SUV (Sport Utility Vehicle) vehicle automatic welding production line and production method thereof

A technology for automated welding and production methods, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding quality and precision, and achieve the effect of unmanned operation, high production efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

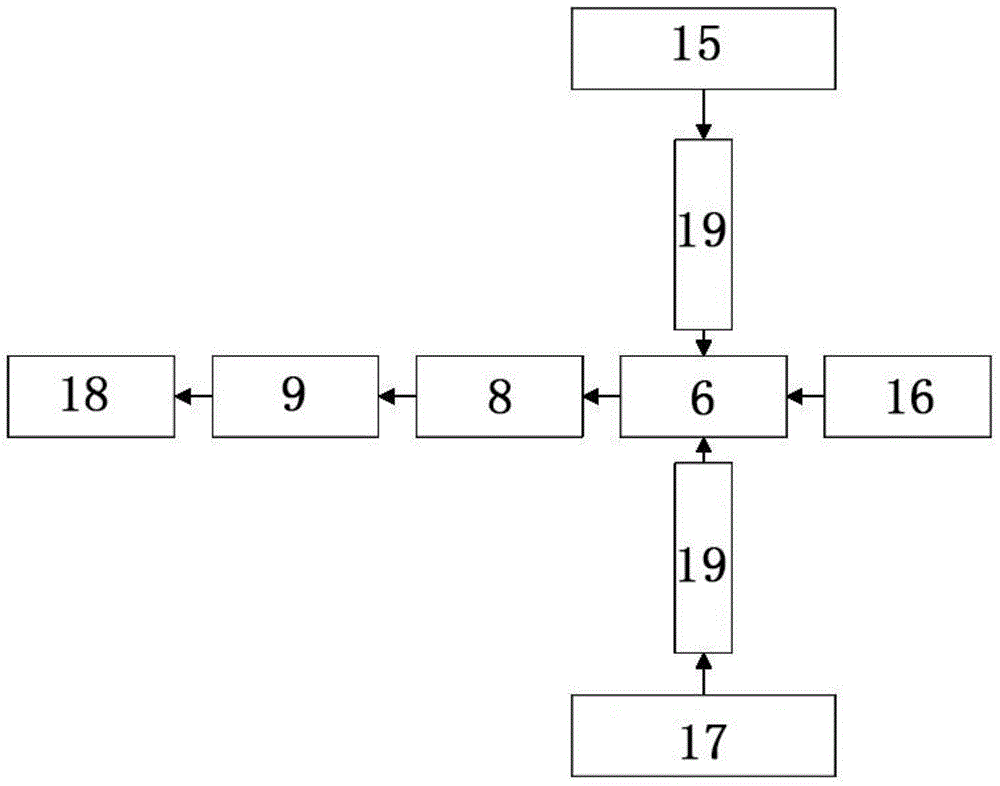

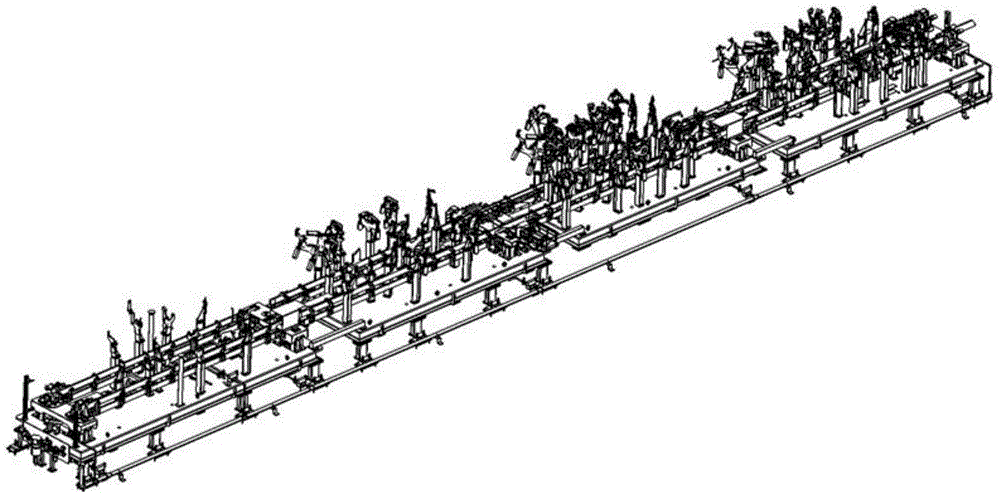

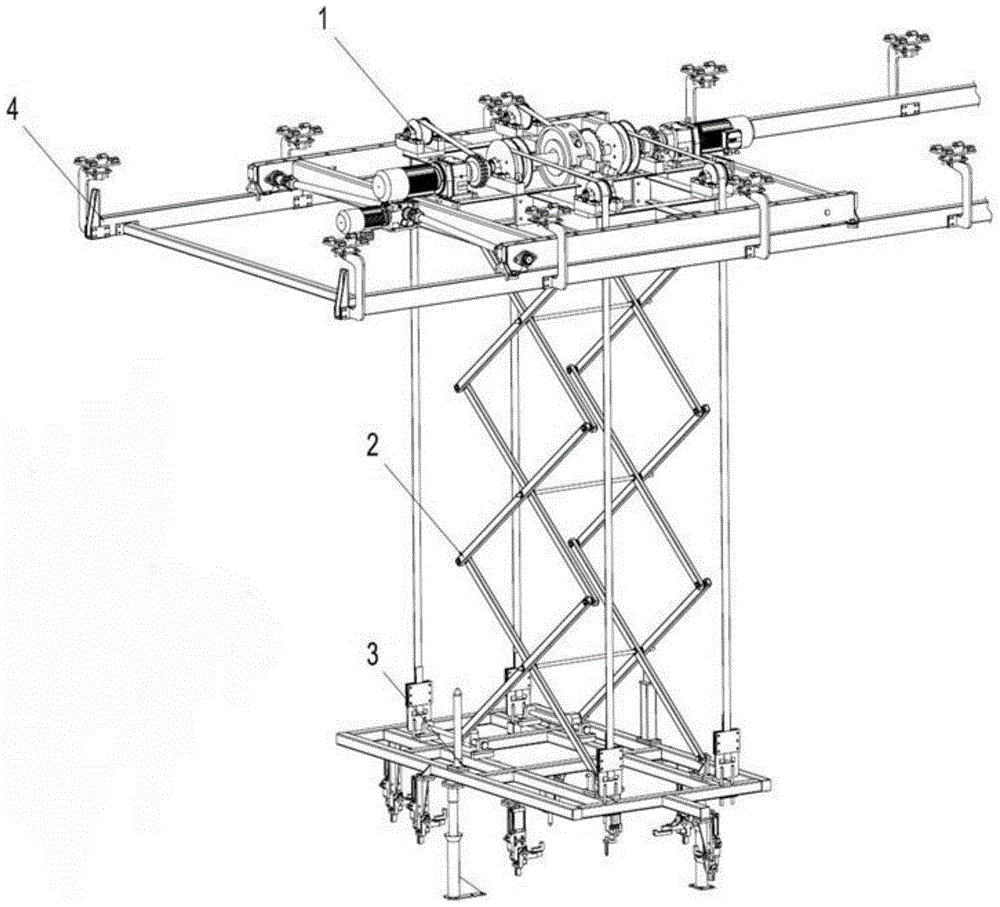

[0026] The SUV automatic welding production line realizes the unmanned operation of the entire SUV body-in-white automatic production line by controlling multiple robots to coordinate operations and cooperate with specific fixtures for clamping. The welding robot automatically welds. figure 1 It is a schematic diagram of the overall layout of the entire SUV automatic welding production line. In the figure, the lower car body conveying roller bed is located at the fifth station, the assembly station is the first station, the first repair welding station is the second station, and the second The repair welding station is the third stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com