Patents

Literature

31results about How to "Strength advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

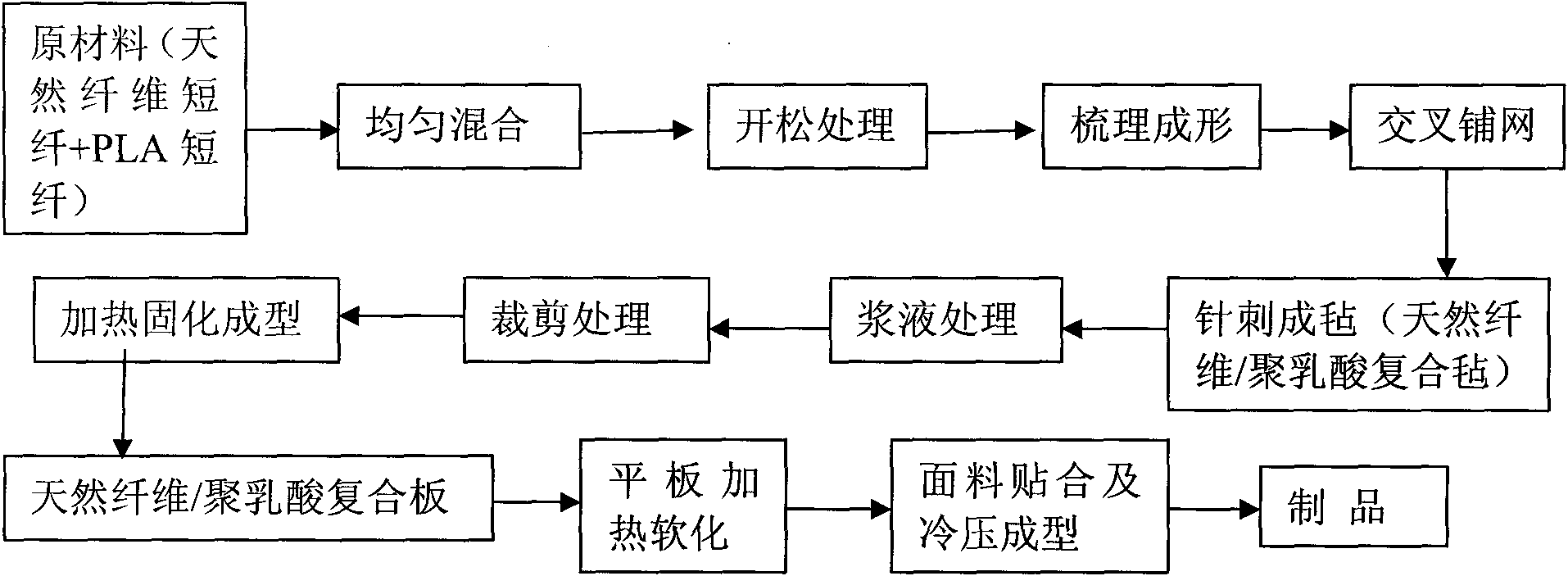

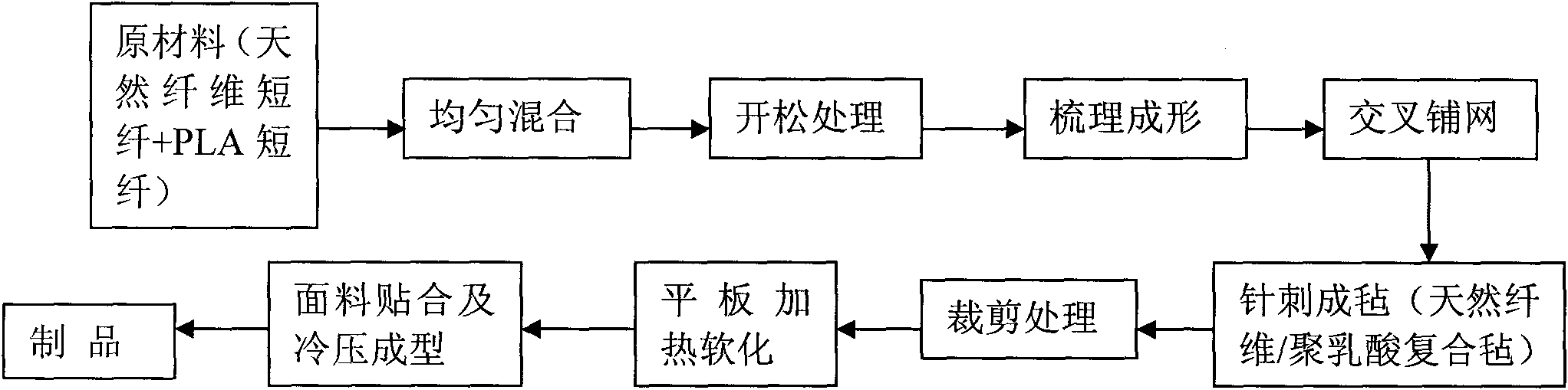

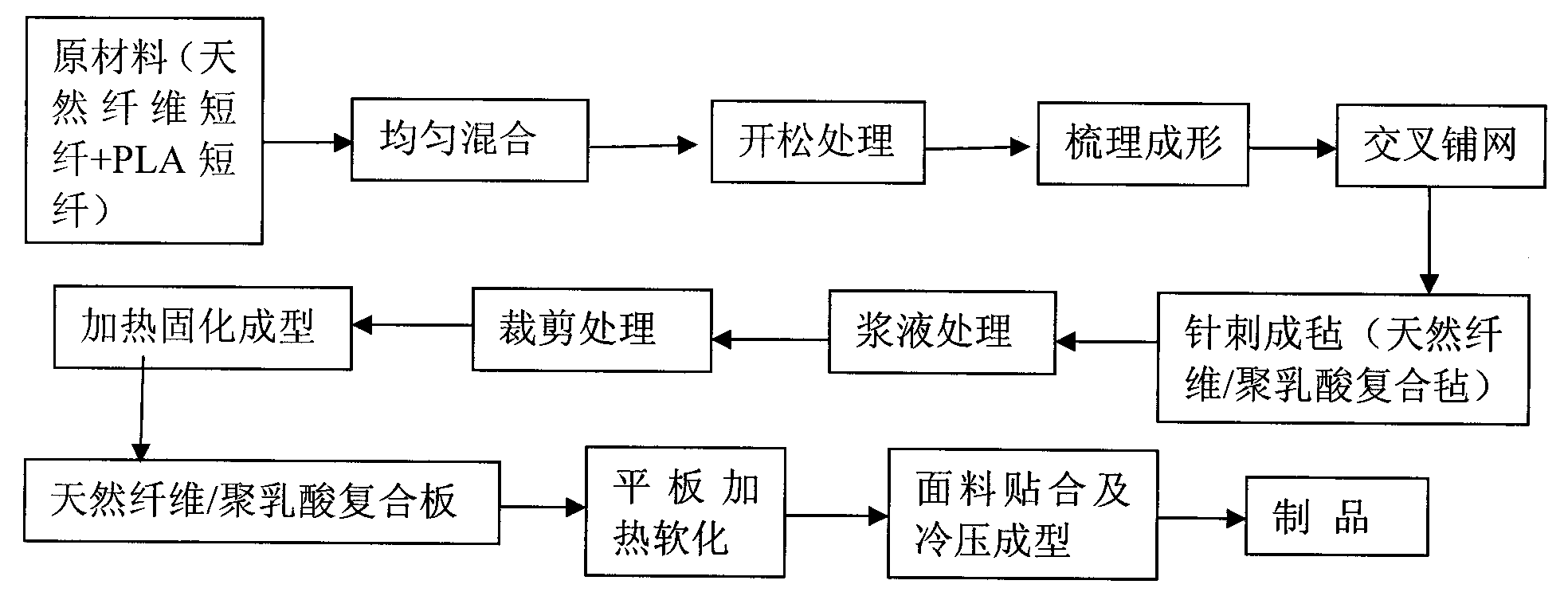

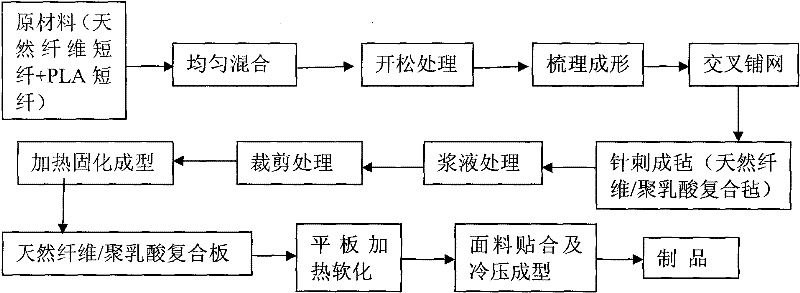

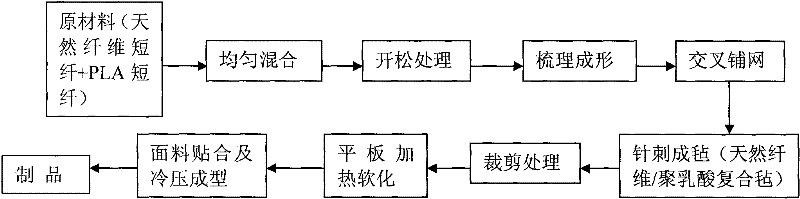

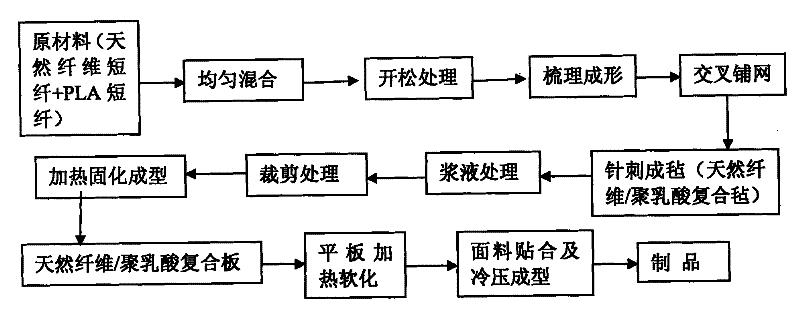

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

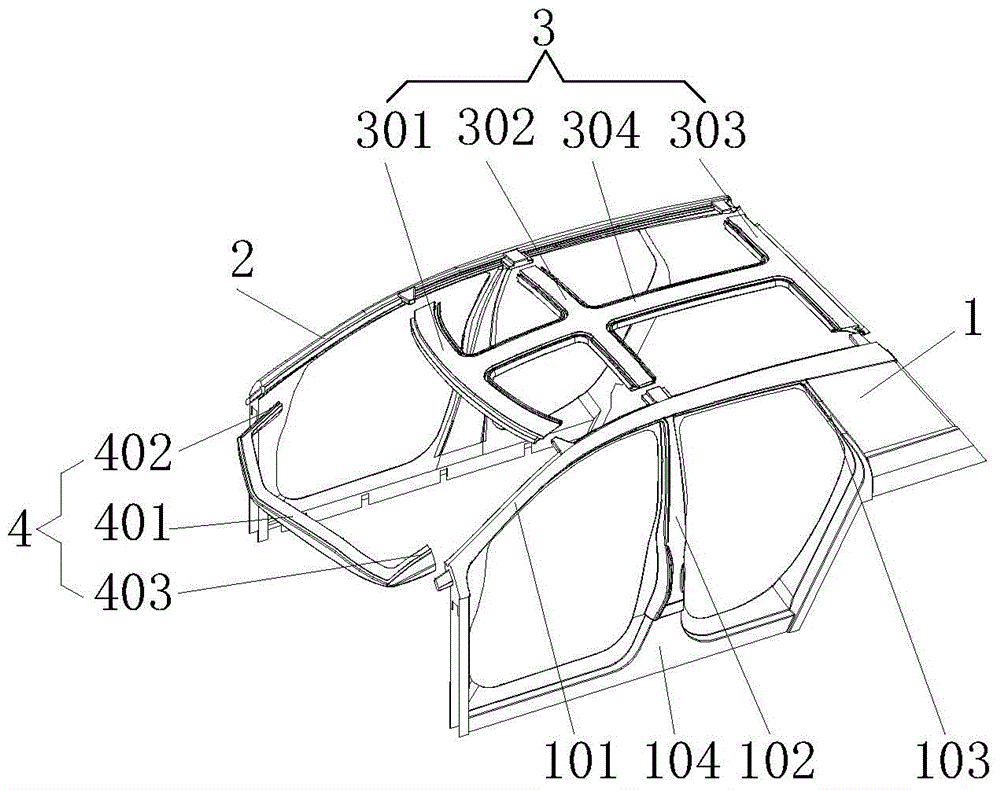

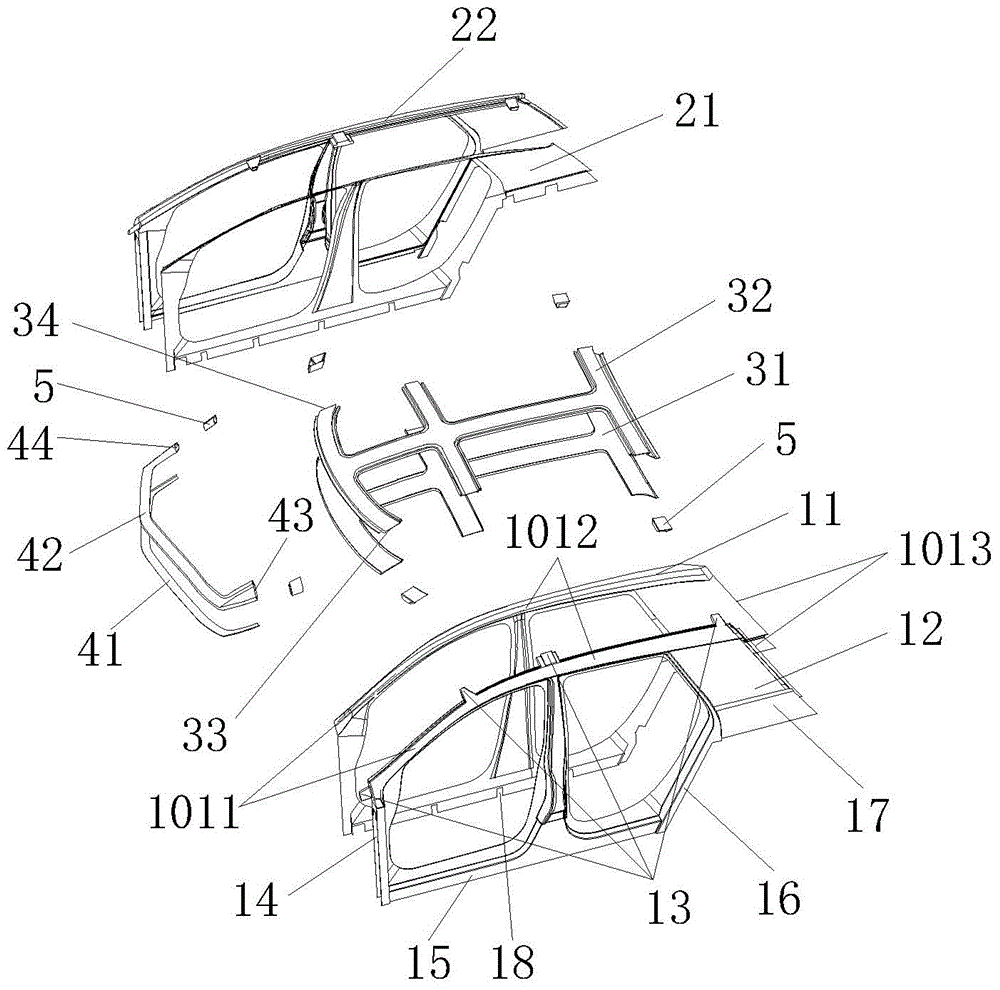

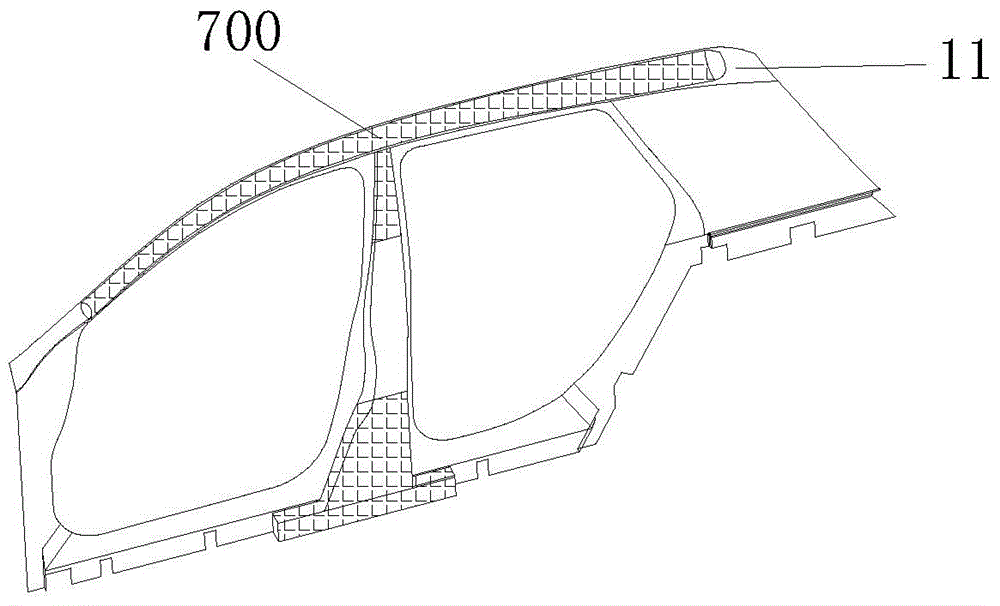

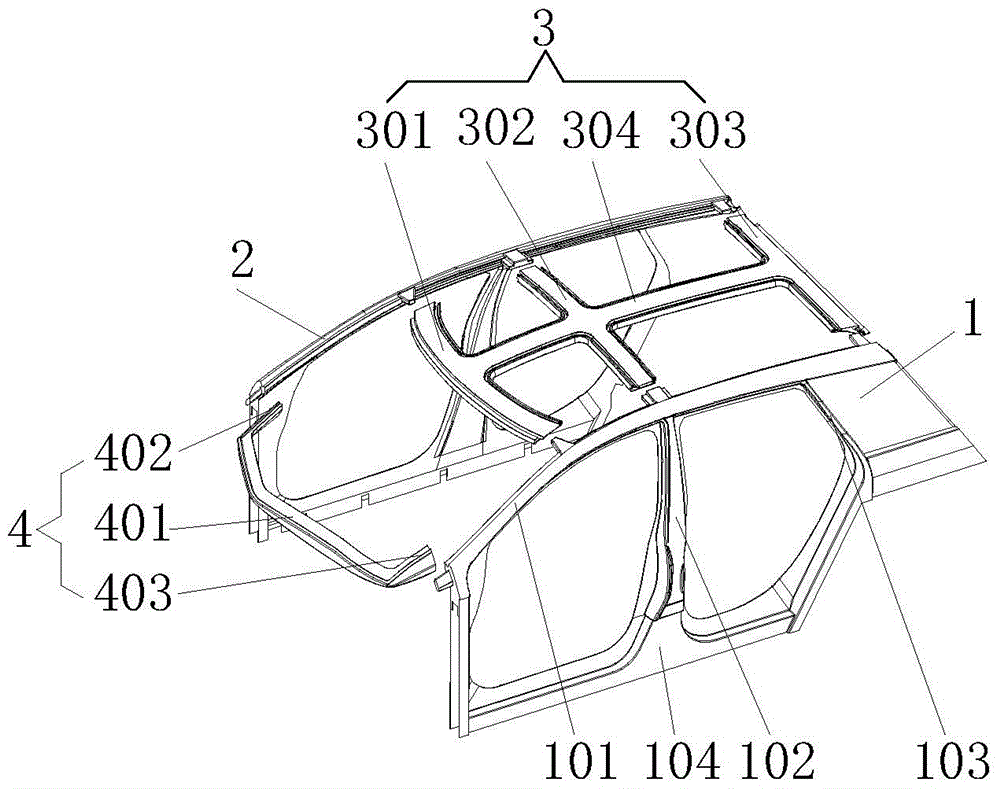

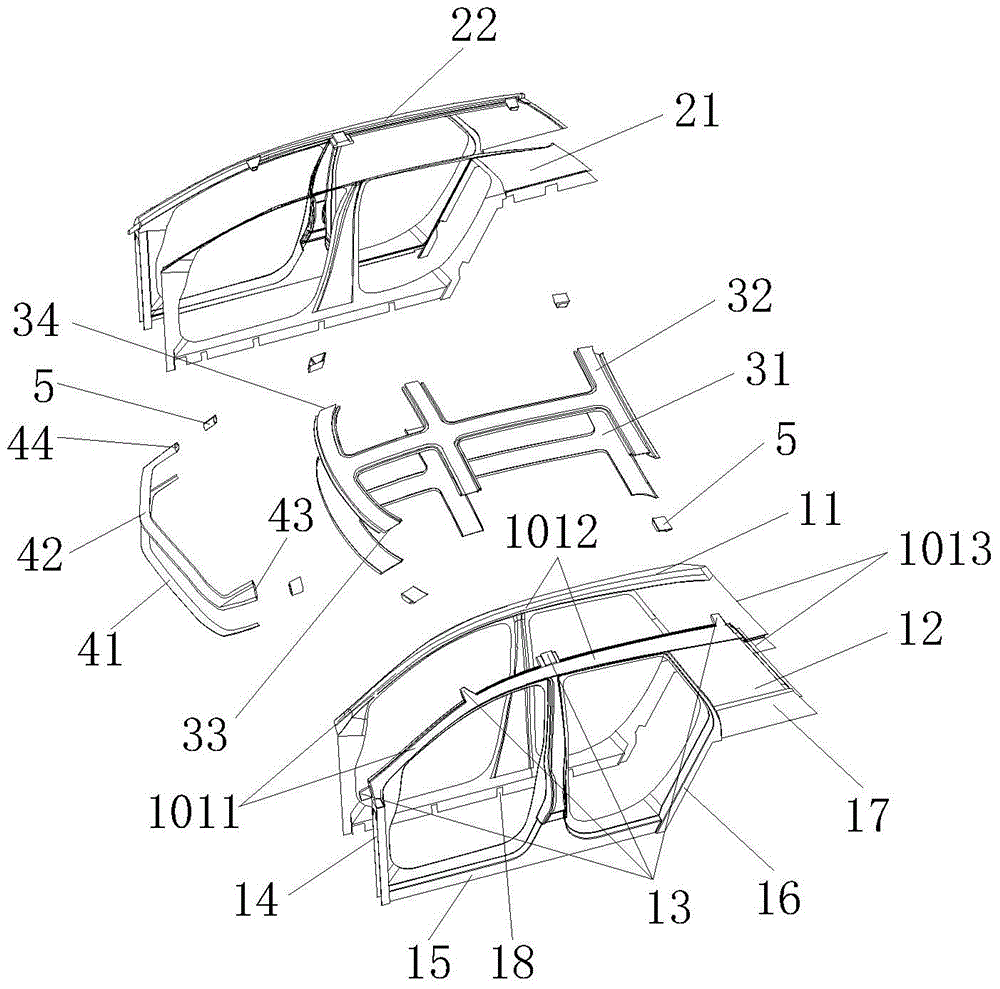

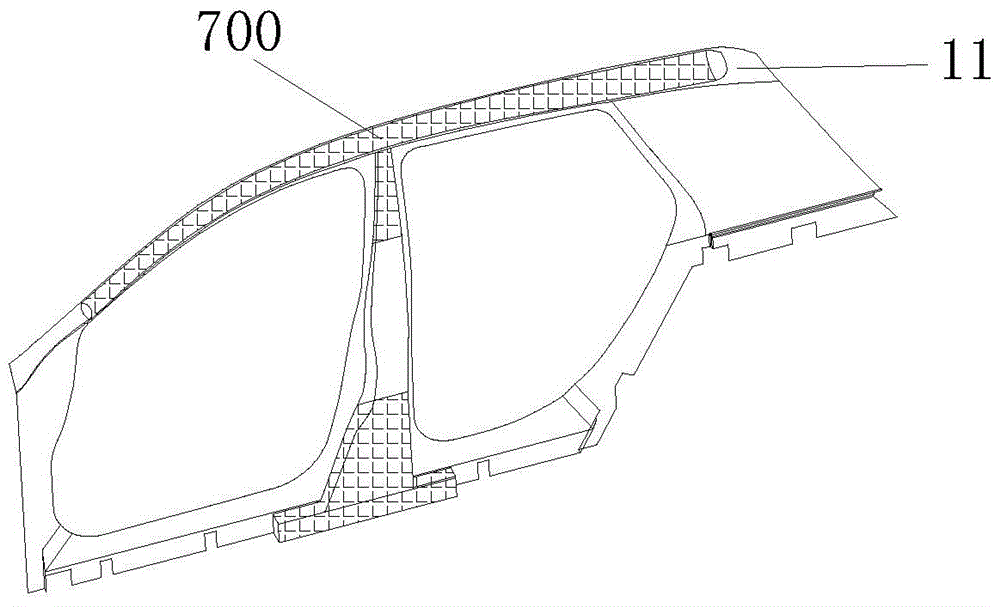

Lightweight electric vehicle body skeleton

InactiveCN103979016AHigh strengthEasy to processSuperstructure subunitsSpatial structureElectric vehicle

The invention relates to the technical field of electric vehicles, in particular to a lightweight electric vehicle body skeleton, which comprises a left side body frame, a right side body frame, a roof and a front glass bracket which are all made of carbon fiber reinforced composite materials, wherein the left side body frame and the right side body frame are respectively assembled with the roof and the front glass bracket in a cementing manner and a bolt fastening manner to form a space cage-shaped tubular body skeleton, each of the four large blocks takes an edge combining area as a piece dividing line and is further divided into an inner piece and an outer piece, and the inner pieces and the outer pieces are connected at the edge combining areas in a cementing manner. The application form of composite materials to the vehicle body is improved from the past single sided board into a double sided tubular space structure, a passenger protecting area is designed into a space cage-shaped skeleton structure, the overall strength of the body skeleton is improved through utilizing the structure characteristics of tubular columns and topological spaces, in addition, the forming efficiency is also considered by adopting the four-large-block and eight-small-piece designing method, and the forming quality is also effectively ensured.

Owner:INST OF DONGGUAN SUN YAT SEN UNIV +1

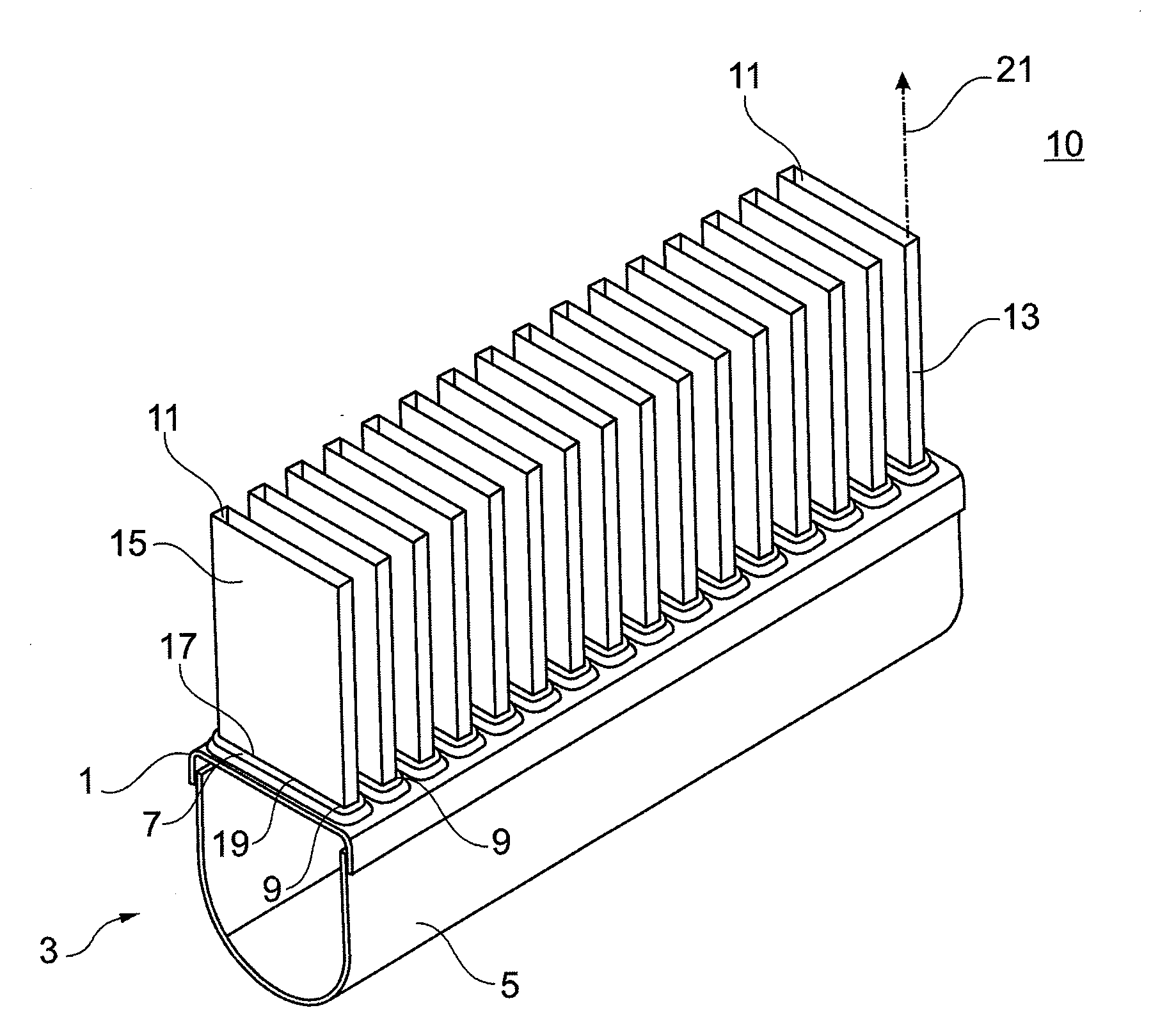

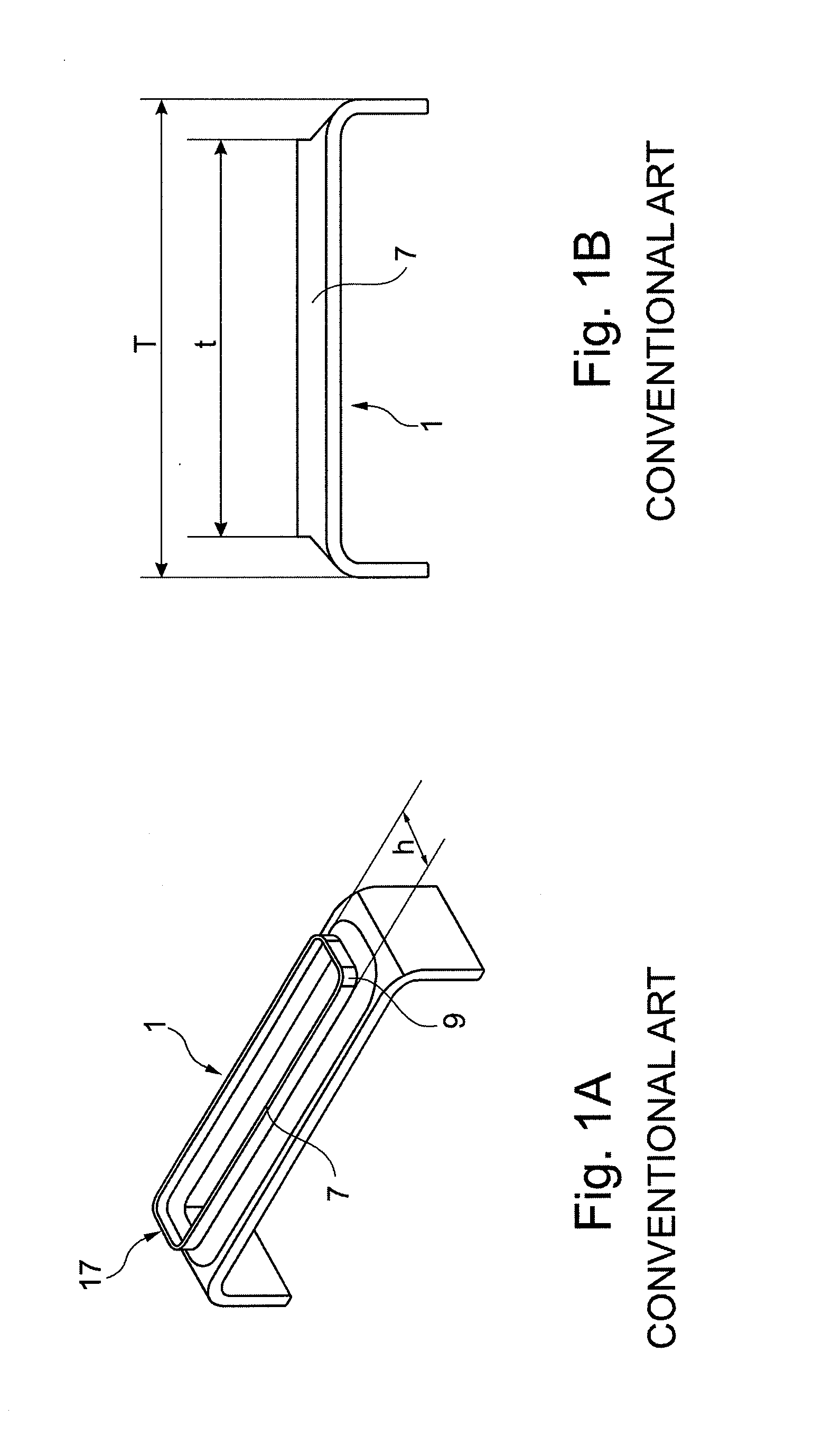

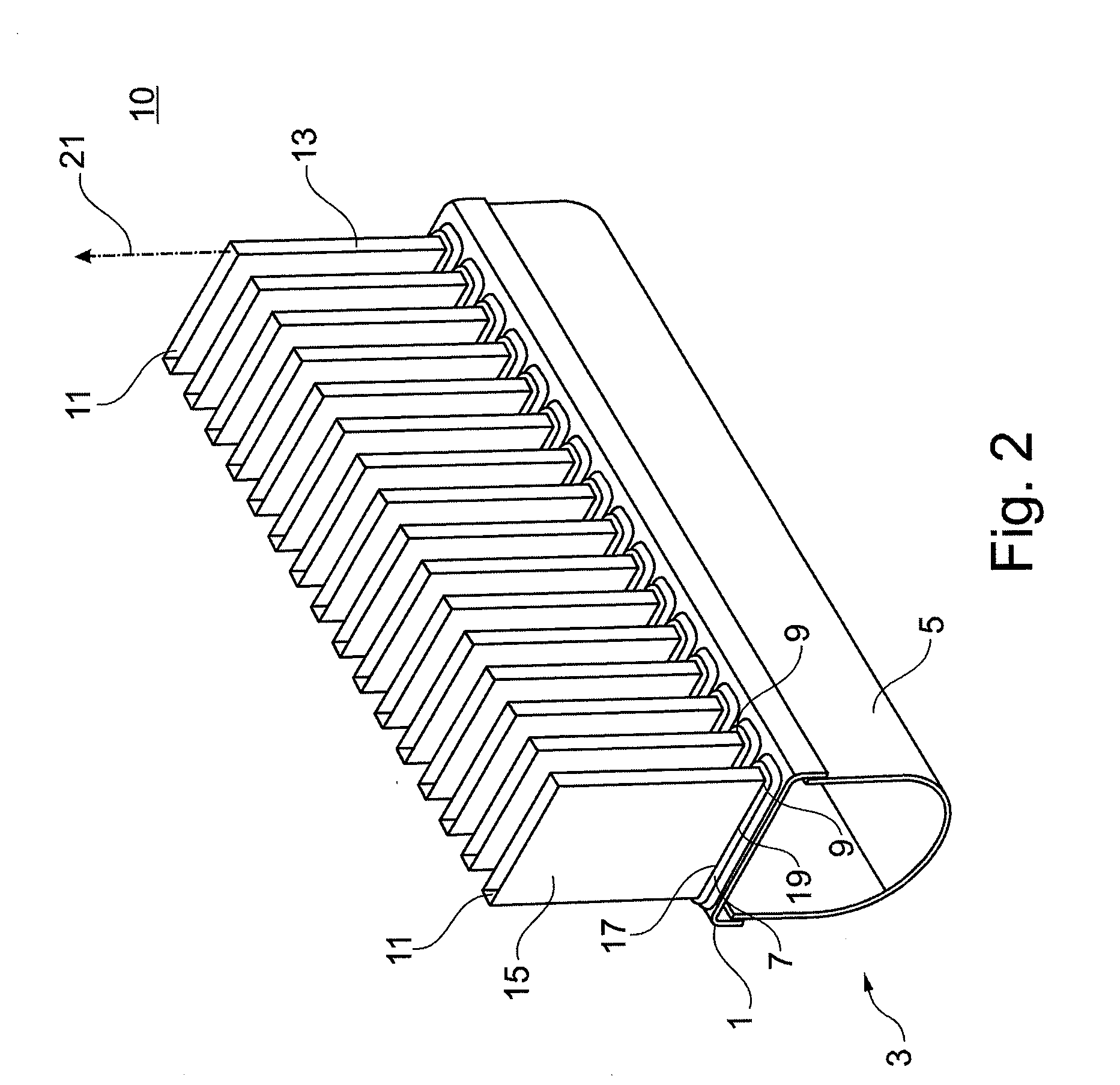

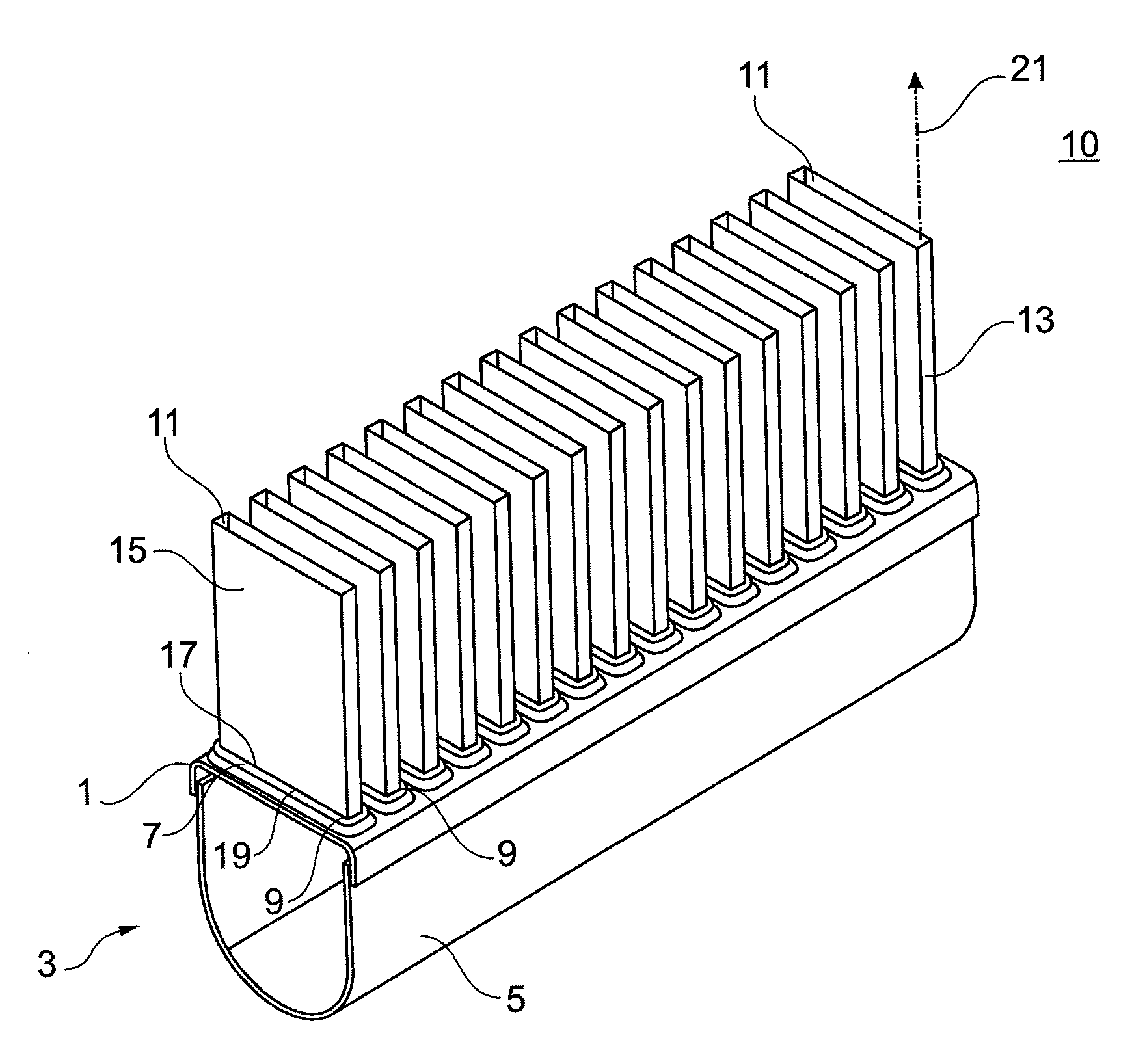

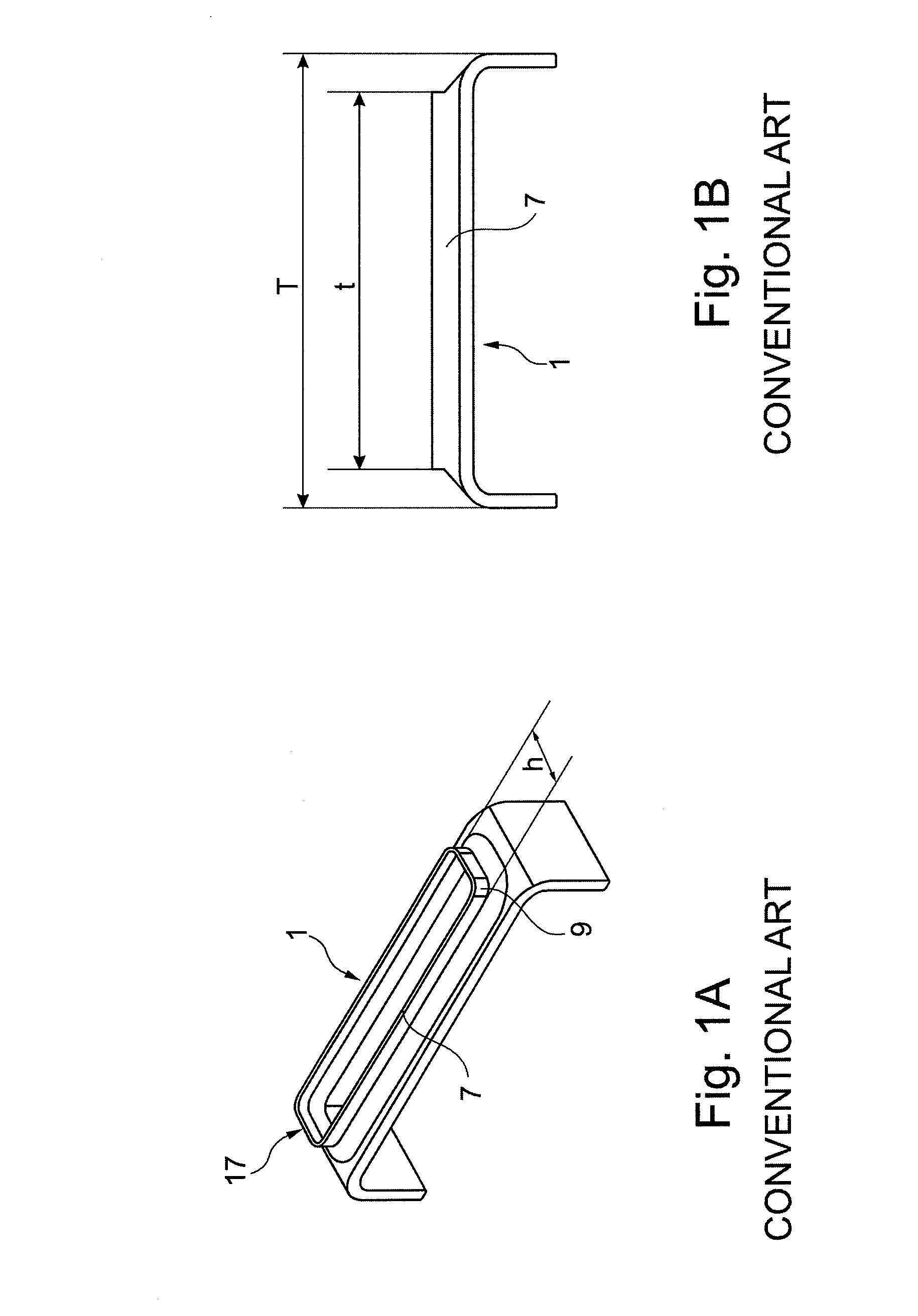

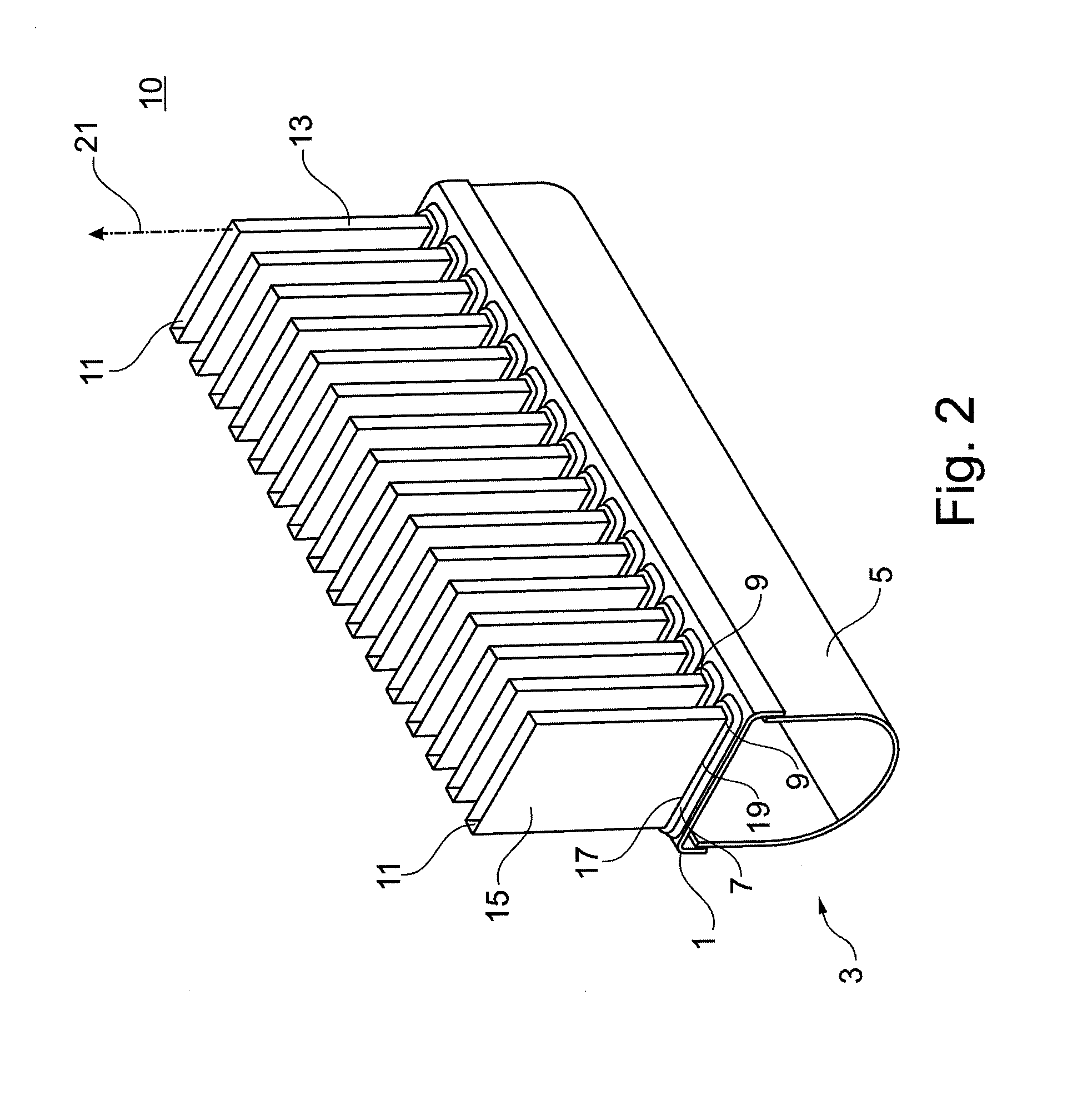

Heat exchanger, use, and manufacturing process for a heat exchanger

ActiveUS20100038063A1Increased durabilityStrength advantageMetal-working apparatusStationary conduit assembliesExhaust gasEngineering

A heat exchanger is provided for heat transfer between a first fluid, particularly charge air or an exhaust gas, and a second fluid, particularly a coolant, which has: a block for the separated and heat-exchanging guiding of the first and second fluid, the block which has a number of flow channels through which the first fluid can flow, at least one box which is assigned to the block and is flow-connected to the flow channels, and at least one base, which is provided with one or with more through openings for feeding through the flow channels between the block and the box, whereby at least one through opening is formed as a passage with a collar. The invention provides that the collar has a near-bottom section and an end-side section, whereby a wall cross section of the end-side section is smaller than a wall cross section of the near-bottom section and between the near-bottom and end-side section at least one shoulder is disposed, which has a shoulder contour running transverse to the contour of the near-bottom section and / or the end-side section and whereby the end-side section is inclined away from a passage axis. A use and manufacturing process are also provided.

Owner:BEHR GMBH & CO KG

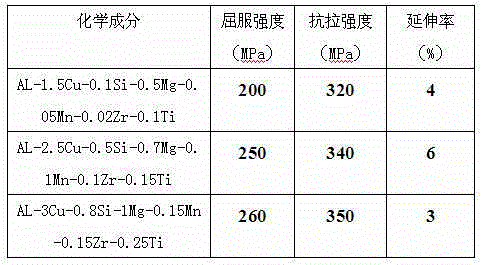

High-strength cast aluminum and preparing method thereof

The invention discloses high-strength cast aluminum alloy. The high-strength cast aluminum alloy comprises, by weight, 1%-3% of Cu, 0.1%-1% of Si, 0.15%-1.5% of Mg, 0.05%-0.2% of Mn, 0.02%-0.2% of Zr, 0.1%-0.3% of Ti and the balance aluminum and other impurity elements. The content of the other impurity elements is smaller than 0.005%. After pure aluminum is molten, corresponding intermediate alloy is added according to the composition proportion, refining is conducted at the temperature of 740 DEG C by means of a specialized refining agent, the temperature is decreased to 730 DEG C after stirring is sufficiently conducted, and standing is conducted for 10 min. An Al-Ti-B modificator is used for modification. The high-strength cast aluminum alloy is adapted to the gravity casting process at the temperature of 20 DEG C; at the temperature of 20 DEG C, the tensile strength of a casting made of the high-strength aluminum alloy ranges from 320 Pa to 370 Pa, the yield strength of the casting ranges from 200 MPa to 260 MPa, the ductility ranges is 2%-6%, and the high-strength cast aluminum alloy can be applied to structural components, having requirements for material performance, in the industries such as the automobile industry and the communication industry. Compared with conventional copper alloy, the high-strength cast aluminum alloy has remarkable advantages on the aspect of strength.

Owner:苏州慧驰轻合金精密成型科技有限公司

High-strength high-toughness die-casting aluminum alloy and preparation method thereof

InactiveCN106319306AStrength advantageAdvantages of high strength and toughnessAluminiumMetallic materials

The invention belongs to the field of metal materials, and particularly relates to a high-strength high-toughness die-casting aluminum alloy and a preparation method thereof. The high-strength high-toughness die-casting aluminum alloy comprises the following components: 4.2-5.3wt% of Mg, 1.5-1.8wt% of Si, 0.14-0.22wt% of Mn, 0.12-0.25wt% of Cu, 0.05-0.08wt% of Ti and the balance of aluminum and other impurity elements, wherein the content of the impurity elements is less than 0.005%. According to the invention, the problems of the existing Al-Mg series alloy such as poor casting performance and low die-casting molding possibility are well solved. After the developed high-strength high-toughness die-casting aluminum alloy is naturally aged at 20 DEG C, the yield strength of a casting is 180-200 MPa, the tensile strength is 340-350 MPa, and the elongation percentage is 10-15%. The alloy can be used for spare parts having complicated shapes and high strength requirements in the automobile and communication industries; and compared with the conventional Al-Si and Al-Cu series alloys, the alloy provided by the invention has remarkable advantages in the aspect of toughness.

Owner:苏州慧驰轻合金精密成型科技有限公司

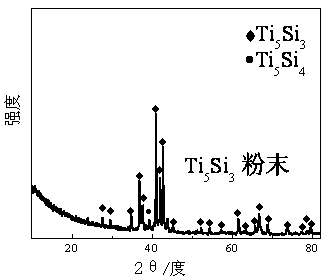

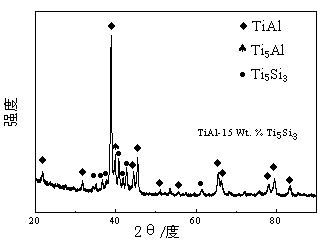

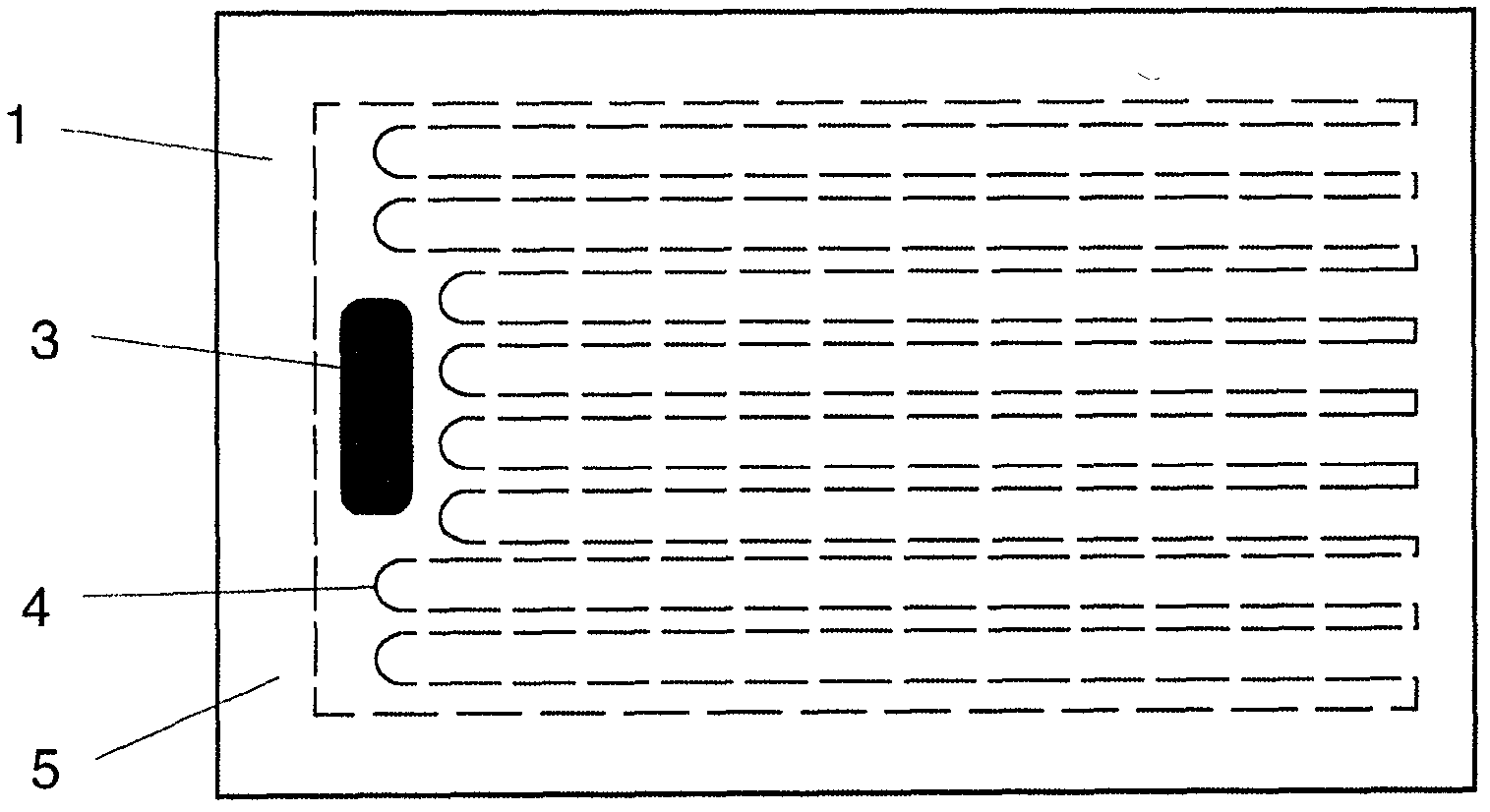

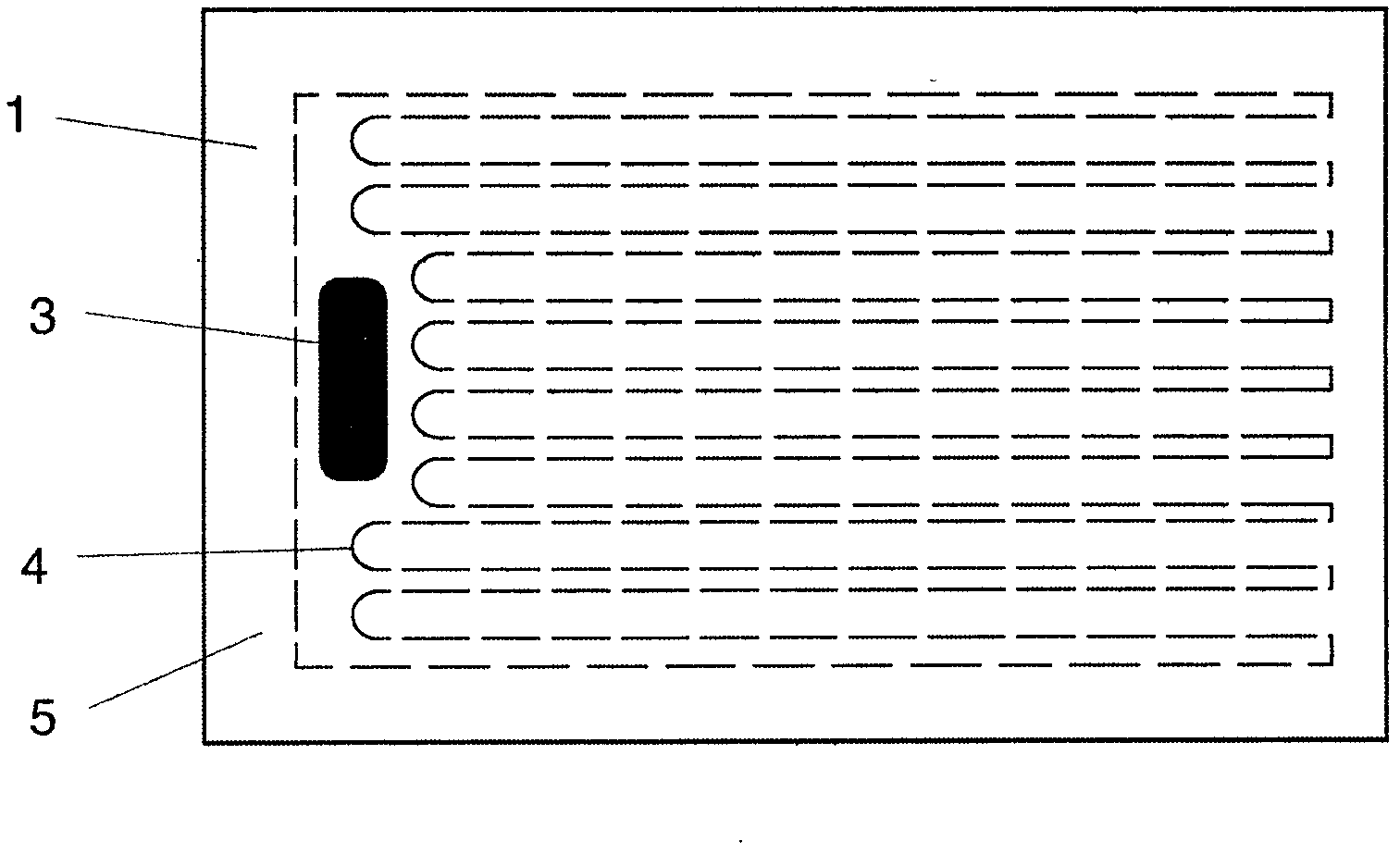

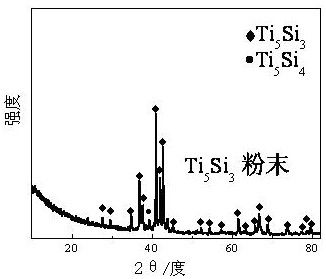

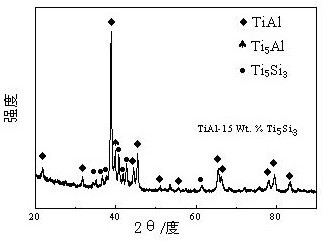

Preparation method of net structure titanium-silicon alloy phase reinforced TiAl-based composite

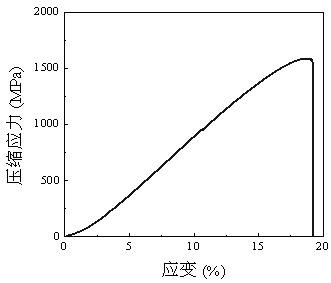

ActiveCN109295336AHigh purityHigh compressive strengthTransportation and packagingMetal-working apparatusSilicon alloyWear resistant

The invention relates to a preparation method of a net structure titanium-silicon alloy phase reinforced TiAl-based composite. The method comprises the step of making, by mass percentage, 65-85% of prealloyed Ti-46Al-2Cr-2Nb powder and 15%-35% of Ti5Si3 powder be sequentially subjected to mechanical uniform mixing, vacuum hot pressing sintering formation and cooling at the room temperature, so that the net structure Ti5Si3 reinforced TiAl-based composite can be obtained. The method is simple in preparation process, low in cost and stable in product performance; and the obtained net structure Ti5Si3 reinforced TiAl-based composite is high in compression strength and excellent in wear resistance and can be used as a novel structural wear-resistant material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

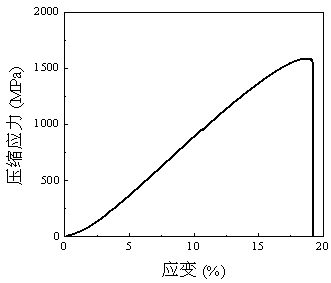

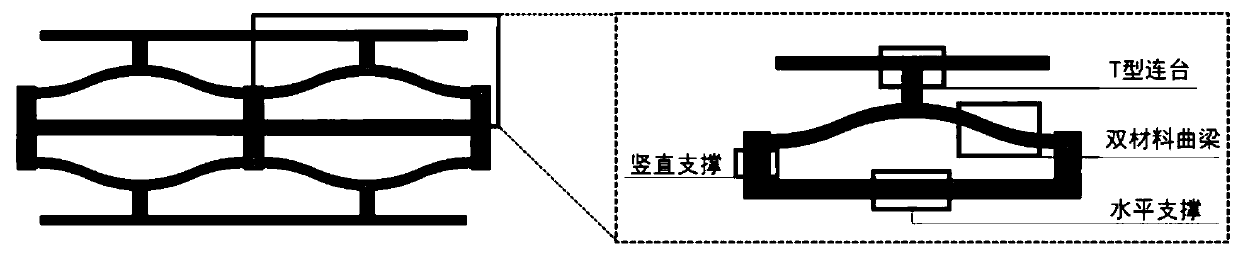

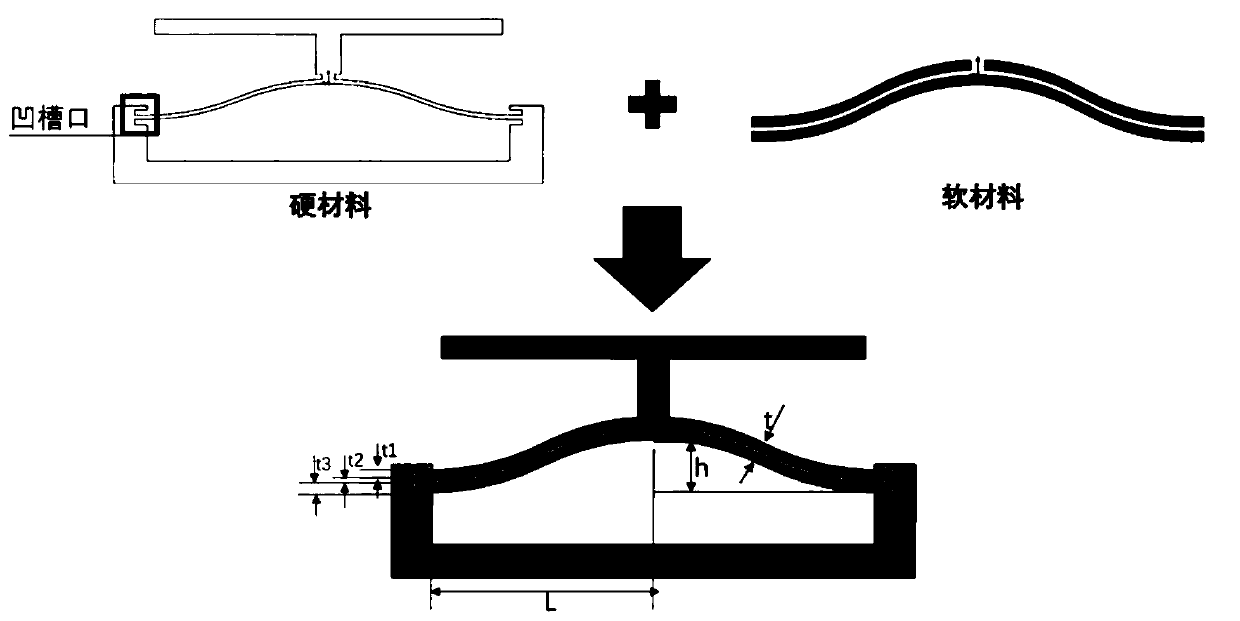

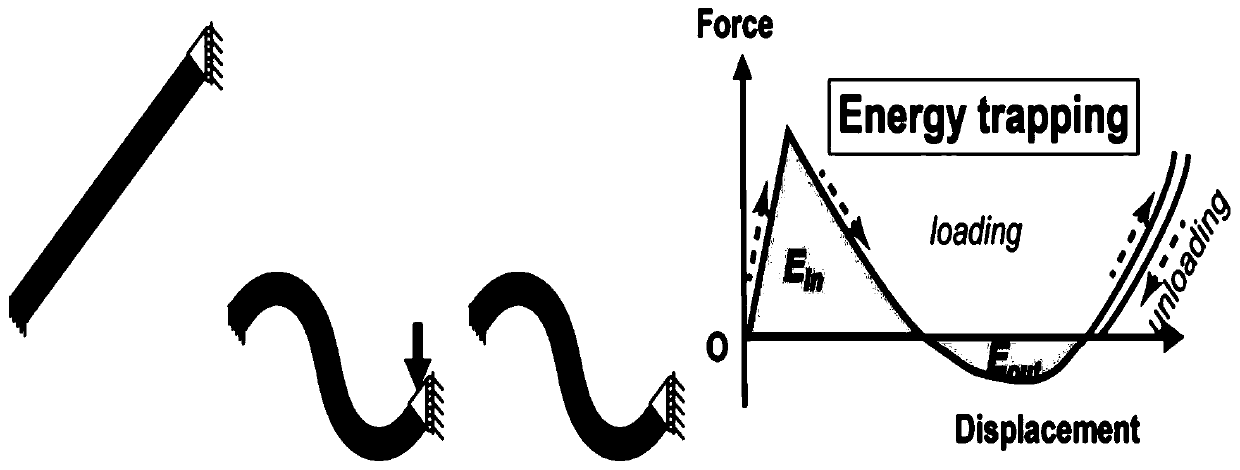

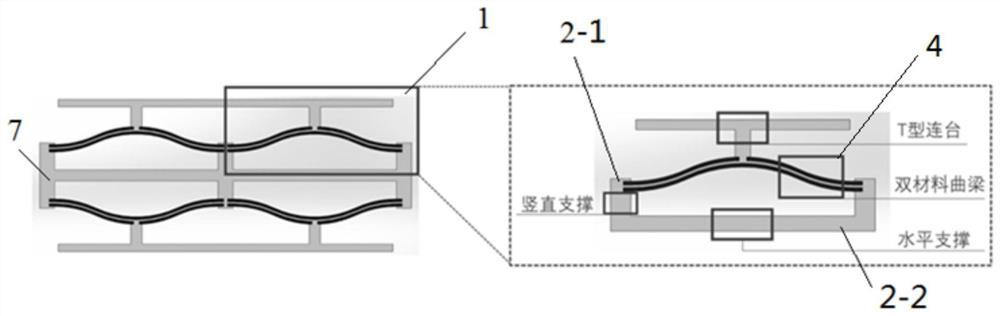

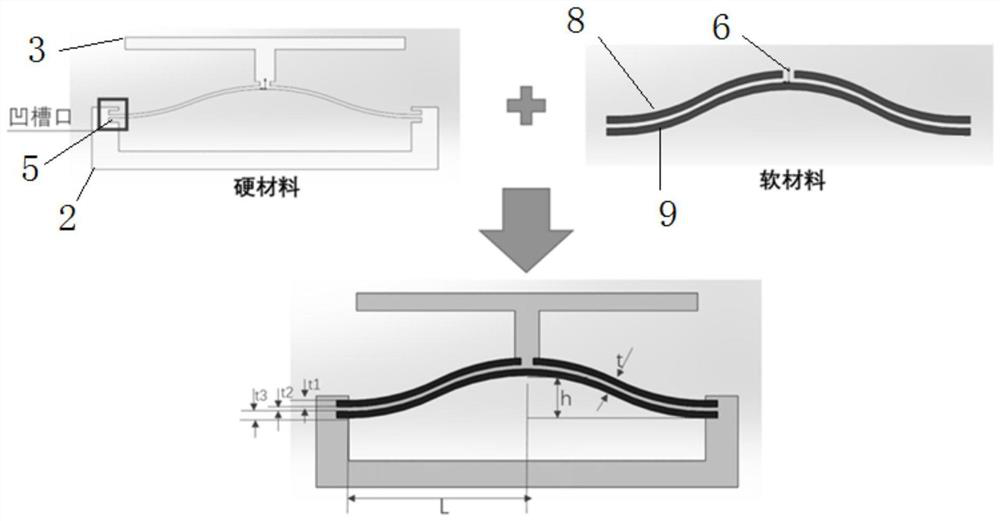

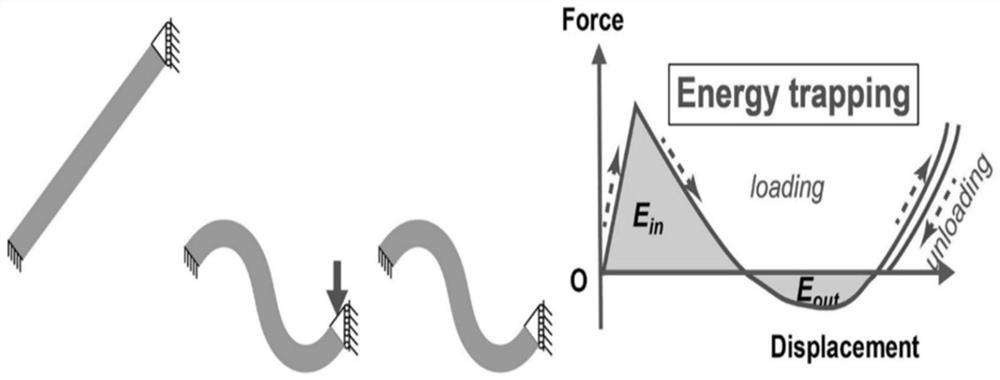

Composite negative-stiffness energy absorption honeycomb structure and preparation method thereof

ActiveCN110792710AImprove mechanical propertiesHigh reusabilityGeometric CADShock absorbersManufacturing technologyEnergy absorption

The invention discloses a composite negative-stiffness energy absorption honeycomb structure and a preparation method thereof, and relates to a composite negative-stiffness energy absorption honeycombstructure. The problems that the number of times of reutilization of an existing negative-stiffness is small, strength is low, and the energy absorption effect is poor are solved. The design philosophy of a composite is used for design of the negative-stiffness structure, two materials of combining a soft material and a hard material are adopted for constructing the negative-stiffness through thecharacteristics that the stress features of all parts are different and stress distribution is not uniform in the deformation process of the negative-stiffness, and the aims of reducing weight and improving the mechanical performance of the structure are achieved on the basis of guaranteeing high-frequency reutilization. Preparation of the composite negative-stiffness honeycomb structure is completed mainly through the additive manufacturing technology such as the SLS technology, the FDM technology and the SLM technology. A new direction is provided for improving energy absorption of metamaterials. The composite negative-stiffness energy absorption honeycomb structure is applied to the field of metamaterials.

Owner:HARBIN INST OF TECH

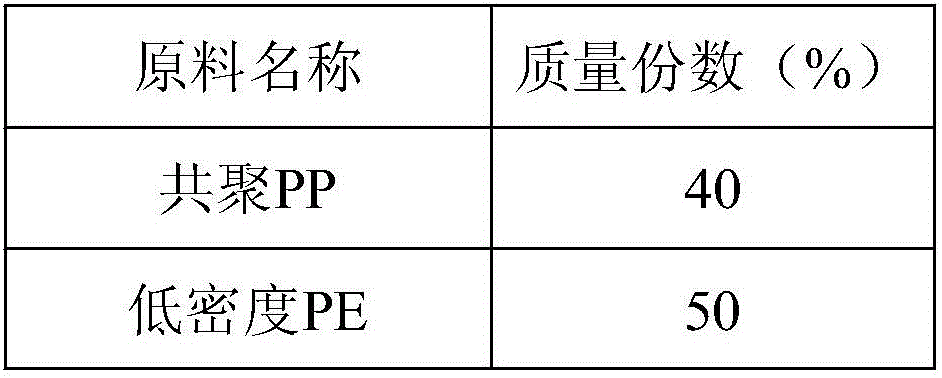

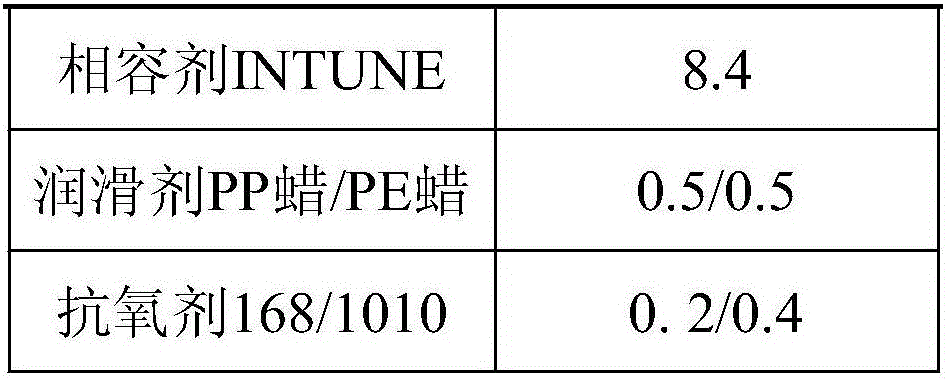

Low-temperature resistance and high-compatibility mixed material and preparation method thereof

ActiveCN105906947AGood compatibilityGood advantage of low temperature shock resistanceAntioxidantMixed materials

The invention relates to a high-temperature resistance and high-compatibility mixed material. The mixed material is prepared from the following components in percentage by mass: 40-50% of copolymer PP, 40-55% of PE, 3-15% of compatilizer INTUNE, 0.5-2% of lubricant and 0.5-1.5% of antioxidant. The mixed material provided by the invention perfectly integrates the advantages of PP and PE, and has good compatibility, high low-temperature impact resistance and good performance in rigidity, toughness, chemical resistance, high-temperature resistance and processability; and a preparation method of the mixed material provided by the invention has the advantages of easiness in operation, low cost and good material performance and has an economic value.

Owner:WEIDIYA CHANGTAI TECH CO LTD

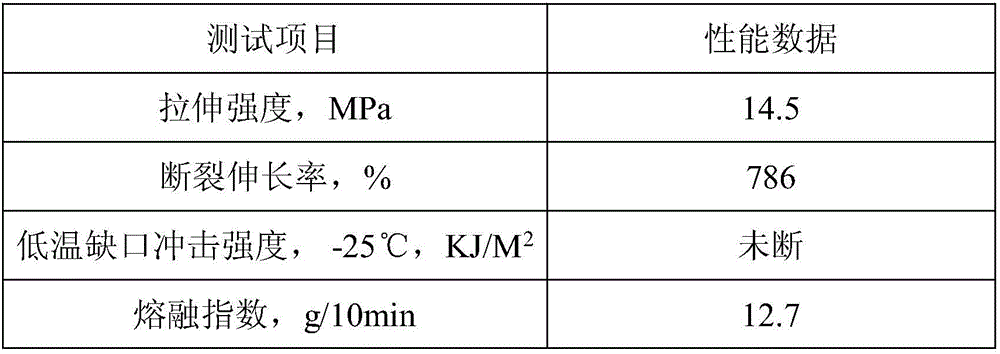

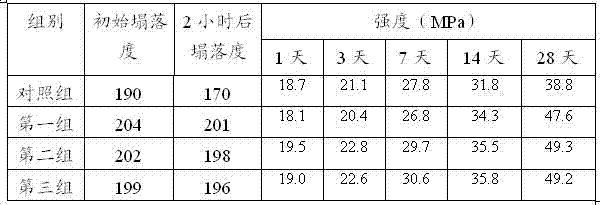

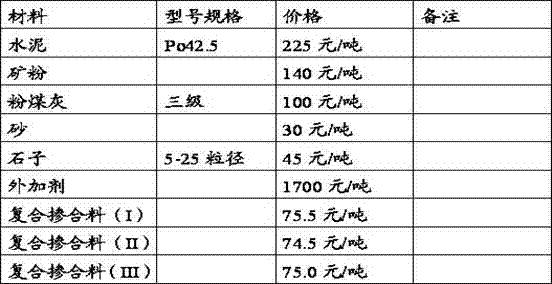

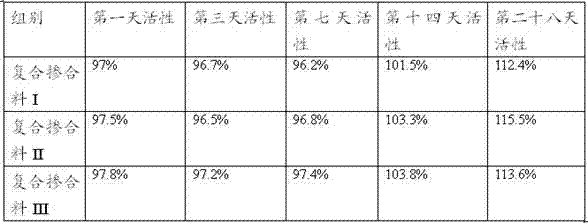

High-performance concrete composite admixture and preparation method thereof

ActiveCN105293965AWide variety of sourcesEasy to getSolid waste managementWork performanceUltimate tensile strength

The invention discloses a high-performance concrete composite admixture and a preparation method thereof. The high-performance concrete composite admixture is prepared from the following raw materials in parts by mass: 30-60 parts of waste residues, 10-16 parts of tailings, 1-2 parts of desulfurization gypsum, 5-12 parts of powder and 1-5 parts of an activating agent. The invention also discloses the preparation method of the high-performance concrete composite admixture. The high-performance concrete composite admixture disclosed by the invention has the following beneficial effects: firstly, the raw materials of the admixture are taken from wastes to realize recycling utilization of solid wastes and solve land occupation and environmental pollution caused by stacking and burying; secondly, the admixture disclosed by the invention, by virtue of treatment and processing of the raw materials, has more excellent performance, so that the working performance and strength of each stage of concrete can be finally promoted significantly, and then the concrete becomes high-performance concrete with high durability, high applicability and high volume stability; and moreover, the admixture can greatly reduce the use level of cement and is very significant in cost reducing effect.

Owner:山东中粉建材科技有限公司

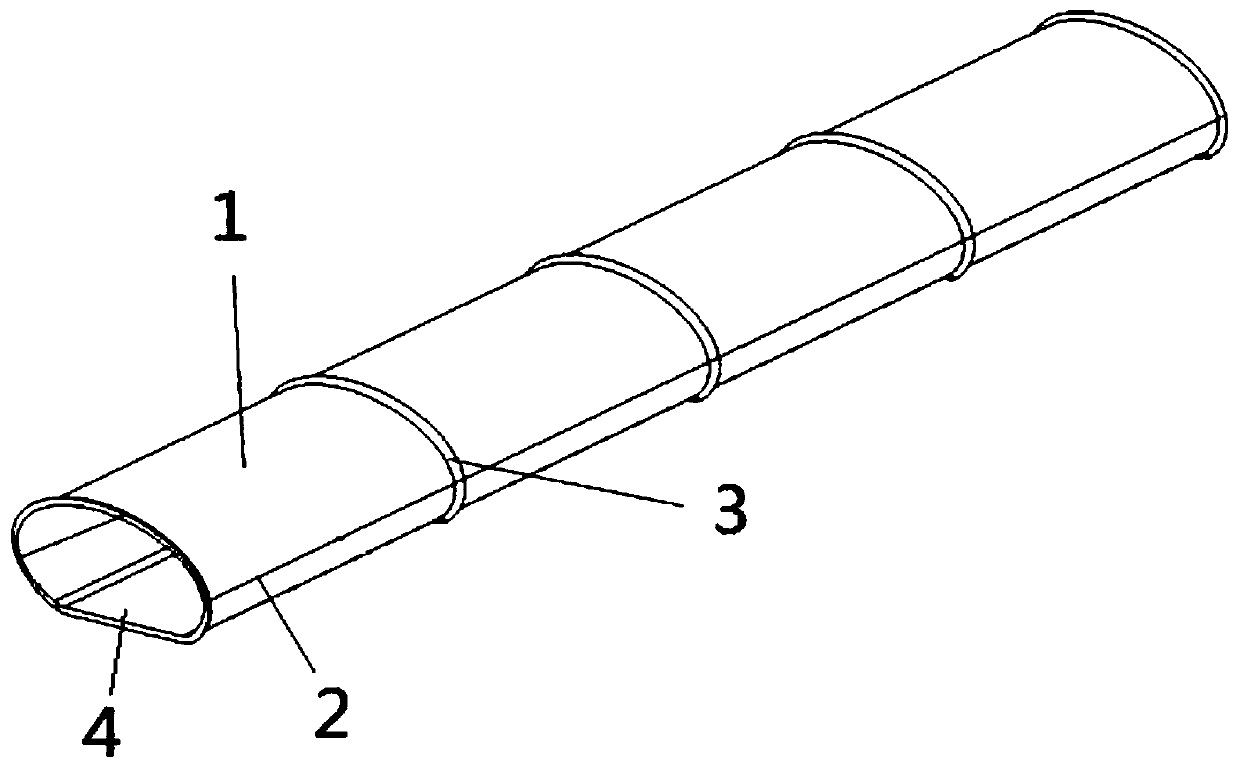

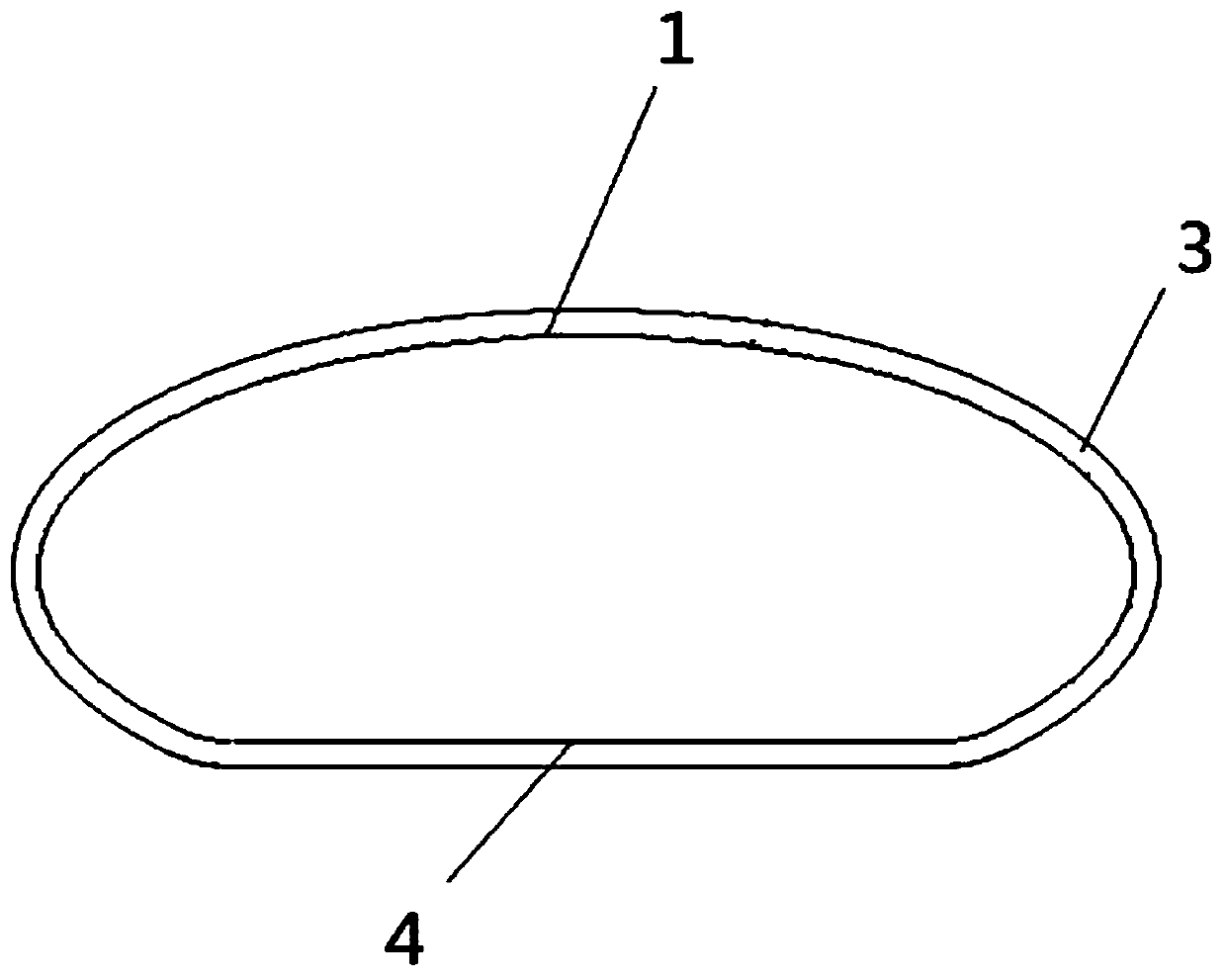

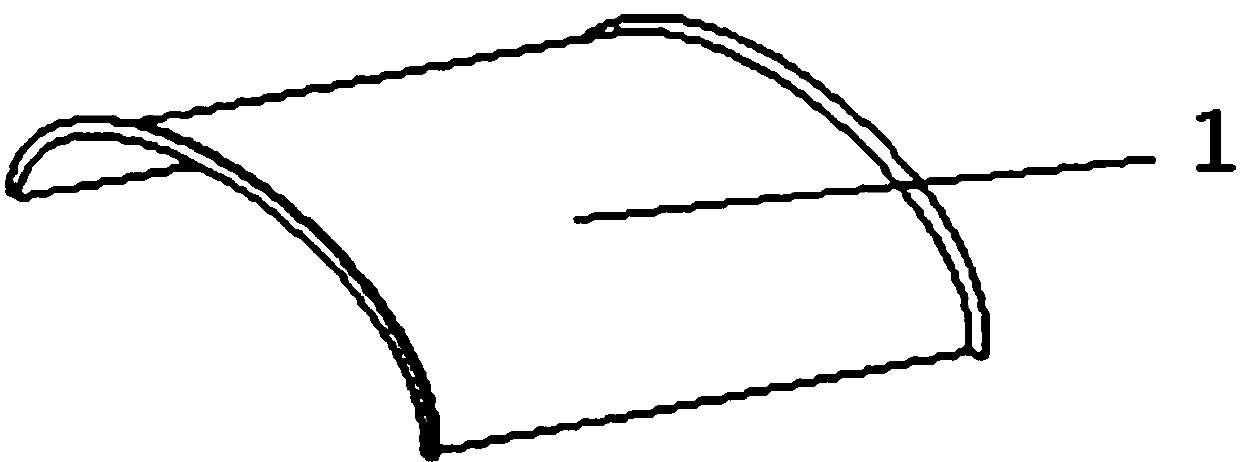

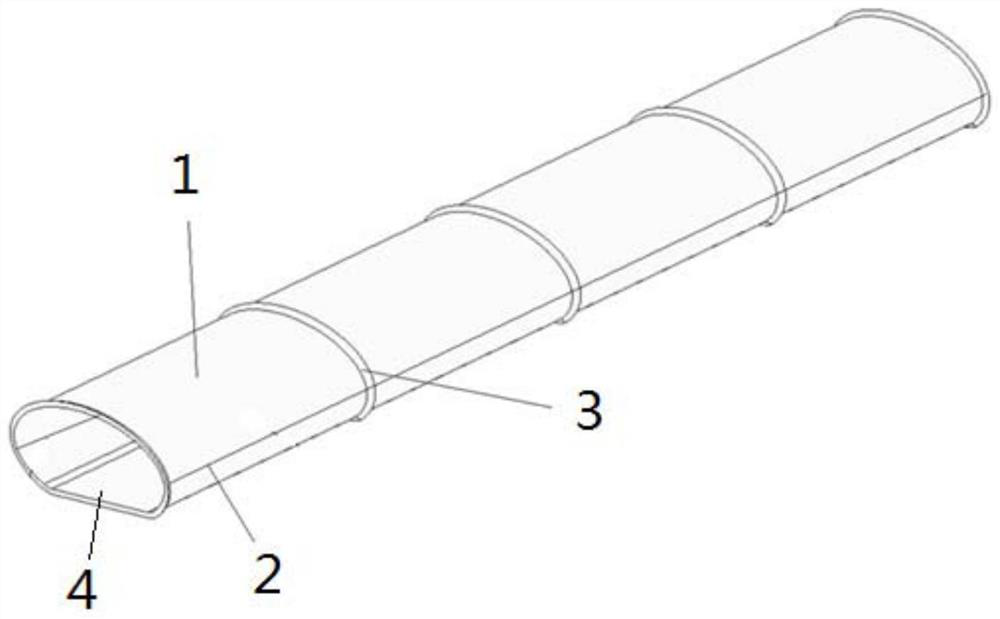

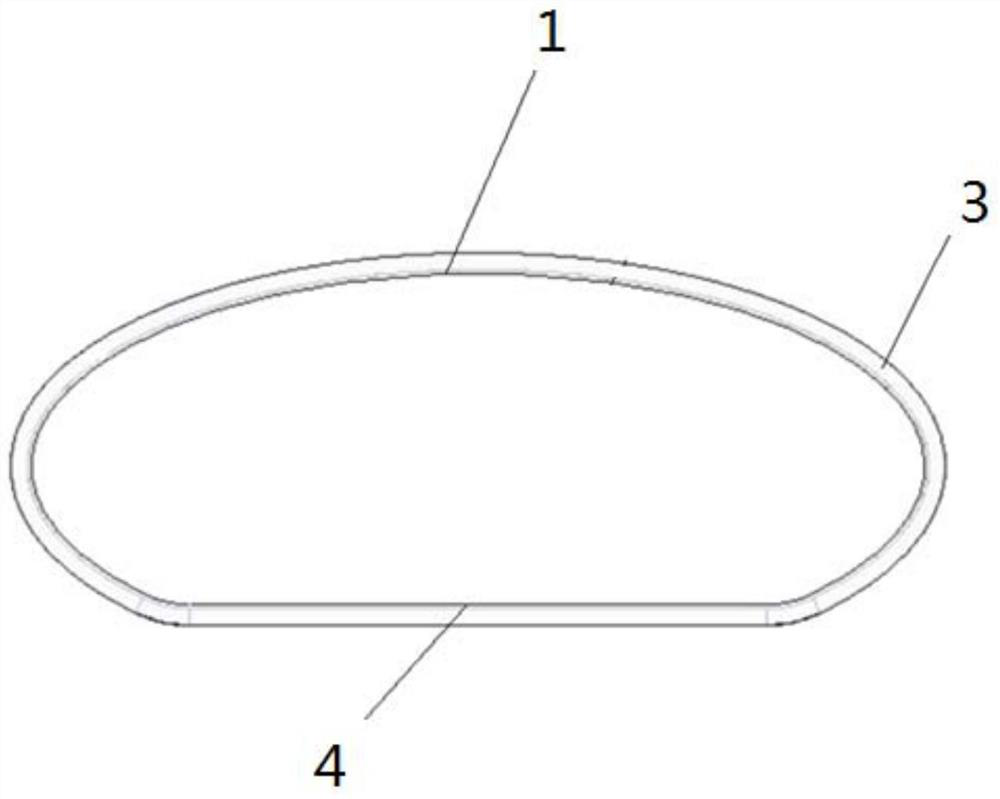

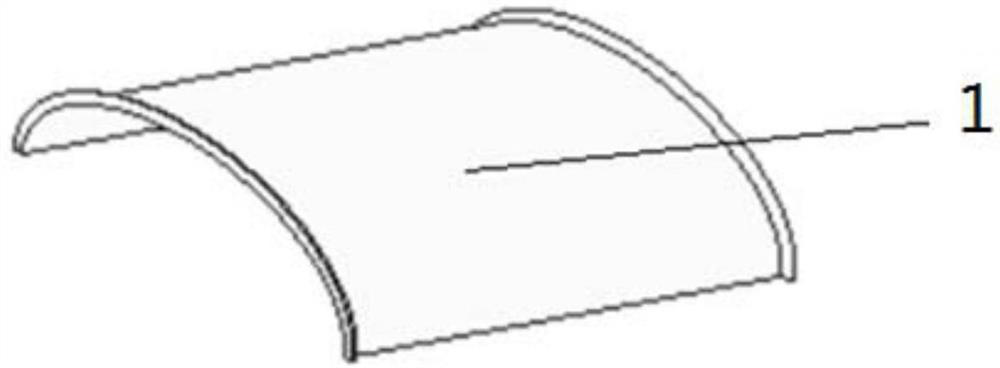

Cooling section flat tube for platinum channel in substrate glass production process and preparation method of cooling section flat tube

The invention discloses a cooling section flat tube for a platinum channel in a substrate glass production process and a preparation method of the cooling section flat tube. The cooling section flat tube comprises N sections of flat tube assemblies; every two adjacent flat tube assemblies are connected through flanging welding, and flangings are used for forming reinforcing ribs; each flat tube assembly comprises a flat tube top plate and a flat tube bottom plate, wherein each flat tube top plate is in an arch shape, and each flat tube bottom plate is a flat plate; two side edges of each flattube bottom plate are bent upwards for being welded to the corresponding flat tube top plate; and each flat tube top plate and the corresponding flat tube bottom plate are connected through butt welding, wherein N is an integer larger than or equal to 3, and the cooling section flat tube is made of platinum-rhodium alloy. Collapse and deformation of the tops of the flat tube can be prevented in production and use processes.

Owner:IRICO DISPLAY DEVICES

A composite negative stiffness energy-absorbing honeycomb structure and its preparation method

ActiveCN110792710BNegative stiffness effect is obviousPromote absorptionGeometric CADShock absorbersManufacturing technologyEnergy absorption

The invention discloses a composite negative-stiffness energy absorption honeycomb structure and a preparation method thereof, and relates to a composite negative-stiffness energy absorption honeycombstructure. The problems that the number of times of reutilization of an existing negative-stiffness is small, strength is low, and the energy absorption effect is poor are solved. The design philosophy of a composite is used for design of the negative-stiffness structure, two materials of combining a soft material and a hard material are adopted for constructing the negative-stiffness through thecharacteristics that the stress features of all parts are different and stress distribution is not uniform in the deformation process of the negative-stiffness, and the aims of reducing weight and improving the mechanical performance of the structure are achieved on the basis of guaranteeing high-frequency reutilization. Preparation of the composite negative-stiffness honeycomb structure is completed mainly through the additive manufacturing technology such as the SLS technology, the FDM technology and the SLM technology. A new direction is provided for improving energy absorption of metamaterials. The composite negative-stiffness energy absorption honeycomb structure is applied to the field of metamaterials.

Owner:HARBIN INST OF TECH

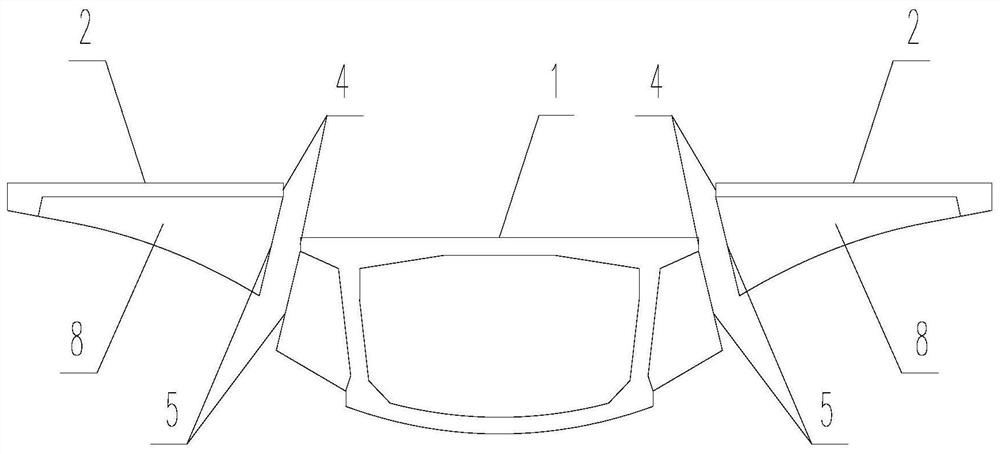

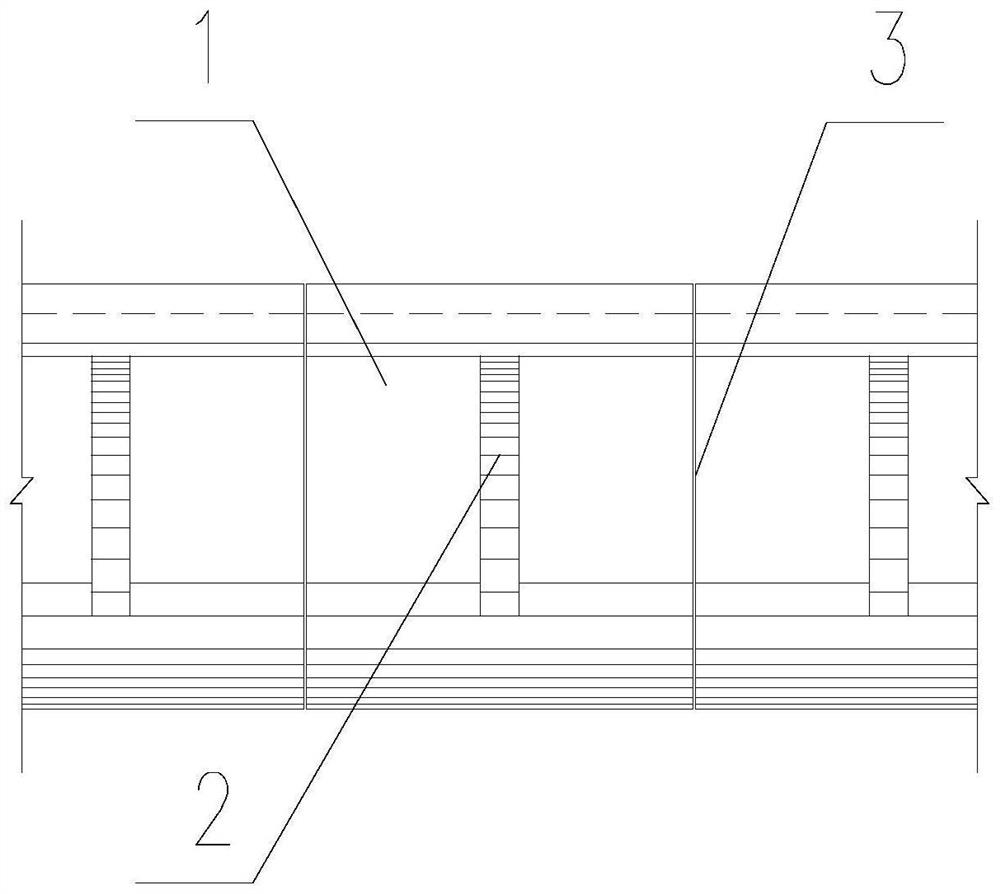

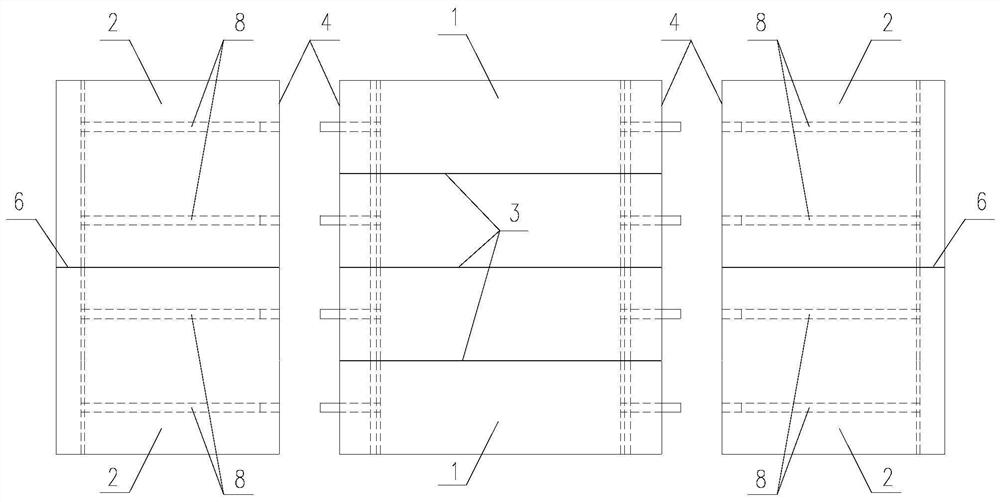

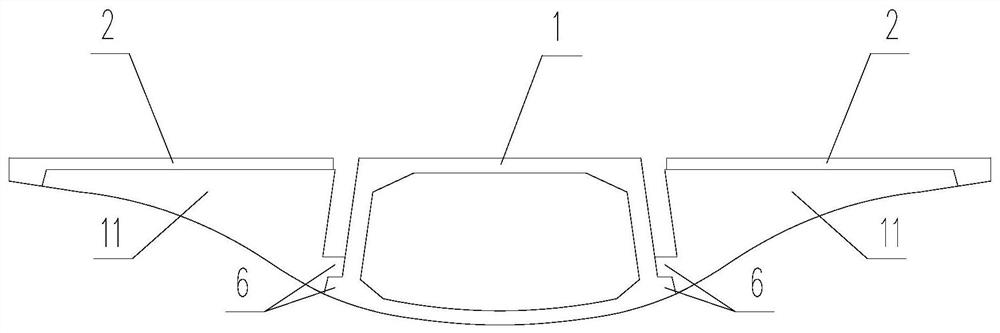

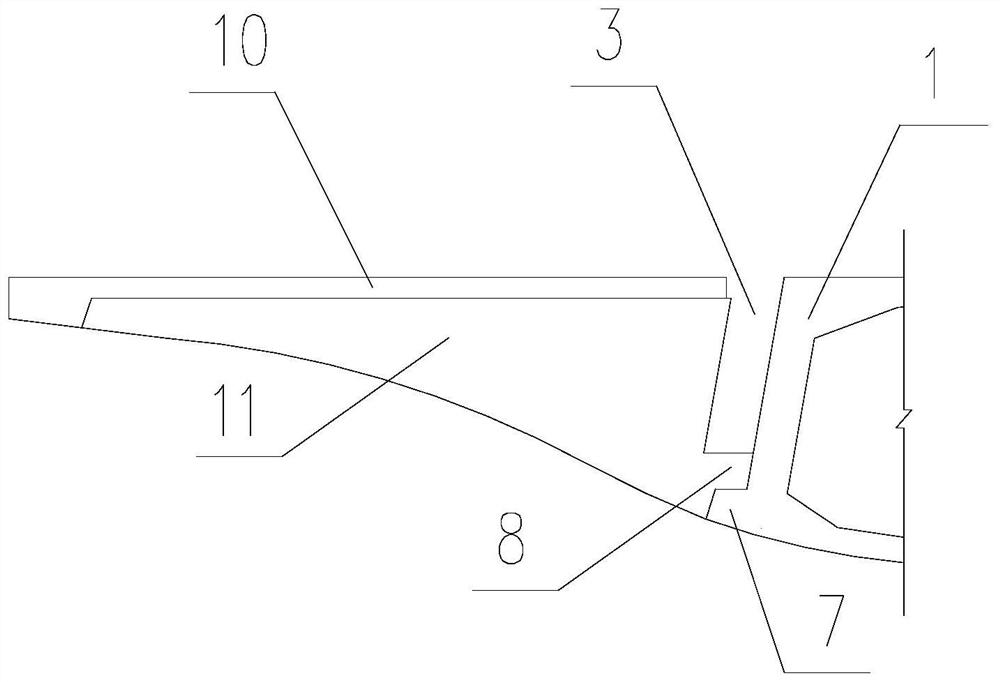

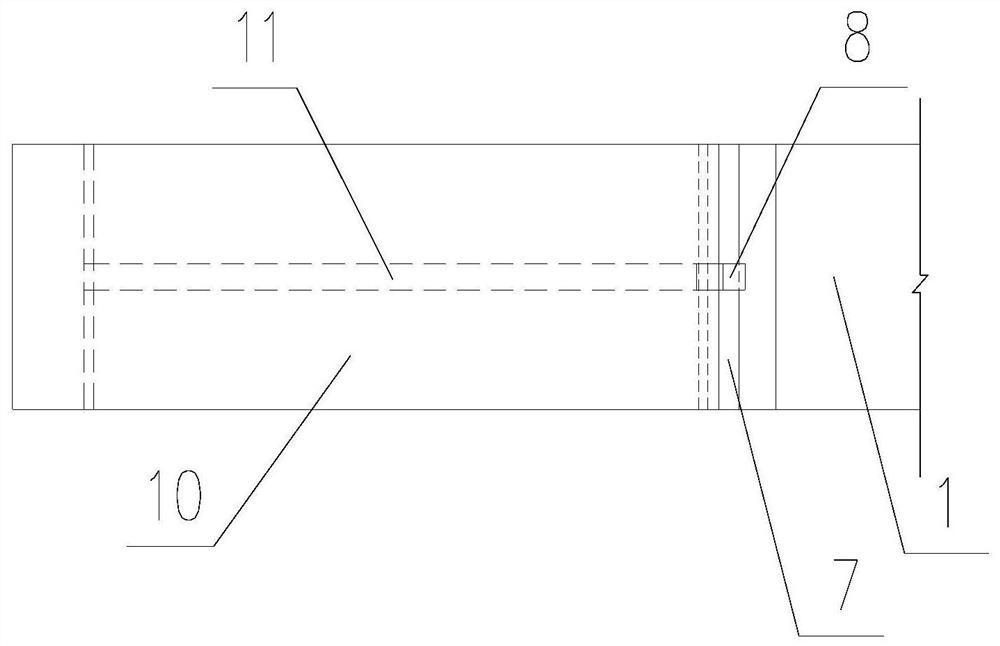

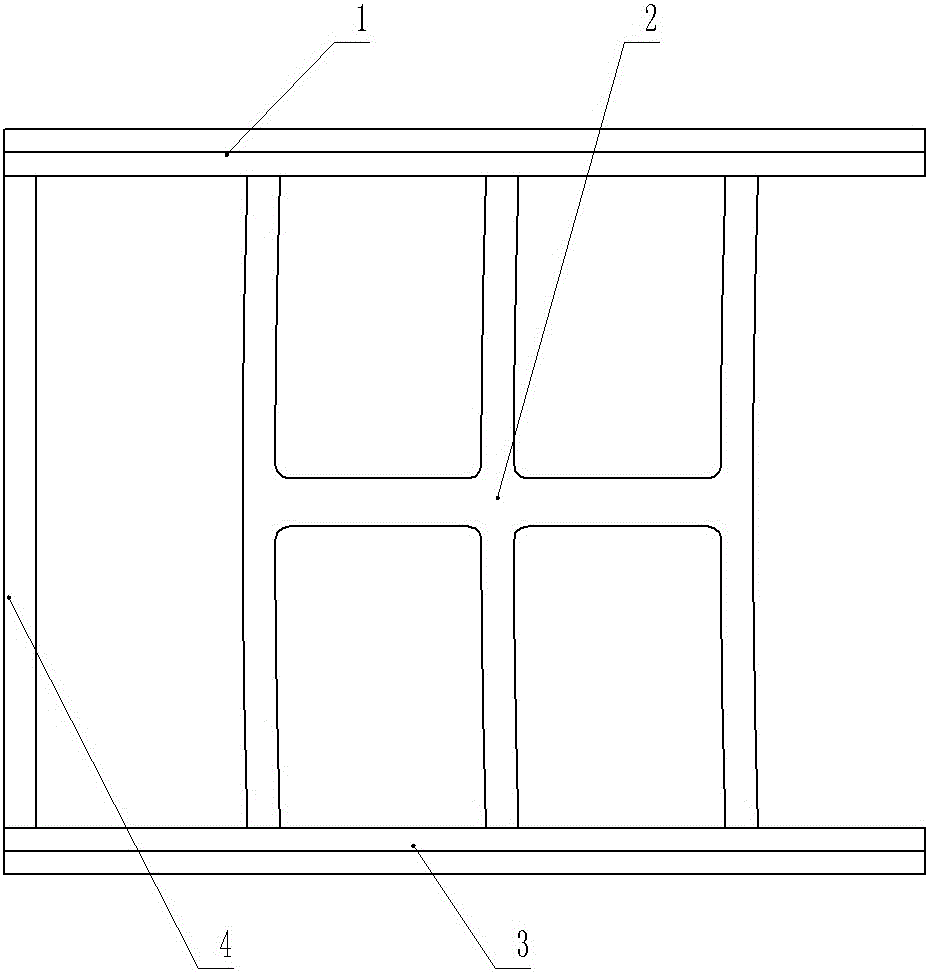

Segmental prefabricated composite section spine girder bridge structure system

PendingCN112281631ASmall segment sizeReduce weightBridge structural detailsBridge erection/assemblyArchitectural engineeringStringer

The invention provides a segmental prefabricated composite-section spine girder bridge structure system. The spine girder bridge structure system is characterized in that the section of a spine girderis mainly formed by compounding a core longitudinal beam and a rear-mounted cantilever arm; the two parts can adopt a precast concrete member assembled by sections at the same time, or can be partially precast and assembled and partially cast in place; on the basis of the two parts, the structural system further comprises various corresponding longitudinal and transverse joints at the same time.The construction sequence of the structure system is as follows, firstly, core longitudinal beam construction within a span is completed, and then the cantilever arm is mounted, so the core longitudinal beam is constructed step by step after the core longitudinal beam is formed. According to the structural system, the construction speed can be increased, the structural economy is improved, the design and construction key technology of the segmental prefabricated assembled concrete bridge is improved, and the development of the segmental beam prefabricated assembling technology is promoted.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

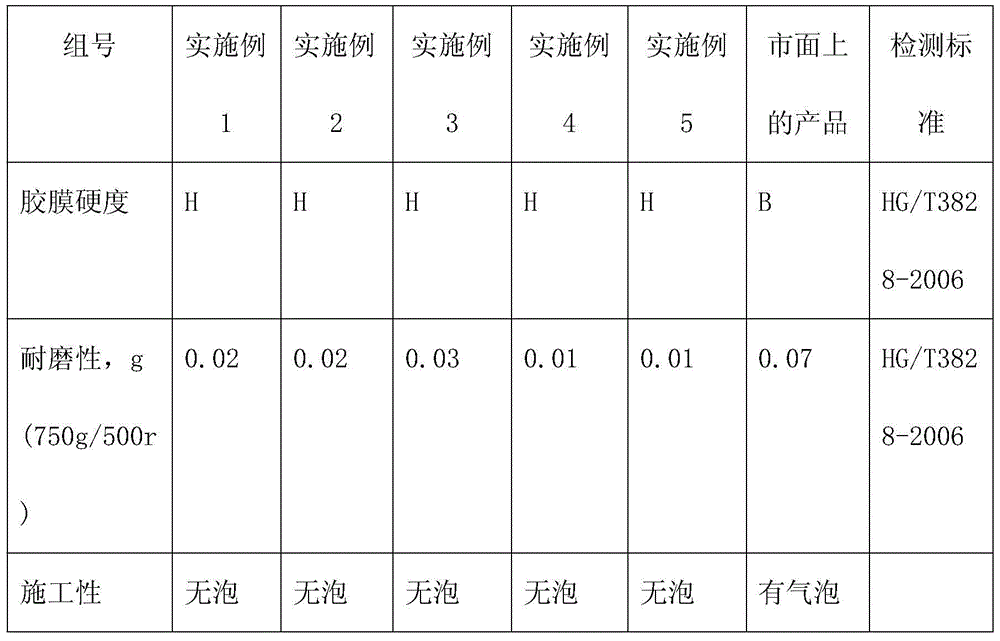

A kind of water-based wood paint and preparation method thereof

ActiveCN105273545BHigh hardnessImprove wear resistancePolyurea/polyurethane coatingsEmulsionHardness

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

Backbone beam bridge rear-mounted cantilever rib plate mixed connection structure with bearing function

PendingCN112281634AFirmly connectedEasy constructionBridge structural detailsBridge erection/assemblyCantileverMechanical engineering

The invention provides a backbone beam bridge rear-mounted cantilever rib plate mixed type connecting structure with a bearing function. The backbone beam bridge rear-mounted cantilever rib plate mixed type connecting structure is suitable for a composite-section backbone beam bridge with prefabricated sections. A rear-mounted cantilever arm is a prefabricated concrete member assembled by sections, and follows the construction time sequence that the core longitudinal beam is erected step by step after being constructed; prefabricated supports are arranged on the lower edges of the roots of thecantilever rib plates and connected with the supports of the core longitudinal beams in a matched and dry mode; the cantilever rib plate is provided with a vertical post-mounted cantilever rib platewet joint above the prefabricated support, and the vertical post-mounted cantilever rib plate wet joint is in wet joint with the core longitudinal beam; the prefabricated support and the rear-mountedcantilever rib plate wet joint are combined to form novel mixed connection. The reasonable rib plate transverse mixing type connecting structure can ensure reliable connection and convenient construction, reduces the risk of aloft work, and is suitable for various bridges with complex sections and ultrahigh gradual change and curve sections.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

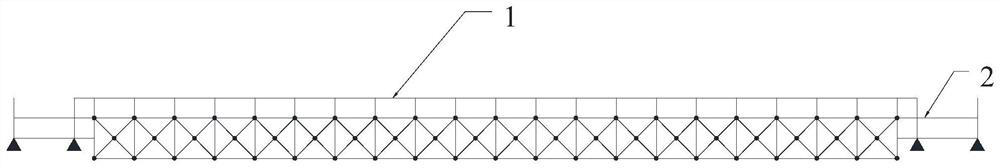

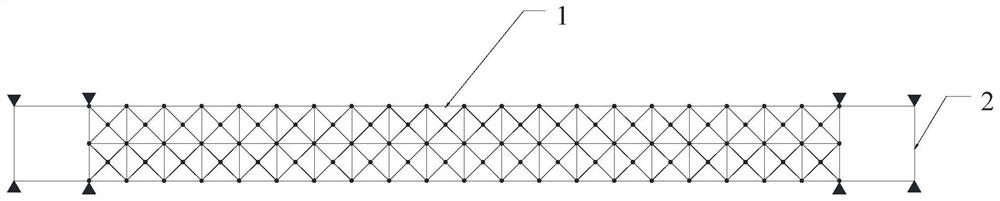

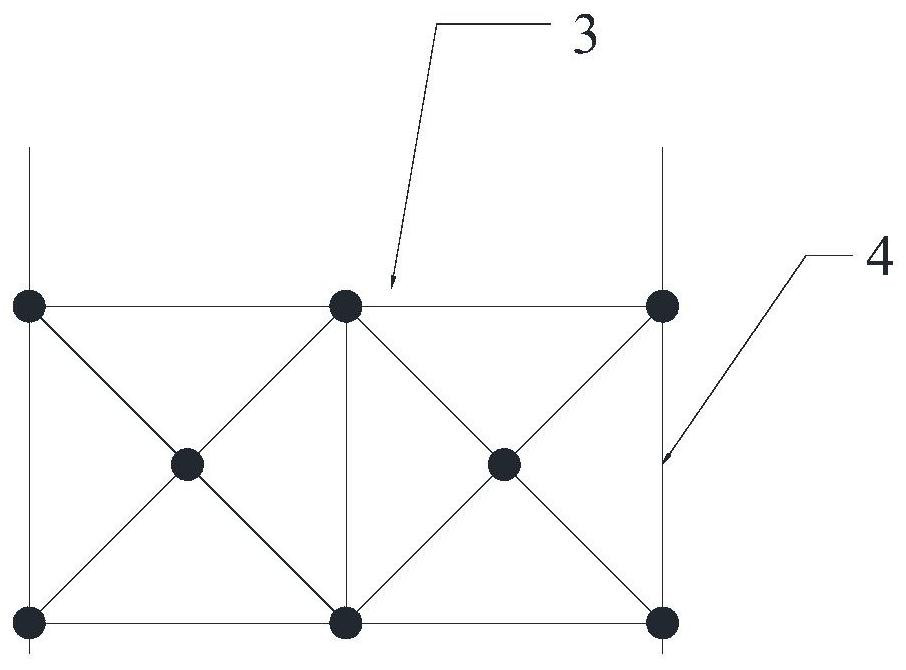

Space truss light steel walking bridge connected through disc nodes and construction method thereof

InactiveCN111962375ASolve the instability outside the pressure planeEven by forceTruss-type bridgeBridge erection/assemblyHandrailEngineering

The invention discloses a space truss light steel walking bridge connected through disc nodes and a construction method thereof. The space truss light steel walking bridge comprises a footpath structure and handrail structures. The handrail structures are arranged on the two sides of the upper portion of the footpath structure, and the footpath structure is formed by arranging a plurality of trussstructures. Each truss structure is a cubic or cuboid structure composed of twelve rod pieces, eight vertexes are each connected with an inclined rod, and the eight inclined rods are connected at thecenter of the truss structure. And the rod pieces, the rod pieces and the inclined rods, and the inclined rods are connected through the disc nodes. By the adoption of the space truss structure, vertical and lateral bidirectional overall rigidity is improved, a problem of instability outside a pressed surface of each handrail structure is solved, the rod pieces are evenly stressed, the rod piecesare connected through the disc nodes, and the strength of the nodes is effectively improved. The invention relates to the technical field of bridge construction.

Owner:SOUTH CHINA UNIV OF TECH

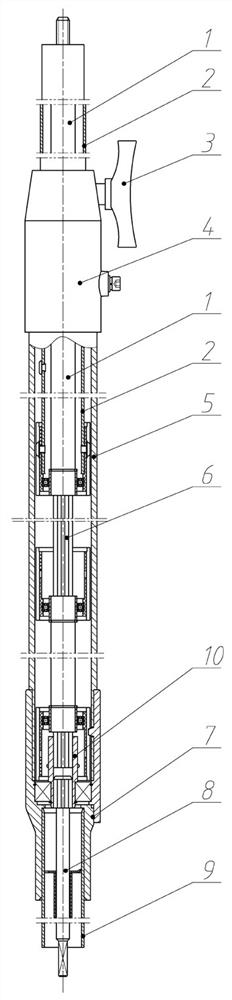

Telescopic high-branch saw transmission rod combination

PendingCN113079846AAvoid weakeningEnough lengthCuttersMotor driven pruning sawsDrive shaftStructural engineering

The invention discloses a telescopic high-branch saw transmission rod combination, which comprises a casing pipe combination and a transmission shaft combination, wherein the casing pipe combination contains a front casing pipe, a front connecting sleeve, a middle casing pipe, a rear casing pipe and a rear connecting sleeve; the transmission shaft combination contains a front transmission shaft, a middle transmission shaft, a connecting shaft and a rear transmission shaft; the transmission shaft combination is installed in the casing pipe combination; the casing pipe combination supports and spaces the transmission shaft combination; the front casing pipe and the middle casing pipe can relatively slide along the axial direction; the position of the middle casing pipe and the position of the rear casing pipe are fixed; the front transmission shaft and the middle transmission shaft can relatively slide along the axial direction; and the position of the rear transmission shaft and the position of the middle transmission shaft are fixed. The telescopic high-branch saw transmission rod combination has the beneficial effects that the telescopic high-branch saw transmission rod combination has a simple structure, is easy in operation, is convenient in storage, can meet the strength requirement of the transmission shaft and avoids excessive weight, and meanwhile, the extending length of the transmission rod is guaranteed to be as long as possible.

Owner:SHANDONG HUASHENG PESTICIDE APPL MACHINERY CO LTD

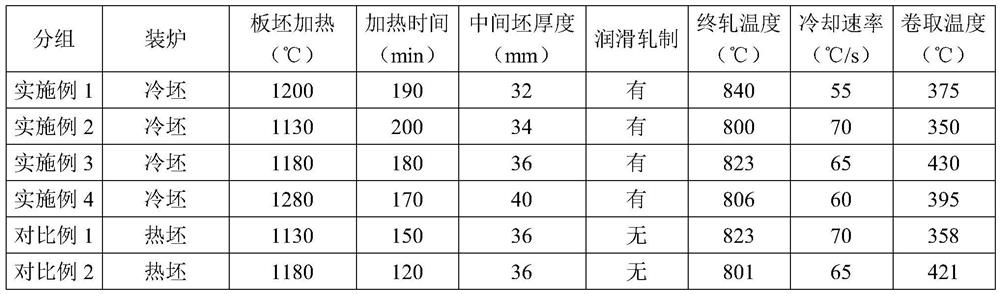

A kind of high-plasticity hot-rolled strip steel with tensile strength of 1180mpa and its production method

ActiveCN112501503BImprove plasticityStrength advantageTemperature control deviceFurnace typesStrip steelTruck

The invention discloses a high-strength and high-plasticity hot-rolled strip steel with a tensile strength of 1180 MPa, which belongs to the field of hot-rolled high-strength steel. 1.3-2.0%, Al: 1.2-2.0%, P≤0.015%, S≤0.005%, Re: 0.003-0.006%, Nb: 0.02-0.07%, Ti: 0.02-0.07%, Cr: 0.03-0.08%, The balance is Fe and inevitable impurities. Compared with the prior art, the present invention is used for the production of parts and components such as commercial vehicles and trucks, and is beneficial to the high-strength thinning and plastic forming of the parts.

Owner:RIZHAO STEEL HLDG GROUP

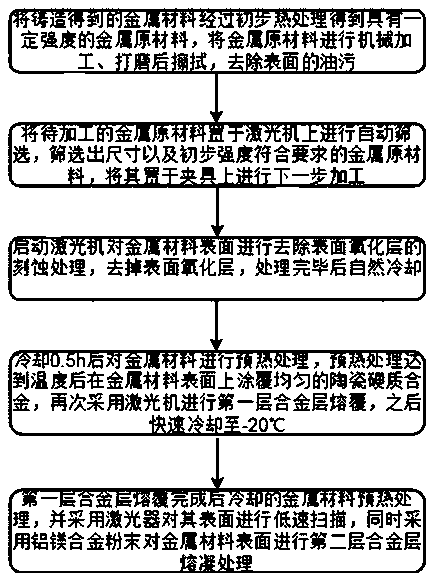

A method for strengthening the surface of metal materials by using a laser machine

ActiveCN109504967BHigh strengthStrength advantageMetallic material coating processesLaser beam welding apparatusMetal coatingAlloy

The invention provides a method for carrying out enhanced treatment on a metal material surface through a laser machine. An IPG pulse optical fiber laser device is used for carrying out surface enhanced treatment on the metal material, the treated metal material has the high strength and is not prone to damage, in the use process, corrosion resisting is achieved, producing and manufacturing are convenient, the manufacturing cost is low, and mass production is easy; the method for carrying out enhanced treatment on the metal material surface can be specifically applied to castings like a mold core, due to the fact that the mold core made of a hard alloy is difficult to machine, a mold core of common steel is cut, punched and formed, the laser machine is used for enhancing the metal materialsurface, machining is convenient, the mold core strength is high, and through coating of multiple layers of metal coatings, strength, wear resisting, and corrosion resisting have more advantages compared with those of mold cores made of a single alloy.

Owner:山东裕德激光科技有限公司

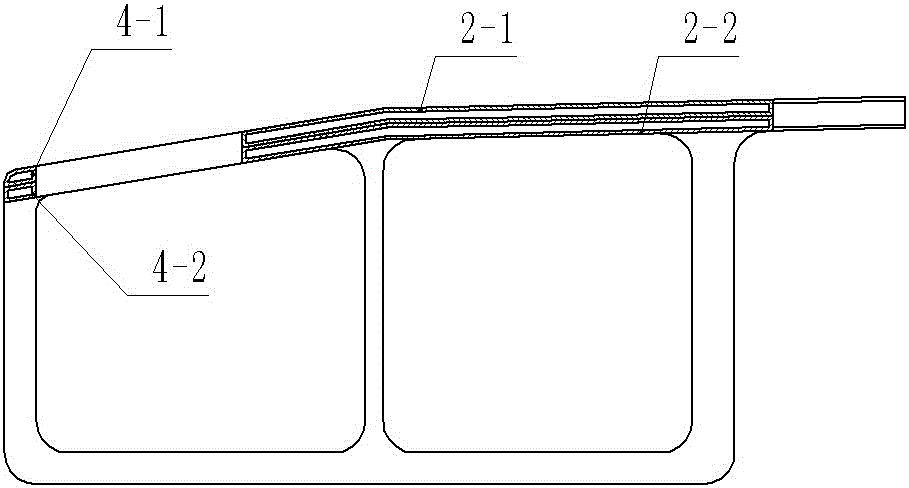

Electric vehicle body frame

InactiveCN105015624AReduce weightHigh strengthSuperstructure subunitsManufacturing technologyElectric vehicle

The invention discloses an electric vehicle body frame which relates to the technical field of electric vehicle manufacture. The electric vehicle body frame comprises an electric vehicle body frame body. The electric vehicle body frame body is provided with side electric vehicle body frames at two sides and an electric vehicle top frame and a front electric vehicle carriage which are connected with the side electric vehicle body frames at the two sides. Each side electric vehicle body frame is composed of a side electric vehicle body outer plate and a side electric vehicle body inner plate which are connected through mortises. The electric vehicle top frame is composed of an electric vehicle top outer plate and an electric vehicle inner plate which are connected through mortises. The front electric vehicle carriage is composed of a front electric vehicle carriage outer plate and a front electric vehicle carriage inner plate which are connected through mortises. Compared with the prior art, the electric vehicle body frame is advantageous in that the integral weight of the electric vehicle body is reduced; strength, consistency and weight of the electric vehicle body frame are respectively better than the strength, the consistency and the weight of the electric vehicle body frame manufactured according to the prior art.

Owner:GUANGXI LIUTUO VEHICLE

A cooling section flat pipe and preparation method for the platinum channel for the substrate glass production process

The invention discloses a cooling section flat tube used for a platinum channel in the substrate glass production process and a preparation method thereof, comprising: N sections of flat tube components; adjacent flat tube components are connected by flanging welding, and the flanging is used to form Reinforcing ribs; each flat tube assembly includes: a flat tube top plate and a flat tube bottom plate; the flat tube top plate is arched, and the flat tube bottom plate is a flat plate with both sides bent upwards for connecting with the flat tube The top plate is welded; the top plate of the flat tube is connected to the bottom plate of the flat tube by butt welding; wherein, N is an integer greater than or equal to 3, and the material of the flat tube in the cooling section is a platinum-rhodium alloy. The invention can prevent the collapse and deformation of the top of the flat tube during production and use.

Owner:IRICO DISPLAY DEVICES

A kind of permeable cement concrete reinforcing agent and preparation method thereof

The invention provides a water-permeable cement concrete reinforcing agent which comprises the following components by total weight: 75-85% of EVA emulsion, 1.5-3% of a thickening agent, 0.1-0.3% of a defoaming agent, 0.5-1.3% of a water reduction agent and 10-30% of water, wherein the EVA emulsion is ethylene-vinyl acetate copolymer emulsion; the content of vinyl acetate is greater than or equal to 15%; the thickening agent is a hydrophilic high-molecular compound; the defoaming agent is an organic silicon compound. Due to adoption of the thickening agent, the dispersibility and the adhesion property of the cement can be improved, the water amount can be reduced, the strength and the properties of water retention, reinforcement, thickening and adhesion improvement of concrete at different stages can be improved, the cohesive force of water-permeableconcrete skeletons can be improved, good construction can be ensured, and the communication porosity of water-permeable cement concrete structure layers can be ensured.

Owner:上海砼仁环保技术发展有限公司

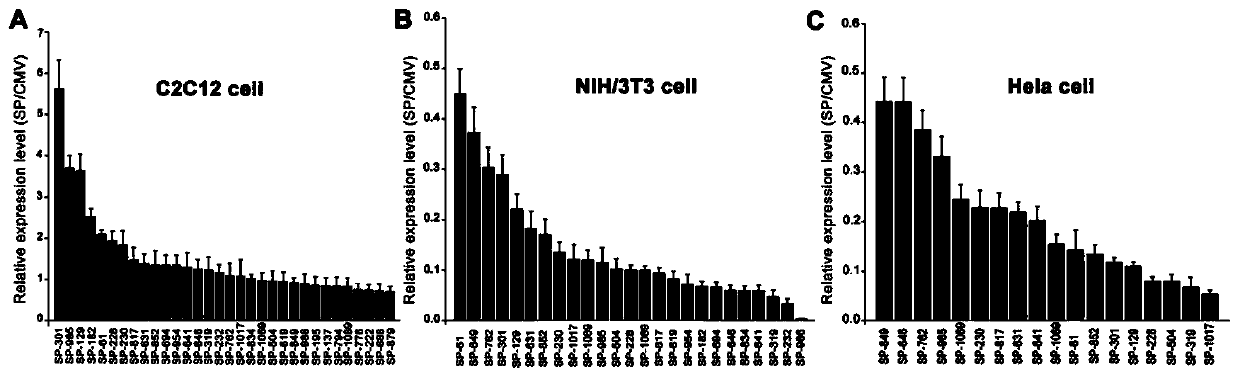

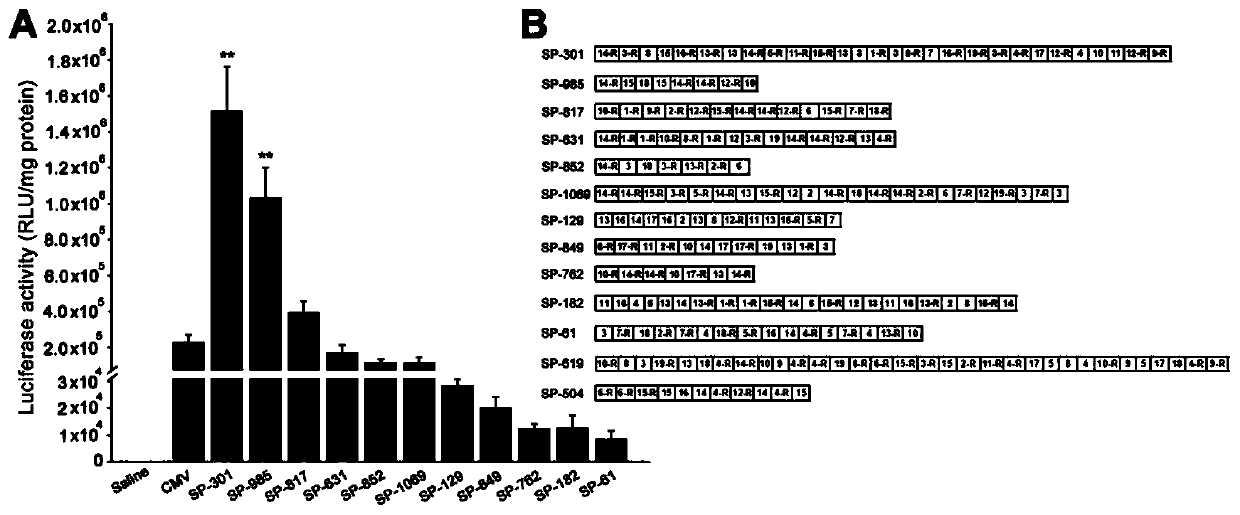

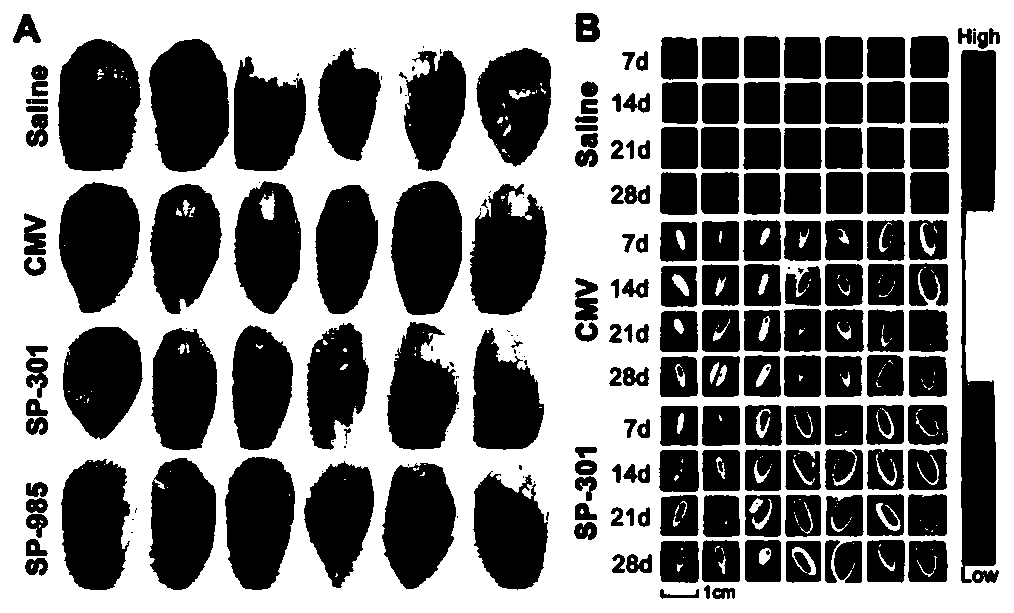

Skeletal Muscle Cell Efficient Specific Promoter and Its Application

ActiveCN106497930BStrength advantageImprove expression efficiencyPharmaceutical delivery mechanismAnimals/human peptidesNucleotideIn vivo experiment

The invention discloses an efficient and specific promoter of skeletal muscle cells and application of the efficient and specific promoter. According to the efficient and specific promoter disclosed by the invention, the nucleotide sequence is shown as any one of SEQ ID NO.1, SEQ ID NO.2 and SEQ ID NO.3. The invention further discloses a recombinant vector and / or recombinant bacterium containing the promoter and application thereof. The expression efficiency of the efficient and specific promoter of the skeletal muscle cells in in-vitro and in-vivo experiments is higher than that of CMV (Cytomegalovirus) and high expression of target genes can be realized; the promoter SP-301 has remarkable advantages in the aspects of strength, specificity and lasting time of promoter gene expression in skeletal muscles, and has a very great potential in a subsequent gene therapy field.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

Heat exchanger, use, and manufacturing process for a heat exchanger

ActiveUS8720535B2Increased durabilityStrength advantageMetal-working apparatusStationary conduit assembliesMechanical engineeringIndustrial engineering

A heat exchanger includes a block for the separated and heat-exchanging guiding of first and second fluids, the block having a number of fluid flow channels, at least one box which is flow-connected to the flow channels, and at least one base that includes one or more openings for feeding the flow channels from the box. At least one opening is formed as a passage with a collar having a near-bottom section and an end-side section, and a wall thickness of the end-side section is smaller than a wall thickness of the near-bottom section. A shoulder between the near-bottom and end-side section has a contour running transverse to the contour of the near-bottom section and / or the end-side section, and the end-side section is inclined away from a passage axis. Also a manufacturing process for a heat exchanger.

Owner:MAHLE INT GMBH

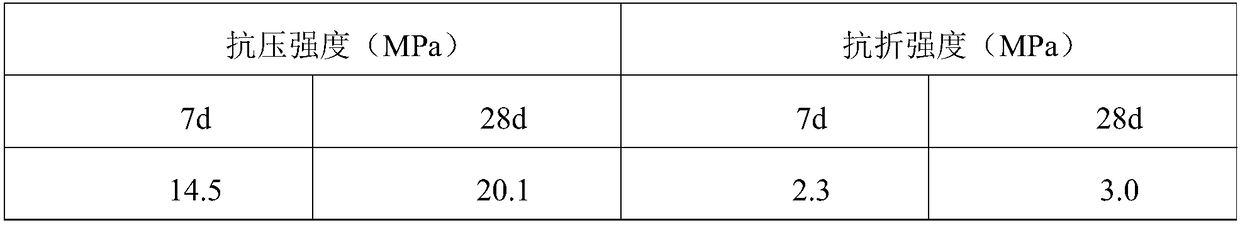

A kind of high-performance concrete composite admixture and preparation method thereof

ActiveCN105293965BWide variety of sourcesEasy to getSolid waste managementWork performanceUltimate tensile strength

The invention discloses a high-performance concrete composite admixture and a preparation method thereof. The high-performance concrete composite admixture is prepared from the following raw materials in parts by mass: 30-60 parts of waste residues, 10-16 parts of tailings, 1-2 parts of desulfurization gypsum, 5-12 parts of powder and 1-5 parts of an activating agent. The invention also discloses the preparation method of the high-performance concrete composite admixture. The high-performance concrete composite admixture disclosed by the invention has the following beneficial effects: firstly, the raw materials of the admixture are taken from wastes to realize recycling utilization of solid wastes and solve land occupation and environmental pollution caused by stacking and burying; secondly, the admixture disclosed by the invention, by virtue of treatment and processing of the raw materials, has more excellent performance, so that the working performance and strength of each stage of concrete can be finally promoted significantly, and then the concrete becomes high-performance concrete with high durability, high applicability and high volume stability; and moreover, the admixture can greatly reduce the use level of cement and is very significant in cost reducing effect.

Owner:山东中粉建材科技有限公司

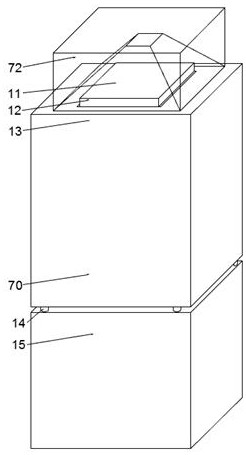

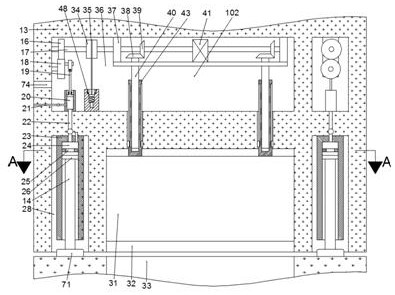

Ceramic exhibition cabinet and use method thereof

The invention discloses a ceramic exhibition cabinet and a using method thereof. The ceramic exhibition cabinet comprises an outer cabinet body, the outer cabinet body comprises an upper shell and a lower shell, a vertically-through first moving groove is formed in the upper shell, a second moving groove with an upward opening is formed in the lower shell, and a telescopic rod is installed in the bottom wall of the second moving groove; ceramic is stored in the first moving groove, the ceramic is protected through the outer cabinet body, meanwhile, a triangular cone made of a transparent material is placed on the top face of the outer cabinet body, a 3D holographic image of the ceramic is formed in the triangular cone through playing equipment for viewing, meanwhile the outer cabinet body is divided into an upper shell and a lower shell, separation of the upper shell and the lower shell is controlled through a telescopic shell and a connecting rod, the ceramic stored in the outer cabinet body can be exposed after the upper shell and the lower shell are separated, meanwhile, the periphery of the ceramic is protected through an anti-explosion transparent plate, and the ceramic can be conveniently viewed.

Owner:王旭

Lightweight electric vehicle body frame

Owner:INST OF DONGGUAN SUN YAT SEN UNIV +1

Composite material for automotive interior parts and production method thereof

ActiveCN101812773BNo pollution in the processReduce lossVehicle componentsNon-woven fabricsSlurryNatural fiber

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

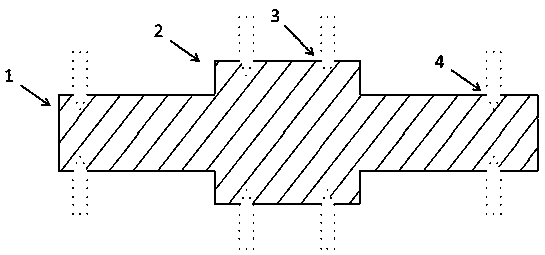

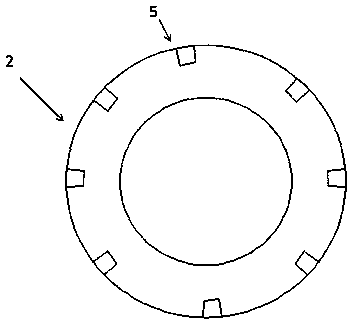

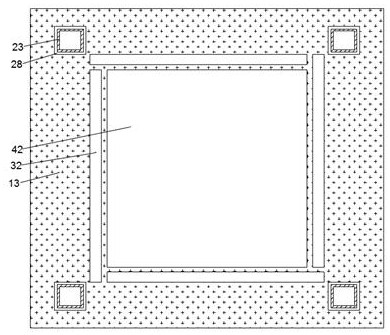

Closed durable moistureproof and anticorrosion ozone sheet

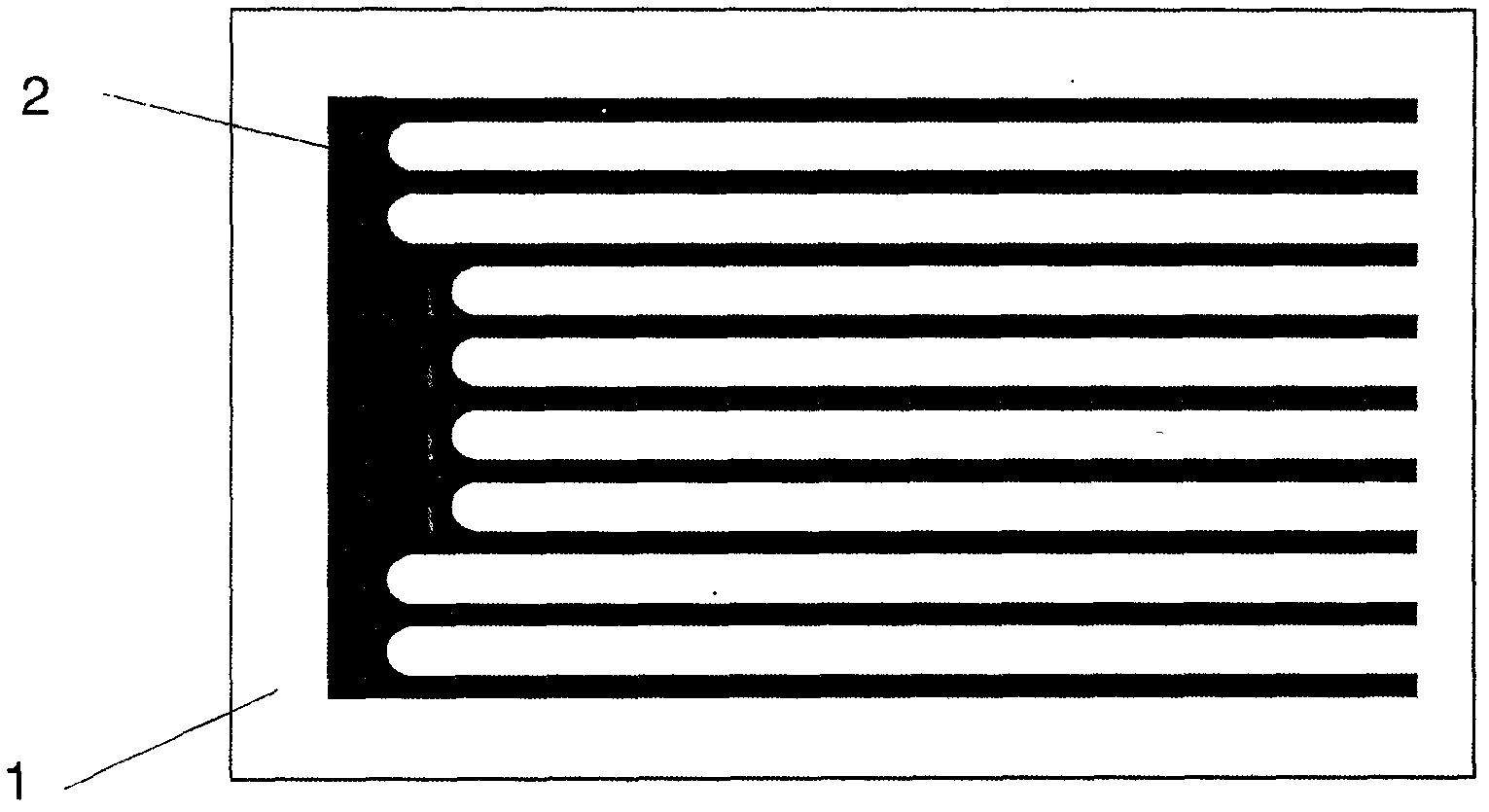

InactiveCN102530880AStable working performanceOzone generation is largeOzone preparationOxidation resistantAlumina ceramic

The invention relates to a closed durable moistureproof and anticorrosion ozone sheet, which consists of an aluminum oxide ceramic substrate (1), an outer layer aluminum oxide ceramic substrate (2), electrode slurry (2) and inner layer electrode slurry (4). According to the closed durable moistureproof and anticorrosion ozone sheet, the strength, high-temperature resistant performance, waterproof and antioxidation performance and closed performance of the outer layer aluminum oxide ceramic substrate have the obvious advantages, so an insulation layer or a high-temperature coating layer of glass slurry which is coated on the surface of the electrode slurry in the prior art is replaced by the outer layer aluminum oxide ceramic substrate. Therefore, compared with the prior art, the closed durable moistureproof and anticorrosion ozone sheet has the advantages of stable operating performance, water prevention, oxidation resistance, large ozone output, quick starting time and long service life.

Owner:陈建中

A kind of preparation method of titanium-silicon alloy phase reinforced tial-based composite material with network structure

ActiveCN109295336BHigh purityHigh compressive strengthTransportation and packagingMetal-working apparatusSilicon alloyNetwork structure

The invention relates to a method for preparing a TiAl-based composite material reinforced with a network structure titanium-silicon alloy phase. The method refers to prealloying 65% to 85% of Ti-46Al-2Cr-2Nb powder in terms of mass fraction With 15%~35% Ti 5 Si 3 The powder is mechanically mixed, vacuum hot-pressed and sintered, and cooled at room temperature to obtain a network structure Ti 5 Si 3 Reinforced TiAl-based composites. The preparation process of the present invention is simple, the cost is low, and the product performance is stable, and the prepared network structure Ti 5 Si 3 Reinforced TiAl-based composites have high compressive strength and excellent anti-wear properties, and can be used as new structural and anti-wear materials.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

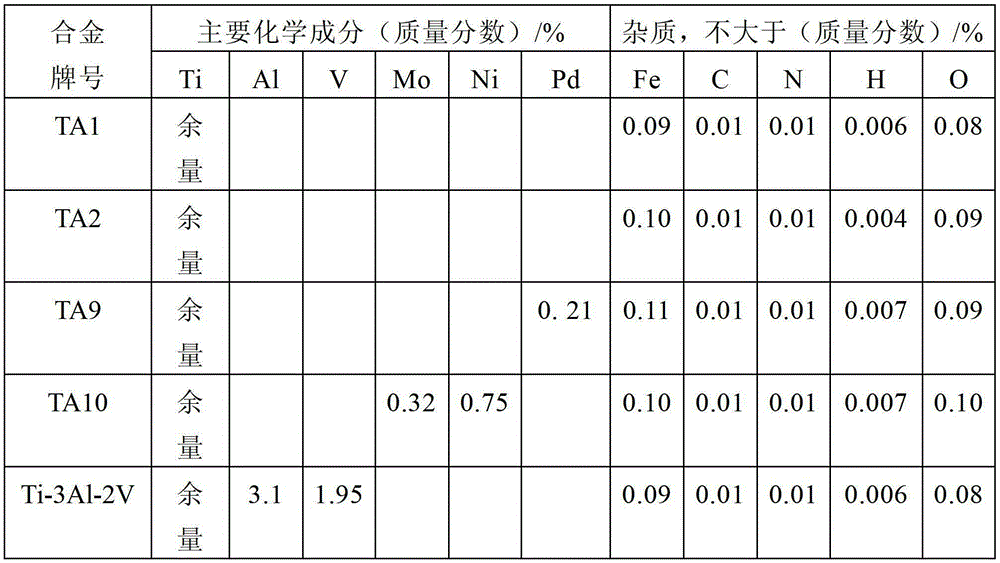

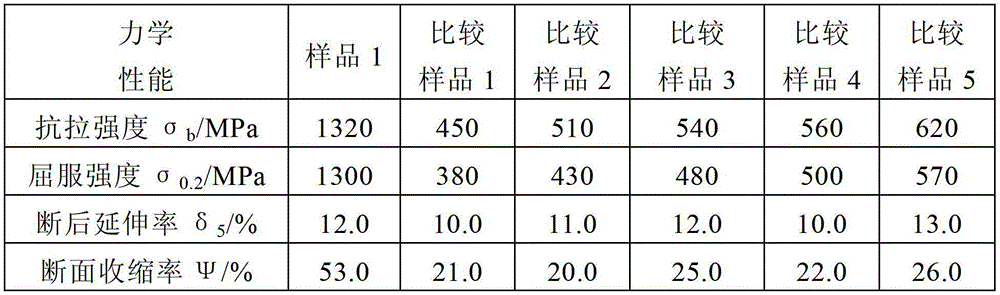

ti-5mo-5v-6cr-3al titanium alloy extruded pipe and its processing method

The invention relates to a Ti-5Mo-5V-6Cr-3Al titanium alloy extruded tubular product and a processing method thereof. The titanium alloy extruded tubular product comprises the main alloy elements by weight percentage: 4.5%-5.7% of Mo, 4.5%-5.7% of V, 5.5%-6.5% of Cr, 2.5%-3.5% of Al, and the balance titanium. The tubular product is prepared on a large-tonnage extrusion machine; and because the tubular product has higher tensile strength, higher toughness and good welding performance, the tubular product can be widely applied in aviation, aerospace, petroleum, chemical industry and other fields.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com