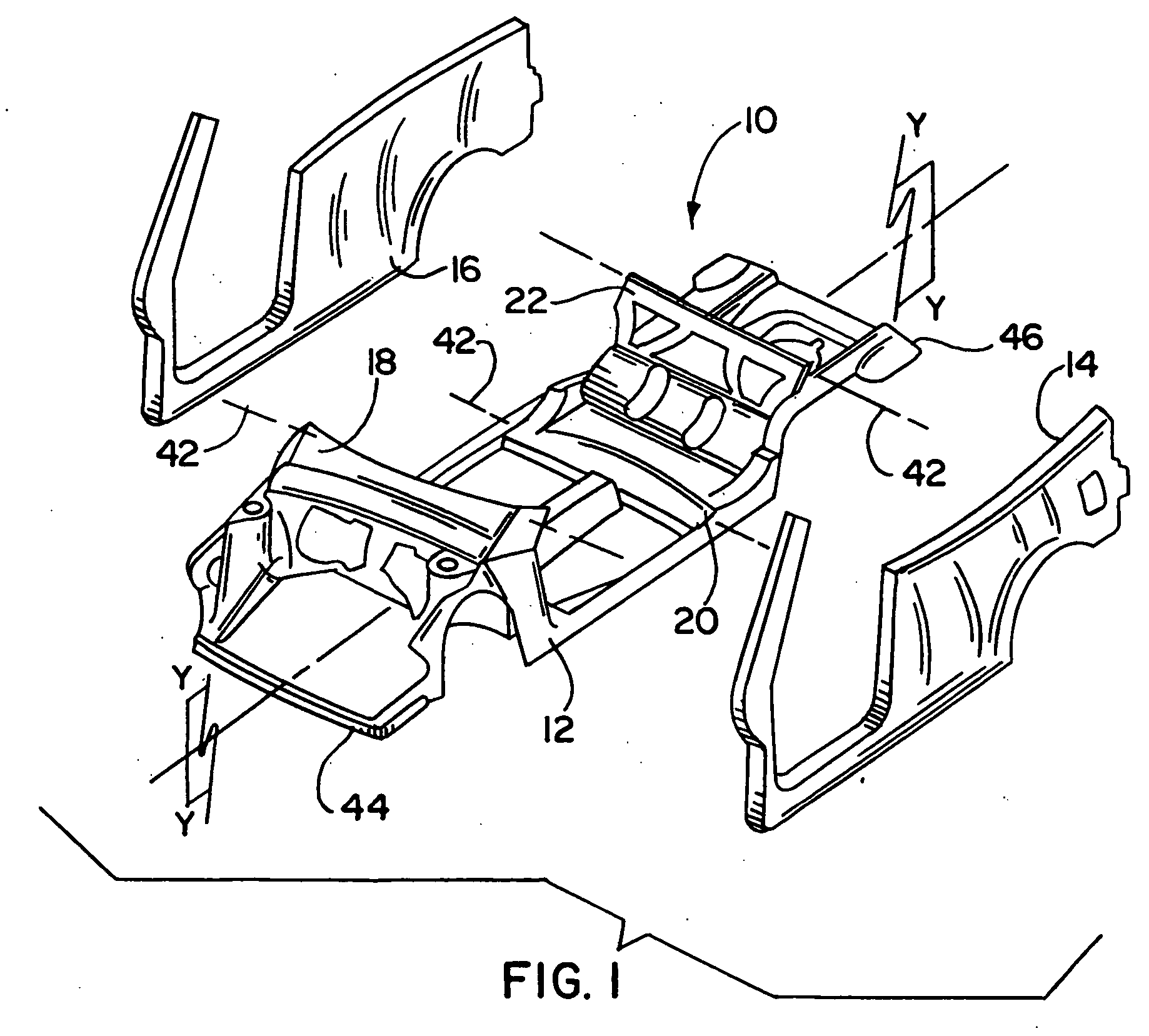

Convertible vehicle uni-body having and internal supplemental support structure

A vehicle body includes an underbody having one or more underbody bolting flanges attached thereto, with each underbody bolting flange being adapted for bolted attachment to a mating bodyside bolting flange. Left and right bodyside subassemblies are joined to the underbody, with each bodyside including a supplemental bodyside support structure having attached thereto one or more bodyside bolting flanges, with each bodyside bolting flange being adapted for bolted attachment to one of the underbody bolting flanges after the bodyside subassemblies are otherwise joined to the underbody. The underbody bolting flanges are attached to supplemental crossmembers that are attached to and extend across the underbody.

Owner:FCA US

Mechanism for simulating jumping of frog rear legs

The invention aims to provide a mechanism for simulating the jumping of frog rear legs. The mechanism comprises a body mechanism, a thigh mechanism, a shank mechanism and a sole mechanism, wherein the body mechanism comprises a left side body supporting plate and a right side body supporting plate; the thigh mechanism comprises a left side thigh supporting plate, a right side thigh supporting plate and a thigh fixing plate; the shank mechanism comprises a shank rotating mechanism, a shank reset mechanism and a shank telescopic mechanism; the sole mechanism comprises two sole seats. According to the mechanism provided by the invention, a four-connecting rod mechanism is formed in a way that connecting rods are replaced by ropes, the design is carried out by utilizing a connecting rod principle, the simulation degree of the frog rear legs is increased, and high simulation performance is realized; the flexibility of legs is enhanced, and the effects of jumping and buffering are increased.

Owner:HARBIN ENG UNIV

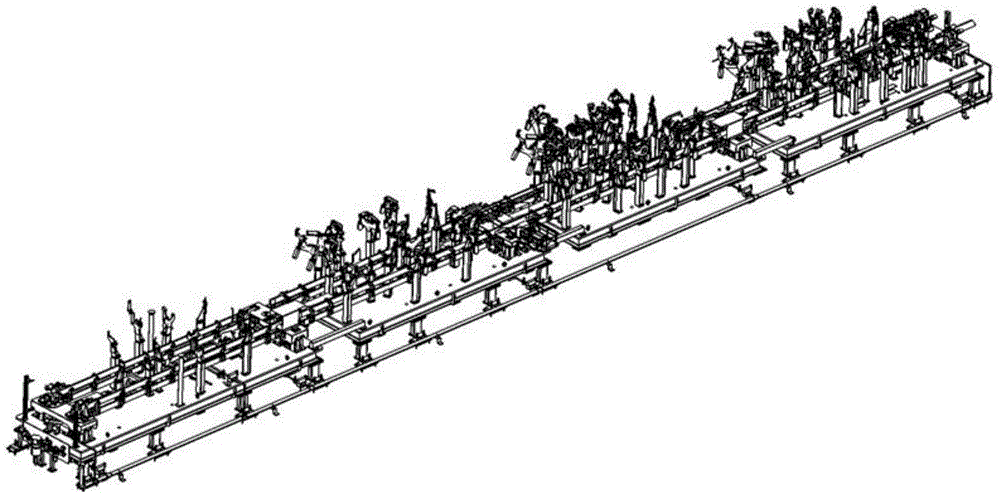

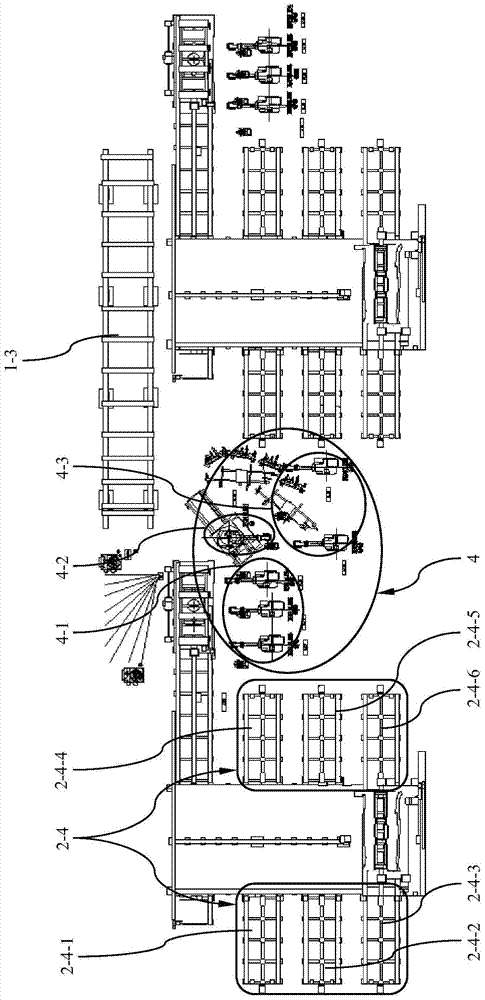

SUV (Sport Utility Vehicle) vehicle automatic welding production line and production method thereof

InactiveCN104801868AHigh degree of automationIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to the mechanical automation technical field, particularly to an SUV (Sport Utility Vehicle) vehicle automatic welding production line and a production method thereof. The unmanned operation on the integral SUV body-in-white automatic welding production line is implemented through the control on coordinative operation of a plurality of robots, the matching of clamping of a particular fixture and the automatic welding of the welding robots. The production method comprises conveying a left side body and a right side body of a vehicle body and a lower vehicle body to an integral assembly workstation through bilateral intelligent air conveying devices and a lower vehicle body conveying roller bed for integral vehicle body assembly respectively and achieving the floor repair welding action through four of the welding robots; continuing to conveying integral welding products of the integral assembly workstation to a first repair welding workstation through the roller bed, performing the repair welding action through four of the welding robots, continuing to conveying the integral welding products to a third workstation and achieving the repair welding action through two of the robots; continuing to conveying the bodies in white conveyed from the third workstation after welding to a storage workstation through the roller bed and placing the bodies in white at the appropriate position of the storage workstation to perform the body-in-white storage. According to the integral body-in-white automatic welding production line, the unmanned operation is implemented, the degree of automation is high, and the production efficiency is high.

Owner:上海澜誉工业自动化设备有限公司

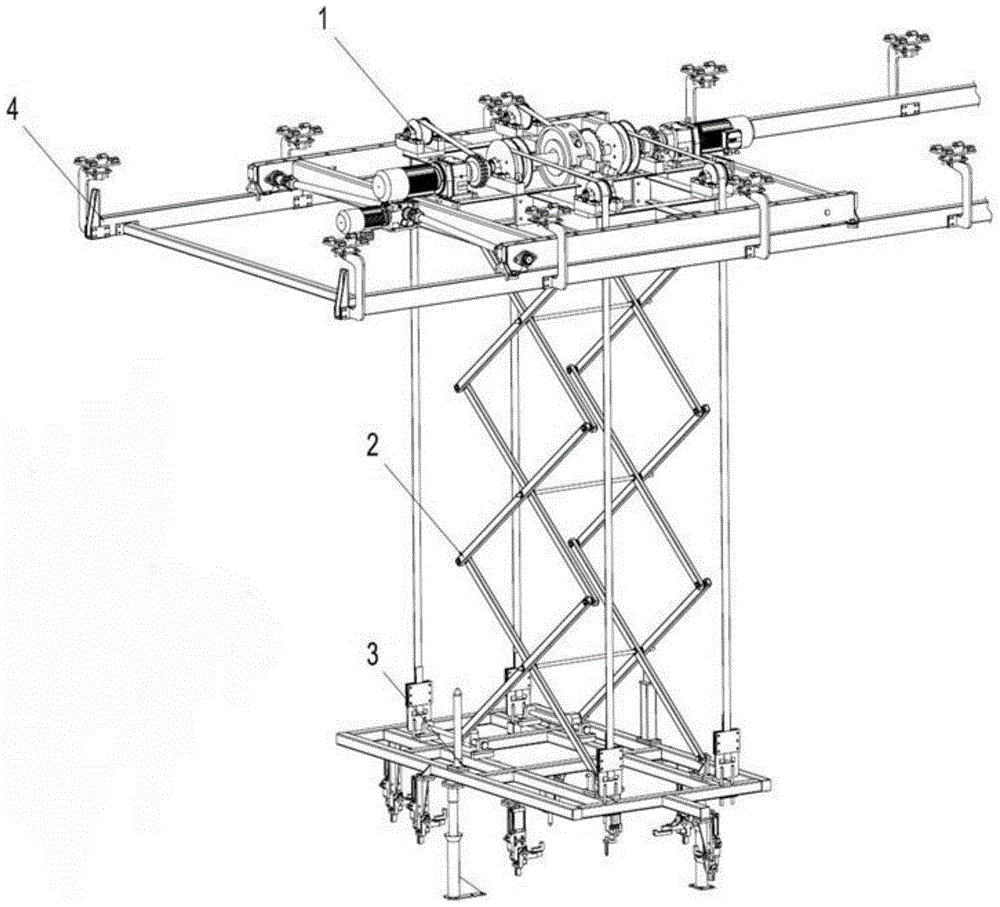

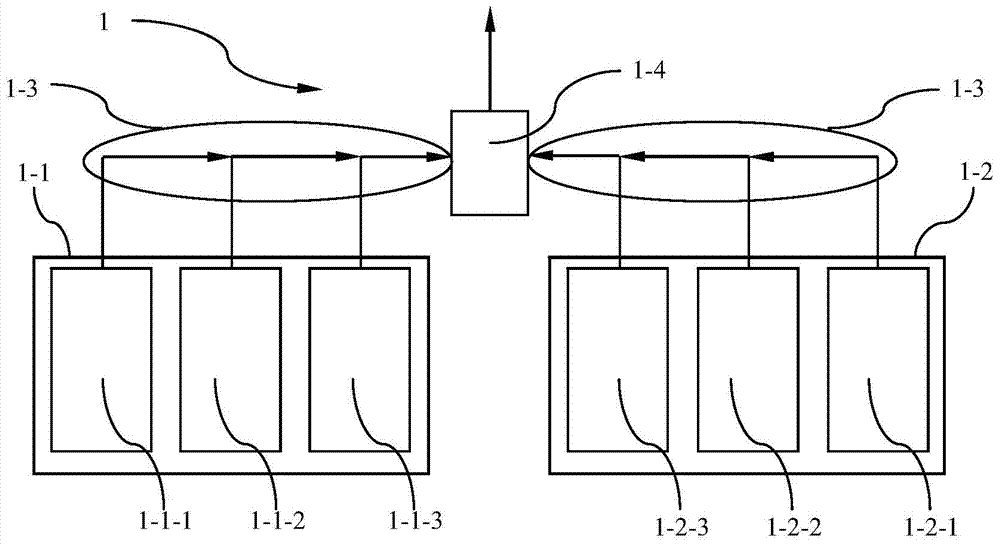

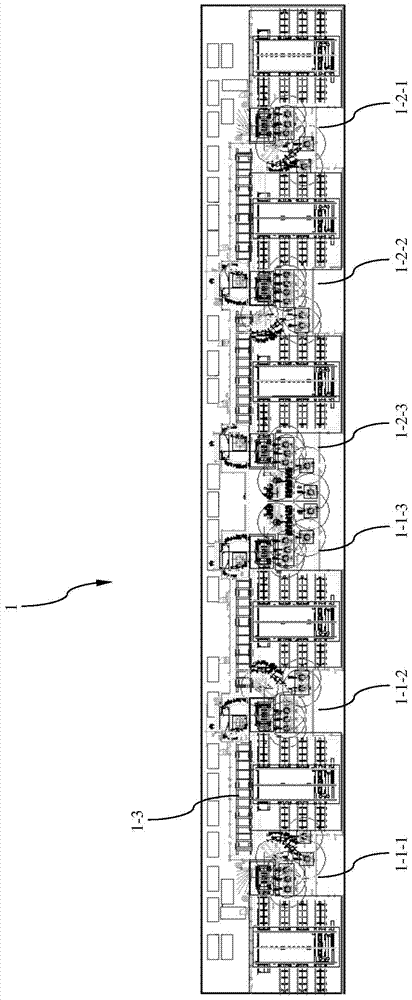

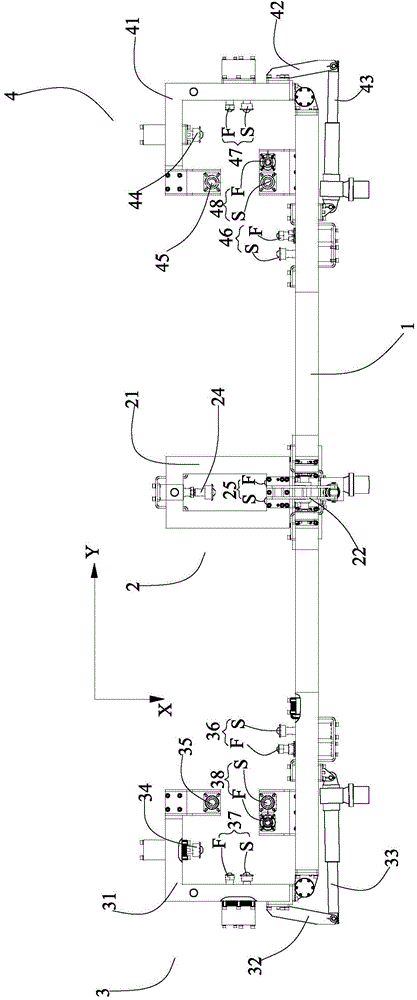

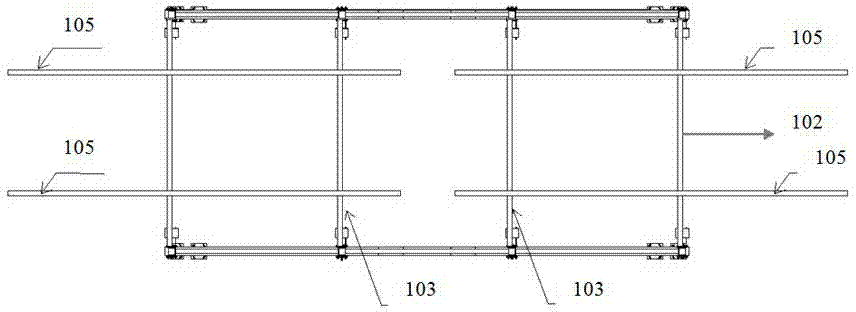

Flexible production line of automobile side bodies

ActiveCN104259676AImprove flexibilitySave space costWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides a flexible production line of automobile side bodies. The flexible production line of the automobile side body comprises a left side body assembling area, a right side body assembling area, a conveying area and a left and right side body matching area. Each assembling area is provided with a sliding table switching conveying system, a vertical type rotating double-face rotatable table and a clamp storage area capable of storing the side bodies of multiple automobile types. According to the flexible production line, collinear flexible production of the side bodies of the multiple automobile types can be achieved, and the occupied space of multi-line production and production, maintenance and management cost can be saved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

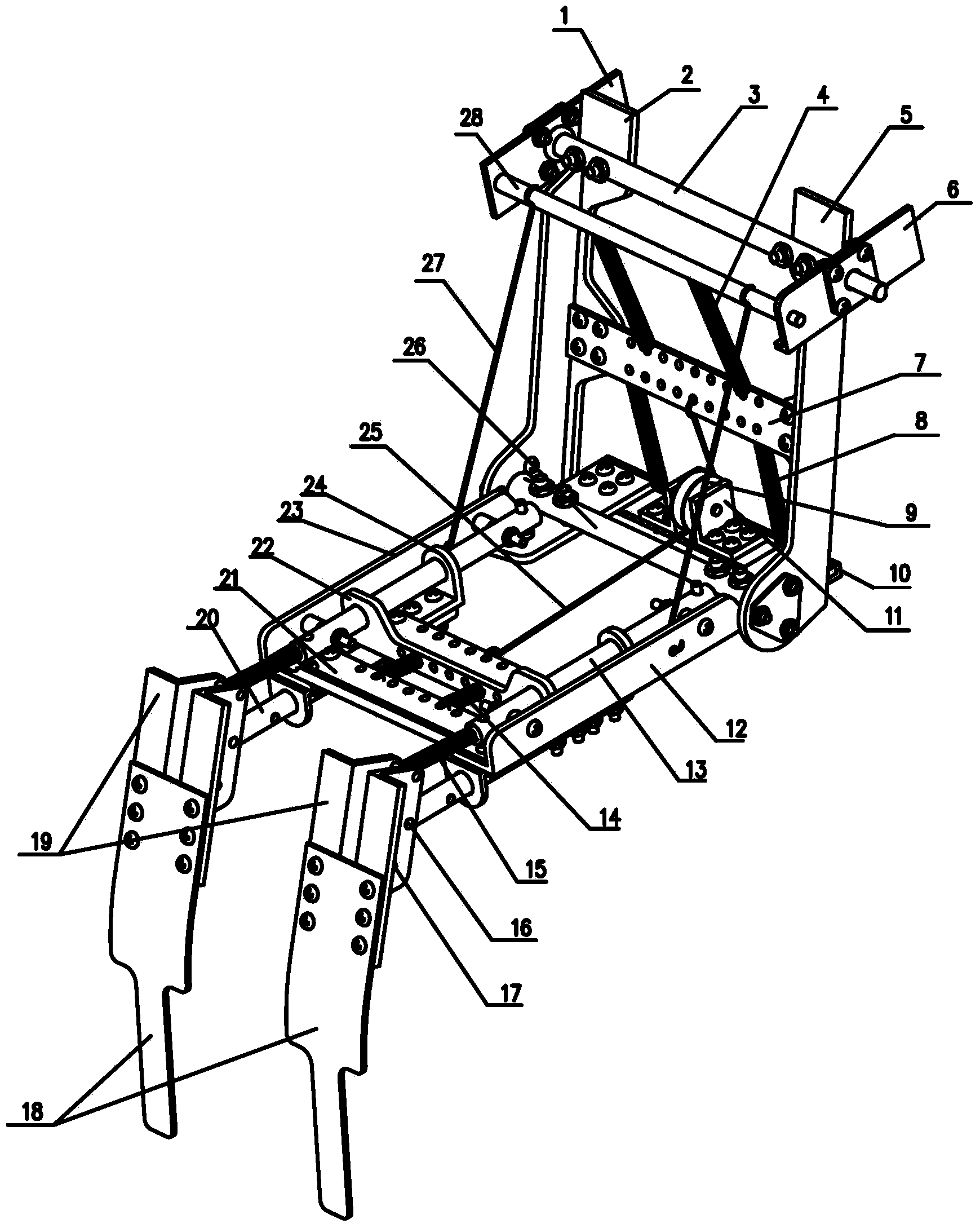

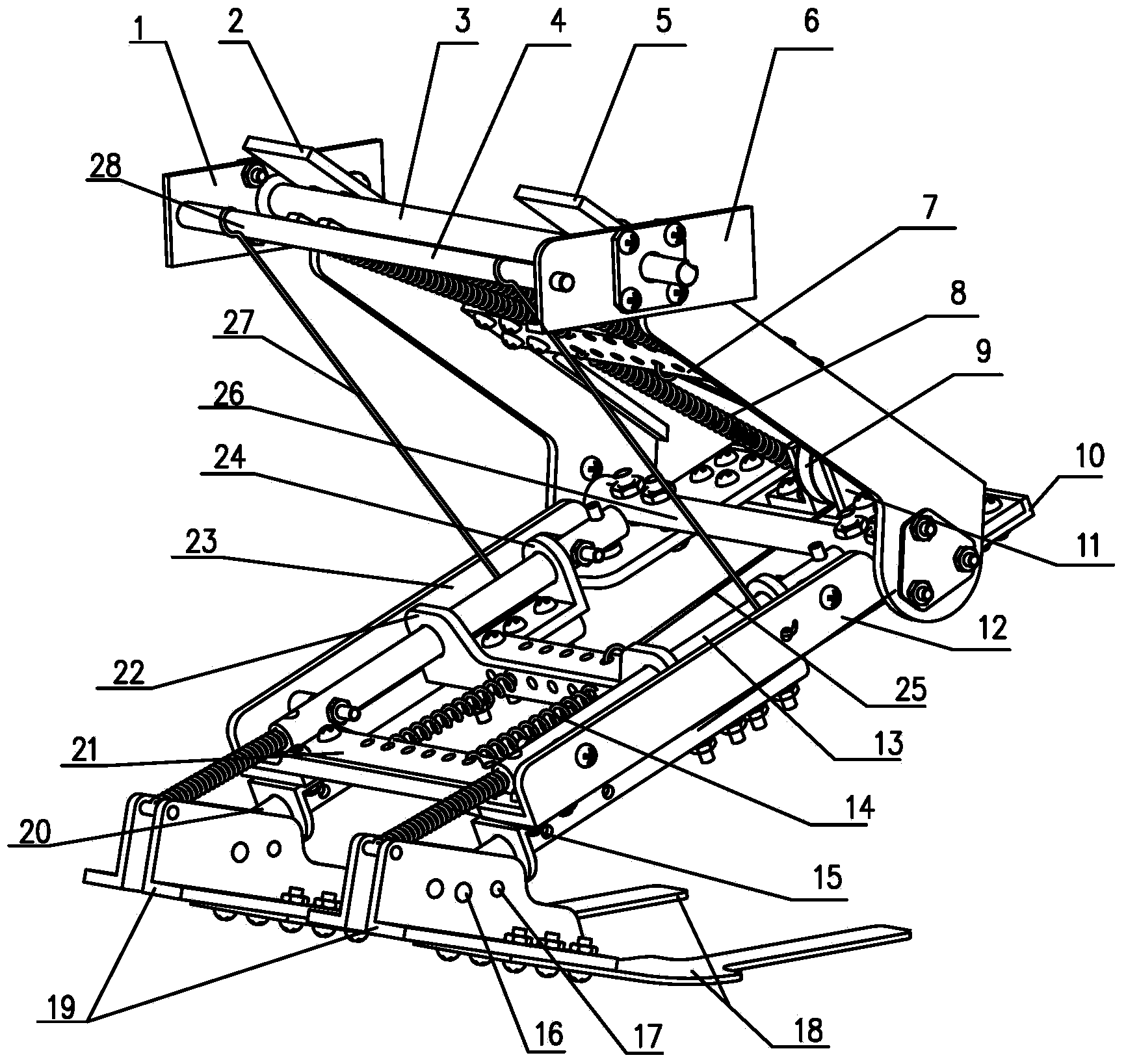

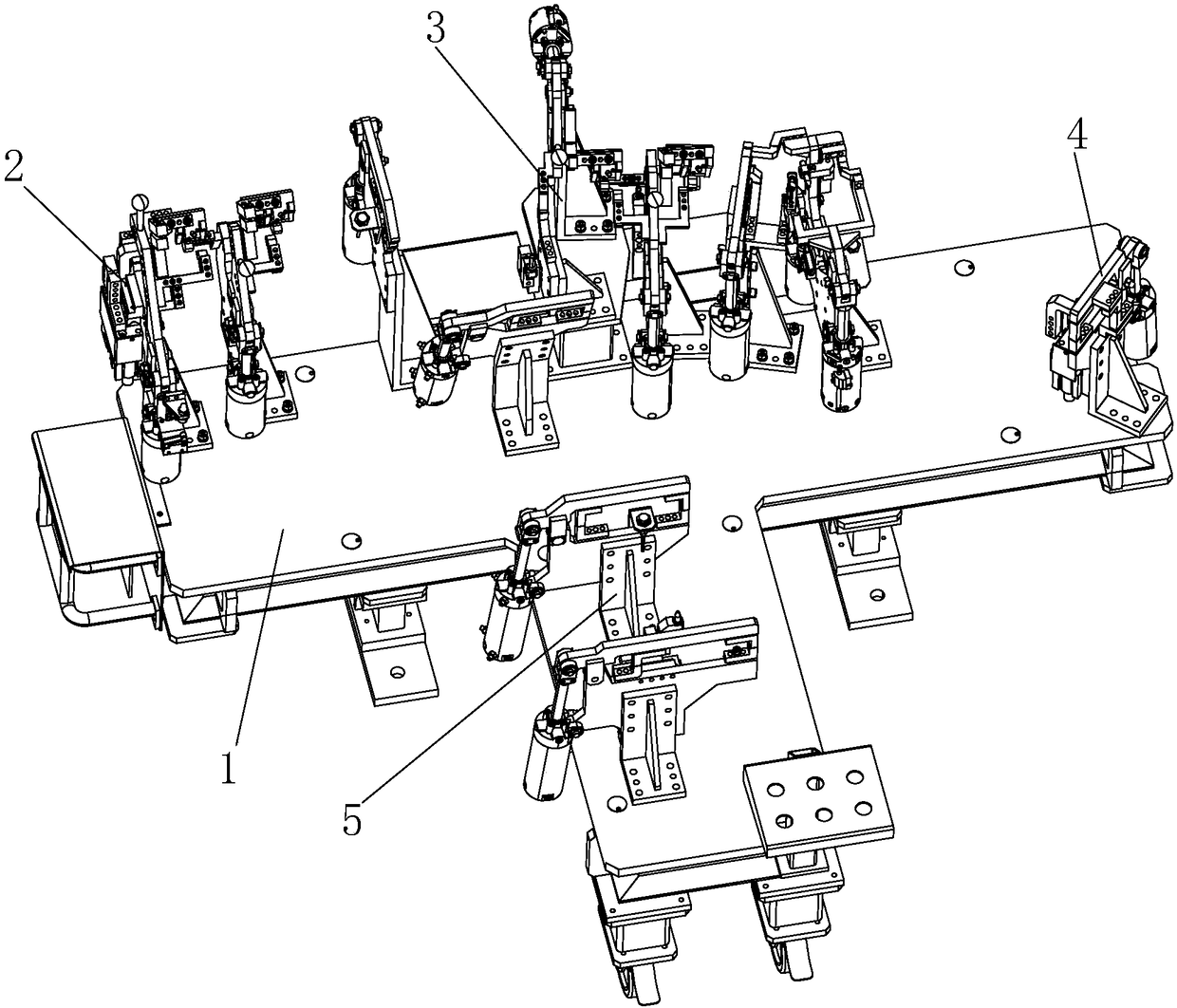

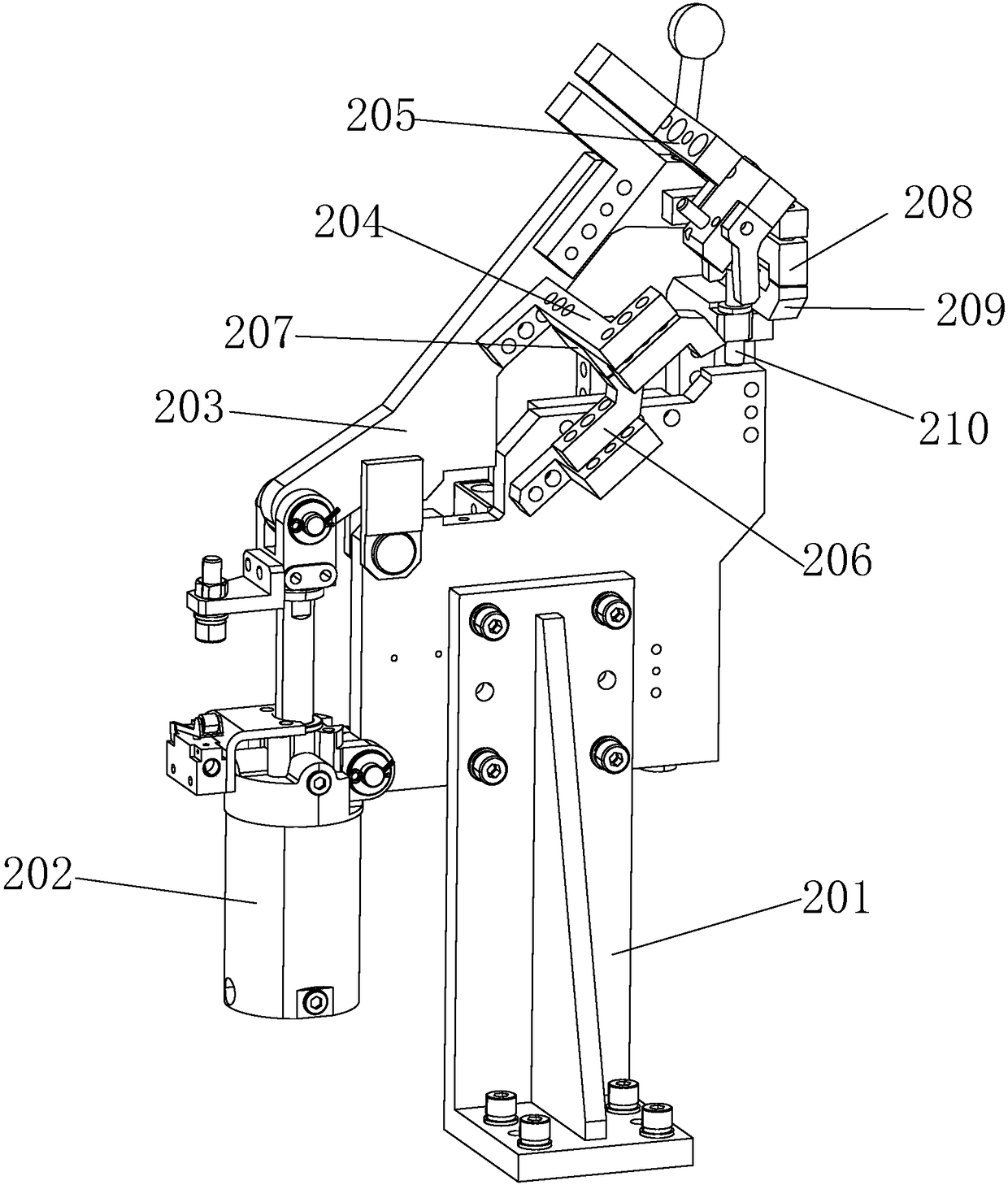

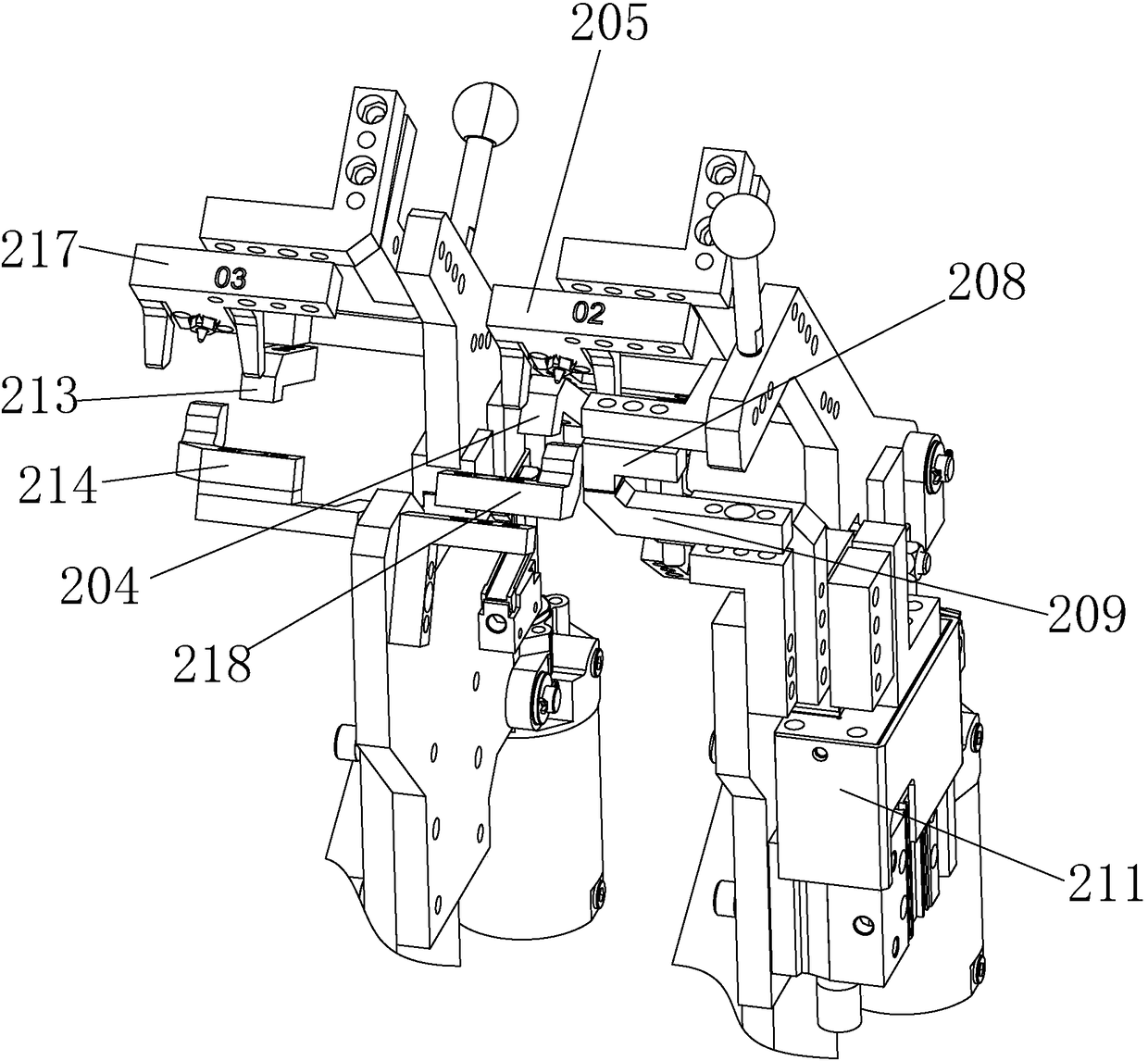

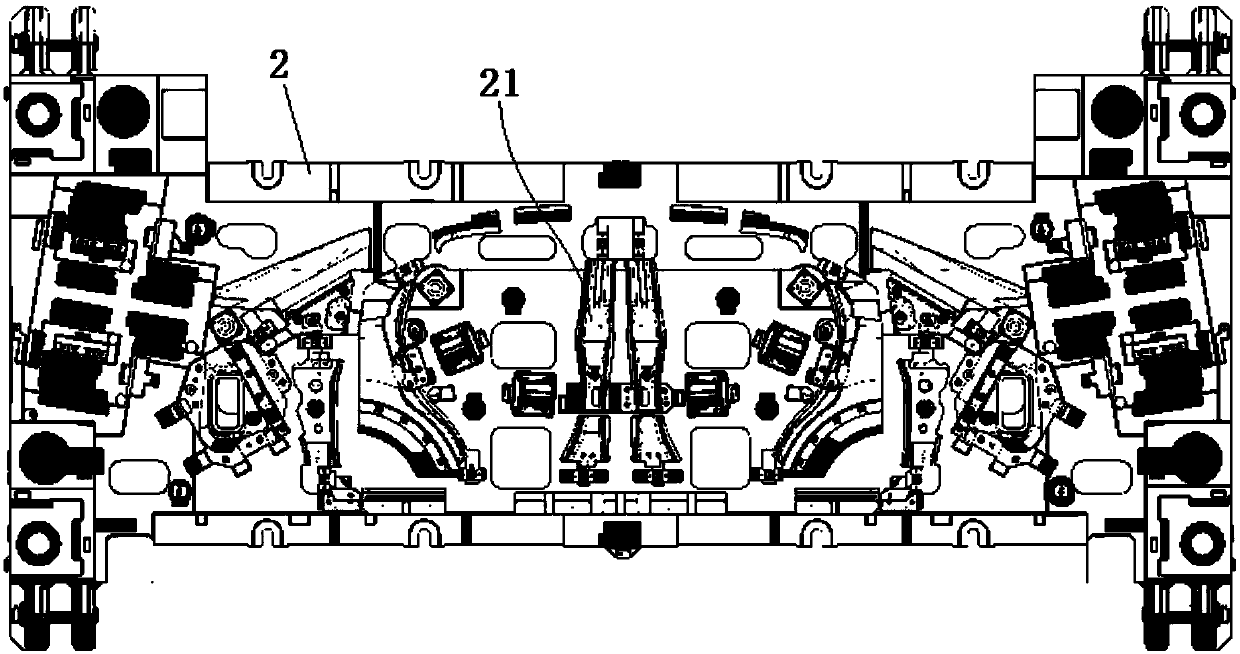

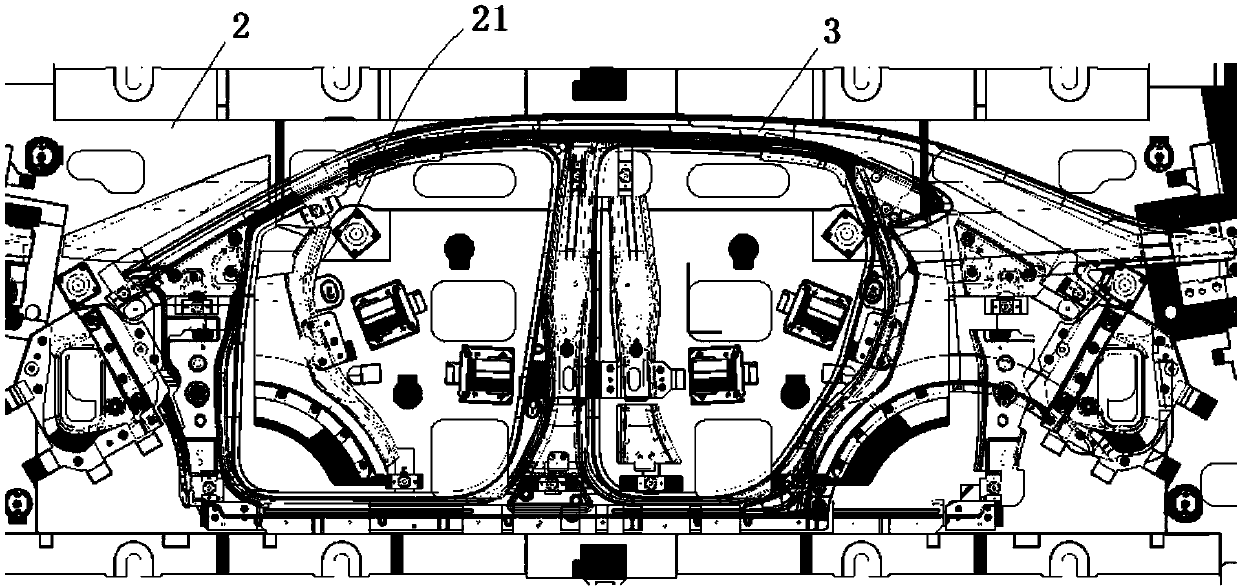

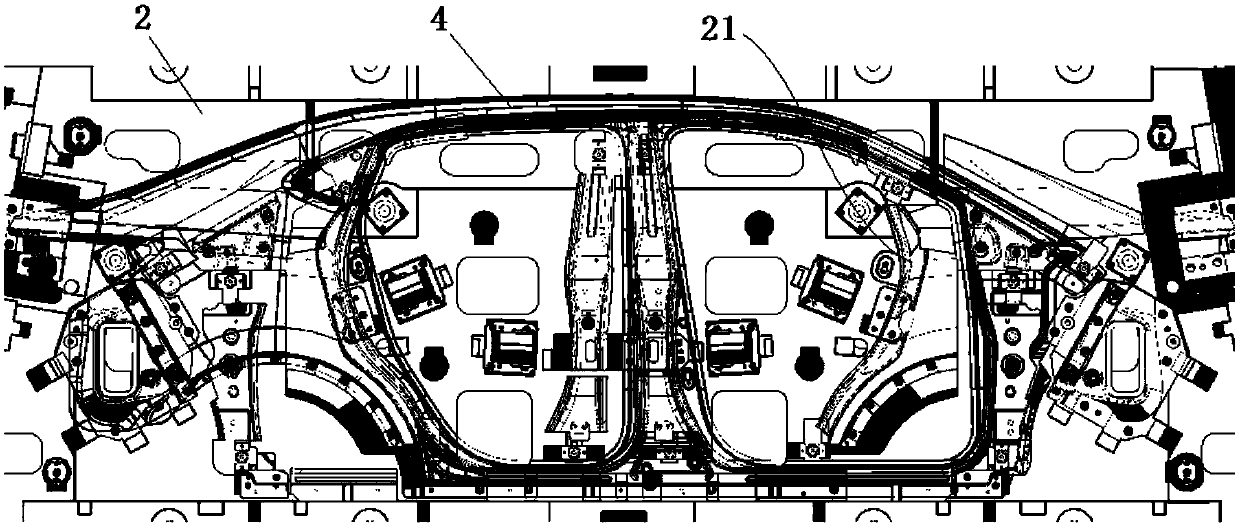

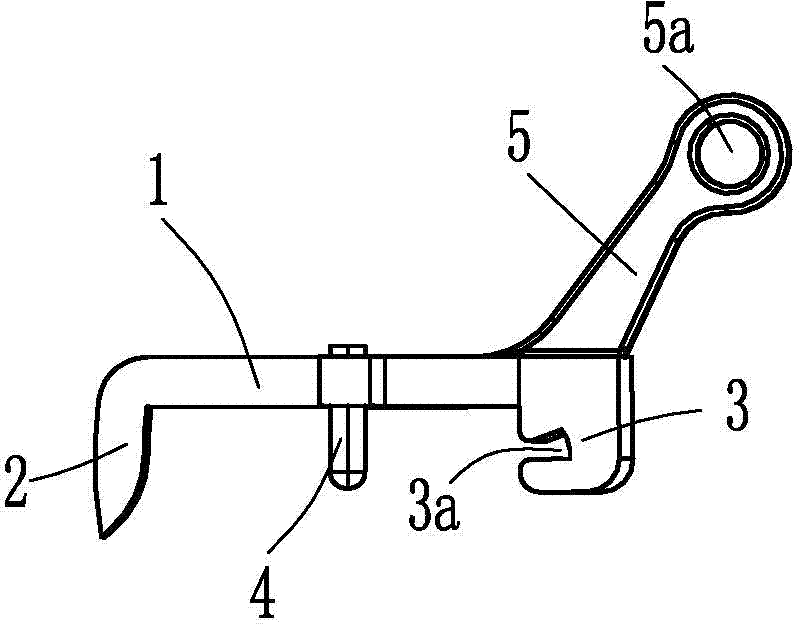

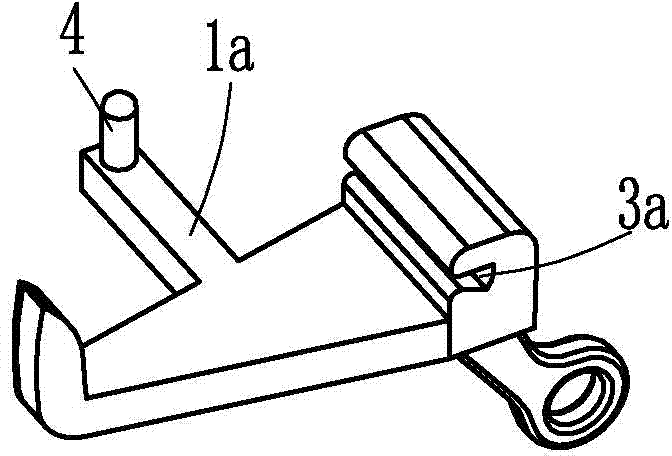

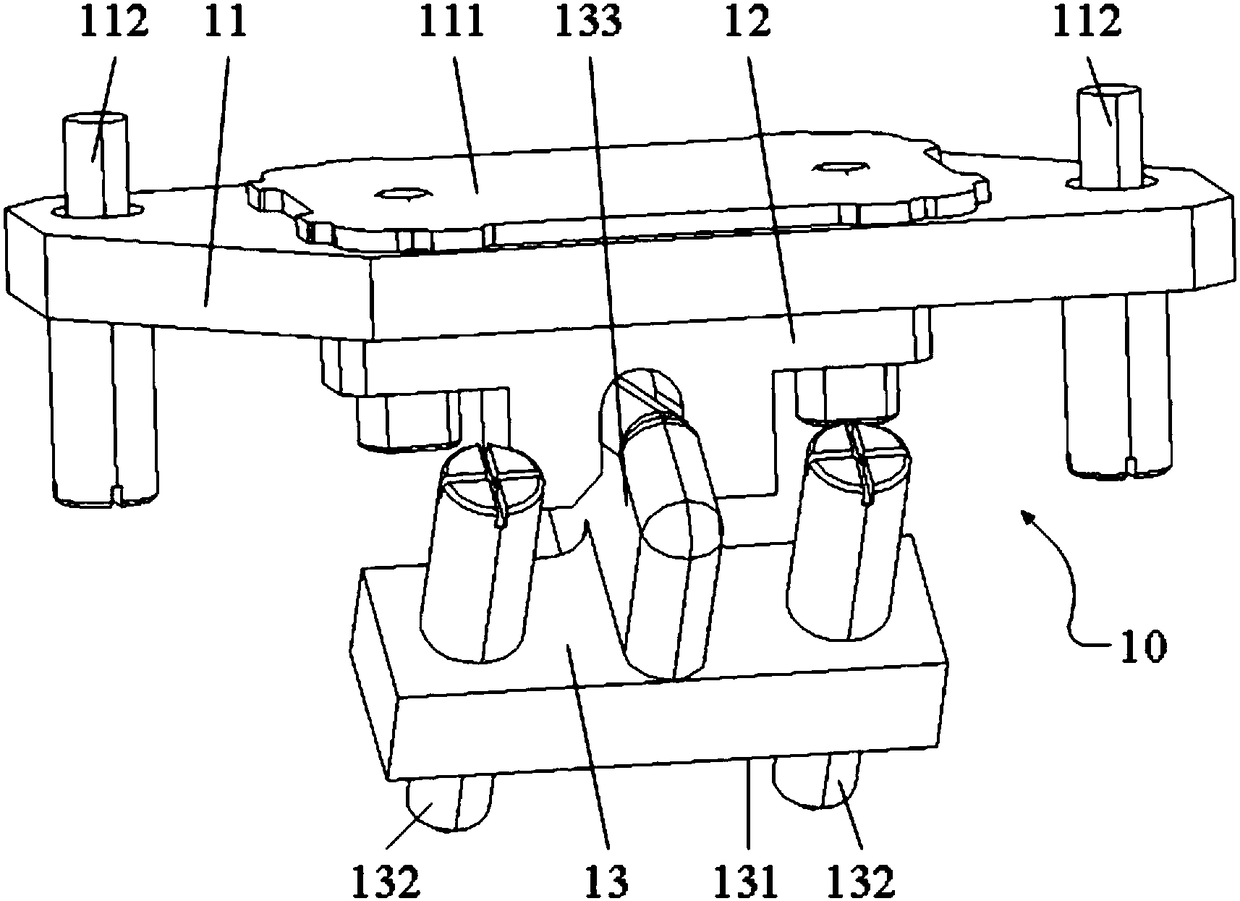

Automobile left and right side body inner plate front assembly clamp

InactiveCN108127318AEasy solderingReasonable structural designWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRight side body

The invention relates to an automobile left and right side body inner plate front assembly clamp. The automobile left and right side body inner plate front assembly clamp comprises a workbench. A leftpositioning and clamping tool, a middle combined clamping tool and a right pressing tool are sequentially arranged at the upper end of the workbench from left to right in a modular manner. A tail clamping tool is arranged at the front portion of the workbench. The automobile left and right side body inner plate front assembly clamp is reasonable in structural design and high in space utilizationrate. Positioning and clamping of an automobile left and right side body inner plate front assembly can be achieved through one tool clamp, and accordingly, an outside welding robot can conveniently conduct automatic welding treatment; and meanwhile, an integral positioning and clamping manner is adopted, precision after integral welding is guaranteed, the production efficiency and the product quality are greatly improved, and the automation degree is high.

Owner:ANHUI DACHANG TECH

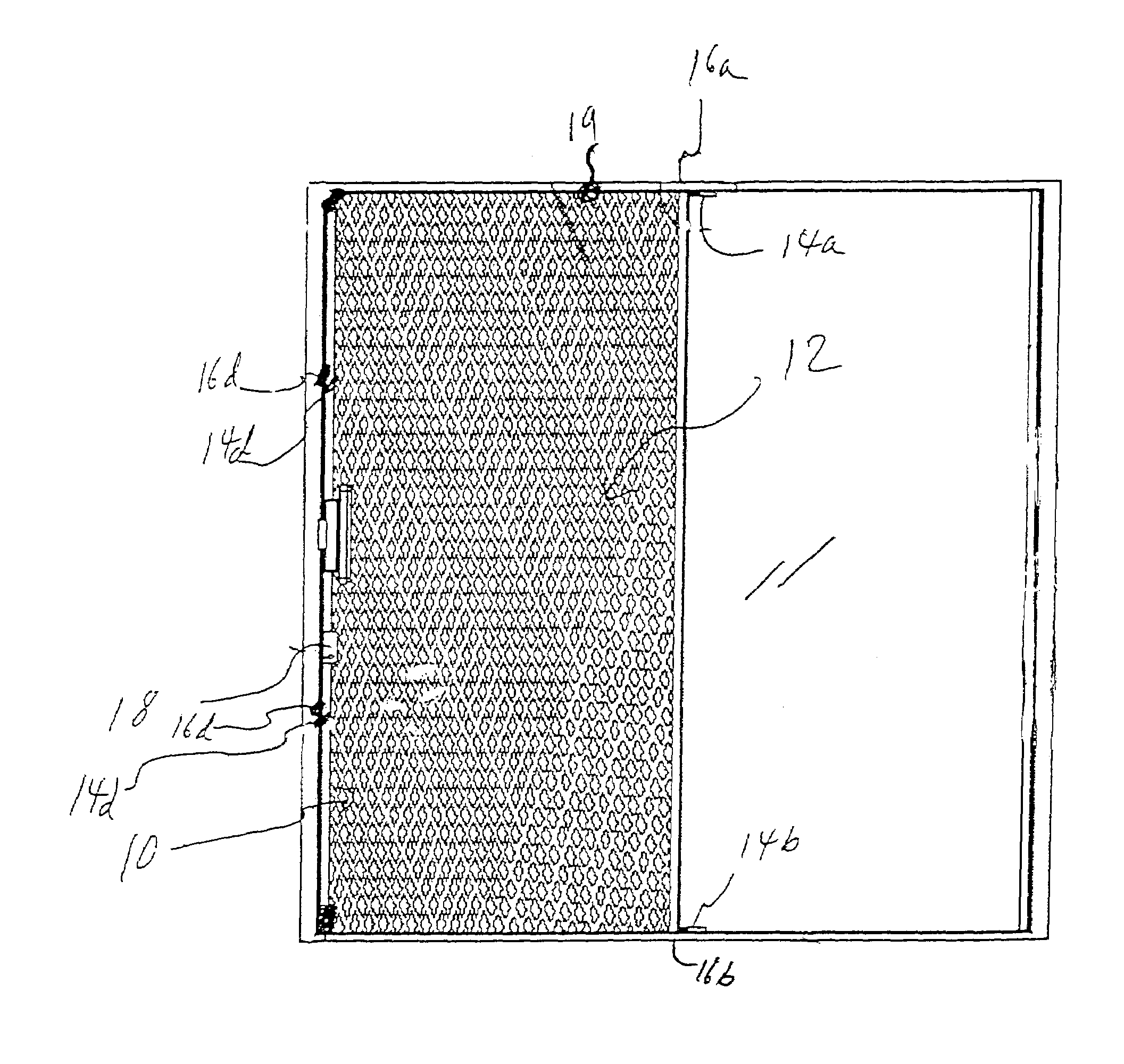

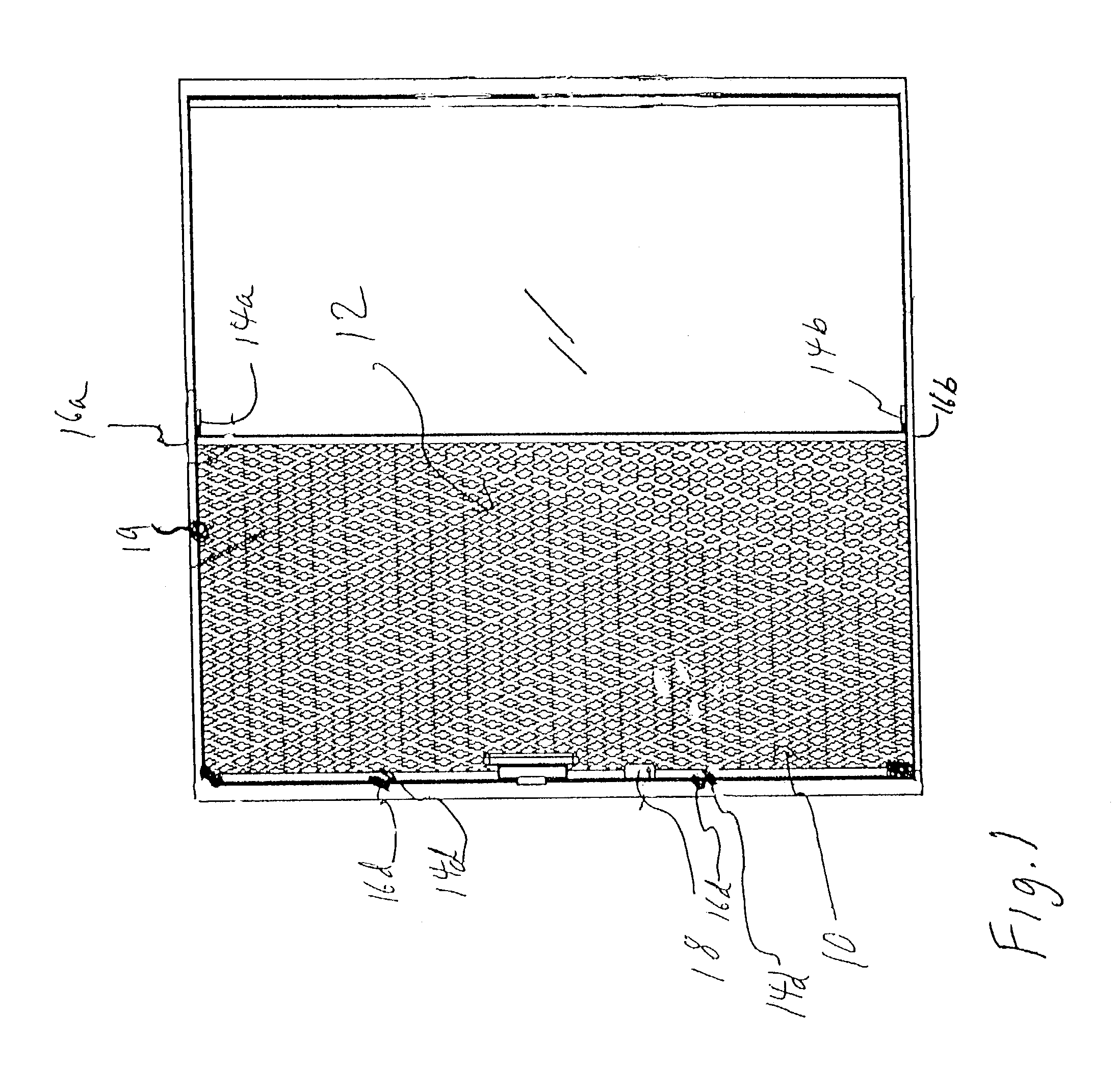

Secure screen

InactiveUS6998981B1Prevent entry of a potential intruderBurglar alarm with fastening tamperingBurglar alarm by openingBody right sideEngineering

A secure screen that includes a sheet of robust metal mesh having separate locking devices, located, but not limited to, the top, bottom, left, and right sides thereof that to provide for independent locking locations on the mesh member that are each lockable to one of four separate dwelling structure locations; a motion sensor being mechanically attached to an outer frame of the robust metal mesh member and, if connected to an existing alarm system, such that tampering with the electrically metal mesh member, can activate the alarm system to summon help and, thereby, prevent entry of a potential intruder.

Owner:MONTAGUE MARYBETH W

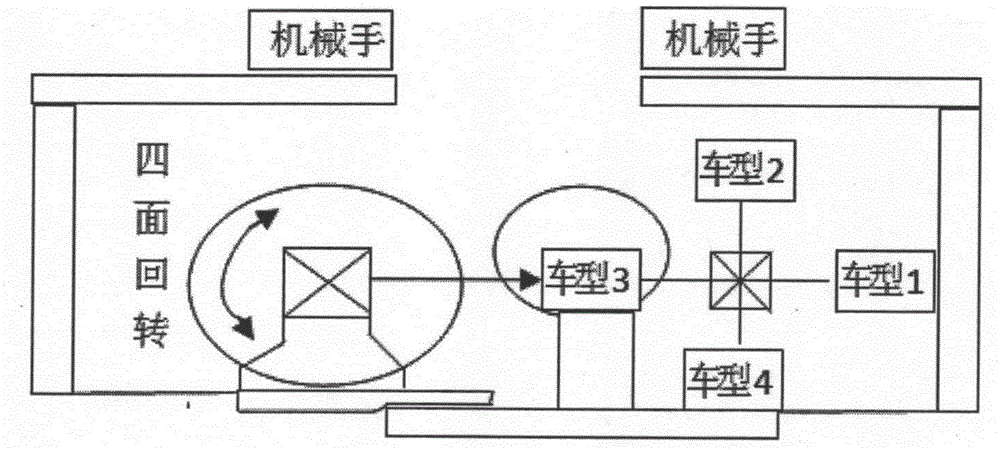

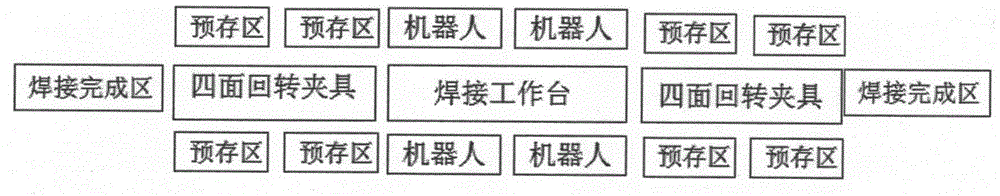

All-side rotation clamp based flexible production workstation for automobile welding production line

InactiveCN104923934AGuaranteed uptimeReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineWorking environment

The invention relates to an all-side rotation clamp based flexible production workstation for an automobile welding production line. The all-side rotation clamp based flexible production workstation comprises a welding worktable and a welding robot and is characterized by further comprising an all-side rotation clamp, a pre-storage area and a welding completion area. The all-side rotation clamp is used in the production workstation, so that the flexible welding production requirements of 4-8 types of vehicles are met, and switching of a left side body and a right side body at the same working position is achieved. Due to the fact that the production workstation uses the all-side rotation clamp, clamps of 4 types of vehicles are integrated, more welding space is saved compared with a traditional single clamp, welding quality is improved, the whole welding production line efficiently and stably operates, a working environment is improved, and the labor intensity of workers is reduced.

Owner:DONGHUA UNIV

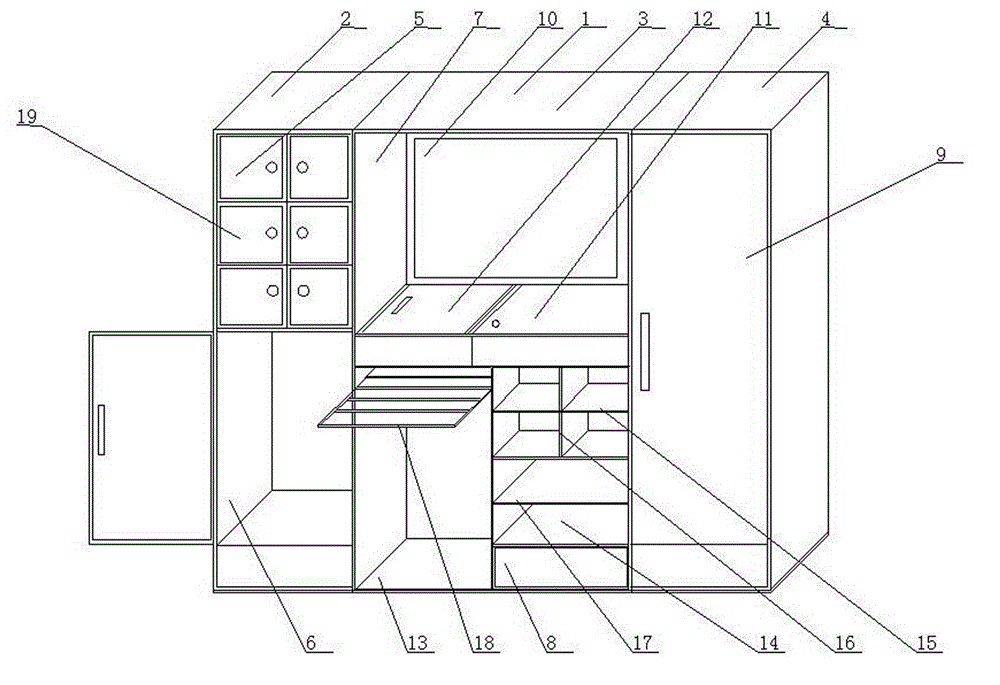

Multifunctional closet

The invention provides a multifunctional closet. The multifunctional closet comprises a closet body; the closet body comprises a left side body, a medium side body and a right side body, wherein the left side body consists of an upper sliding-door type cabinet and a lower storing cabinet; the medium body comprises an upper cosmetics area and a lower storing area; the right side body is used as a cloths hanging area; the upper cosmetics area in the upper part of the medium body comprises a rectangular mirror and a dressing table top, wherein the rectangular mirror is clung to the rear side of the medium body; the dressing table top is a mini cosmetics storing cabinet of which the top surface is equipped with a sliding door; the storing area in the lower part of the medium body comprises a left trousers hanging area and a right hat storing area; the hag storing area comprises four storing areas which are separated through an upper transverse separating plate and a vertical separating plate, and two storing areas which are separated through a transverse separating plate at the lower part. The multifunctional closet is novel in structure, unique in style, high in practicability, and clear in internal storing; the independent cloths hanging area, the trousers hanging area and the hat area are arranged; in addition, the dressing table is arranged, a large rectangular mirror is provided, and therefore, the female friends can dress conveniently or people can try on clothes conveniently.

Owner:HARBIN SHUOHONG FURNITURE

Toy vehicles having interchangeable body styles

A child-sized toy vehicle comprising a vehicle chassis upon which any number of a plurality of stylistically different interchangeable vehicle body modules may be removably secured. The various vehicle body module styles may be comprised of separate body module sections such as a front body module, a rear body module, a left side body module, and a right side body module. In addition, body modules from different body styles may be attached to the same vehicle chassis such that a hybrid vehicle is produced.

Owner:THE BEST AUTOMOTIVE TOY ART THE B A T A

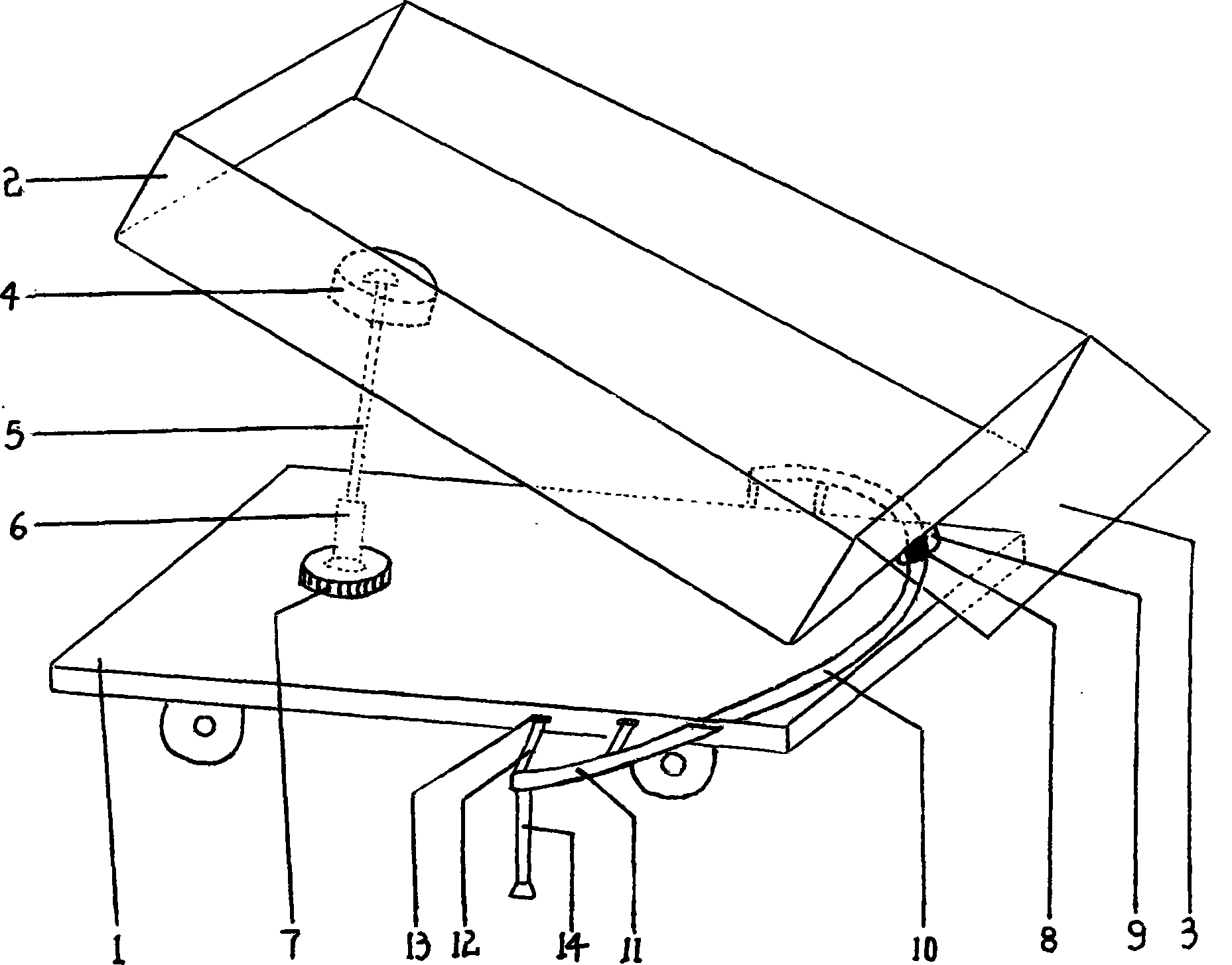

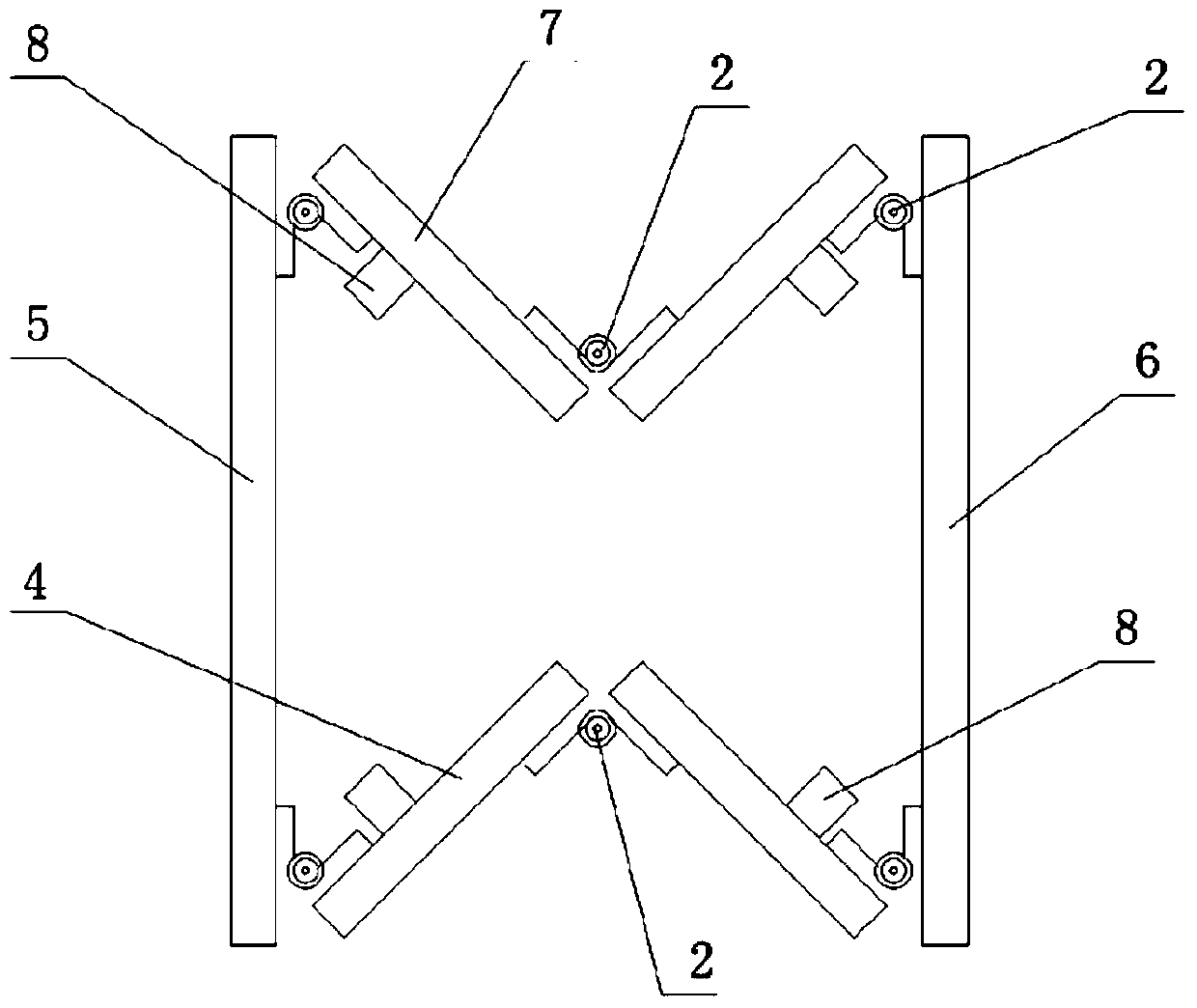

Virtual-reality or augmented-reality viewer for a mobile electronic device

A virtual-reality or augmented-reality viewer (1) for a mobile electronic device (2), the viewer (1) including a central body (3), a left lens (4) and a right lens (4) arranged in the central body (3), a left side body (5) connected to the central body (3), a right side body (5) connected to the central body (3), and a tension mechanism (6) which biases the left and right side bodies (5) towards each other. In a first viewer state, a left portion of the central body (3) is accommodated in the left side body (5) and a right portion of the central body (3) is accommodated in the right side body (5). In a second viewer state, the left portion of the central body (3) is not accommodated in the left side body (5) and the right portion of the central body (3) is not accommodated in the right side body (5), so that the left and right lenses (4) are not covered by the left or right side body (5).

Owner:SPECULATIVE PROD DESIGN

Robot obstacle avoidance method

InactiveCN109669445AMeet the needs of obstacle avoidanceEasy to operatePosition/course control in two dimensionsBody right sideOperability

The invention discloses a robot obstacle avoidance method. The robot obstacle avoidance method is characterized by comprising the following steps that (1) distance sensors are mounted on the right front, left side and right side of a robot; (2) when no barrier is detected in the right front and barriers are detected on only one of the left side and the right side, a steering device is controlled to keep the distance with the barriers not lower than a first threshold value; (3) when no carrier is detected in the right front and the carriers exist on the left and right sides, the steering deviceis controlled to keep the distance with the barriers on the two sides not lower than a second threshold value, if not, an angle is turned; and (4) when the carriers are detected existing in the rightfront, the angle is turned for moving on after moving on is carried out until the distance with the barriers is the second threshold value, at this moment, the detected distance of the left side andthe right side is kept not smaller than the second threshold value, if not, the angle is turned continuously. The robot obstacle avoidance method has the beneficial effects that the robot obstacle avoidance method can meet the requirement of obstacle avoidance, and the operability during implementation is higher due to the arranged two threshold values.

Owner:南京龙贞自控科技发展有限公司

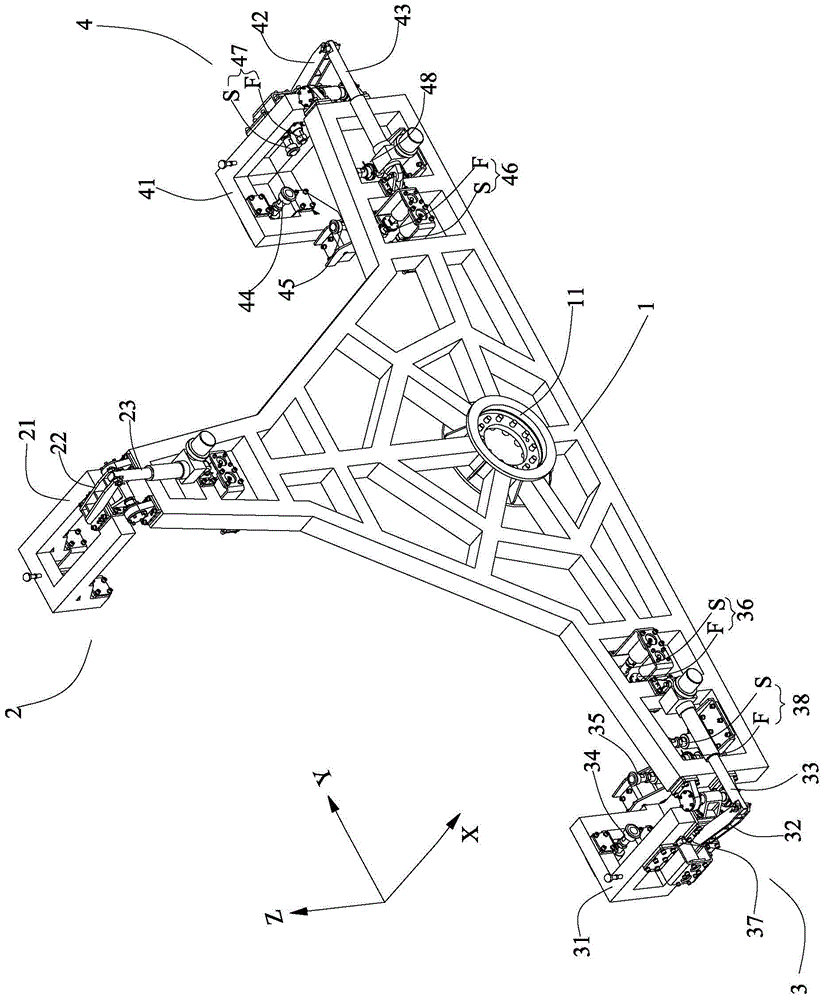

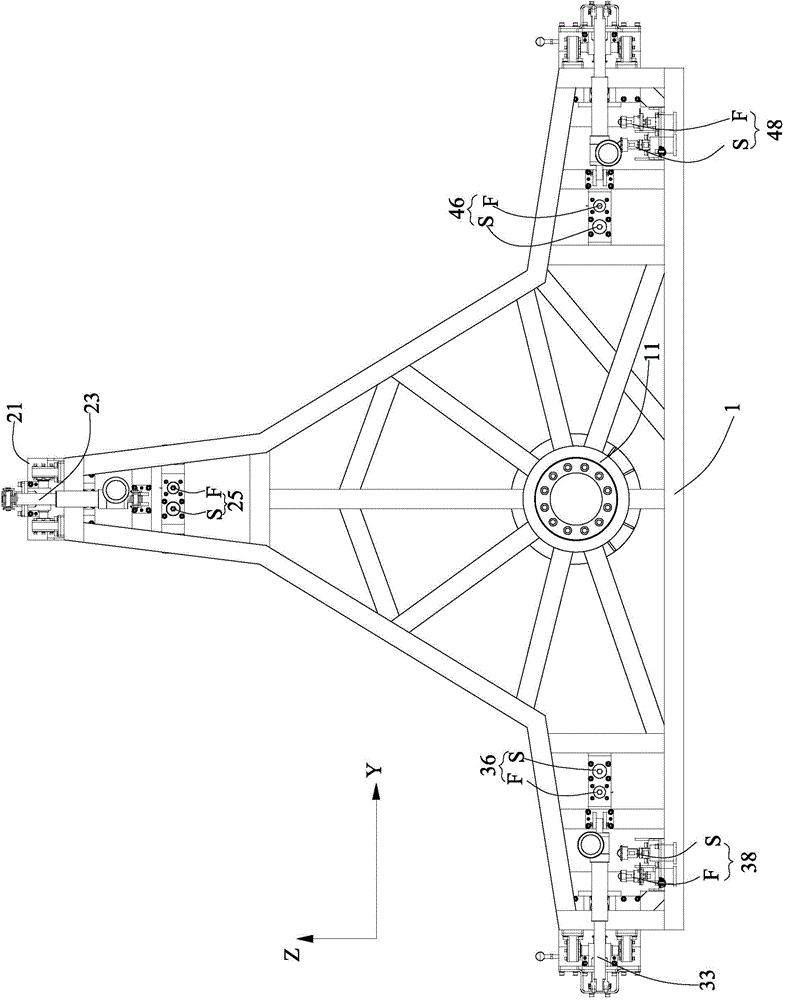

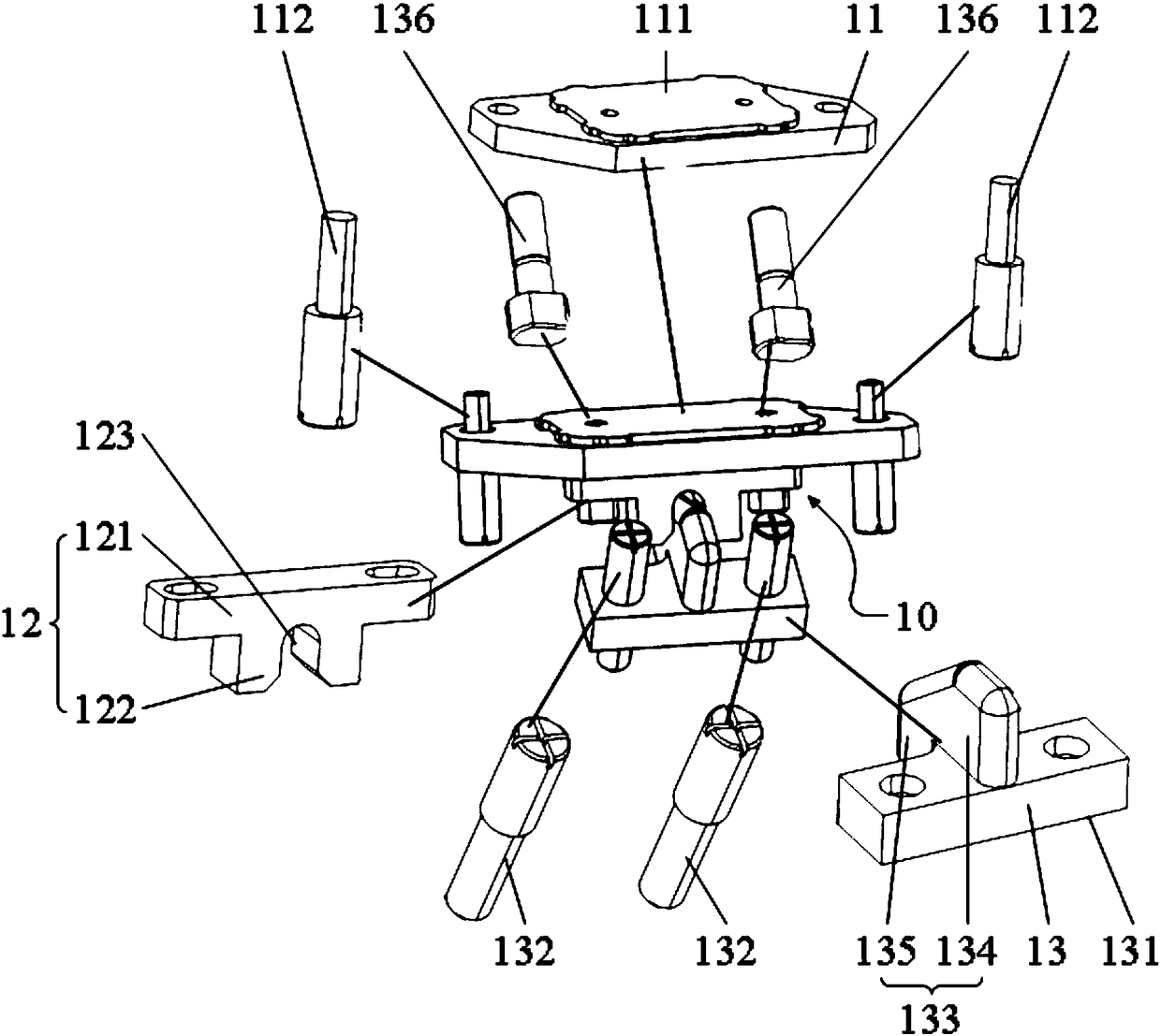

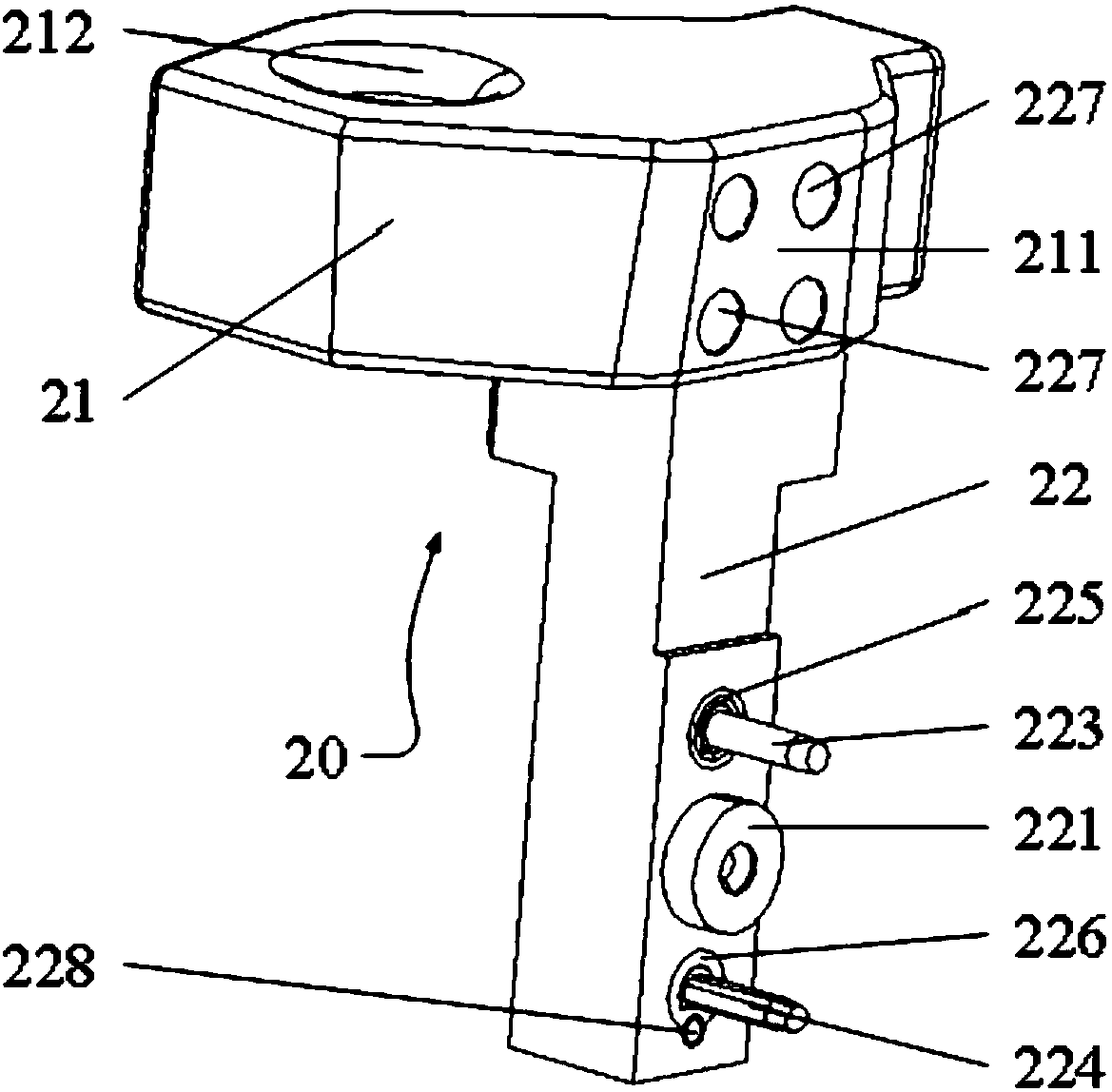

Gripper

The invention provides a grippe. The gripper comprises a body, an upper side gripper assembly, a left side gripper assembly and a right side gripper assembly. The upper side gripper assembly comprises an upper side body, an upper side pivoting connection arm, an upper side telescopic connection rod, an upper side X-direction bearing spring body and an upper side X-direction side force bearing spring body. The left side gripper assembly comprises a left side body, a left side pivoting connection arm, a left side telescopic connection rod, a left side X-direction bearing spring body, a left side Z-direction bearing spring body, a left side X-direction side force bearing spring body, a left side Y-direction side force bearing spring body and a left side Z-direction side force bearing spring body. The right side gripper assembly comprises a right side body, a right side telescopic connection rod, a right side X-direction bearing spring body, a right side Z-direction bearing spring body, a right side X-direction side force bearing spring body, a right side Y-direction side force bearing spring body and a right side Z-direction side force bearing spring body. Thus, assembly force applied to a workpiece in the assembly process can be passively and flexibly monitored.

Owner:TSINGHUA UNIV +1

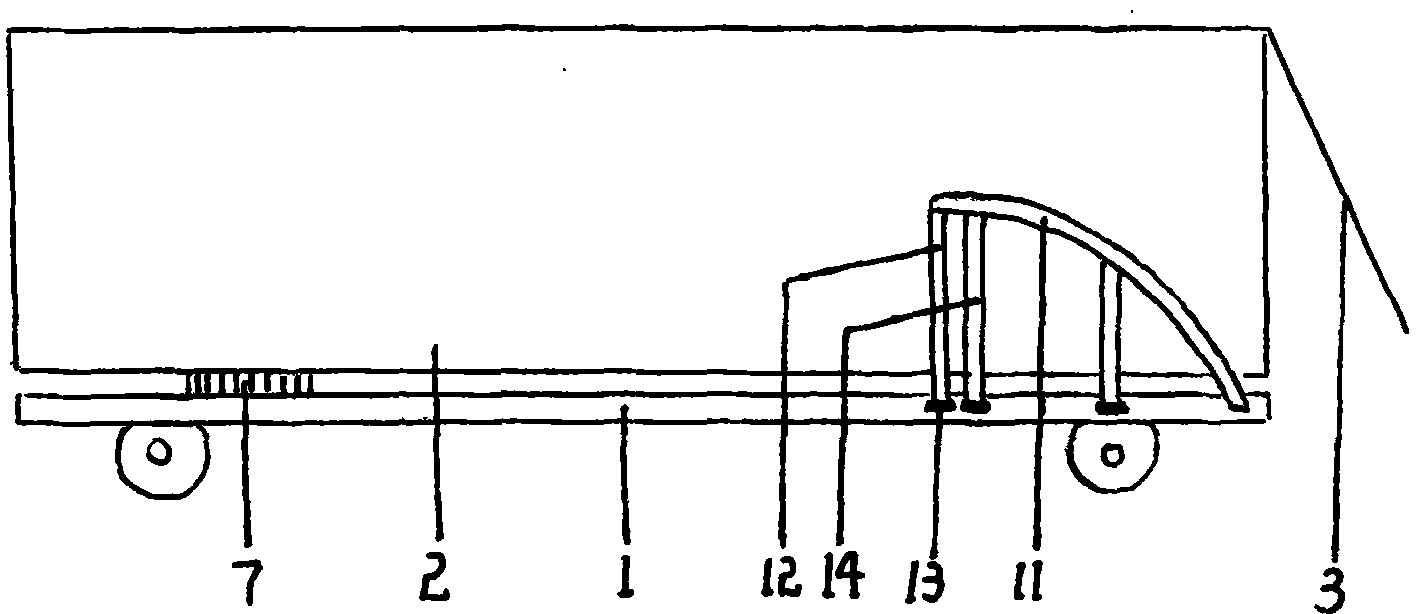

Back-tipping dumper with carriage capable of steering

The invention discloses a back-tipping dumper with a carriage capable of steering. The back-tipping dumper comprises a frame, a carriage body, a rear carriage door, a rotating disk, a piston rod, a lifting oil cylinder, a rotating seat, an overturning shaft, locking devices, first rails, second rails, a support rod, movable pin shafts and a support oil cylinder, wherein the rotating seat and the first rail are arranged on the frame; the carriage body is arranged above the frame; the rotating disk and the revolving shaft are arranged at the bottom of the carriage body; the rotating disk and the rotating seat rotate in a matching way; the lifting oil cylinder is arranged in the rotating seat; the top of the piston rod of the lifting oil cylinder is arranged in the rotating disk; the movable pin shafts are symmetrically arranged on a left side body and a right side body of the frame; the second rails are symmetrically and fixedly connected to both sides of the frame through the movable pin shafts and the support rod; the second rails are matched with the first rails, so that an arc-shaped rail taking the rotating seat as an axle center is formed; the second rails can be folded on both sides of the carriage body through the movable pin shafts; the support oil cylinder is arranged below the second rails; the locking devices are arranged around the overturning shaft. According to the back-tipping dumper, back-tipping dumping can be performed in multiple directions.

Owner:徐欣荣

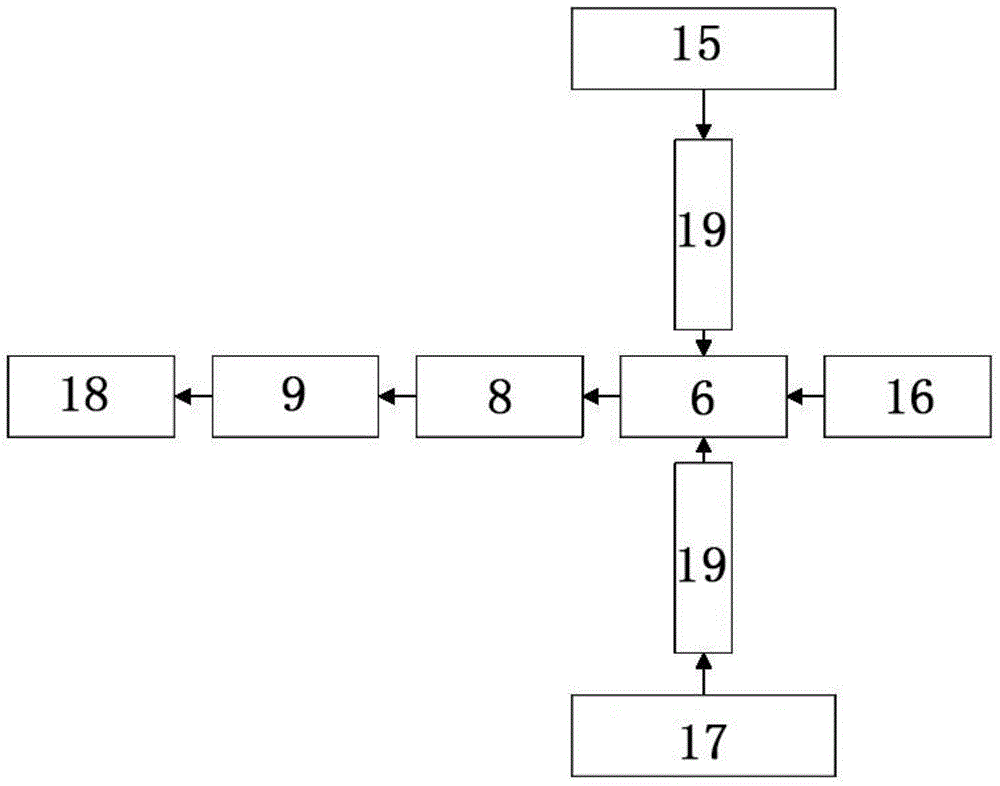

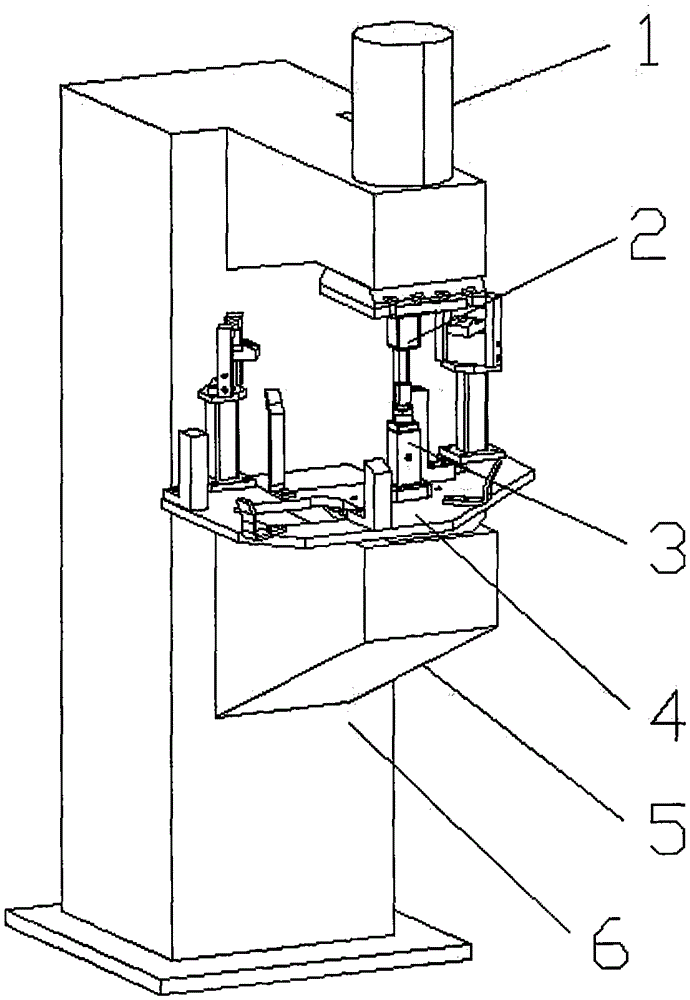

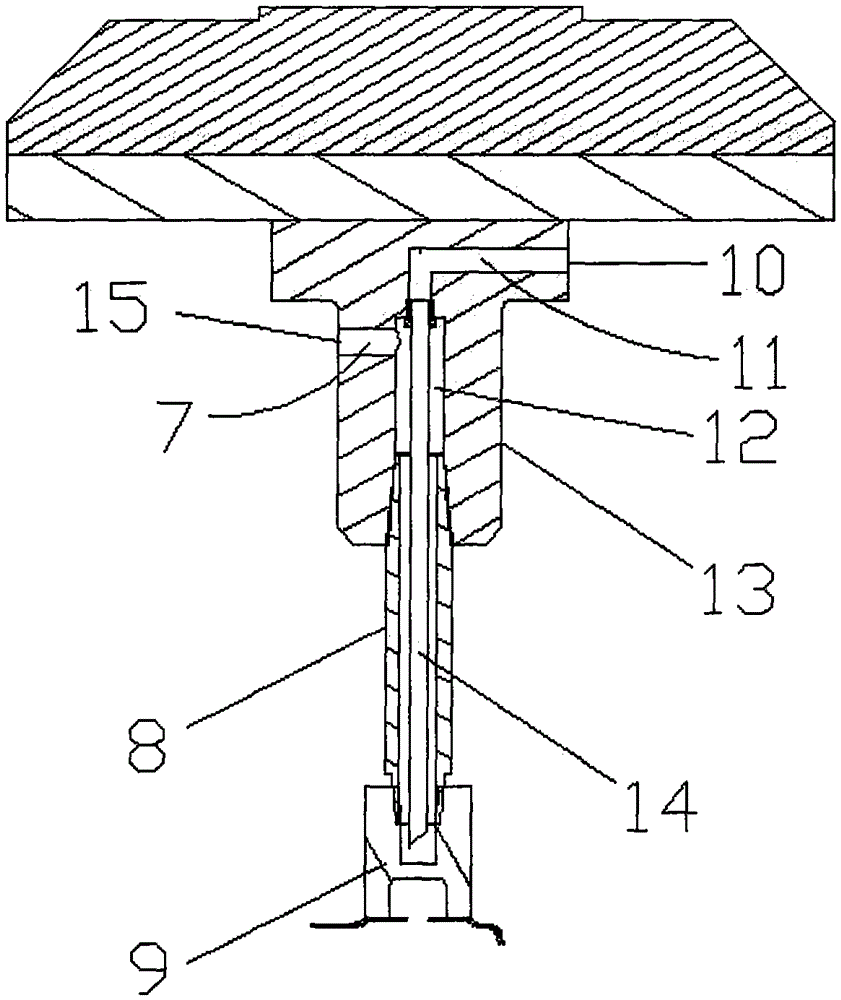

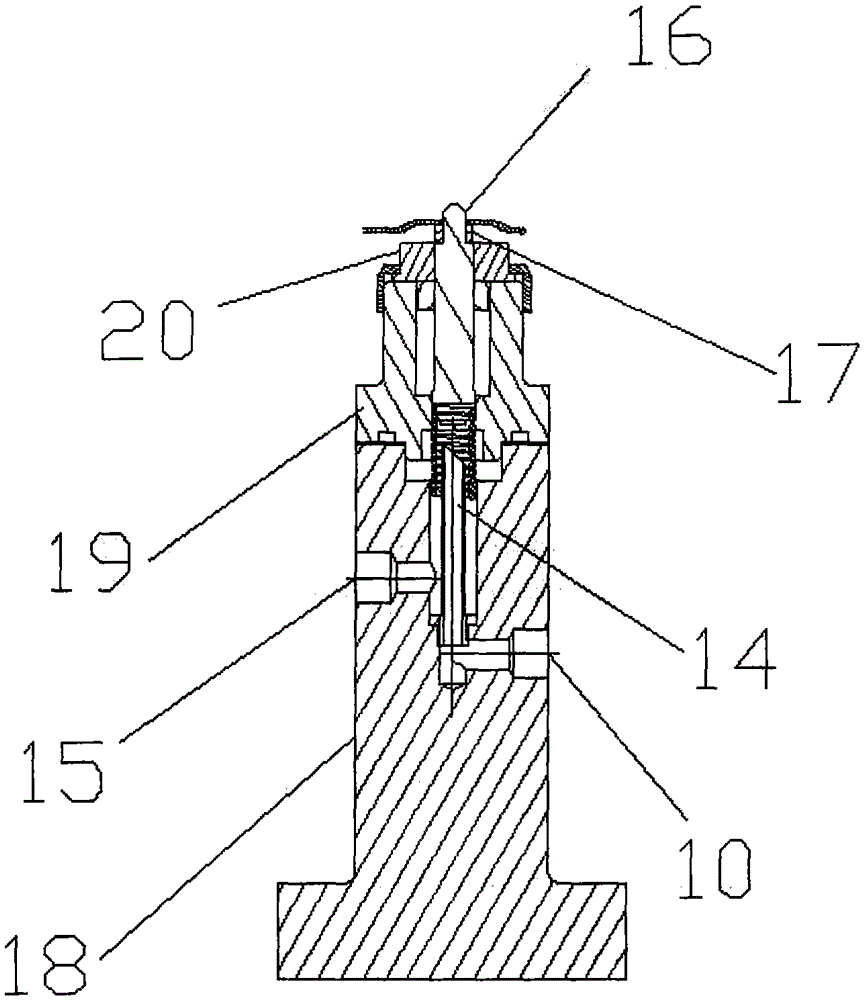

Convex spot welding equipment for passenger car

InactiveCN105562916AIncrease productivityEasy to operateResistance electrode holdersWelding/cutting auxillary devicesSpot weldingMechanical engineering

The invention discloses convex spot welding equipment for a passenger car. The convex spot welding equipment comprises a seat spot welding machine. The seat spot welding machine comprises a body (6), an upper electrode assembly (2) and a lower electrode assembly (3), an upper electrode seat and a lower electrode seat are both arranged on the front side of the body (6), the lower electrode assembly (3) is fixedly arranged on a substrate (4), and a left side body column B locating and supporting unit, a right side body column B locating and supporting unit, a rear wheel cover locating and supporting unit and a rear wheel cover guide assembly are arranged on the substrate (4). According to the convex spot welding equipment for the passenger car, a convex welding workpiece can be located through a locating system.

Owner:CHANGCHUN UNIV OF SCI & TECH

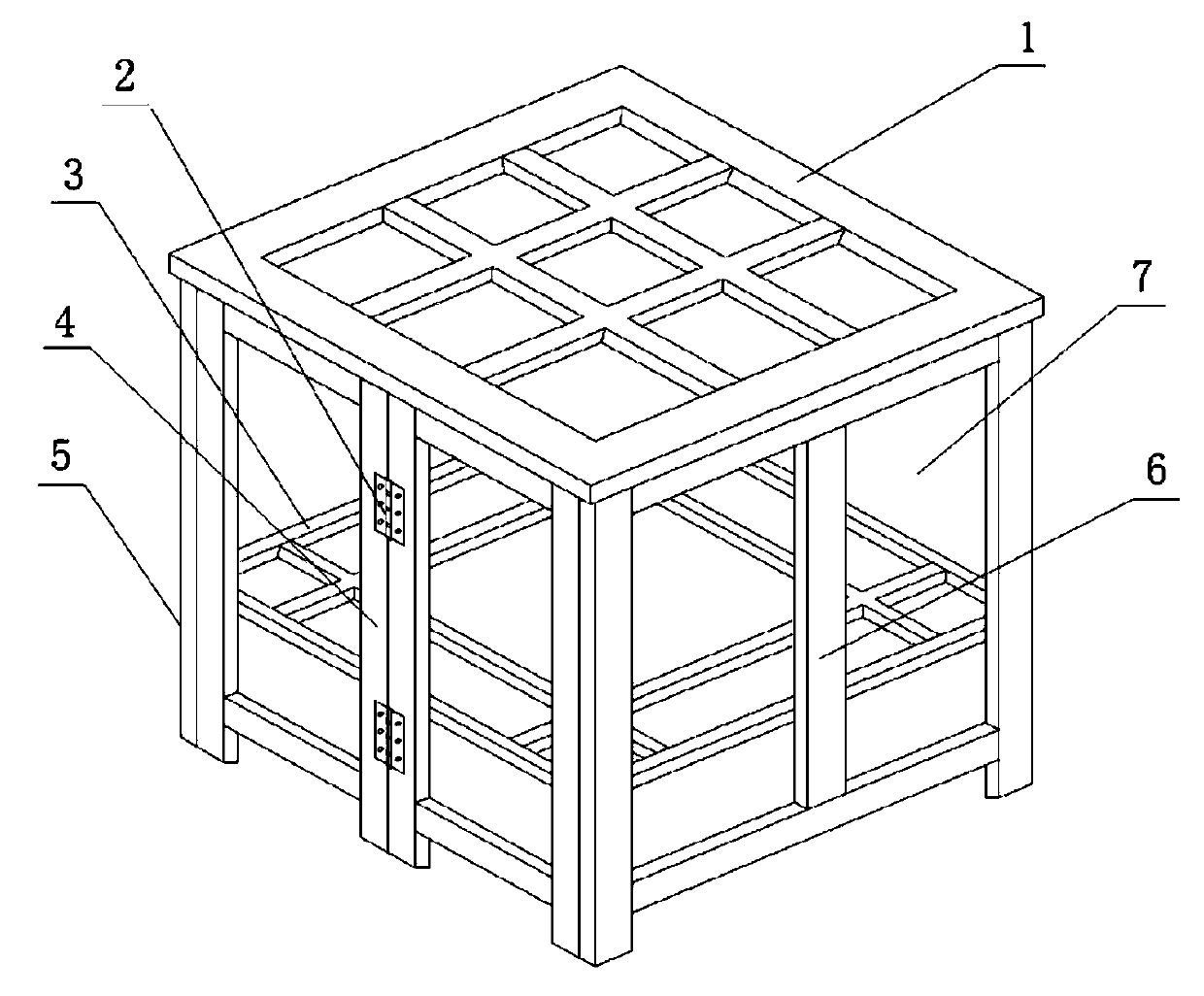

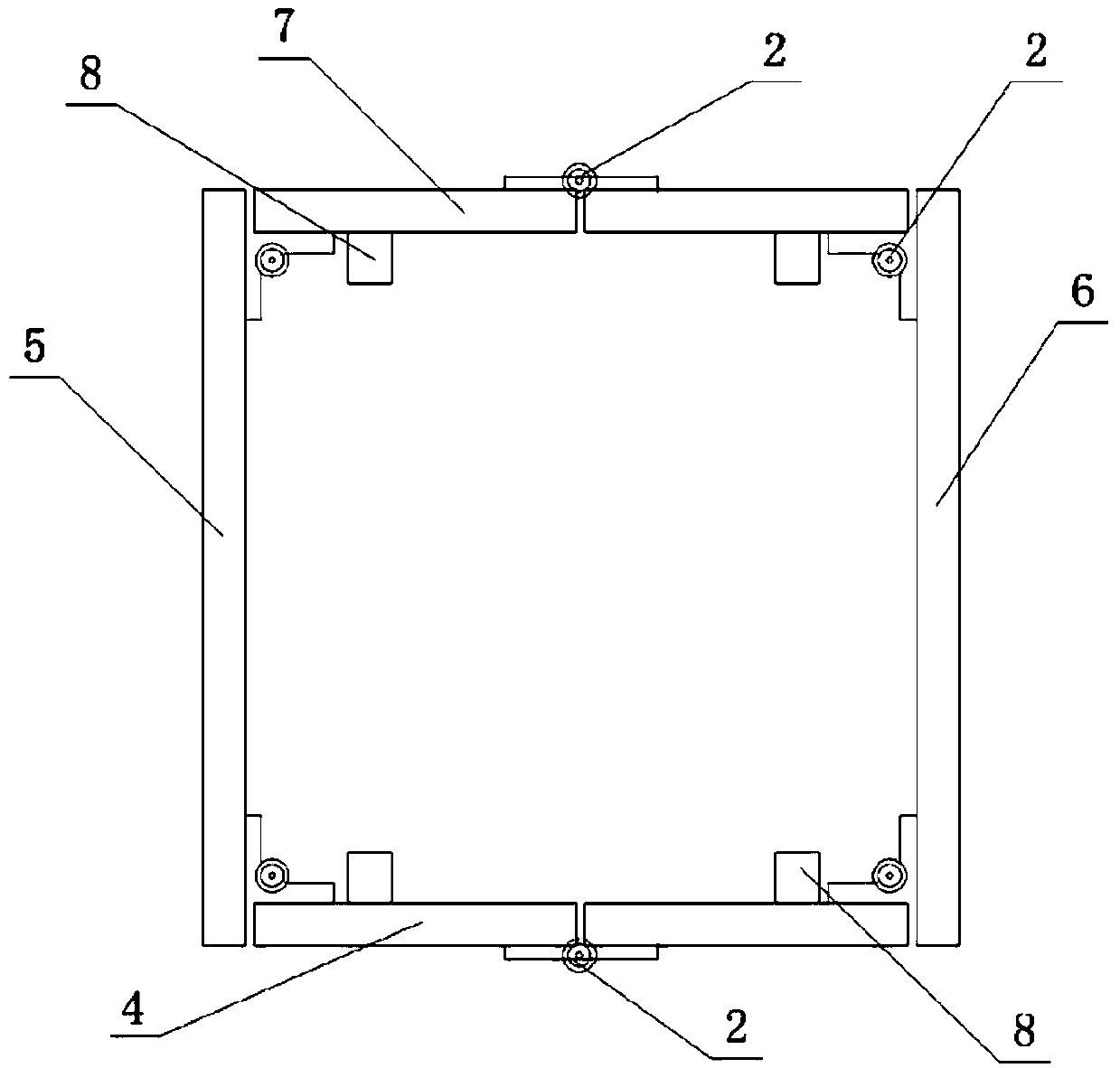

Combined foldable table

InactiveCN104188348ASimple structureLoading and unloadingFoldable tablesStowable tablesEngineeringRight side body

The invention provides a combined foldable table which comprises a left side body, a right side body, a front folded body, a rear folded body, an upper supporting body and a lower supporting body. The front folded body and the rear folded body are movably connected with the left side body and the right side body respectively through connecting parts to form a frame body which can be folded or unfolded. The lower supporting body is arranged in the unfolded frame body. The upper supporting body is arranged on the upper portion of the unfolded frame body. According to the combined foldable table, as the front folded body and the rear folded body are movably connected with the left side body and the right side body respectively through the connecting parts to form the frame body which can be folded or unfolded, the lower supporting body is arranged in the frame body, and the upper supporting body is arranged on the upper portion of the frame body, the structure is simple and convenient to assemble and disassemble, supporting is firm, and the foldable table is not prone to loosening.

Owner:赵宽学

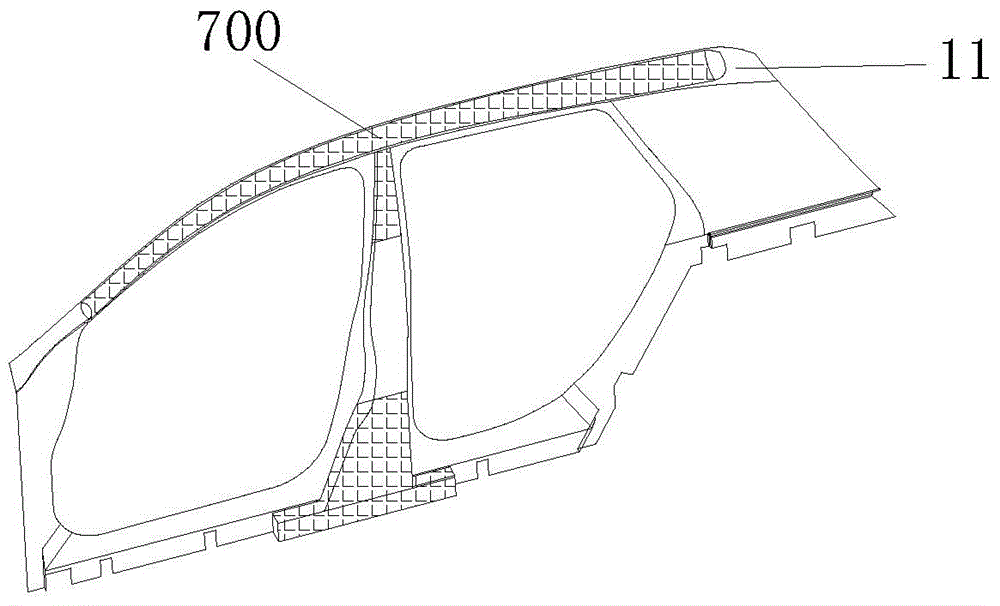

Side body outer board forming die assembly and automobile production line

ActiveCN109570353ASmall footprintAvoid separate developmentShaping toolsVehicle componentsProduction lineRight side body

The invention relates to the field of automobile manufacturing, and provides a side body outer board forming die assembly and an automobile production line. The forming die assembly comprises an upperdie and a lower die which are oppositely arranged. A sign profile used for supporting a side body outer board and arranged in an axis symmetry structure manner is formed on the side, opposite to theupper die, of the lower die, and accordingly any one of a left side body outer board body and a right side body outer board body can be selectively supported. According to the forming die assembly, co-die production of the left side body outer board body and the right side body outer board body can be achieved, excessive constraint from the workpiece size is avoided, the occupied space is small, the situation that during product research and development, dies are respectively developed for the left side body outer board body and the right side body outer board body is avoided, the developmentcost is saved, the development period is shortened, and the enterprise competitiveness is effectively improved.

Owner:GREAT WALL MOTOR CO LTD

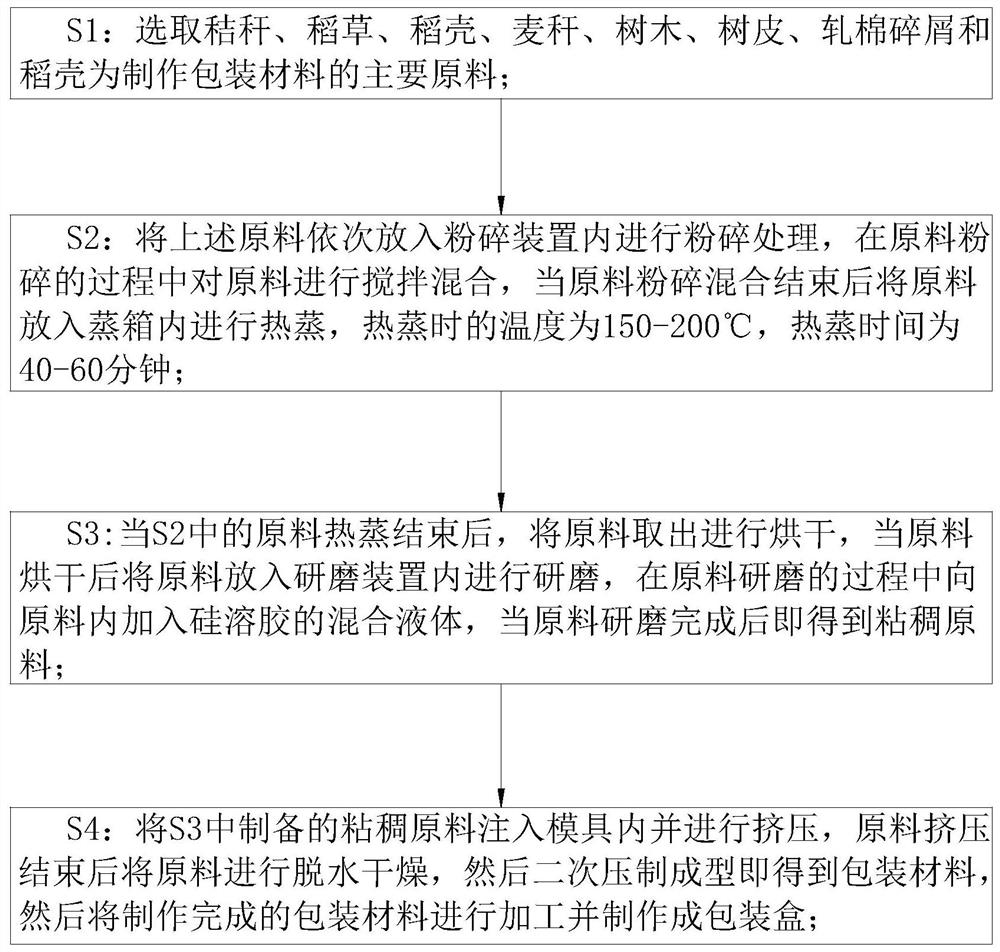

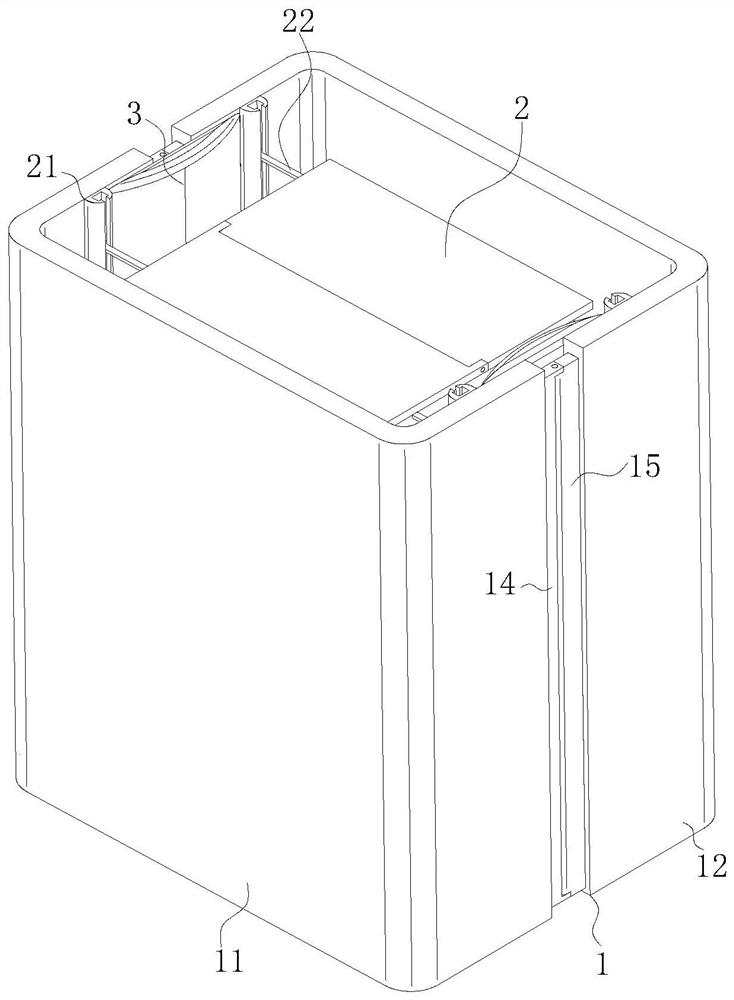

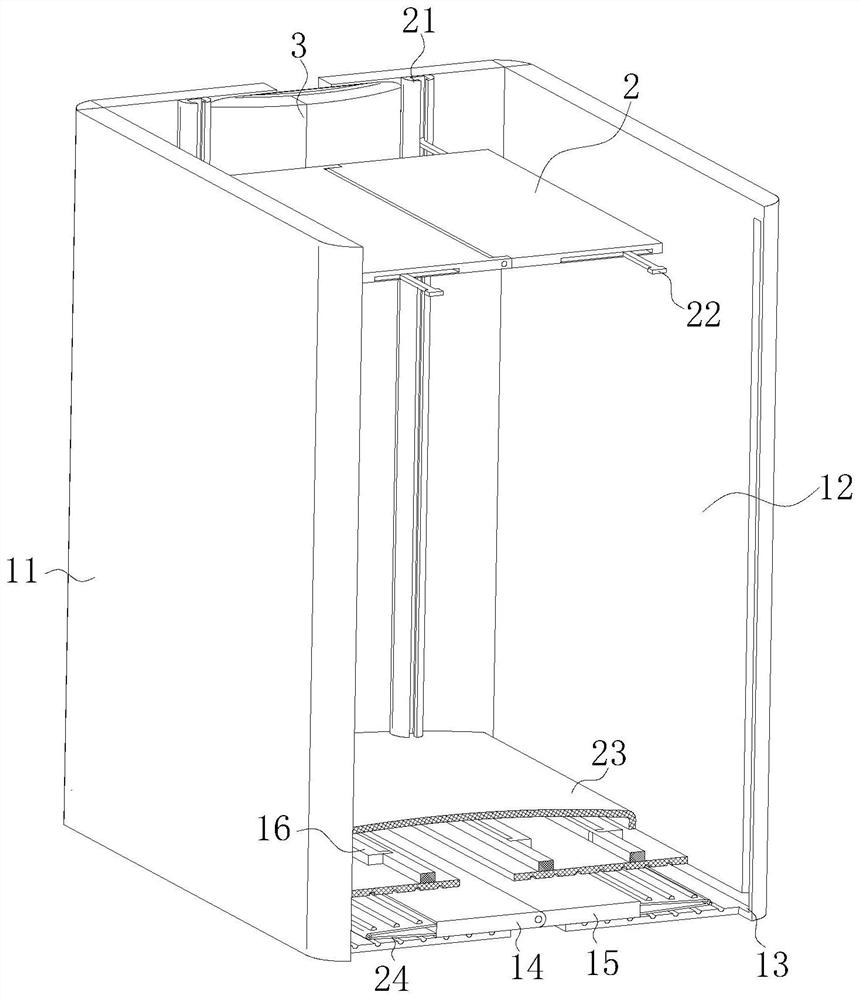

Environment-friendly packaging material

InactiveCN111846532AIncrease the difficultyAvoid damageFlexible coversWrappersEngineeringPack material

The invention belongs to the technical field of packaging materials, and particularly relates to an environment-friendly packaging material. A packaging box comprises a box body, wherein the box bodycomprises a left side body and a right side body, first sliding grooves are formed in the inner walls of the bottoms of the left side body and the right side body, the first sliding grooves correspondto each other, a first pull plate is slidably connected into the inner wall of the first sliding groove on the left side through a spring, and a second pull plate is slidably connected into the innerwall of the first sliding groove on the right side through a spring. The environment-friendly packaging material is mainly used for solving the problems that most of existing environment-friendly packaging materials are made of waterborne polyurethane materials, although waterborne polyurethane is non-toxic and harmless and has good environmental protection performance, the degradation speed of the waterborne polyurethane materials is low, meanwhile, most of packaging boxes made of the environment-friendly materials are of fixed specifications, when objects with different specifications needto be loaded and unloaded, the packaging boxes with the same specifications as the objects can be used, so that the use range of the packaging boxes is greatly limited.

Owner:田海峰

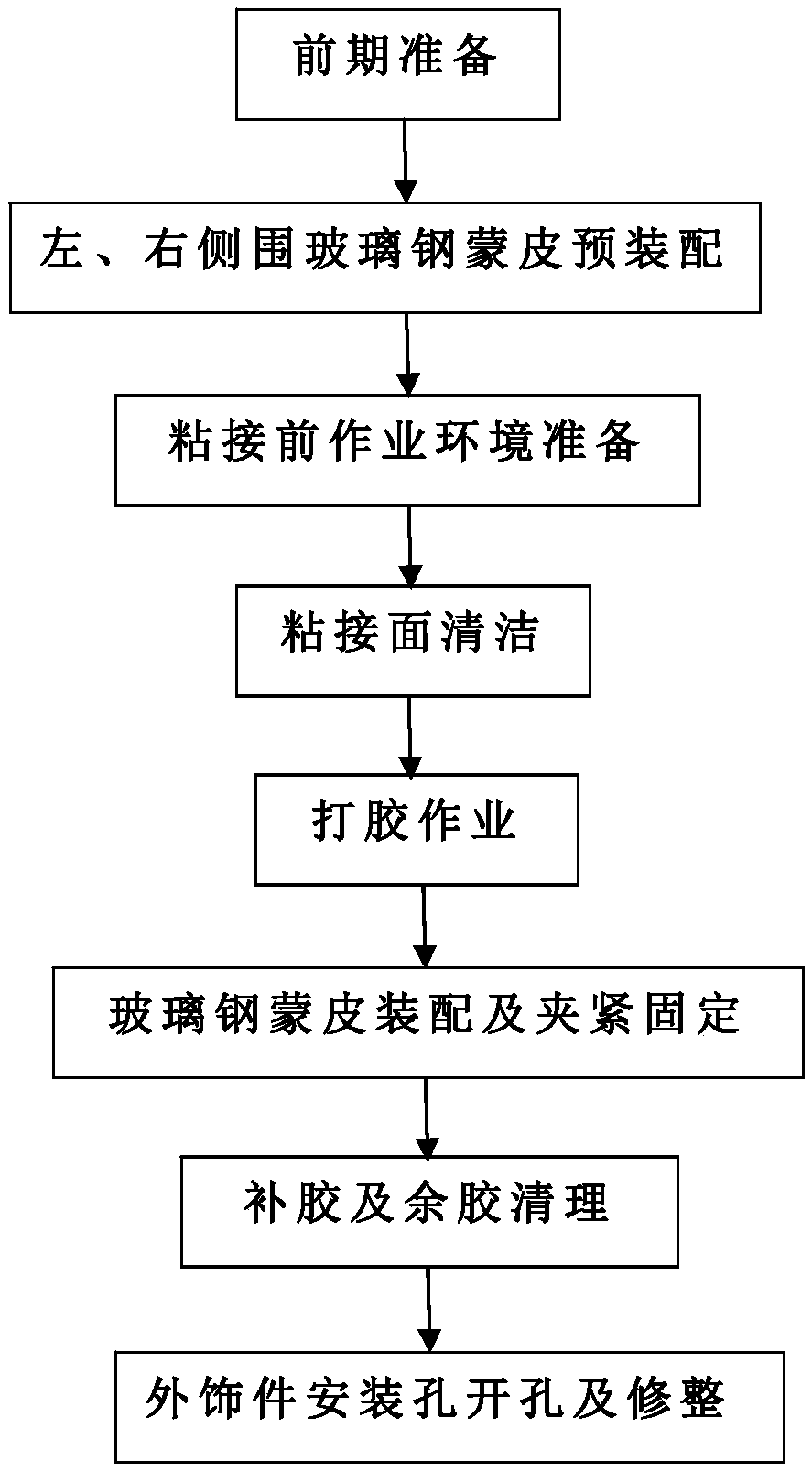

Glass fiber reinforced plastic side skin assembly method for public transportation bus

InactiveCN108639157AImprove anti-corrosion performanceEasy to operateSuperstructure subunitsVehiclesStress distributionGlass fiber

The invention discloses a glass fiber reinforced plastic side skin assembly method for a public transportation bus. The glass fiber reinforced plastic side skin assembly method comprises the followingsteps that step (1) preliminary preparation is performed, specifically, the material and surface treatment method of a skeleton of a body side are determined, and selection of structural adhesive, primer coat and cleaning agent is performed; step (2) pre-assembly of glass fiber reinforced plastic side skins of left and right side bodies is performed; step (3) preparation of a working environmentbefore bonding is performed; step (4) skeleton verification and cleaning of glass fiber reinforced plastic skin bonding surfaces and body side skeleton bonding surfaces are performed; step (5) glue operation is performed; step (6) glass fiber reinforced plastic skin assembly and clamping and fixing are performed; step (7) glue filling and residual glue cleaning are performed; and step (8) exteriortrim mounting hole opening and trimming are performed. The glass fiber reinforced plastic side skin assembly method for the public transportation bus has the advantages that the raw material waste caused by replacing side skins can be effectively reduced, the time for replacing the side skins is shortened, the cost for replacing the side skins is reduced, the physical harm to operators during operation is reduced, the pollution to the environment is reduced, the range of stress distribution between the skins and the body skeleton is reduced, and noise is reduced.

Owner:HIGER

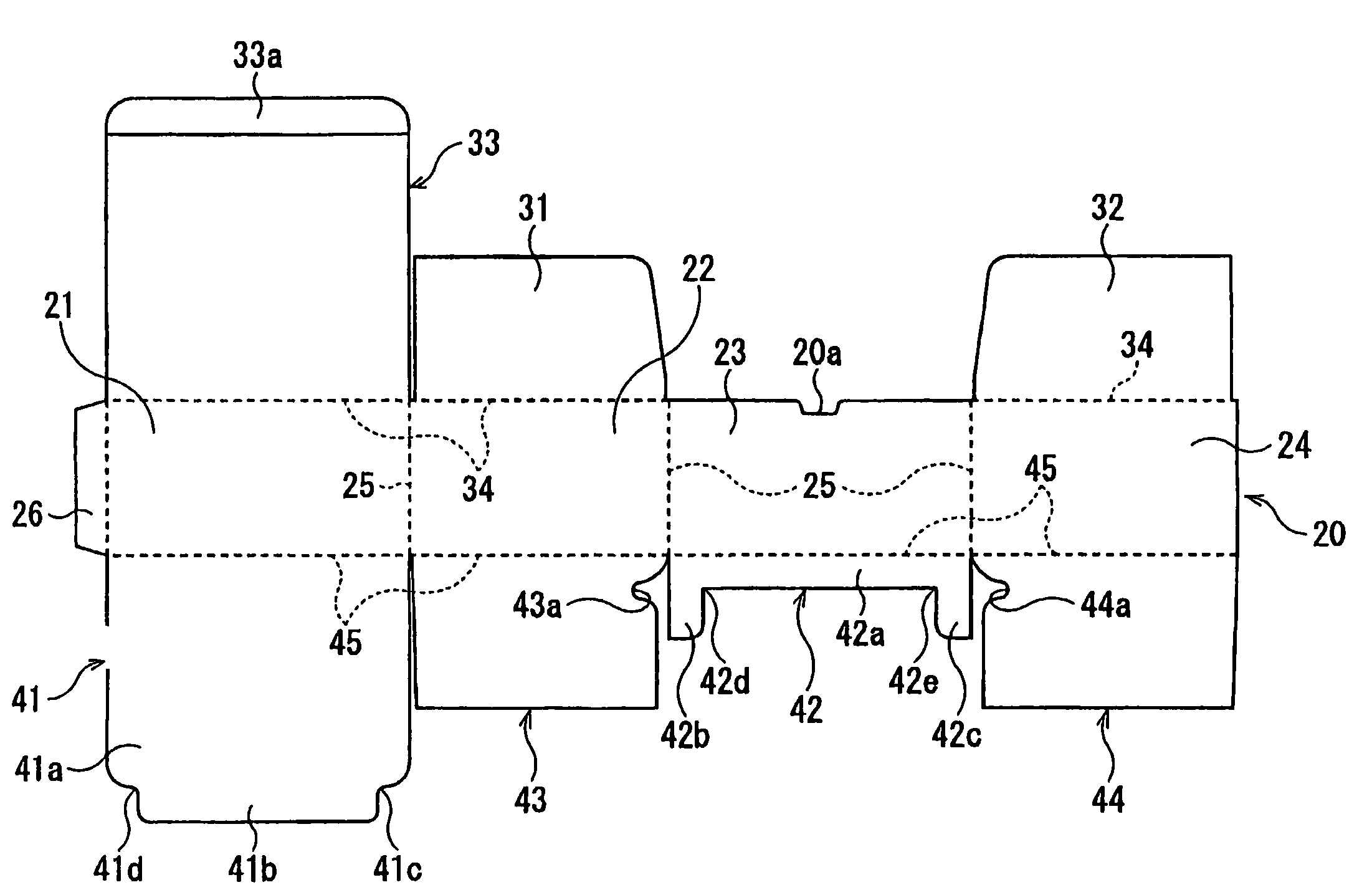

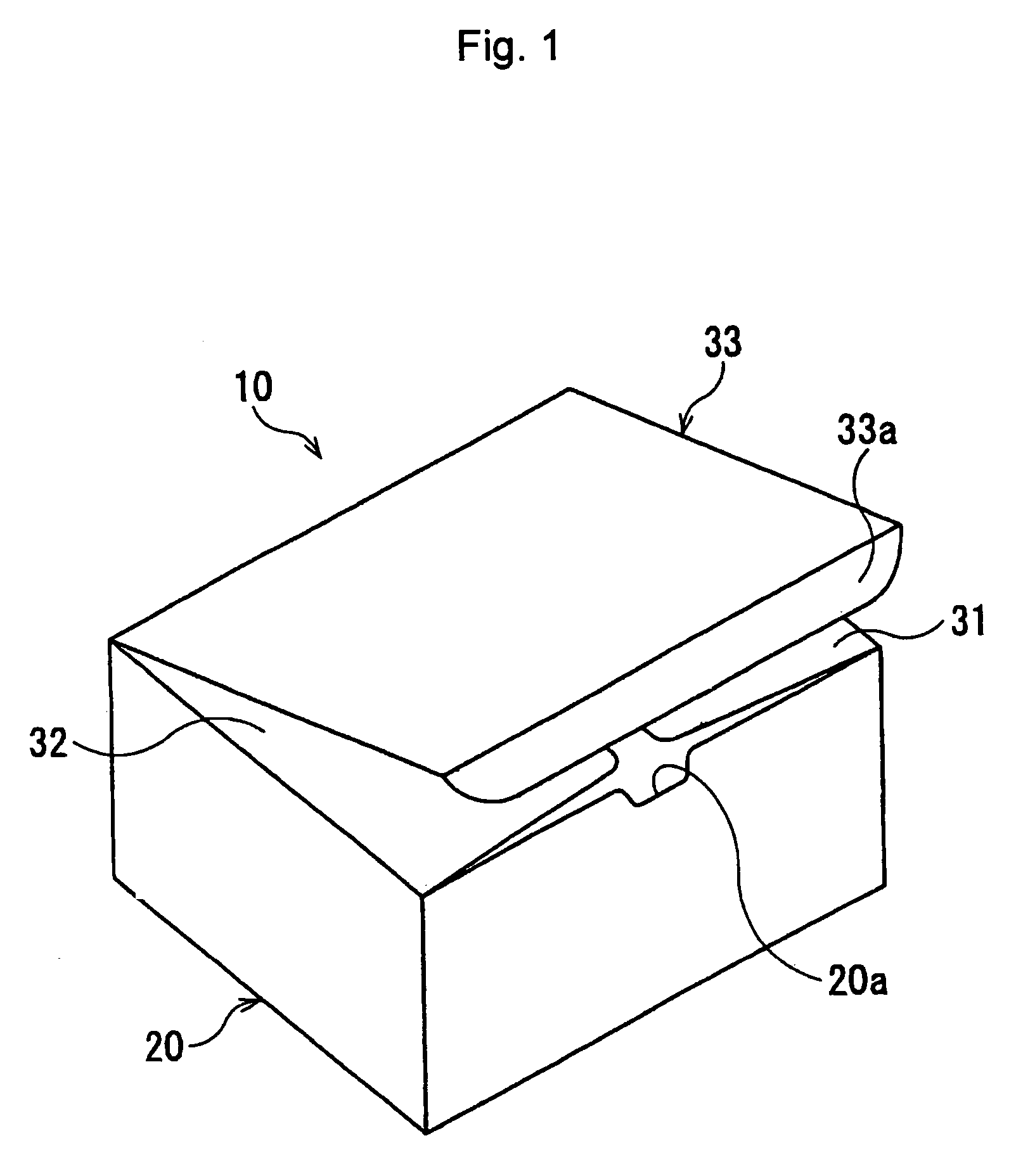

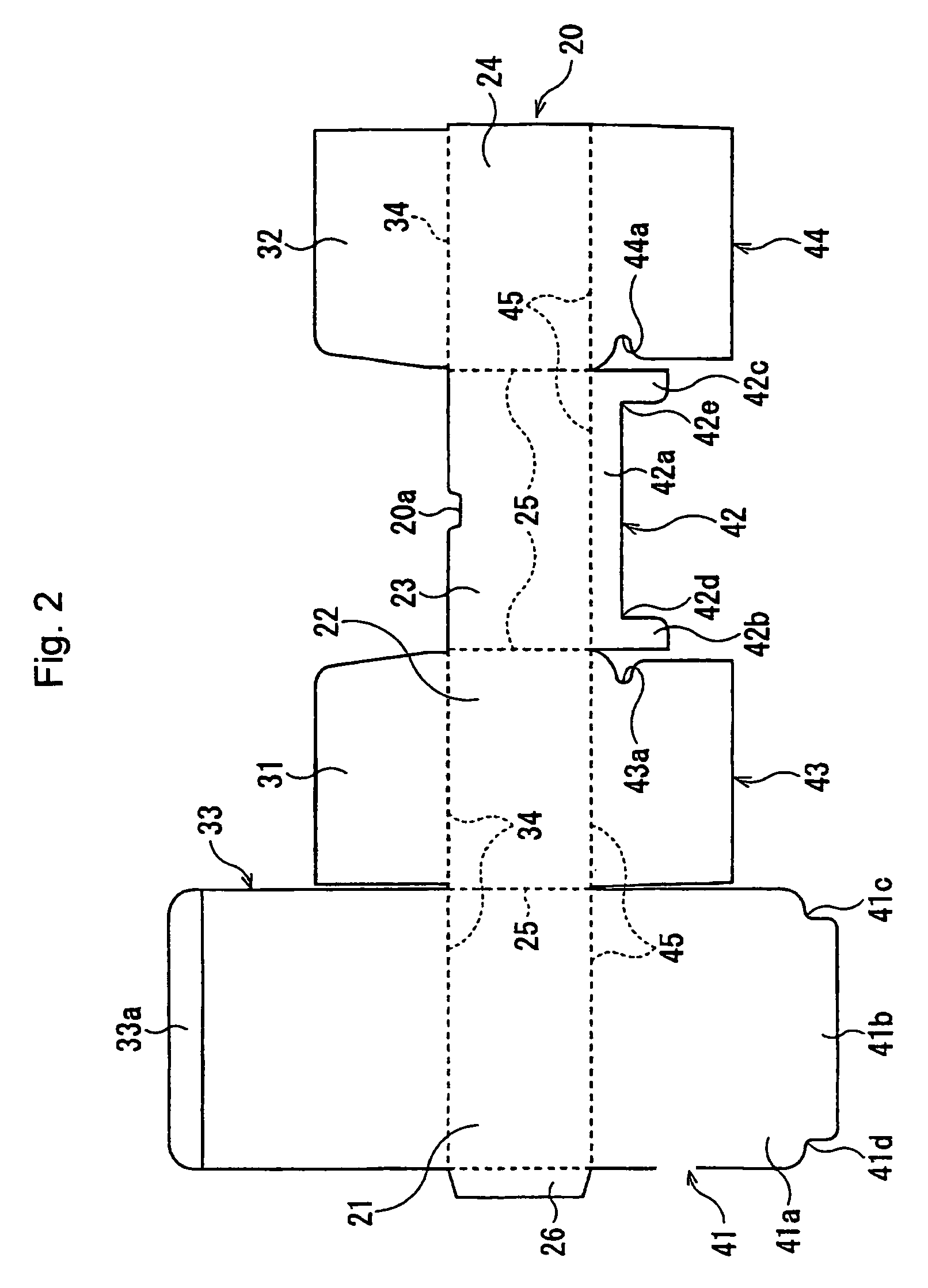

Flexible board for forming package

InactiveUS7607568B2Great freedomIncrease the areaInsect protectionRigid containersEngineeringMechanical engineering

A flexible board, for forming a package, comprises a body portion, a big bottom piece, a small bottom piece, a left-side bottom piece, and a right-side bottom piece. The body portion has a rear body piece, a left-side body piece, a front body piece, and a right-side body piece. The big bottom piece is connected to a lower side of the rear body piece. The small bottom piece is connected to a lower side of the front body piece, and has a strip piece, and first and second projecting pieces. The left-side bottom piece is connected to a lower side of the left-side body piece, and is formed with a cut-out section close to the first projecting piece. The right-side bottom piece is connected to a lower side of the right-side body piece, and is formed with a cut-out section close to the second projecting piece. The length of the insert piece is shorter than the distance between the first and second projecting pieces.

Owner:HOYA CORP

Automobile side body outer plate mould with double-layer sliding block structure

The invention provides an automobile side body outer plate mould with a double-layer sliding block structure. The automobile side body outer plate mould comprises a double-layer sliding block structure. The double-layer sliding block structure slides in a lower mould seat according to different directions, side flanging is completed through working of the double-layer sliding block structure and flanging embedded parts on an up-down movement sliding block during working, and the double-layer sliding block structure includes a sliding block and a secondary sliding block. The sliding block is arranged in the lower mould seat and fixed to the lower mould seat by relying on a pressing plate, and a side sliding plate installed on the side face is matched with a sliding guide face on the lower mould seat for sliding guide. The secondary sliding block is installed in front of the sliding block and does movement in the sliding block by relying on the pressing plate, a sliding plate and the side sliding plate. According to the automobile side body outer plate mould with the double-layer sliding block structure, the structure with the double-side sliding blocks and a material pressing plate which is provided with the slides is adopted, elusion of side body outer plate avoiding angles is achieved, and forming of side flanging on the same mould is completed; the development cost of the mould is lowered by the structure, 2,600,000 yuan is totally reduced for the development cost of the left and right side body outer plate mould, the occupied area of the stamping workshop area is saved, working efficiency is improved, and the accuracy requirement for automobile assembling is met.

Owner:LIUZHOU TONGWEI MACHINERY

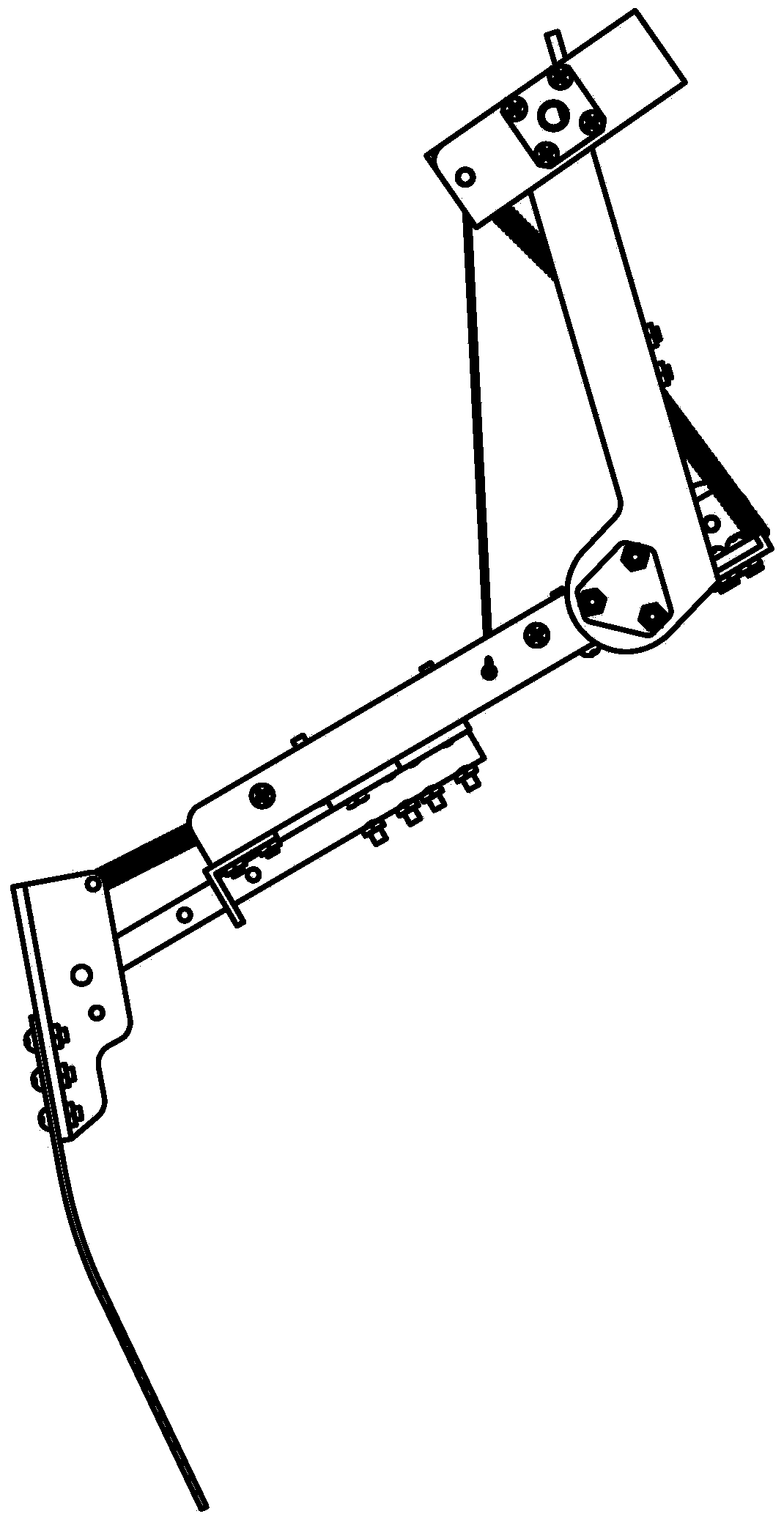

Car side body overturning lifting appliance

InactiveCN103693550AReduce labor intensityReduce labor costsLifting devicesLoad-engaging elementsUltimate tensile strengthCantilever

The invention discloses a car side body overturning lifting appliance. A side body limitation plate is arranged on the left end of a lifting appliance main body; a side body bearing block is arranged on the right end of the lifting appliance main body; the side body limitation plate and the side body bearing block are placed under the lifting appliance main body and are perpendicular to the lifting appliance main body; a side body clamping groove which is communicated from front to back and permits the upper edge of a side body door frame to be inserted into is formed in the left side body of the side body bearing block; when the upper edge of the door frame of the side body is inserted into the side body clamping groove, the upper edge of the side body is just pressed by the right side body of the side body limitation plate; a side body moving prevention pin matching with a side body process hole is fixedly arranged under the lifting appliance main body; a cantilever is slantways arranged above the lifting appliance main body; the left lower end of the cantilever is connected with the top of the right end of the lifting appliance main body; the right upper end of the cantilever is provided with a flying ring. By adopting the car side body overturning lifting appliance, lifting and automatic overturning of the side body are achieved, the car body can be lifted up and overturned to be an upright state from a side overturning state on a final work position, the labor intensity is greatly reduced, the human cost is reduced, and the car side body overturning lifting appliance is simple in structure and low in manufacturing cost.

Owner:力帆科技(集团)股份有限公司

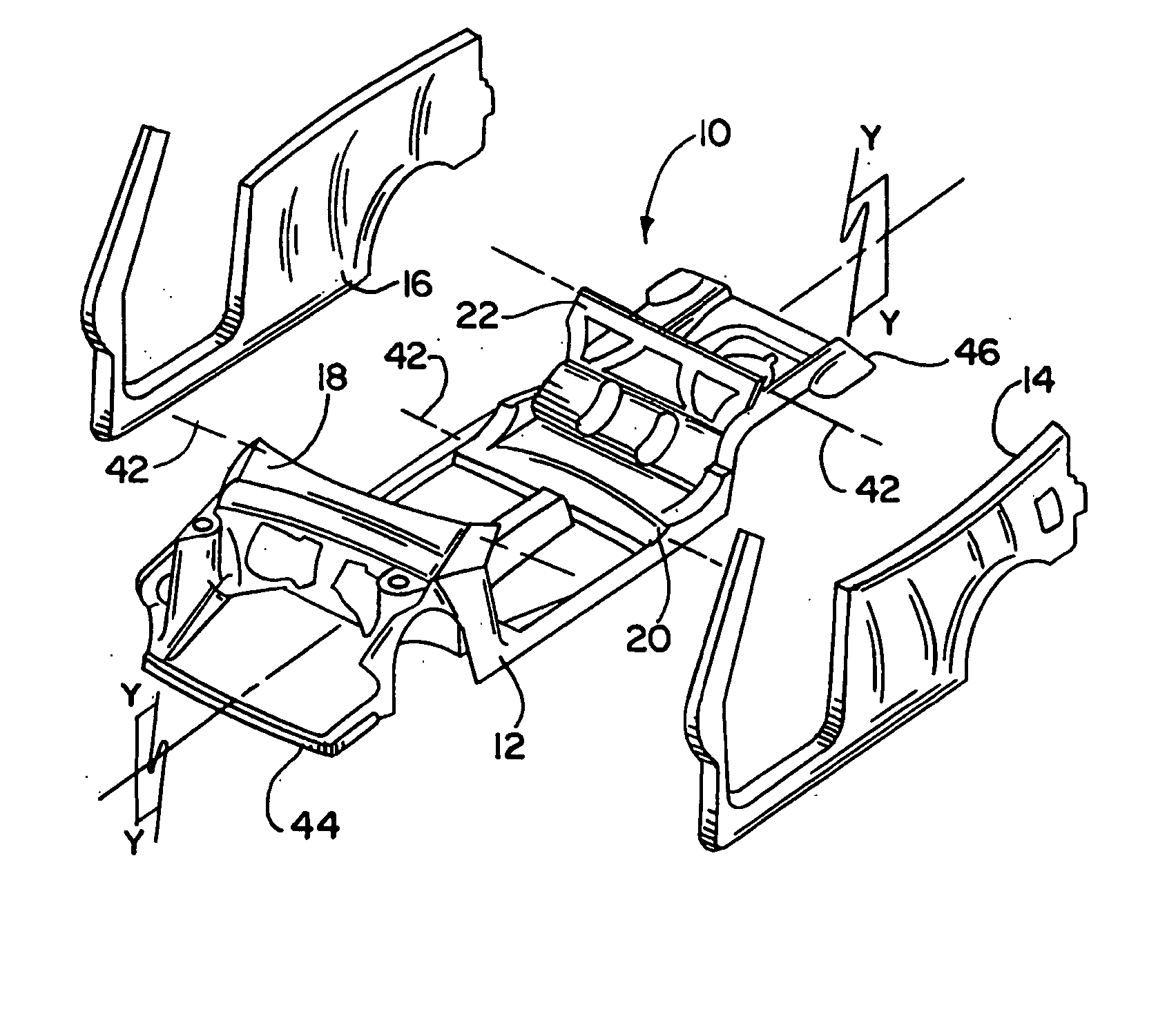

Convertible vehicle uni-body having an internal supplemental support structure

A vehicle body includes an underbody having one or more underbody bolting flanges attached thereto, with each underbody bolting flange being adapted for bolted attachment to a mating bodyside bolting flange. Left and right bodyside subassemblies are joined to the underbody, with each bodyside including a supplemental bodyside support structure having attached thereto one or more bodyside bolting flanges, with each bodyside bolting flange being adapted for bolted attachment to one of the underbody bolting flanges after the bodyside subassemblies are otherwise joined to the underbody. The underbody bolting flanges are attached to supplemental cross members that are attached to and extend across the underbody.

Owner:FCA US

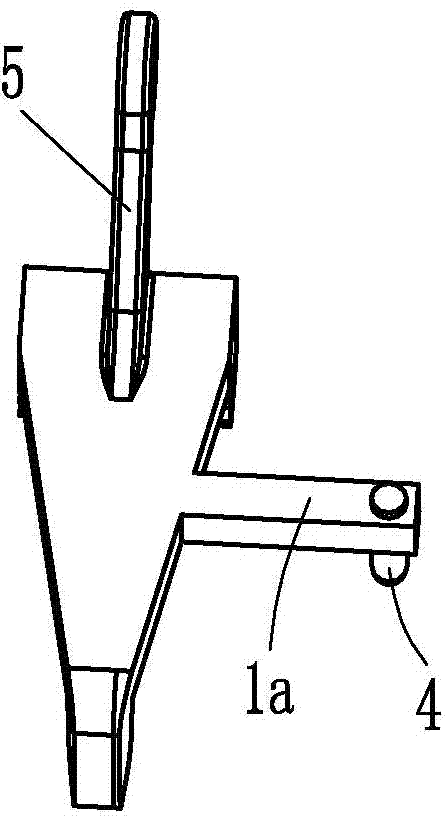

Back door ancillary supporting tool

InactiveCN108527213AAvoid natural saggingAvoid manual supportWork holdersMetal-working hand toolsSoftware engineeringBack door

The invention discloses a back door ancillary supporting tool which comprises a bottom supporting assembly, a left side body supporting assembly and a right side body supporting assembly. The bottom supporting assembly comprises a limiting supporting block, a transferring block and a bottom supporting block which are sequentially and fixedly connected from top to bottom; and the bottom supportingassembly is supported between the bottom of a back door and the tail of a car side body, the left side body supporting assembly comprises a left supporting block and a left positioning block which arefixedly connected and is supported between the left side of the back door and the left side of the car side body, and the right side body supporting assembly comprises a right supporting block and aright positioning block which are fixedly connected and is supported between the right side of the back door and the right side of the car side body. According to the back door ancillary supporting tool, a gap between the back door and the side body is kept through the bottom supporting assembly, the left side body supporting assembly and the right side body supporting assembly, natural falling ofthe back door due to gravity is avoided, the actual installing state of the back door is simulated, the accuracy and the stability of the assembly size are effectively guaranteed, manual supporting of the back door through a worker is avoided, and the working efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

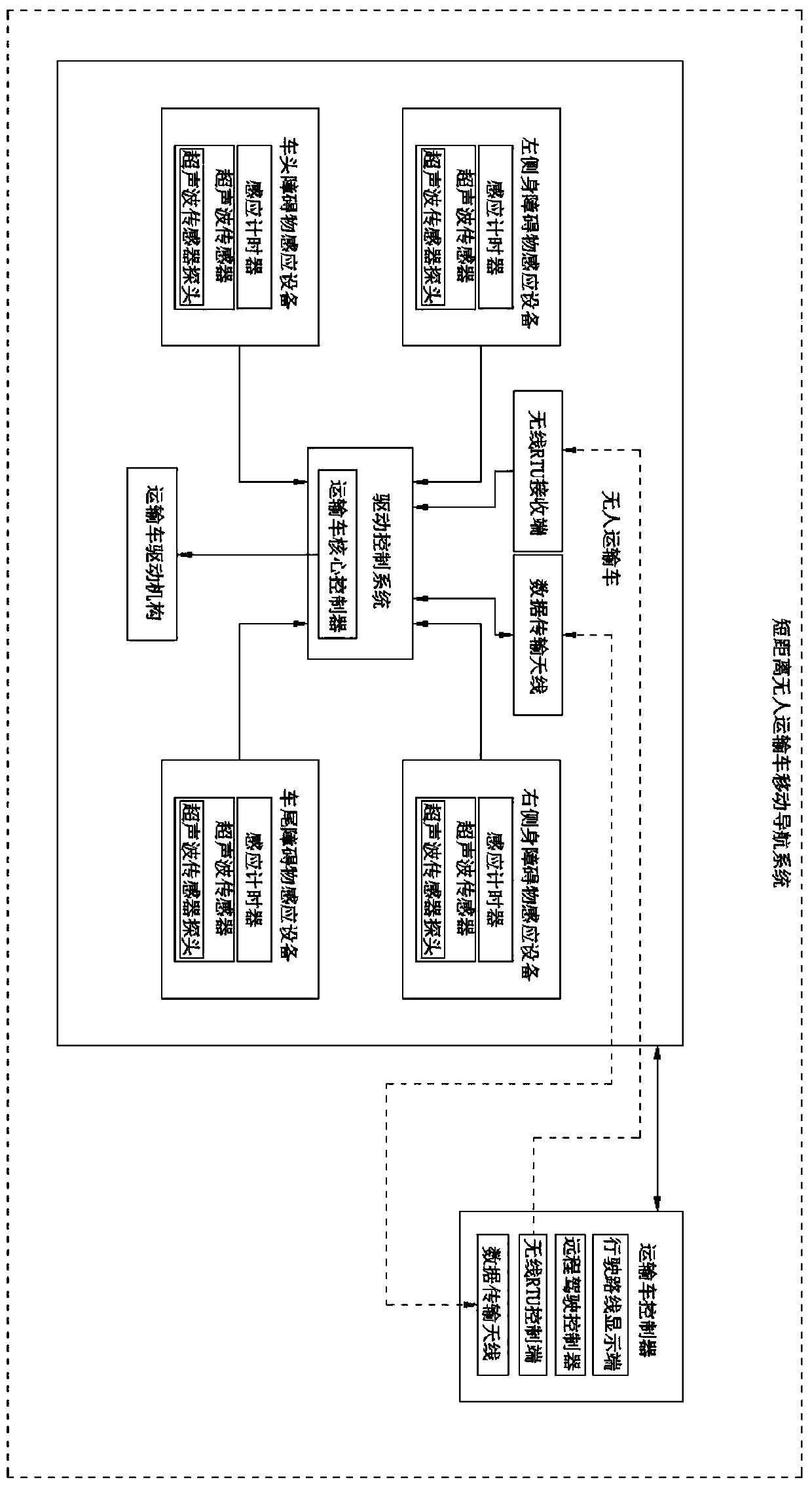

Ultrasonic navigation system

InactiveCN110244726AEasy to changeConvenient wireless connectionPosition/course control in two dimensionsNavigation systemMarine navigation

The invention relates to the technical field of ultrasonic navigation, and discloses an ultrasonic navigation system. The ultrasonic navigation system comprises an unmanned transport vehicle and a transport vehicle controller; the two sides of a vehicle body of the unmanned transport vehicle are provided with a left side body barrier sensing device and a right side body barrier sensing device respectively; and the vehicle head part of the unmanned transport vehicle is provided with a vehicle head barrier sensing device. By means of the barrier sensing devices, whether barriers exist around the transport vehicle or not can be sensed through an ultrasonic sensing principle conveniently; the transport vehicle can conveniently change a running route; a control end can better control the unmanned transport vehicle; whether the unmanned transport vehicle deviates from an initial running track or not can be well monitored; the normal running route of the unmanned transport vehicle can be corrected in time conveniently; the advantages of ultrasonic navigation running and transportation are achieved; and the problems that cargo transportation is easily delayed and safety accidents are easily caused because an existing unmanned transport vehicle, in a transportation process, cannot distinguish the barriers on the running route are solved.

Owner:安徽永顺信息科技有限公司

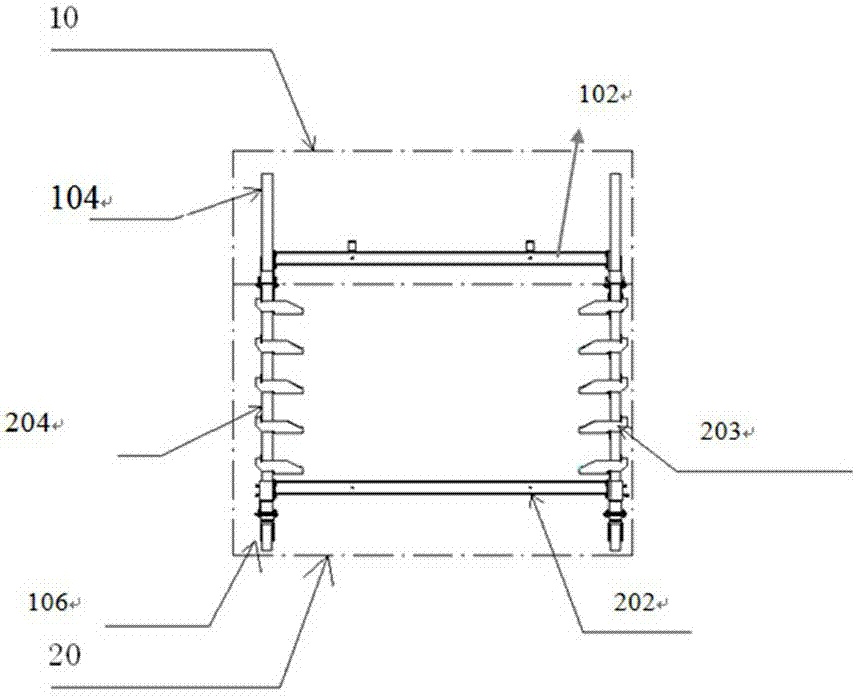

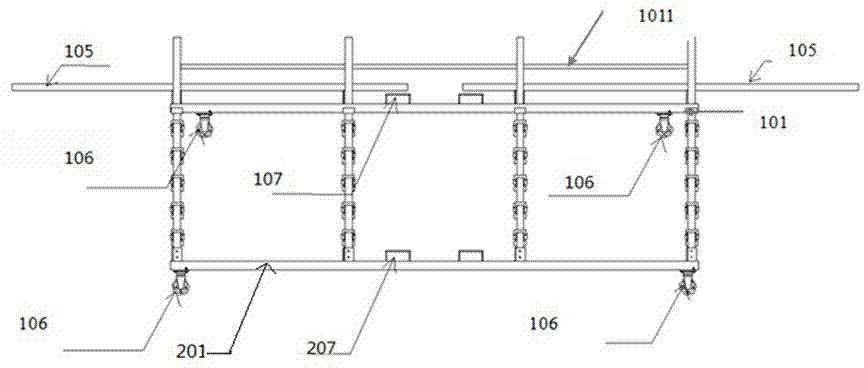

All-aluminum bus detachable transport bracket

ActiveCN104326178ARealize the transport functionEasy to work at low positionsPackaging vehiclesContainers for machinesTransit busRight side body

The invention discloses an all-aluminum bus detachable transport bracket. The transport bracket comprises a transport bracket upper layer structure for storing left and right side body products of a bus, and a transport bracket lower layer structure for storing top cover products of the bus, wherein the transport bracket upper layer structure can be overlapped on the transport bracket lower layer structure. A vertical overlapping form is adopted, and the transport bracket can be detached into single small portions after transportation, so that the occupied space is small, a plurality of sets of transport frames can be transported at a single time, and the transportation cost and material cost are reduced; meanwhile, the transport bracket can be used for realizing the transportation functions of a plurality of vehicles through a fine adjusting structure in a simple and convenient way.

Owner:苏州奥杰汽车工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com