A kind of high-plasticity hot-rolled strip steel with tensile strength of 1180mpa and its production method

A technology of tensile strength and hot-rolled strip steel, applied in the field of hot-rolled high-strength steel, to achieve the effects of reducing rolling load, reducing cost and increasing plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

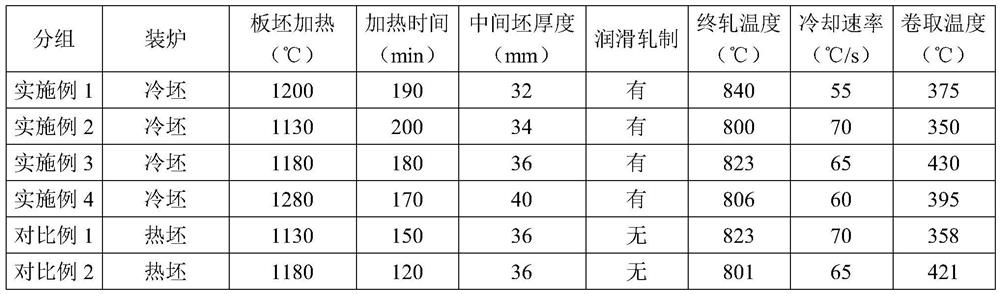

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments.

[0016] The invention is used for producing a high-strength and high-plasticity hot-rolled strip steel with a tensile strength of 1180 MPa, and the chemical composition of the strip steel includes: C: 0.15-0.24%, Si: 1.3-2.0%, Mn: 1.3~2.0%, Al: 1.2~2.0%, P≤0.015%, S≤0.005%, Re: 0.003~0.006%, Nb: 0.02-0.07%, Ti: 0.02-0.07%, Cr: 0.03-0.08%, The balance is Fe and inevitable impurities.

[0017] The principle of its elements and content is as follows:

[0018] C: It can significantly improve the strength and has the effect of interstitial solid solution strengthening; it can also increase the stability of austenite and obtain retained austenite. However, the C content should not be too high to ensure the formability and welding performance. The C content of the present invention does not exceed 0.24%.

[0019] Si: It can improve the strength through solid solution strengthen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com