Lightweight electric vehicle body skeleton

A lightweight technology for electric vehicles, applied to vehicle components, superstructures, superstructure subassemblies, etc., can solve problems such as low energy storage density of power batteries, low effective load efficiency, and large battery pack volume, and achieve consensus The advantages of high performance and light weight, guaranteed forming quality and connection reliability, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

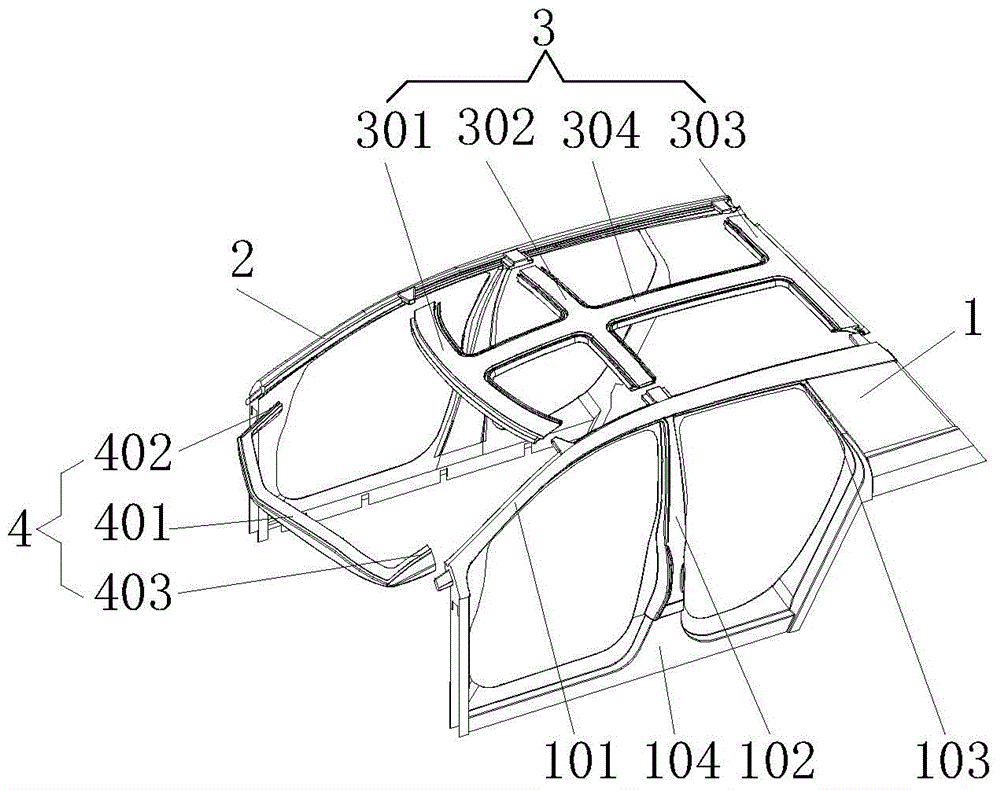

[0040] Such as figure 1 Shown is a lightweight electric vehicle body frame, the body frame is made of carbon fiber material, and is designed and produced using the design method of "four blocks and eight small pieces".

[0041] The four blocks are the left body frame 1, the right body frame 2, the roof 3 and the front glass bracket 4. The left body frame 1 and the right body frame 2 pass through the roof 3 and the front glass bracket 4 respectively. Gluing and bolt fastening are assembled to obtain a space-cage tubular body frame.

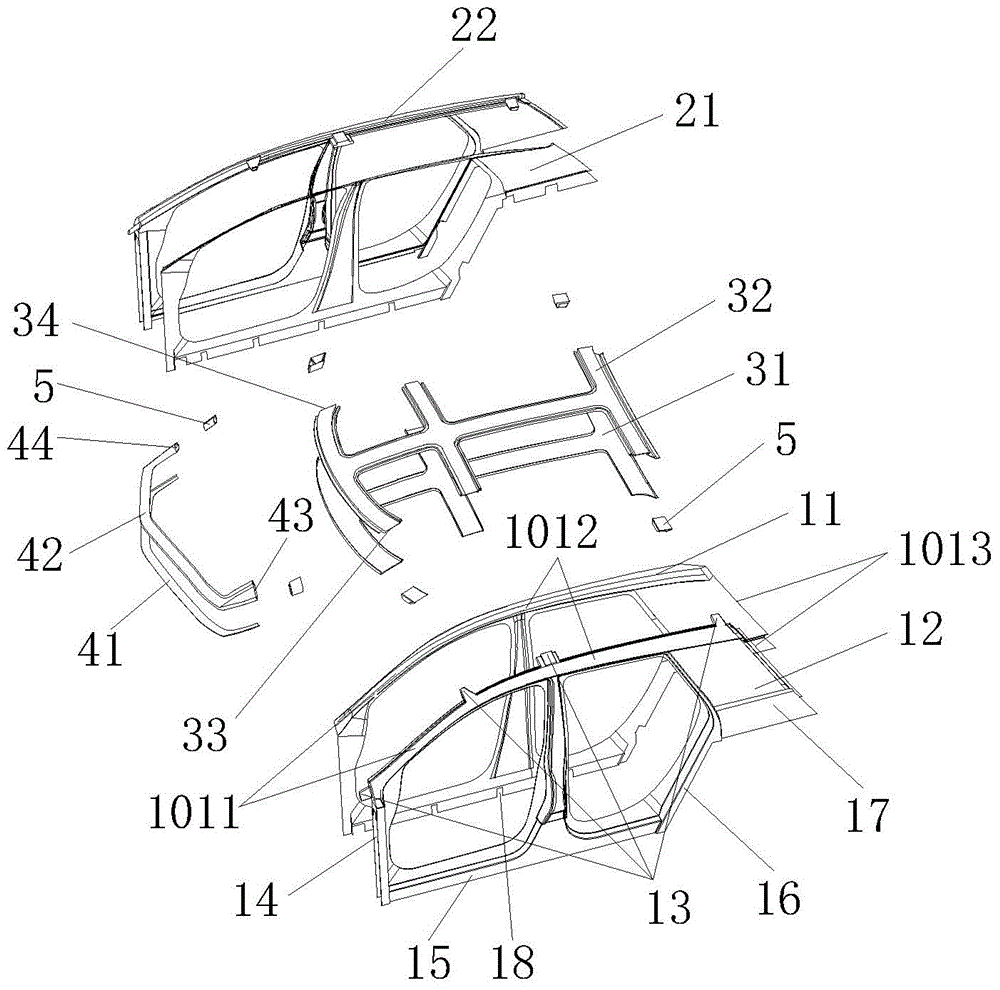

[0042] The eight small pieces are obtained by dividing each of the four major blocks into two pieces, the inner and outer pieces, with the edge area as the parting surface, as shown in figure 2 As shown, the left body frame 1 is divided into a left inner body piece 11 and a left outer body piece 12, the right side body frame 2 is divided into a right inner body piece 21 and a right outer body piece 22, and the roof 3 is divided into The inner ro...

Embodiment 2

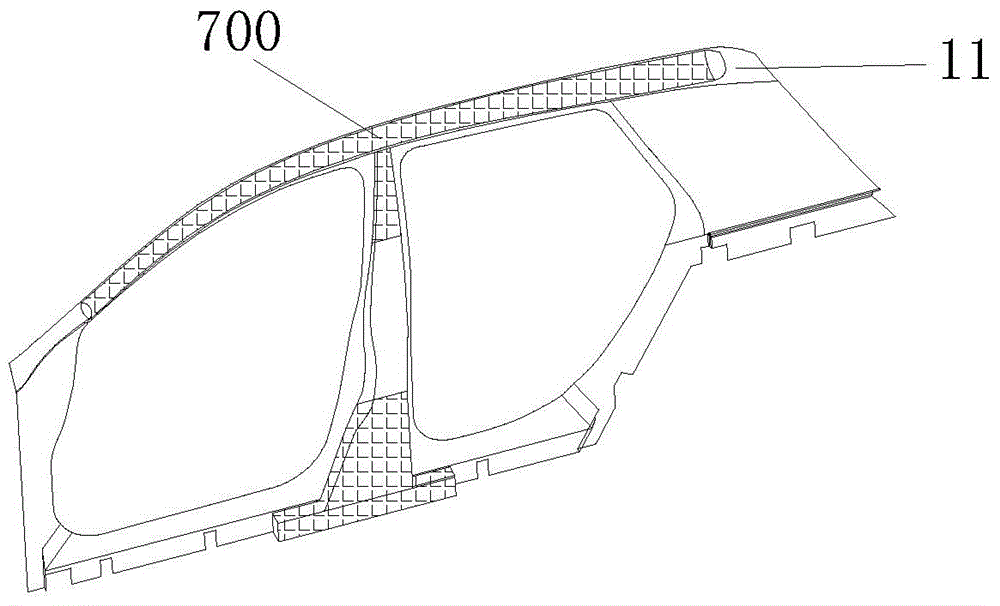

[0057] Such as image 3 As shown, on the basis of the first embodiment, this embodiment adopts the method of thickening the layup 700 to require higher load-bearing positions, such as the "A" pillar 101, the "B" pillar 102 and the bottom "mountain" character structure 104 , for local reinforcement. The feature of this scheme is that in the process of product layup, the local reinforcement area is reasonably selected and designed, and in the process of carbon fiber layup, the purpose of increasing the overall strength of the area is achieved by increasing the number of carbon fiber cloth layers. The advantage of this scheme is that detailed design is carried out in the production process, the operation is simple and the enhancement effect is obvious.

Embodiment 3

[0059] Such as Figure 4 As shown, on the basis of the first embodiment, this embodiment adopts the method of adding a partition 800 to a higher load-bearing position, such as the "A" pillar 101, the "B" pillar 102 and the bottom "mountain" character structure 104, Do local reinforcement. The feature of this solution is that after the product layering is completed, between the inner and outer slices of the hollow area, reinforcement is carried out by arranging partitions 800 to play the role of internal reinforcement. The material of the partition 800 can be hard materials such as carbon fiber, and the partition can be in the form of interlaced vertical and horizontal plates. This solution can greatly improve the overall rigidity, strength and crashworthiness of the hollow structure, but requires additional partition processing and staggered design.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com